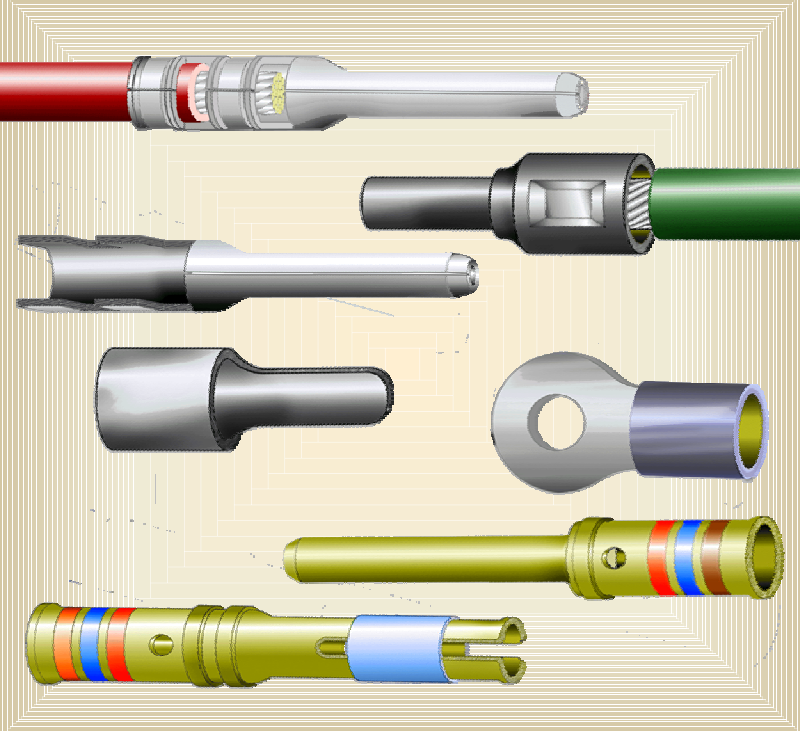

It looks Crimping is an easy and nobody wants to discuss but same time its very important for electrical safety. Crimping – Termination of conductors is more efficient and highly reliable method than soldering conductors. There are different crimping termination styles based on application and electrical connections.

Here we are going to discuss crimping termination techniques as per international crimping standards.

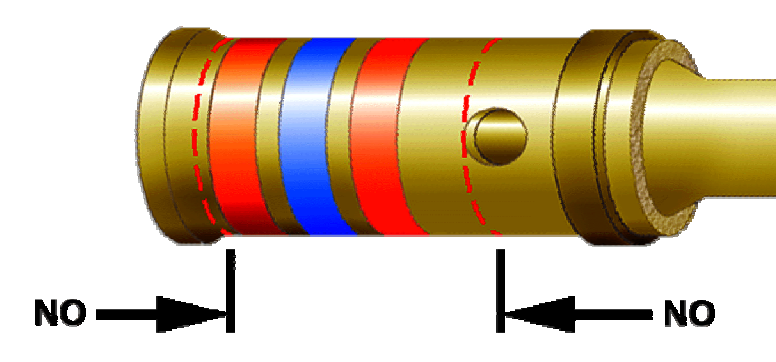

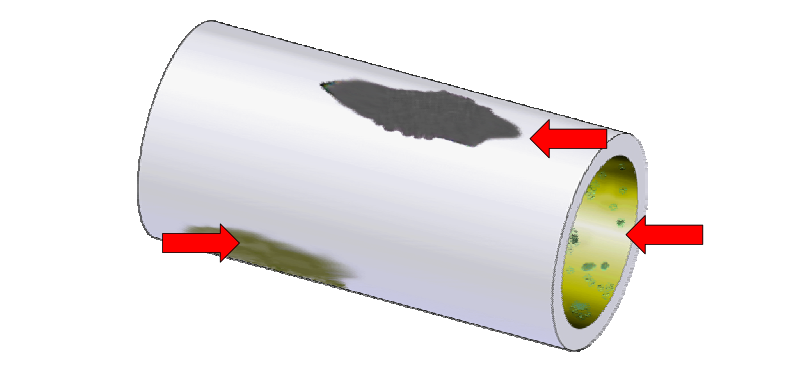

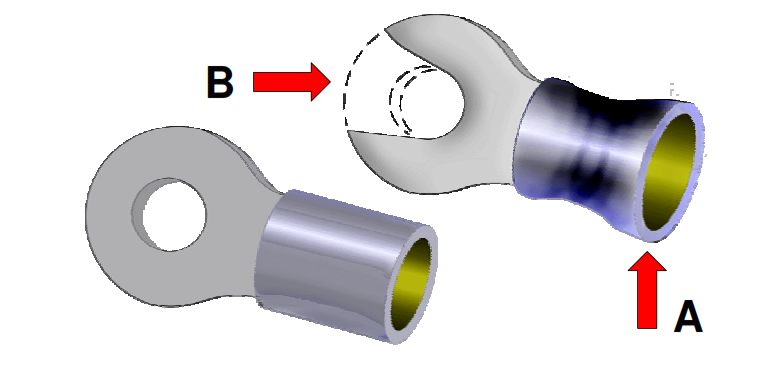

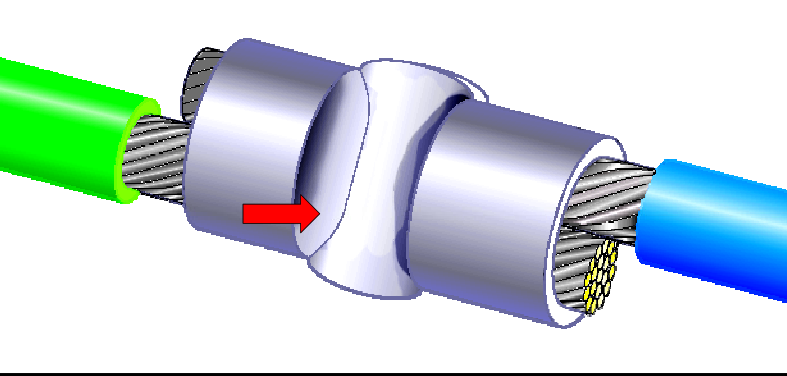

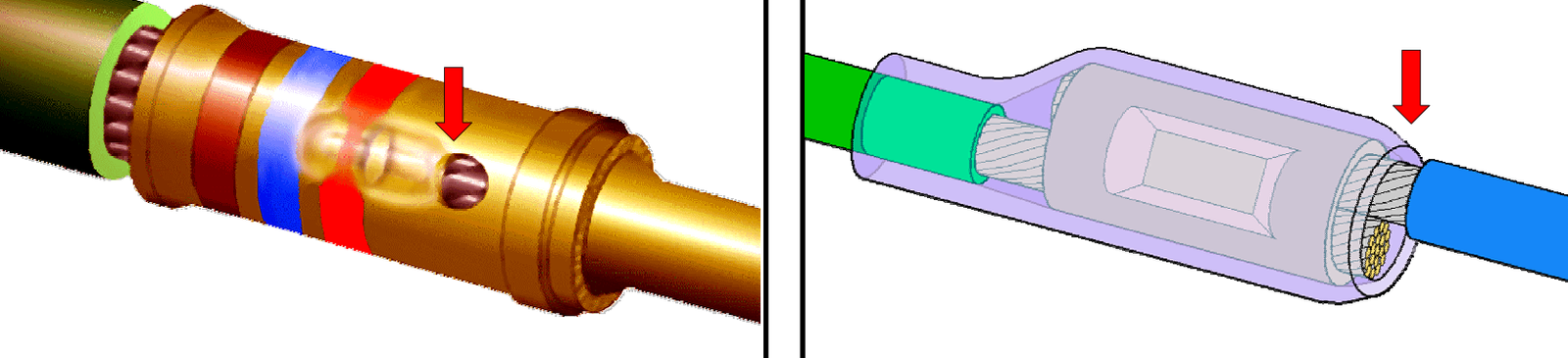

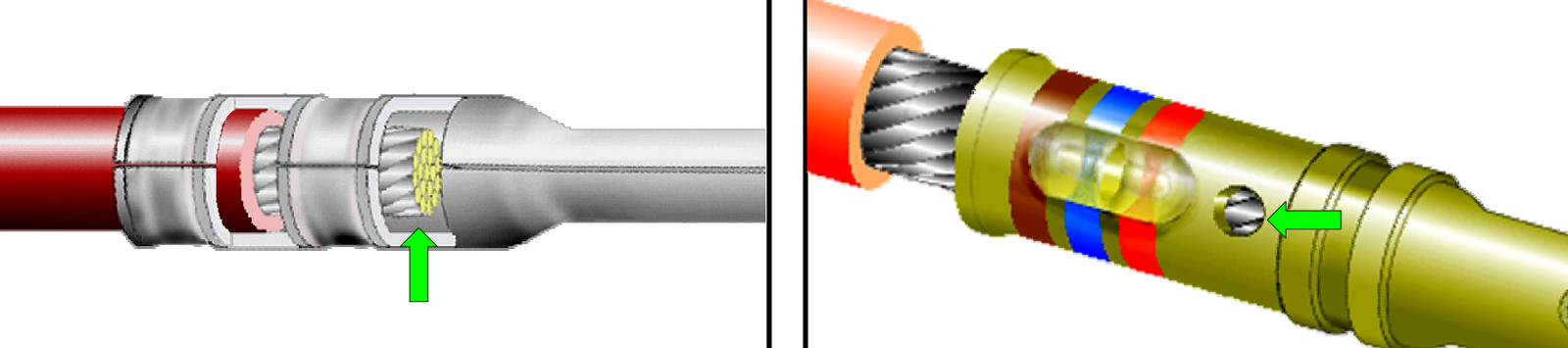

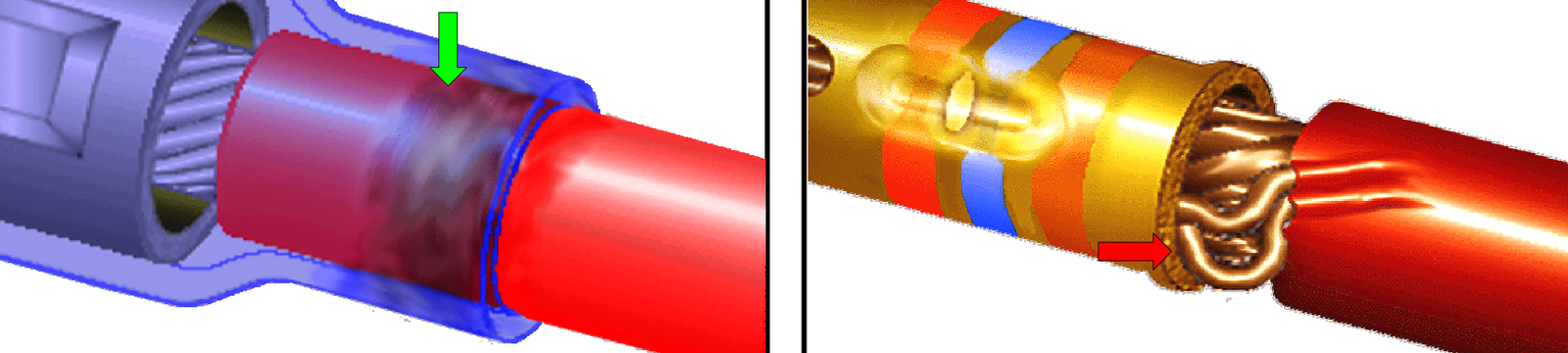

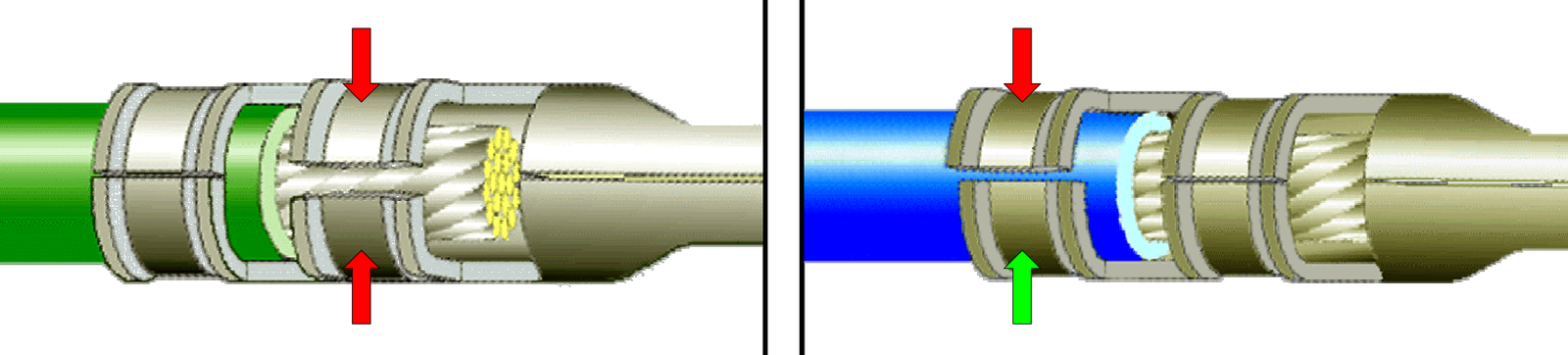

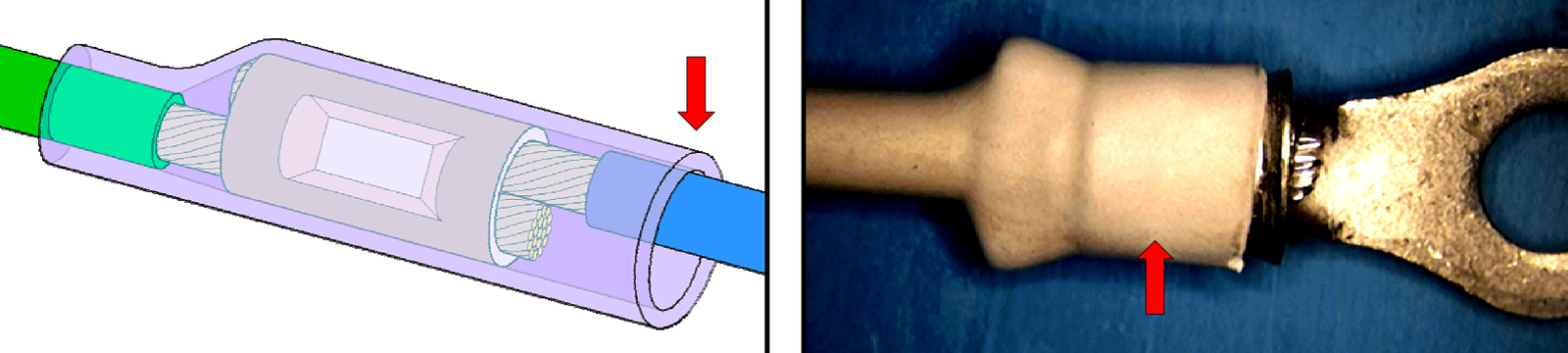

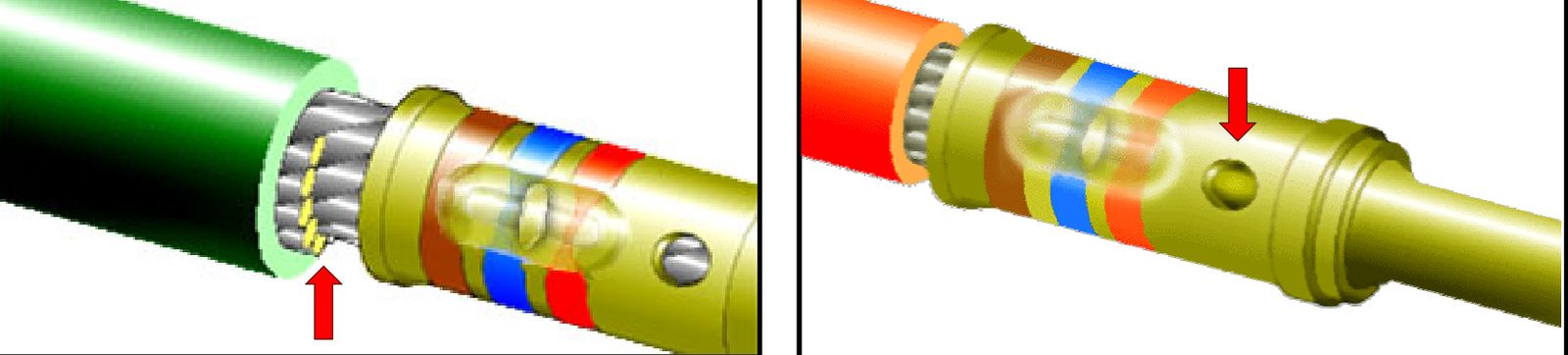

CRIMP LOCATIONS (ALL CRIMP TYPES)

What is best location to crimp conductors generally.

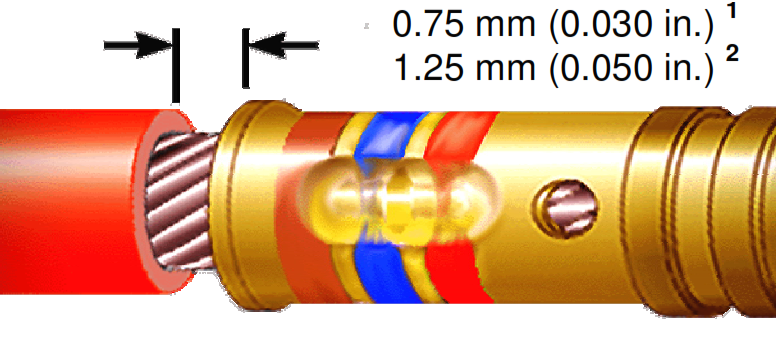

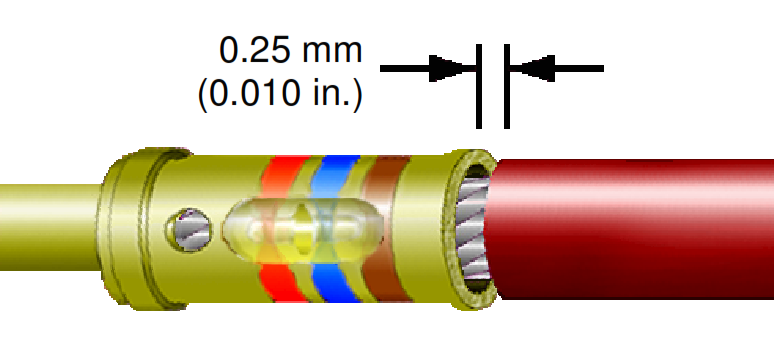

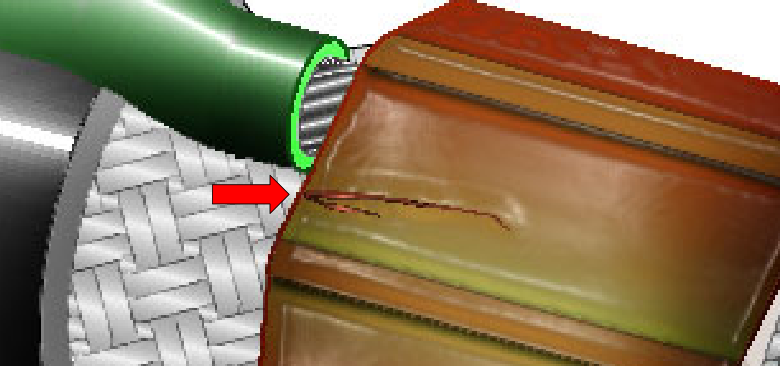

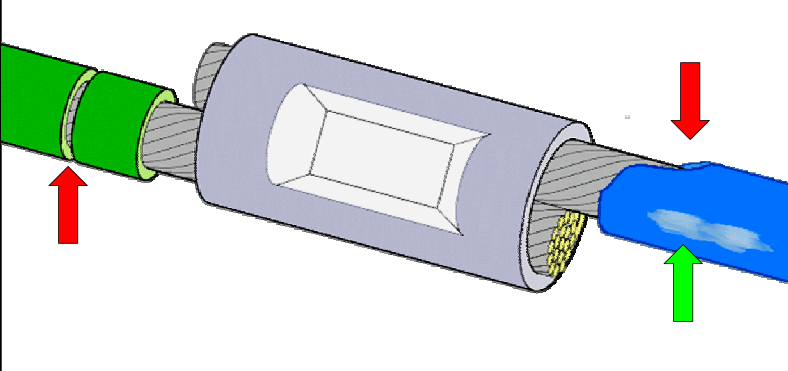

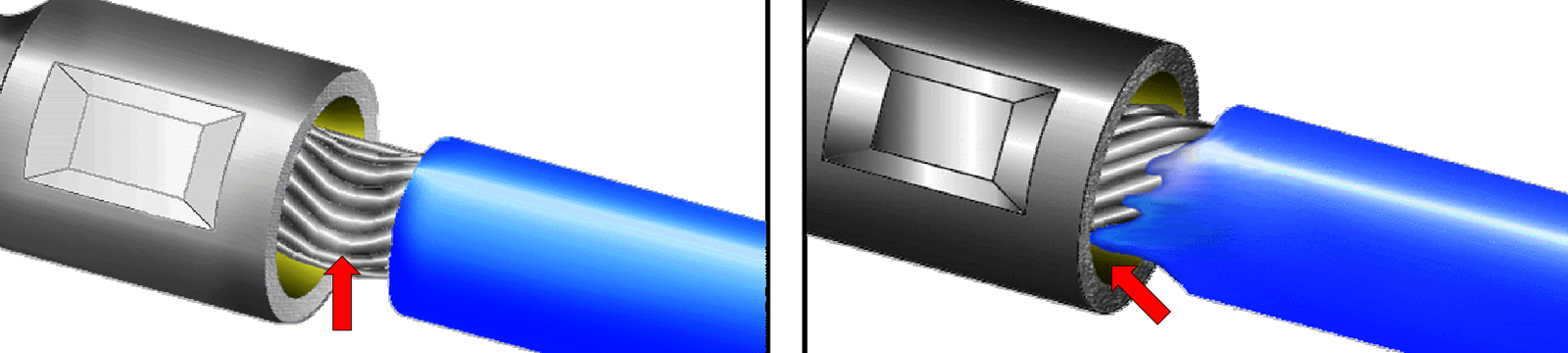

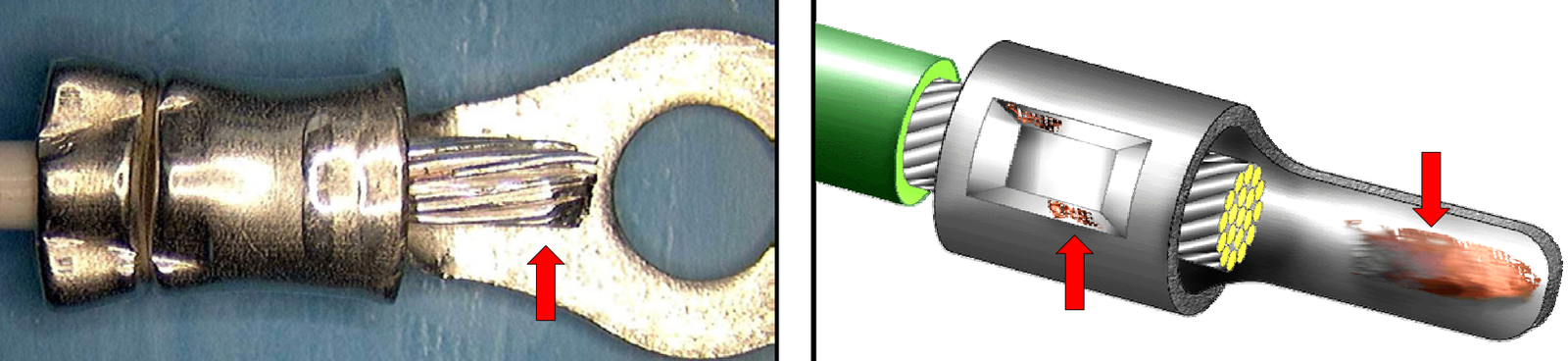

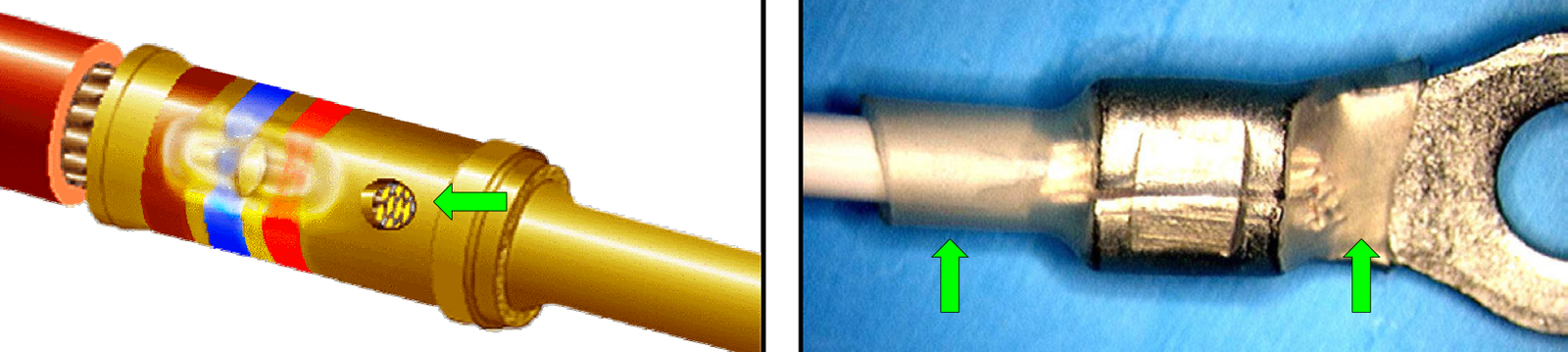

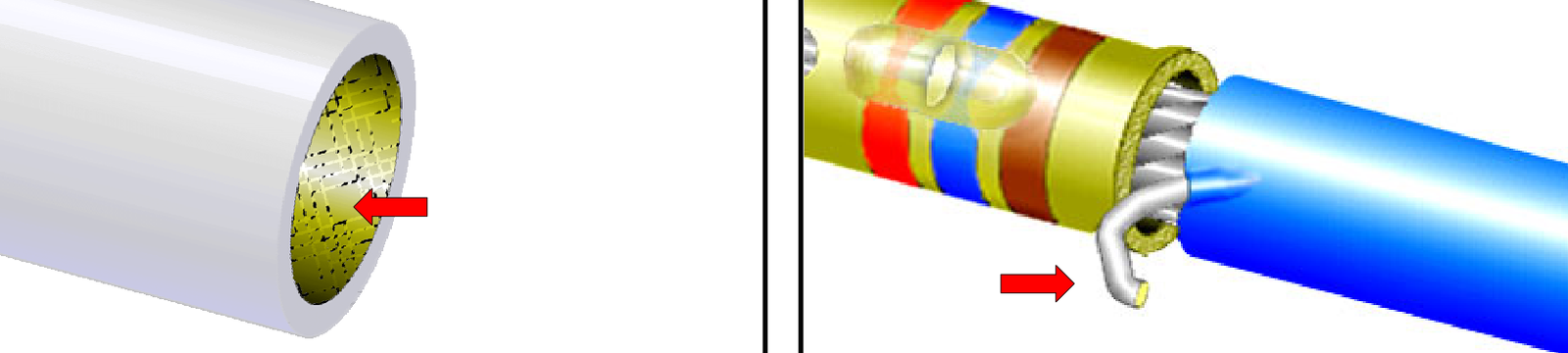

MAXIMUM INSULATION CLEARANCE (ALL CRIMP TYPES)

Here we need to mention what is maximum insulation clearance for all crimp connections.