1) EQUIPMENT AIM :

To detect the presence of combustible gas in the air or the presence of layers of liquid hydrocarbons.

2) STANDARDS OF INSTALLATION :

GS-AMO-SL-029 and STD-AMO-SL-354.

3) CONCERNED INSTALLATIONS :

All liquid hydrocarbon tanks with a storage temperature higher than the flash-point and with operational capacity up to 100 m³.

All liquid hydrocarbon tanks with a storage temperature lower than the flash-point and with operational capacity up to than 5.000 m³.

All separators of liquid hydrocarbon depots whatever are their capacities.

4) TIMELINE OF EQUIPMENT INSTALLATION:

Mandatory for new depots.

All existing depots must be equipped before the end of 2017.

5) DESCRIPTION OF THE EQUIPMENT:

| Vapour HC optic detector « HCV » with infrared absorption (type OLDHAM OLCT IR Version E) |

|

| Liquid HC detector « HCL » consists of 1 sensor connected to a float. It uses the density difference between water and hydrocarbons for detection (LARCO HK1H type) – 2 sensors for separator (LARCO HK2H type) |

|

Sensors are fail safe connected: in case of failure they have to indicate the defect (loss of current, break in the cable…). Information acquisition could be managed by automate or by a dedicated station. The minimal action will be audible and visual alarm activation. This equipment will be protected with an uninterruptible power supply (UPS).

| Stored products | Bund compartment (at the lowest point) | Pump house (at the lowest point) | Separator |

| Product with T°C of storage higher than the flash-point |

1 HCV |

1 HCV |

1 HCL (HK2H type) Into the second last

separator compartment (concrete) Or into the last separator compartment (prefabricated) |

| Product with T°C of storage lower than the flash-point | 1 HCL | 1 HCL | |

| Mixed | 1 HCV + 1HCL | 1 HCV + 1HCL |

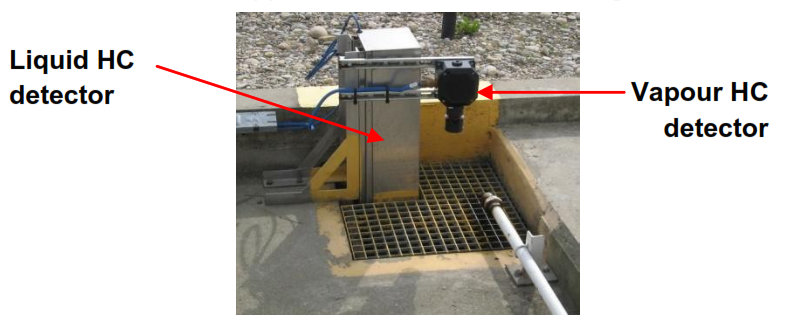

6) VISUAL OF THE EQUIPMENT AND BUDGET ESTIMATION:

Installed on a support at about 40 cm from the ground level.

Estimative cost: 3 k€ per detector

Add:

– preparatory costs (works, cables)

– installation costs and commissioning AME’s contract with purchasing department.

7) MAINTENANCE OF THE EQUIPMENT :

HCL DETECTOR – LARCO type |

||

| Frequency | Control | Actor |

| Daily | Check the cleanness of the pit where the detector is installed – clean it if needed. | Depot collaborator |

| Quarterly | Check if the float slides without constraints on its rail. Test the operation of the detector by immersing it in water to check the transmission of the visual and sound alarm to the control panel and the linked actions. Clean the detector. | Depot collaborator |

HCV DETECTOR – OLDHAM type |

||

| Monthly | Check if the detector is in good condition. | Depot collaborator |

| Quarterly | Calibrate the detector with a standard gas (be careful: the standard gas cylinders have a best before date) and realize a functional test. Check the transmission of the alarm to the detection system (visual and sound). | Depot collaborator |

| After each vapour detection | Check the good functioning of the detector and the absence of drift. | Depot collaborator |

HC DETECTION SYSTEM – CONTROL PANEL |

||

| Daily | Check the absence of detection and alarm and that all LED of detectors are green. | Depot collaborator |

| Weekly | Use the TEST button to check the good functioning of the LED and buzzer (sound alarm). | Depot collaborator |

Every intervention has to be recorded on the life-sheet of the equipment.

8) DOWNGRADED SITUATION :

HCL DETECTION |

|

| Problem on the detector or on the connection between the HCL detector and the electrical office | Increase frequency of rounds – replacement by a HCL detector in stock if available. |

| Failure of site general power supply | The power supply of the HCL detectors has to be automatically secured by a generator or UPS (electronic cards have to be protected). |

| Defect of a HCL detector | Increase frequency of rounds – replacement by a HCL detector in stock if available. |

HCV DETECTION |

|

| Problem on the detector or on the connection between the HCV detector and the electrical office | Increase frequency of rounds and implementation of a mobile detector (reload it regularly and alternate with another mobile detector). |

| Failure of site general power supply | The power supply of the HCV detectors has to be automatically secured by a generator or an inverter (electronic cards have to be protected). |

| Defect of a HCV detector | Increase frequency of rounds and implementation of a mobile detector (reload it regularly and alternate with another mobile detector). Replacement if possible with another HCV detector. |