To guide the responsible persons in conducting Current Transformer Insulation testing.

Insulation testing for current transformers (CTs) is crucial to ensure their proper functionality and safety. The insulation resistance of CTs needs to be checked regularly to identify any potential issues that could compromise their performance. Below is a general procedure for insulation testing of current transformers:

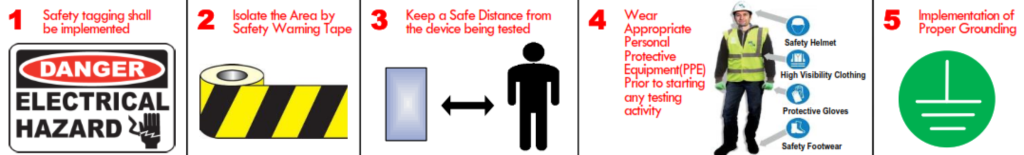

SAFETY PRECAUTIONS – The following Safety precautions shall be taken in consideration prior, during and after conducting the test measurements.

- Safety tagging shall be implemented.

- Isolate the Area by Safety Warning Tape.

- Keep a Safe Distance from the device being tested.

- Wear Appropriate Personal Protective Equipment(PPE) Prior to starting any testing activity.

- Implementation of Proper Grounding.

TEST EQUIPMENTS: IR Tester (Megger)

Current Transformer Insulation Testing

- Setup the CALIBRATED test instrument in a firm, reasonably level base and dry area.

- Identify test parameters and terminals for proper connections.

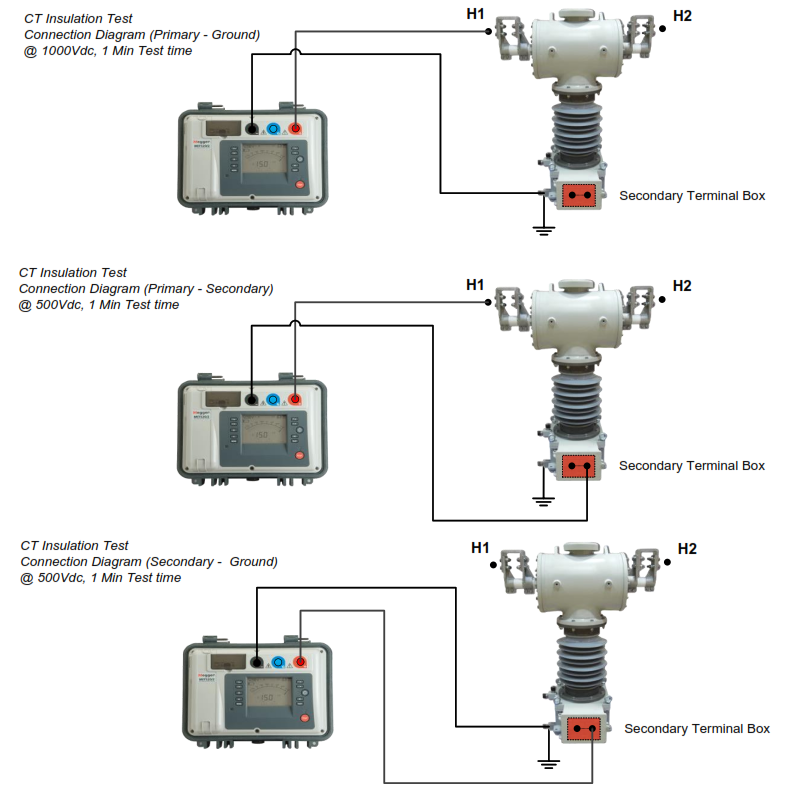

- Conduct testing as per the following illustrated test Connections:

- Stabilize all measured values before recording.

- Evaluate and record test results as per Standards in standard test forms.

Important Points:

1. Safety Precautions:

- Ensure that all safety precautions are followed, and appropriate personal protective equipment (PPE) is worn.

- Confirm that the current transformer is isolated from the power system before starting any tests.

- Verify that the testing equipment is in good condition.

2. Visual Inspection:

- Conduct a visual inspection of the current transformer for any signs of physical damage, loose connections, or contaminants.

- Check for any corrosion or rust on the terminals and connections.

3. Disconnect CT from the Circuit:

- Disconnect the current transformer from the power system or the associated equipment.

- Ensure that the CT is properly isolated to avoid any accidental energization during testing.

4. Measure Insulation Resistance:

- Use a high-insulation-resistance (megohmmeter) tester to measure the insulation resistance of the current transformer.

- Connect the megohmmeter between the CT primary terminals and the ground.

- Apply a DC voltage (usually 500V or 1000V) and measure the insulation resistance.

- Record the insulation resistance value.

5. Acceptance Criteria:

- Compare the measured insulation resistance value with the acceptance criteria specified by the manufacturer or industry standards.

- Typically, an insulation resistance value of several megohms is considered acceptable. The specific value may vary depending on the application and standards.

6. Temperature Correction:

- If the test is conducted at a temperature significantly different from the reference temperature, apply temperature correction factors as specified in the testing standards.

7. Polarization Index (PI) Test:

- Optionally, perform a polarization index test, which involves taking additional insulation resistance measurements at specific time intervals (usually 1 minute and 10 minutes).

- Calculate the polarization index by dividing the 10-minute insulation resistance by the 1-minute insulation resistance.

- A PI value greater than 1.5 is generally considered acceptable.

8. Record and Report:

- Document all test results, including the insulation resistance values, test conditions, and any relevant observations.

- If the insulation resistance is below acceptable levels, further investigation and corrective actions are necessary.

9. Reconnect CT:

- After completing the insulation resistance test and ensuring that the results are satisfactory, reconnect the current transformer to the circuit.

Always refer to the manufacturer’s documentation and relevant industry standards for specific guidance on insulation testing procedures for current transformers. Additionally, adhere to safety guidelines and regulations during the testing process. If you are not experienced in performing these tests, consider seeking assistance from qualified personnel.