Field Direction

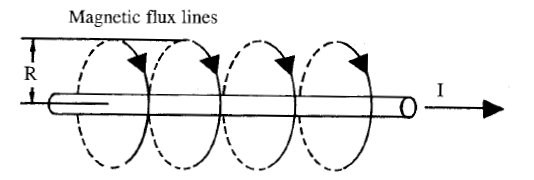

The proper orientation of the magnetic field in the test object in relation to the direction of the discontinuity is a more important factor than the value or amount of the magnetizing current. Field direction for circular magnetization is shown in Figure. For best results, the magnetic lines of force should be at right angles to the discontinuity to be detected.

If the magnetic lines of force are parallel to the discontinuity, there will be little magnetic leakage at the discontinuity and therefore, if any indication is formed it is likely to be extremely small. Discontinuities located in the direction of current flow have the lowest probability of detection. Discontinuities perpendicular to current flow have the highest robability of detection.

Field direction for circular magnetization

Measurement of Magnetic Fields

The measurement of magnetic flux or field strength, either within a test object or at the test surface, is extremely complicated. There have been several attempts to develop practical methods or devices for this purpose, but these methods or devices have all been limited in success and contain serious limitations. They do serve a purpose in technique development if their limitations are understood. A procedure or technique typically will be developed for a particular test object using rules of thumb and past experience. The actual test object will then be subjected to the proposed procedure, and the

devices will be used to check the field strength at critical points as a comparative reference.

A hall effect gauss meter is a versatile magnetic field indicating instrument. It applies a current to a hall effect probe or sensor and amplifies the output voltage that is proportional to the measured magnetic flux density. There are several limitations that generally prevent its use as a shop instrument. First, it is a laboratory instrument and relatively fragile. It does not withstand normal use

required in a magnetic particle testing shop.

Another major limitation is that it measures only the flux passing through the probe or sensor at right angles. Placing the probe on the test object surface merely indicates the flux at that point and does not measure the field in the test object surface. Some attempt has been made to cut slots or drill holes in critical areas of sample test objects and then insert the probe.

This greatly improves the sensitivity and is perhaps the best approach at this time. Unfortunately, the availability of test objects in maintenance is extremely limited, and practical application of the hall effect gauss meter is confined to either the laboratory or new manufacturing operations.