Procedure of Vessel Internal Works

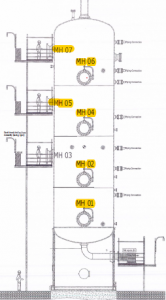

Ventilation System

Ventilation system shall be done using fans/blowers with sufficient capacity. Vacuum mode operation shall be preferred for ventilation, where required force ventilation to vessel top and allow fresh air from the bottom. Distance of the ventilation is also critical as it will obstruct access to the manhole, so careful planning shall be done prior to positioning of the fans/blowers in order to address the air circulation inside the vessel. See following photo.

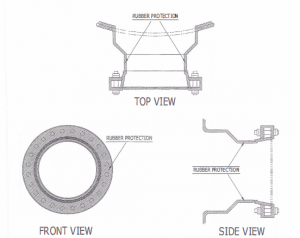

Manhole Opening, Inspection and Protection Method

All manhole opening shall be done as per construction and safety procedure. Approved safety permit shall be procured prior to nitrogen gas removal. Inspection of manhole flange serration shall also be done. After inspection of manhole flange

serration, put a rubber cover for protection. See attached following photo. Bolts, nuts and gasket shall be kept for reinstatement.

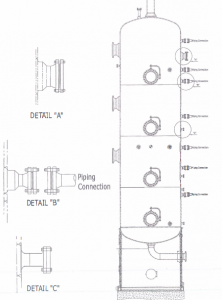

Nozzle Inspection and Protection Method

All equipment nozzles shall be inspected for its flange face serration. Should there be any unacceptable damage, it shall be corrected by re-facing it prior to vessel internal works. Appropriate cover and protection on its nozzle flanges face shall be

done. Notice shall be given to Mechanical Department should there be any piping connections to be made. Blind flanges, bolts and nuts and gaskets of correct material shall be used to cover the nozzles of equipment. Equipment nozzle shall

never be use as support by any piping connections. Gaps shall be made between two connections (equipment nozzle and pipe flanges) until final box up of the vessels and piping works are done. See attached photo.

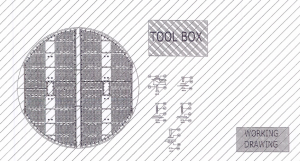

Tray Pre-assembling Working Bed

Tray pre-assembling working bed shall be of the same size as the diameter of the vessel involved. Materials to be use on top of the working bed shall be of the same materials of the vessel internal. Carefully pre-assembled the required vessel

internals (level wise) and check precisely that all components are complete and of the correct position as if you installed it inside the vessel. Check also for its cleanliness and if contaminated with rust, clean thoroughly with approved cleaning

method and solvent solution prior to installation inside the vessel. After confirmation of material and cleanliness, carefully install it piece by piece inside the vessel. See attached photo.

Scaffolding Inside and Outside the Vessel

Scaffolding inside and outside of the vessel shall be done by an approved Scaffolders only. Scaffolders shall install scaffolding with maximum effort not to damage the shell surface of the equipment most especially inside the vessel as it

will result into scratches and will lead to rust development/contamination.

All sharp corners and protruding metal ends of scaffolding shall be adequately covered with rubber. Inside scaffolding shall be installed in such a way that enough working space is provided for installation of vessel internals. Outside scaffolding shall be installed with enough platform size in front of all manholes for worker’s access during working activities. Safety for all workers inside and outside the vessels shall be given much consideration in the scaffolding erection. A temporary cabinet shall be placed (shall not obstruct manhole access) for safekeeping of personal belongings of workers inside the vessel.