1. PURPOSE

This is about current practice in designing the power distribution system for instrumentation systems.

2. SCOPE

This article covers power distribution to the various instrumentation systems, but does not cover selection and design of equipment normally specified by the Electrical Department (e.g., how to select a UPS system, power distribution “further up” the system, or noninstrument loads such as plant lighting power).

Note:

1. For third-party plants, the client might have specific requirements concerning the power distribution system. Although these might vary from those stated in this document, the same philosophies shall be borne in mind.

2. The client requirements will be specified in the project scope definition document, but may require further elaboration.

3. To suit particular project requirements, backup supplies can also be in the form of solar power and pneumatic systems.

3. RELATED DOCUMENTS

3.1 Siemens

A5E00105505-03 Programmable Logic controllers S7-300 Module data

3.2 Engineering Articles

⊕ 3PS10004 Application of AC Power Sources for Electronic Instrumented Systems

⊕ 3PS10558 Application and use of Siemens PCS7-400AS

4. DEFINITIONS

- ASU is Air Separation Plant.

- CCTV is Close Circuit Television.

- CVT is Constant Voltage Transformer.

- PCS is Process Control System.

- FID is Flame Ionisation Detectors.

- LV is Low Voltage.

- MCB is Miniature Circuit Breaker.

- HMI: Human Machine Interface.

- TSA is Temperature Swing Adsorber.

- UPS is Uninterruptible Power Supply.

- VA is the product of voltage and current, similar to power for instrument systems (i.e., 110 V at 20 A is 2.2 kVA).

Designing Power Distribution System for Instrumentation Systems

5. Power Distribution Philosophy

- The power supply system is designed to ensure that the various parts of the instrument system have the maximum availability consistent with their function.

- Normally, the availability of the instrument system should be designed to be the same as the plant availability (i.e., if the plant trips because of electrical supply failure, the instrument system would not be required to function because the plant will have been designed to fail safe). In the case of dual-fed systems from the UPS and CVT, loss of either supply shall not cause a plant trip or major disruption to the operation of the plant.

- The electrical distribution and instrumentation power supply system configurations should match the main process and back up configuration. Such that a trip of the main incoming power supply does not affect the plant back up system and similarly the loss of the UPS system should not affect the normal plant operation.

- Exceptions to paragraph 5.1.2 are as follows:

- Instruments required for product’s backup and some product analysis shall have the same integrity and availability as the backup system.

- Complex plants might require the control system to function for a short period after power supply failure. This is necessary to perform a controlled shutdown of some equipment to facilitate start-up.

- Safety-related equipment required to operate during periods of power failure might require long-term power backup (i.e., firefighting equipment, safety-related analyser systems).

- When safe shutdown is required on the TSA if there is power loss (e.g., the valves are usually “fail lock”).

- In practice, the plant reliability, safety, and customer requirements determine the level of power supply redundancy installed. Large plants commonly have dual UPS/CVT feeds, but simplex feeds with an active UPS system are used as a lower cost alternative at the smaller end of the market.

- The use of switched mode power supplies on the plant, if they are a major portion of the load, can have an adverse effect on the performance of static UPS and CVT systems. It is important that details be provided to Electrical Design group as early as possible in the design of the power distribution systems.

- It is important that the power supply distribution system design incorporates an effective level of Fuse/MCB discrimination to protect the system without tripping those areas of the system not affected by any fault.

5.2 Power Sources

5.2.1 Unless otherwise specified, AP-E’s preferred instrument supply is 110 Vac, (50 Hz in Europe) single phase. PC-based equipment and printers installed in control rooms will usually be powered at 230 Vac single phase derived from three phase 400 Vac supplies. The instrument system itself usually operates at 24 Vdc.

5.2.1.1 It is important that dual feeds to Air Products plants are truly independent of common mode failure. The electrical single line diagram shall show two independent feeders.

5.2.1.2 Segregation of supplies is important to ensure that a single failure of supply does not cause a plant trip. Design of the system shall ensure that all critical instrumentation is supplied from two sources in dual-fed plants (i.e., UPS and CVT systems).

5.2.2 UPS Systems

5.2.2.1 UPS will continue to provide a power source if the incoming power supply has been interrupted and should be transparent to the downstream loads (i.e., the load will not see supply interruption).

5.2.2.2 Typically, the power supply is maintained by battery-supplied inverters and, therefore, is a finite energy store. In addition, UPS is normally sized to provide an autonomy time of 5–30 minutes.

5.2.2.3 UPS design shall include a bypass switch to enable essential maintenance to be performed without interrupting supply to the load.

5.2.2.4 Power outlets that are located within the control rooms and within the plants which are supplied from the UPS should be red in colour and be clearly identified as UPS-fed outlets. A warning should state that only designated loads should be connected to this outlet, thus preventing overloading of the UPS and reduced UPS autonomy times.

5.2.3 CVT Systems

5.2.3.1 When required, a CVT is used to regulate a source of 110 Vac. This source is dependent on its supply, so that equipment supplied from the CVT will de-energise on a full power outage.

5.2.3.2 A CVT differs from a standard transformer in that it is designed to smooth out variations in its input voltage, so that the variations are not passed onto the load. Typically, a 10% variation in supply will cause only a 2% variation in output.

5.2.3.3 CVT systems have a much lower cost than a UPS system.

5.2.3.4 Power outlets that are located within the control rooms and within the plants which are supplied from the CVT should be yellow in colour and be clearly identified as CVT-fed outlets. A warning should state that only designated loads should be connected to this outlet, thus preventing overloading of the CVT.

5.2.4 Normal ac Voltage (usually 230V)

5.2.4.1 The normal ac voltage is often required within the control room for noninstrument equipment. Examples include plant communication systems, CCTV equipment, and general-purpose outlets. The design of the local ac supply is by Electrical Design.

5.2.4.2 This local voltage may also be used for lighting, “convenience,” and outlets within panels, but not for instrument supplies, as this voltage is not backed up and is not “clean.”

5.2.5 Back-up Diesel Generators

5.2.5.1 To provide power for interruptions longer than the capacity of the UPS, a backup generator may be used. This may also be used to supply other loads (e.g., product backup pumps).

5.2.5.2 As these machines take a finite time to start, a UPS is needed to maintain a supply to the instruments to “ride-through” the start-up time.

5.2.5.3 Control and Instrumentation needs to liaise carefully with Electrical Design to ensure that only essential instrument loads are connected to critical backup systems, such as diesel generators.

5.3 Power Consumers

5.3.1 DCS

Note: The following description references Siemens PCS7 Control Systems, but the principles apply to other suppliers’ equipment.

5.3.1.1 The DCS equipment must be supplied from a source consistent with the plant reliability requirements, but as a minimum, must be from a CVT source.

5.3.1.2 The system cabinets have twin input ac distribution boards that accept 110 Vac from either of the two feeds. To enhance reliability, one feed is usually from the UPS and the other is from the CVT. This distribution board then feeds ac power to the two system power supplies (one from UPS board and one from CVT board) and the two field power supplies (one from UPS board and one from CVT board). The System Power supplies 24 Vdc to the Module racks powering the I/O modules, digital inputs, and all analogue loops. The field power supplies power digital output loops only via the relay contacts on the relay output boards.

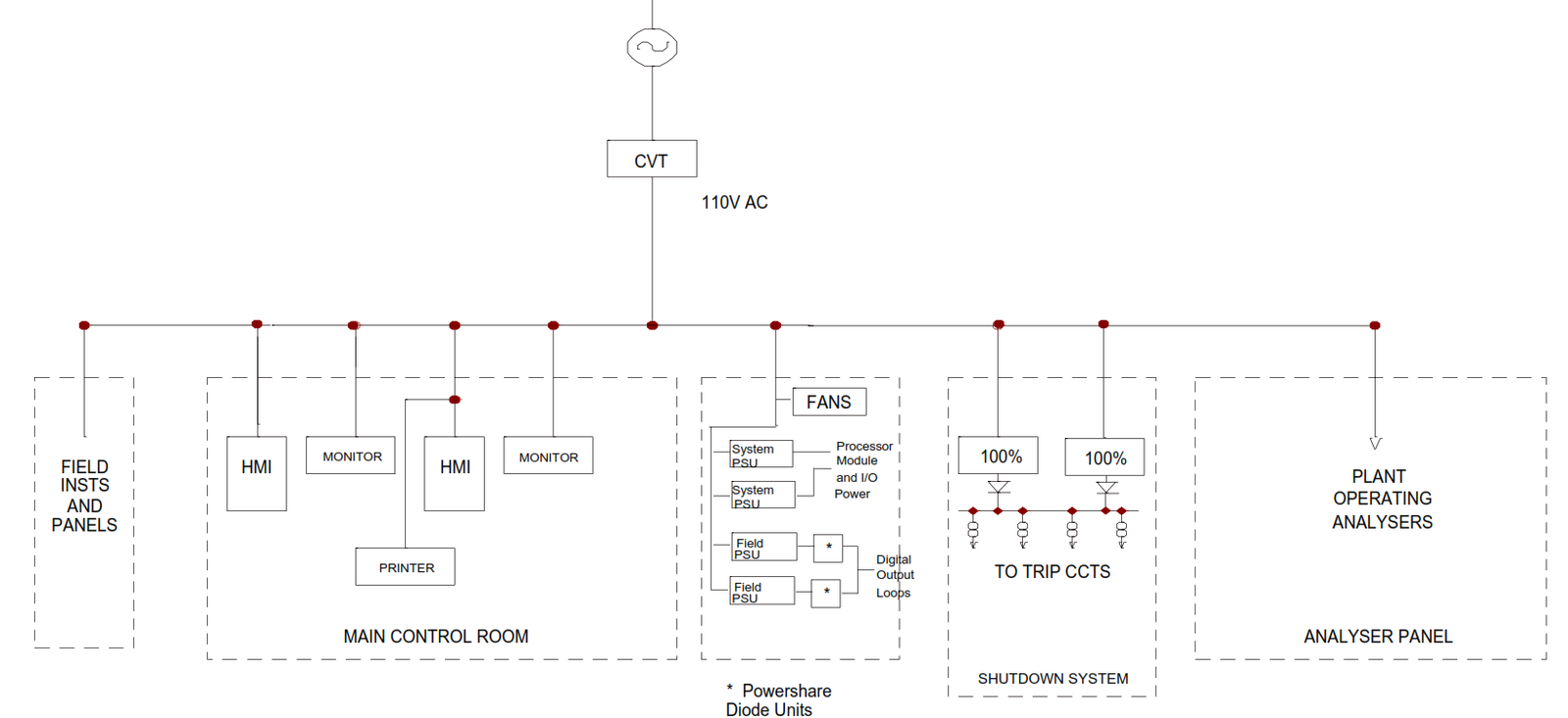

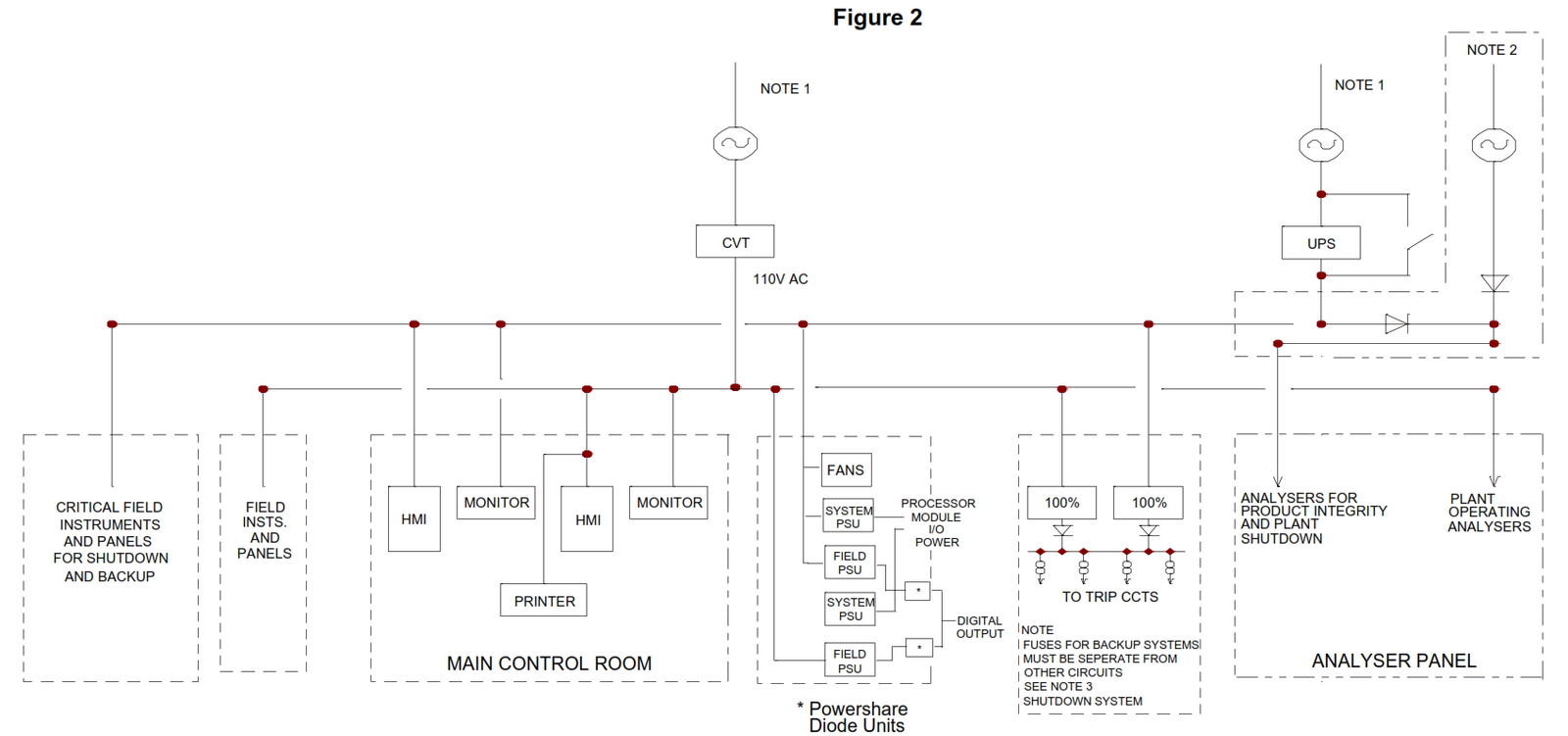

5.3.1.3 DCS HMI console and printers will be supplied at either 110 Vac or 230 Vac according to Figures 1, 2, and 3. For 230 Vac HMI systems, consoles are supplied from the UPS before the step-down transformer.

5.3.1.4 For details on the power consumption of Moore equipment, refer to the respective hardware device in A5E00105505-03 Programmable Logic controllers S7-300 Module data.

5.3.1.5 See Figures 1, 2, and 3 for typical schematics.

5.3.2 Hardwired Shutdown System Equipment

5.3.2.1 The shutdown system is designed for a 110 Vac supply. Multiple power packs offer the option for supplying this system from more than one source.

5.3.2.2 See Figures 1, 2, and 3 for typical schematics.

5.3.2.3 A secondary supply for internal lights and a utility outlet are often used. Consideration shall be given to taking the secondary supply from the prevailing “Normal ac voltage” as it shall not be taken from either a UPS or CVT source.

5.3.3 Analyser System

- Typically, analysers run from 110 VAC. However, some chromatographs and FID analysers have heavy power requirements.

- See Figures 1 and 2 for typical schematics.

- The analyser panel shall normally have dual supplies. Those analysers on emergency, safety, or product pipeline service will be UPS supplied; others will be supplied by CVT. For low reliability plants, a simplex supply with an active UPS is a cost-effective alternative. For high reliability plants, dual feds should be used for analysers which have trip functionality on loss of power supply to them.

Note: When product delivery is discontinued on loss of power (i.e., liquid to storage will trip anyway on loss of plant power), a UPS supply to the product analyser is not required.

5.3.4 Local and Field Instruments

- Instrument power is required in the field for items such as local/field panels, individually powered electronic instruments (ultrasonic flow meters, level switches), analyser sample pumps, and others. If these instruments are on safety or backup service, UPS supply is required; otherwise, a CVT supply shall be used. For high reliability plants, dual feds should be used for instruments which have trip functionality on loss of power supply to them.

- See Figures 1 and 2 for typical schematics.

5.3.5 Equipment Packages

Equipment packages might need instrument power.

5.3.6 High Level Control Systems (i.e., host computer)

5.3.6.1 Since the host computer is not an essential service, nor a safety item, UPS supply is not required. However, it is desirable to supply power from the instrument supply system (via the CVT), rather than from the local ac voltage. The computer system will normally be powered at 230V ac via a step-up transformer.

5.3.7 Communication Equipment

- Communication equipment, whilst not strictly part of the instrument system, requires power. This category includes such equipment as radios, CCTV, gate controls, and trailer fill intercoms. The design of power systems for this equipment is the responsibility of Electrical Design.

- Man down (lone worker protection) systems shall be powered from UPS.

5.4 Power Distribution

- Figures 1 and 2 show typical instrument power distribution for plants with pipeline customers that might require a UPS and a stand-alone liquefier that might not need a UPS.

- The decision to include a UPS shall depend on economic and supply reliability grounds. Operations will normally insist on a UPS for all plants including stand-alone liquefiers, because the cost of an unscheduled plant shutdown outweighs the cost of a UPS.

5.5 Responsibility

- The Instrument Engineer is responsible for identifying the total instrument loads for inclusion in the LV load list. When the loads have been identified, this enables Electrical Design to proceed.

- During detail design, the Instrument Designer identifies and rates all instruments/panels requiring power supply. In addition, the Instrument Designer designs the layout of the distribution boards and the MCB ratings and locates them in a convenient location.

- The Electrical Department is responsible for sizing according to paragraph 5.5.2, running the cables to the distribution boards, and for specifying the distribution boards, which will be provided as part of the installation contract. Power distribution from these boards will be

supplied by Electrical Design.

Figure 1 – TYPICAL INSTRUMENT POWER DISTRIBUTION WITHOUT BACKED UP SUPPLY

Typical Instrument Power Distribution for Plants

Notes:

1. Individual or one common feed to be agreed on each project.

2. If required an essential services supply will be connected as shown.

3. Fuses for backup systems must be separate from other circuits and each backup circuit must be individually fused to prevent common mode failure.

Typical Instrument Power Distribution for Plants