1.0 PURPOSE

2.0 SCOPE

3.0 APPLICABLE DOCUMENTS

4.0 RESPONSIBILITY

5.0 MANPOWER

6.0 TOOLS & EQUIPMENT

7.0 METHODS/PROCEDURES

8.0 QUALITY CONTROL

9.0 SAFETY PRECAUTION

10. ATTACHMENTS.

CCR REACTOR INTERNALS INSTALLATION PROCEDURE | METHOD STATEMENT

1.0 PURPOSE:

This method statement shall provide minimum Guidelines for typical installation of CCR Reactor Internals, for Plants and Refinery Projects in accordance with Project Drawings and Project Specifications.

2.0 SCOPE:

This specification covers the minimum requirements for typical installation of CCR Reactor internals to be applied at Plants and Refinery Projects.

3.0 APPLICABLE DOCUMENTS:

3.1 ARAMCO Project Specifications and Standard

3.1.1 SAEP-302 Instruction for obtaining a waiver of a mandatory Saudi ARAMCO Engineering requirement.

3.1.2 SAES-H-101V Approved Saudi Aramco Data Sheets-Paint and Coatings

3.1.3 Related Vendors Installation and maintenance manuals and /or specifications.

3.2 Industry Codes and Standards:

3.2.1 AWS D1.1 Structural Welding Codes

3.3 Inspection and Testing Plan/SAIC

3.3.1 SAIC-D-2002 Receiving Inspection of Pressure Vessels- External

3.3.2 SAIC-D-2003 Receiving Inspection of Pressure Vessels- Internal

3.3.3 SAIC-D-2005 Storage, Handling and Preservation (Vessels & Tanks)

3.4 Latest Revision of the following Documents shall be used.

3.4.1 Vendor Drawings

3.4.2 Structural Drawings

3.4.3 Equipment Details

3.5 Saudi ARAMCO Safety, Health and Environmental Standard:

3.5.1 Construction safety manual — compliance with schedule D.

3.5.2 General Instructions (G.l’s) at the work site.

4.0 RESPONSIBILITY:

4.1 Construction Manager is responsible for implementing HSE, study, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources required for the successful implementation of the construction work activities. Study all aspects of work procedure as per technical Scope of Work and Saudi Aramco Standard.

4.2 Mechanical Superintendent/ Supervisor shall study and review all necessary documents for the Erection works in his area to include, technical scope of work, specification, bill of quantities, planned milestone dates and construction procedure in support to his Mechanical Foreman. He shall monitor the availability of materials in accordance with the schedules and construction analysis. He shall be directly reporting to the Construction Manager. He shall coordinate with other discipline to visualize possible conflicts in the drawings as well as in the schedules to provide other options in preventing unnecessary delays and obstructions.

4.3 The Welding Supervisor and/or Foreman are solely responsible to ensure that all welding works are in conformance with applicable codes, standards, specifications and approved procedures.

4.4 Mechanical Foreman shall be responsible for the direct work supervision at site and ensure that the work is performed in accordance with Technical Scope of Work, Saudi Aramco Standard and latest approved for construction drawings. He shall monitor the availability of materials in line with his required schedule.

4.5 QC Inspector shall be responsible in monitoring and inspection of the work and ensured that the work is performed and properly documented in accordance with Technical Scope of Work and Saudi Aramco Standard.

4.6 Safety Officer/Supervisor shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with Safety Standard Procedure and Saudi Aramco Construction Safety Manual. He shall discuss to the workers the characteristics of related materials and Status of work area giving reminders as an additional point to work safely.

5.0 MANPOWER

5.1 The Mechanical Supervisor shall control the overall activity on erection of Air fin fan cooler. The basic manpower under him shall consist but not limited to the following:

5.1.1 Supervisor Mechanical

5.1.2 Foreman mechanical

5.1.3 Rigger (certified)

5.1.4 Welder

5.1.5 Millwright

5.1.6 Mechanical Fitter

5.1.7 Crane Operator (certified)

5.1.8 Truck driver

5.1.9 Surveyor

5.1.10 Helper

5.1.11 Structural Fitters

5.1.12 Scaffolders (by others)

5.2 Safety Engineer

5.3 QC Inspector

6.0 TOOLS AND EQUIPMENT

6.1 Tools and equipment needed should be in good condition and must be checked by Mechanical Supervisor/Safety Officer prior to use in the construction area. These Includes but not limited to:

6.1.1 Calibrated engineering level with calibration certificate

6.1.2 Corrective wrenches all required range

6.1.3 Certified sling and hoists

6.1.4 Rigging accessories

6.1.5 Lifting Beam

6.1.6 Welding machine

6.1.7 Millwright Precision meter

6.1.8 Crane

6.1.9 Tag line nylon rope

6.1.10 Ladder Rope

6.1.11 Trailer

7.0 METHODS/ PROCEDURES:

7.1 Jobsite Receiving and Inspection:

7.1.1 Upon withdrawal and receipt of equipment from warehouse, receiving inspection shall be conducted immediately as per SAIC-D-2003 to verify compliance and latest revision of vendors drawing.

7 .1.2 Record of inspection shall be documented as per SAIC-D-2003 (Material Receiving Inspection); findings and deviations shall be documented in Quality control Inspection Report (QCIR) and Non Conformance Report (NCR).

7.1.3 Compare data with reference drawings. Note the discrepancies and unacceptable tolerances and report through QCIR.

7.2 Preparatory Works

7.2.1 Secure all the valid documents such as confined space permit prior to work commence.

7.2.2 Tools and equipment shall be made operational and available for use. Ensure tools are color-coded accordingly. Calibration certification where required shall be valid.

7.2.3 Prior to the arrival of equipment on site, Installer shall review the manufacturer’s requirement and the requirements of this specification regarding on site storage of the equipment. These requirements shall be incorporated into the preservation plan in all respects.

7.2.4 Mobilize all manpower, tools and equipment needed for the job.

7.2.5 Manpower who will do the job should secure training on confine space and necessary training to do the job.

7.2.6 Install barricades to confine the area for authorized personnel only.

7.2.7 Prepare lifting location where the crane will be positioned.

7.2.8 Checked wind condition, lift shall not proceed when wind velocity is greater than required of crane.

7.2.9 Stabilized ground areas, crane mats shall be provided in accordance to findings of soil bearing pressure.

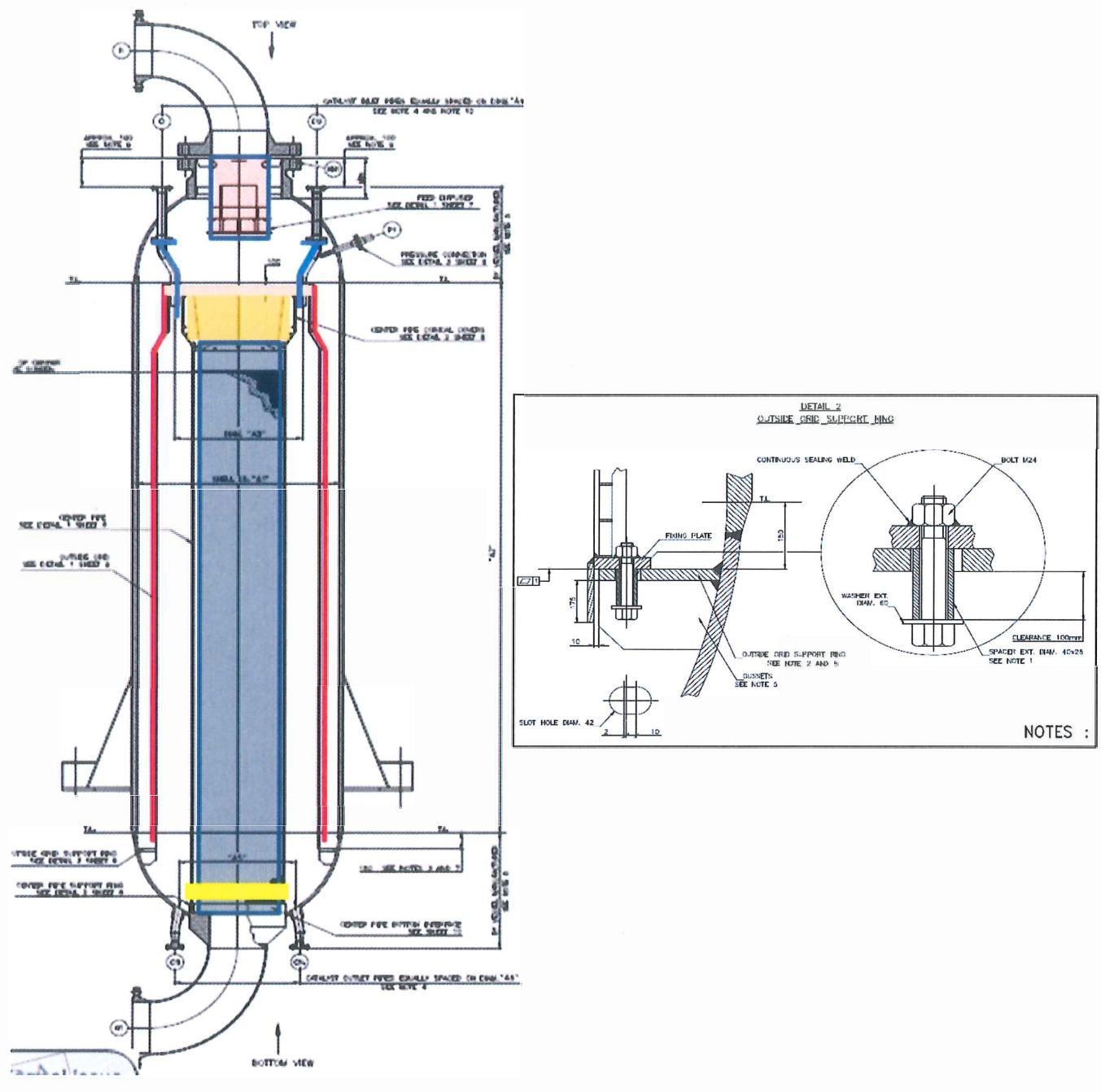

7.3 Installation of Reactor Internals

7.3.1 After erection of Reactor J1 0-C-0404 equipment, scaffold installation shall commence (by others).

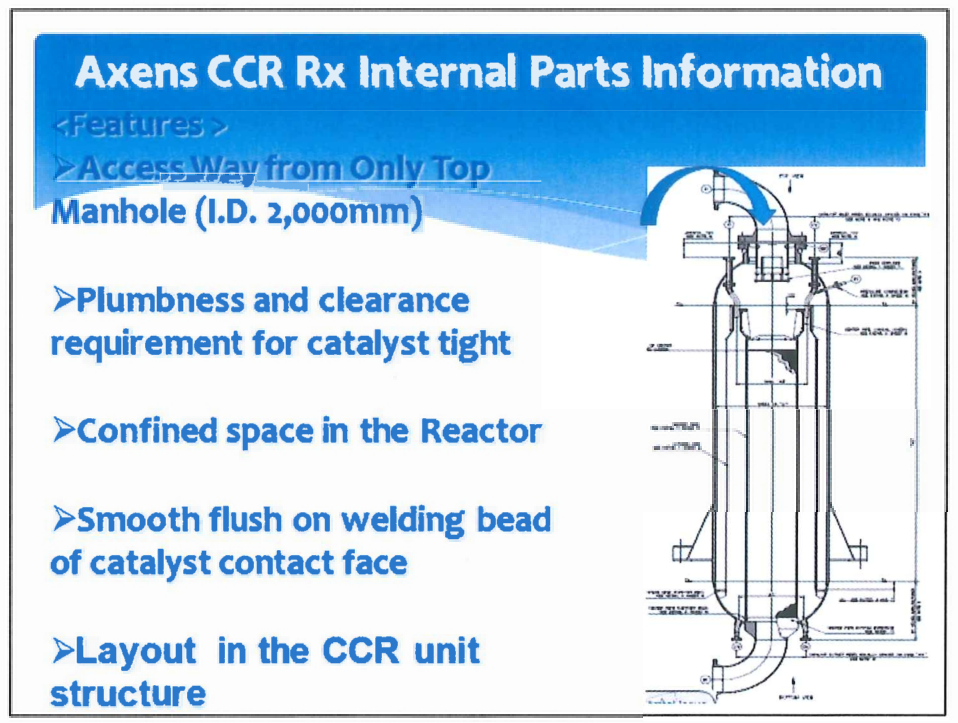

7.3.2 Access way is only on top of manhole (I.D. 2000mm) as shown above.

7.3.3 Check plumbness and clearance requirements for catalyst tight.

7.3.4 Secure tools or equipments prior to move-in inside the reactor.

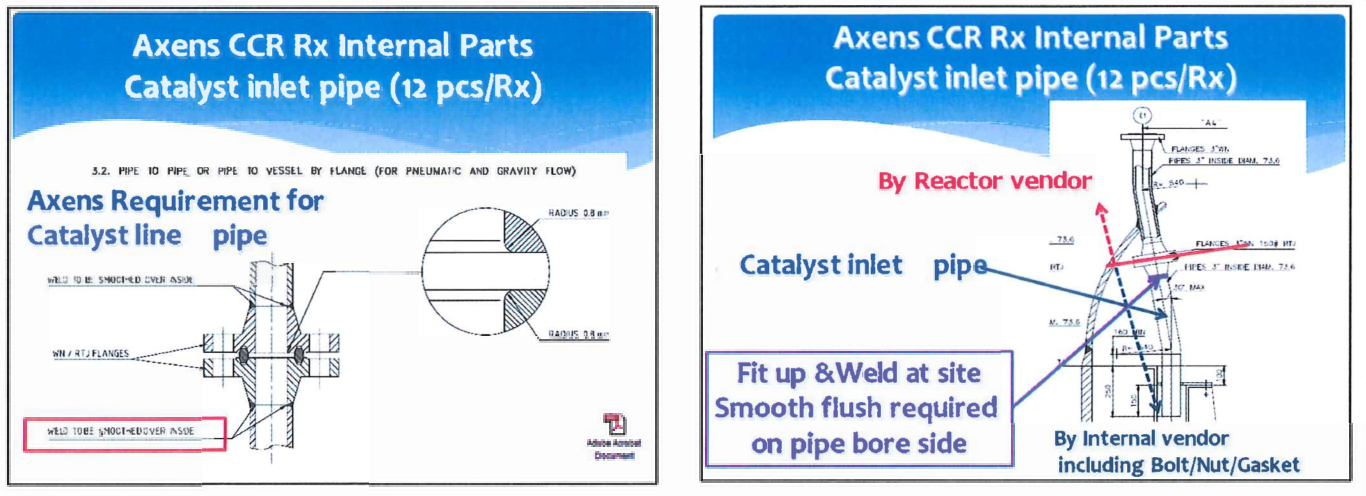

7.3.5 Smooth flush on welding bead of catalyst contact face.

7.3.6 Remove outer grid temporary support ring.

7.3.7 Remove scaffolding platform inside of the outer grid (by others)

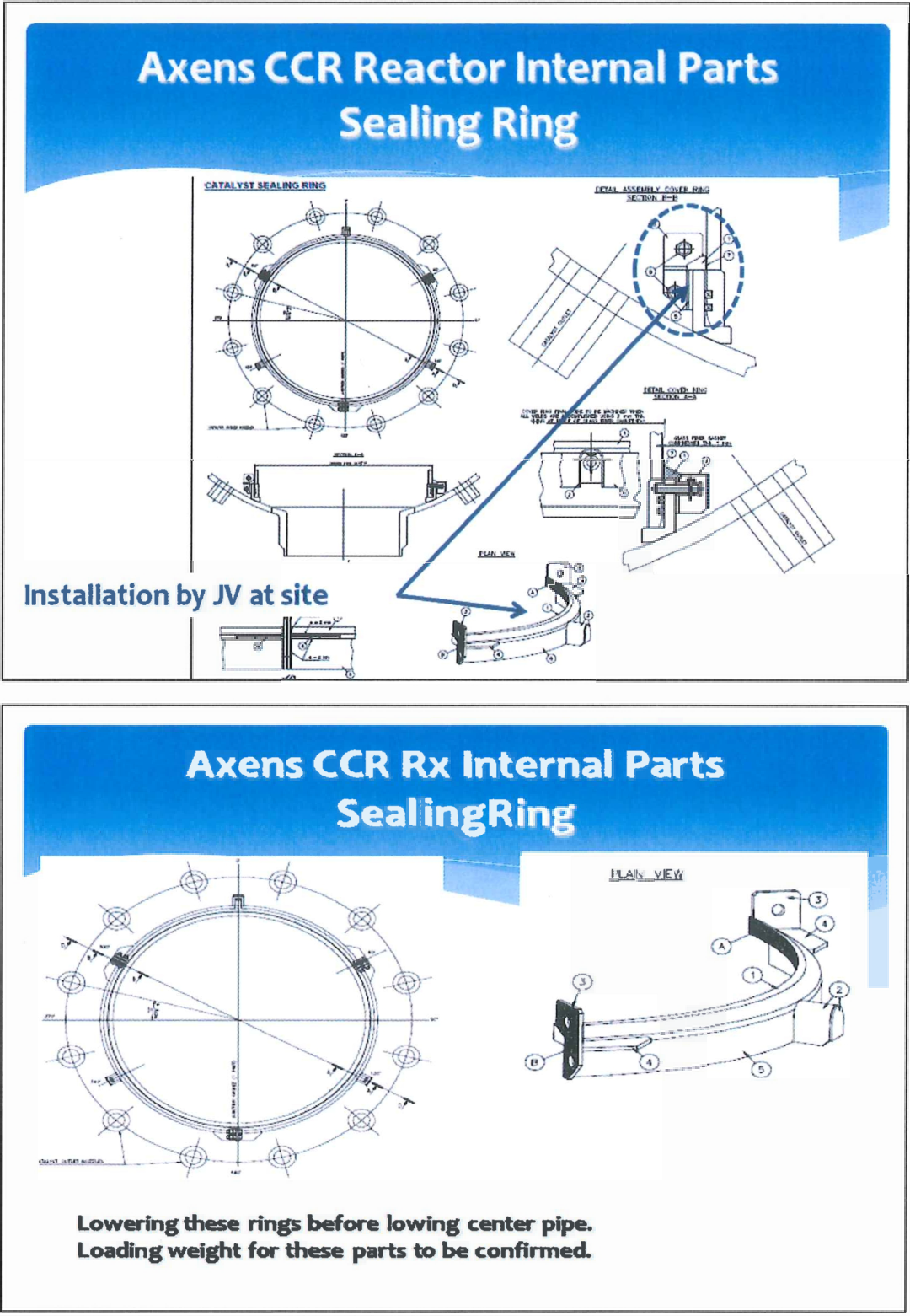

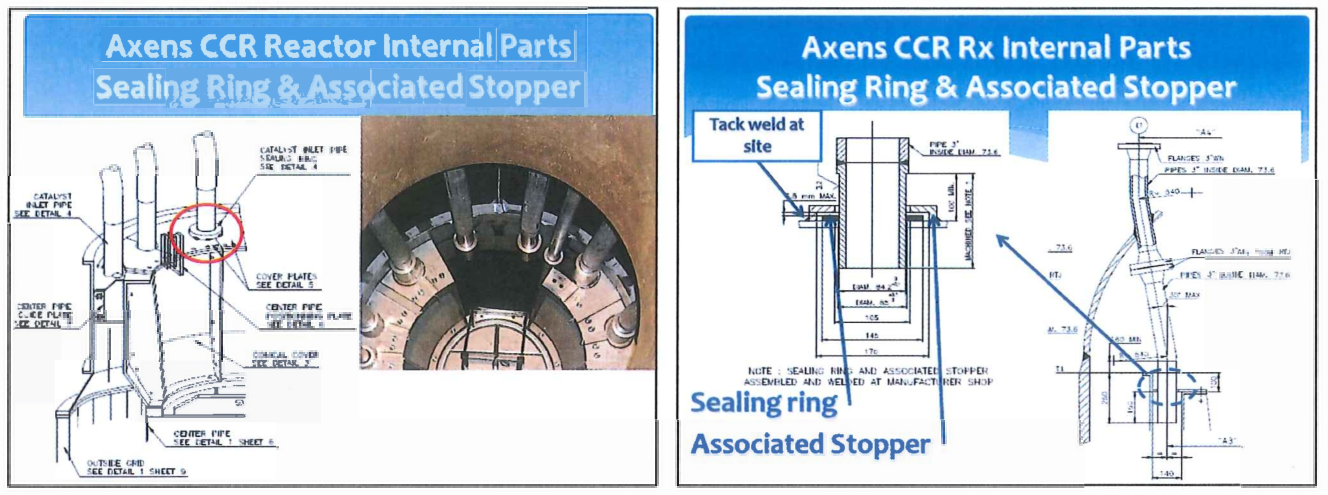

7.3.8 Lower down sealing ring and install to its exact location

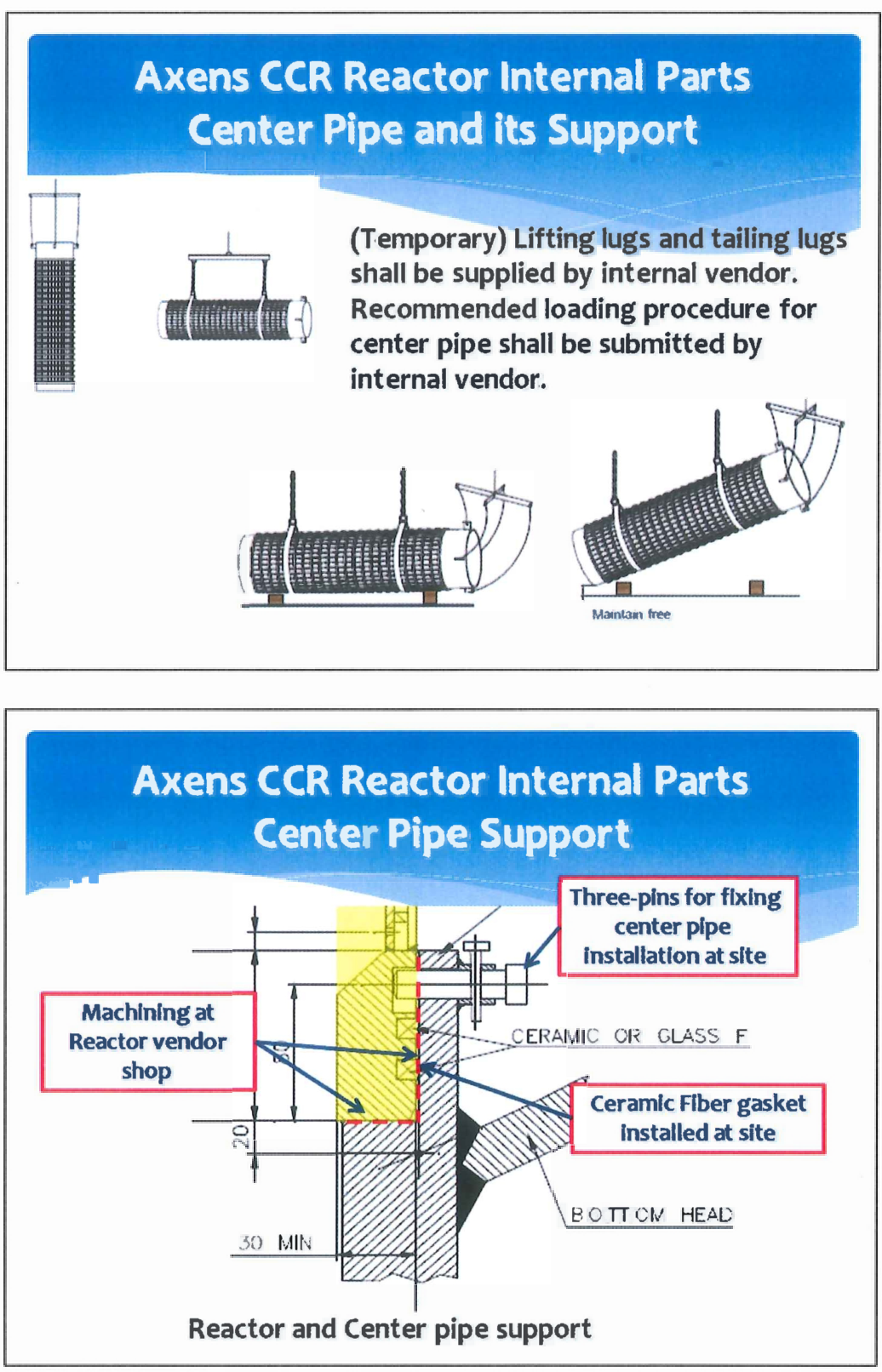

7.3.9 Install center pipe into its support ring.

7.3.10 Set sealing ring and center pipe .

7.3.11 After installation of center pipe, QC inspection shall commence.

7.3.12 After acceptance of QC, proceed to welding activity.

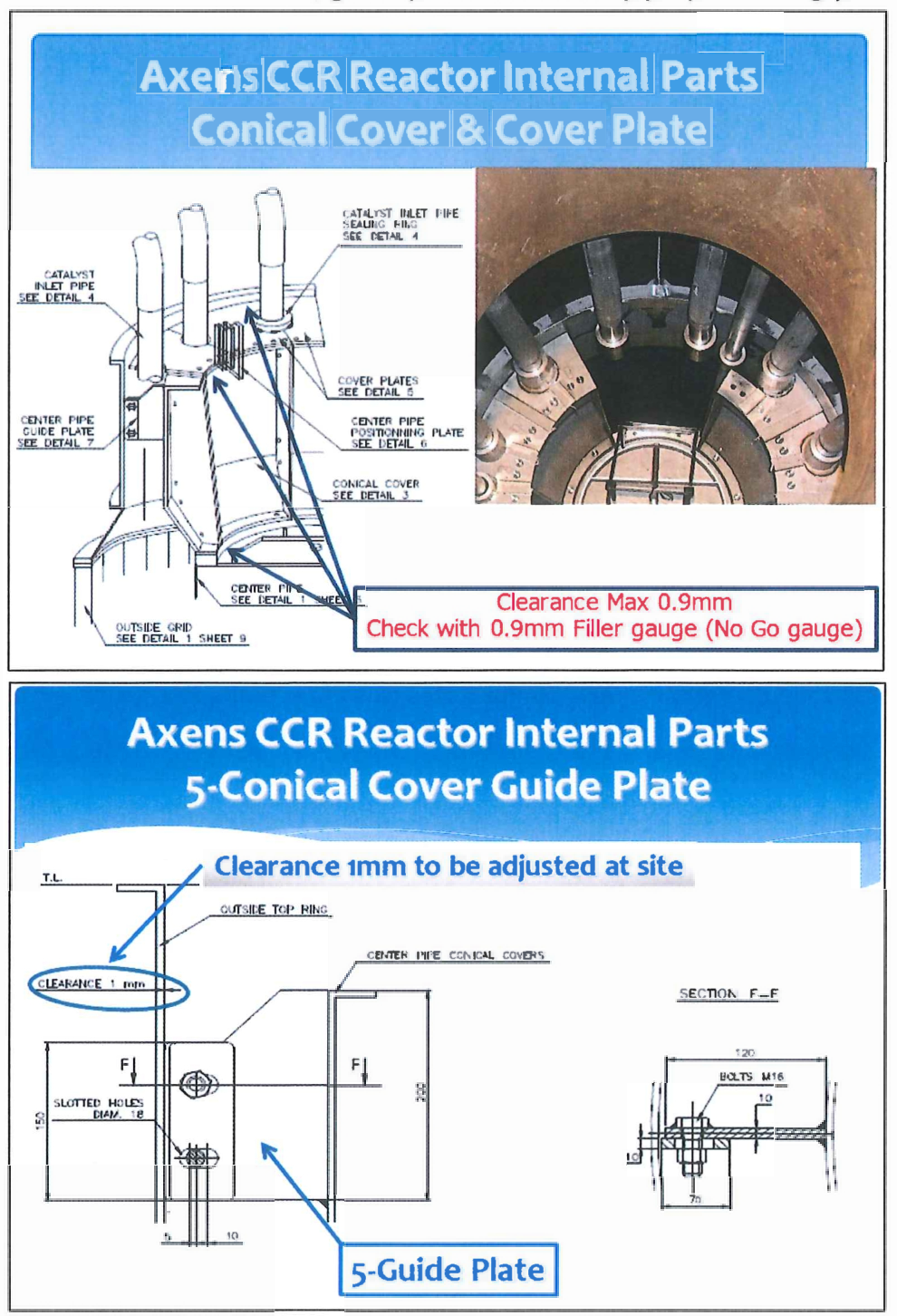

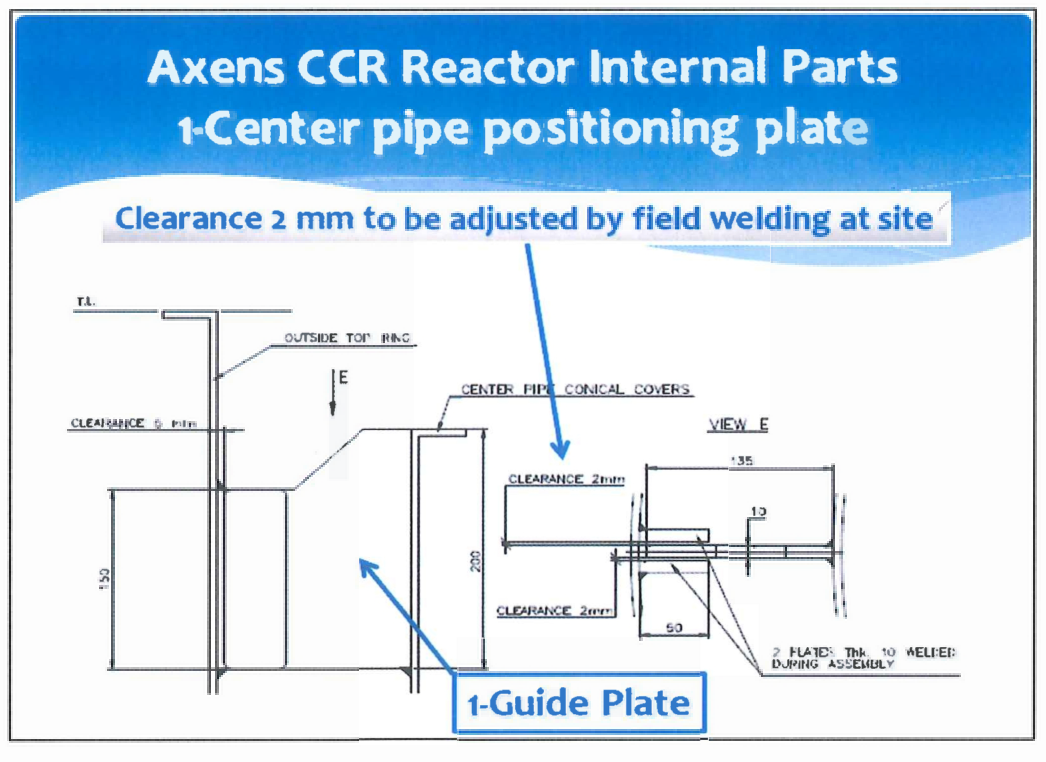

7.3.13 Install conical cover, guide plate and center pipe positioning plate.

7.3.14 After installation of conical cover, guide plate and center pipe positioning plate, QC inspection shall commence.

7.3.15 Check center pipe plumbness and centering using center pipe guide plate for adjustment.

7.3.16 Install cover plate.

7.3.17 Install catalyst inlet pipe, sealing rings and associated stopper.

7.3.18 After installation, QC inspection shall commence.

7.3.19 Install feed diffuser

7.3.20 Install piping works (down comer and catalyst pipe)

7.3.21 After completion of installation ARCC QC will inspect prior to final inspection by client.

7.3.22 For vendor detailed procedure, refer to axens CCR Reactor Site assembly procedure.

7.4 Damages and Nonconformity

7.4.1 Any damages and defects and nonconformity found at site and lay down yard shall be reported immediately.

7.4.2 QC Inspector will be responsible for all required documentation.

8.0 QUALITY CONTROL

8.1 QC Personnel shall be assigned to ensure the quality control requirement of the project.

8.2 QC Personnel well coordinate with inspector to conduct inspection as required.

8.3 ARCC QC Inspector shall be responsible to conduct all required inspection/documentation and to ensure that all applicable requirements, codes, and standards are complied with SAIC/SATIP.

8.4 Contractor has to utilize the applicable SAIC for every activity.

8.5 Calibration shall be done as required for all machines and tools going to be used in the work in accordance with schedule Q.

9.0 SAFETY PRECAUTION

- Obtain the approval of the work permit from the concerned Representative before starting any work:

- Work execution shall be carried out in accordance with method statement. And in compliance with Saudi ARAMCO General Instruction G.1.7.028, Crane Lifts; Types and Procedure.

- Fire Watcher with Fire Extinguisher shall be at work area whenever there is hot work.

- Continuous monitoring and inspection shall be implemented to detect and correct unsafe practices while performing the work activities.

- Provide warning sign and sufficient barricade on working area and only assigned personnel will be allowed in the area.

- Worker shall wear PPE’s needed for the work.

- All rigging equipment shall be in good condition and possess a valuable certificate from authorized certifying and inspection department. In compliance with Saudi ARAMCO General Instruction G.1.7.030 Inspection and Testing Requirements for Elevating/lifting Equipment.

- Safety Supervisor/Officer shall monitor the work activities to help and to protect all assigned workers against exposure to safety hazards. He shall ensure that Personal Protective Equipment (PPE’s) are supplied and used and comply with applicable standards.

- Housekeeping shall be maintained and working area shall be kept in a clean and tidy manner.

- Job Hazard and Risk Assessment (JHRA) of this method statement shall be disseminated and explained to workers for safety awareness.

10.0 ATTACHMENT:

Job Hazard and Risk Assessment (JHRA)