10. Duct Insulation in HVAC | Insulate HVAC Heating and Cooling DuctWork

10.1 General

10.1.1 Adhesive and Insulation materials shall be non-combustible as defined in NFPA Standard 220 and shall have a composite fire and smoke hazard ratings maximum 25 for flame spread and 50 for smoke developed. Adhesives shall be waterproof and comply with ASTM C916.

10.1.2 Jacketing material shall be ASTM C921, Class 1 unless indicated otherwise.

10.1.3 All insulation shall confirm to ASHRAE 90.1 minimum R-values.

10.1.4 Fire test characteristics shall be in accordance with the requirements of this section and ASTM E84.

10.2 Materials and Components

10.2.1 Exposed rectangular duct and plenum insulation shall be mineral fiberboard thermal insulation with glass fibers bonded with a thermosetting resin. Insulation shall comply with ASTM C612, Type1B, without facing and with all service jacketing manufactured from kraft paper, reinforcing scrim, aluminum foil and vinyl film.

10.2.2 Rectangular Ducts (Acoustic Liner): Fiberglass insulation with k value at 24°C maximum 0.035 W/M °C, absolute roughness of exposed surface not to exceed 0.0013, surface treated for fire and abrasive resistance at air velocities up to 20 m per second, 48 kilograms per cubic meter density applied with rubber based

10.2.3 Round duct and concealed rectangular duct insulation shall be mineral fiber blanket insulation with glass fibers bonded with a thermosetting resin. Insulation shall comply with ASTM C553, Type 2, without facing and with all service jacketing manufactured from kraft paper, reinforcing scrim, aluminum foil and vinyl film.

10.2.4 Aluminum jacketing shall be deep corrugated sheet manufactured from aluminum alloy complying with ASTM B209M. Jacketing shall have an integrally bonded moisture barrier over the entire surface in contact with the insulation.

10.2.5 Glass cloth jacketing and tape shall be a woven glass fiber fabric, plain weave, pre-sized a minimum 270 g/m2. Glass tape width shall be 100 mm.

10.3 Execution

10.3.1 Preparation:

- Covering shall not be installed before ductwork and equipment has been tested and approved.

- Dust surface shall be clean and dry prior to installation. Insulation shall be dry before and during application. System shall be finished at operating conditions.

10.3.2 Installation:

- Insulation materials, accessories and finishes shall be applied according to the manufacturers written instructions, with smooth, straight and even surfaces, free of void throughout the length of ducts and fittings.

- Thermal insulation shall be applied externally. Duct penetrations shall be packed with fireproof self-supporting insulation material, properly sealed.

- c. Insulation shall be finished neatly at hangers, supports and other protrusions. d. Insulation or cover seams shall be located in the least visible locations.

- Glass cloth jacketing shall be provided on exposed insulation throughout the building interior, including equipment room. Insulation located in crawl spaces, shafts and suspended ceiling spaces shall not considered exposed. Pre-sized paper shall be used under jacketing at uneven insulated surfaces.

- f. Aluminum jacketing shall be provided for exterior insulated ductwork.

- Exposed rectangular duct rigid insulation shall be secured with 50 percent coverage of adhesive and 12 gauge galvanized impale anchor tabs on 400 mm centers.

- Joints and breaks shall be sealed with 100 mm wide strips of open mesh glass cloth or tape embedded between 2 coats of vapor barrier sealant. Other joints and breaks shall be pointed up with hydraulic setting cement.

- Concealed rectangular duct blanket insulation shall be adhered to ductwork with adhesive applied in 150 mm wide strips on 400 mm centers. Sixteen gauge annealed tie wire tied, spiral wound or half hitched shall be installed on 400mm centers for securing duct insulation until adhesive sets. Insulation and seal joints and breaks shall be butted with 50 mm lap of foil adhered over joint.

- Separation of joints or cracking of insulation due to thermal movement or poor workmanship shall be repaired.

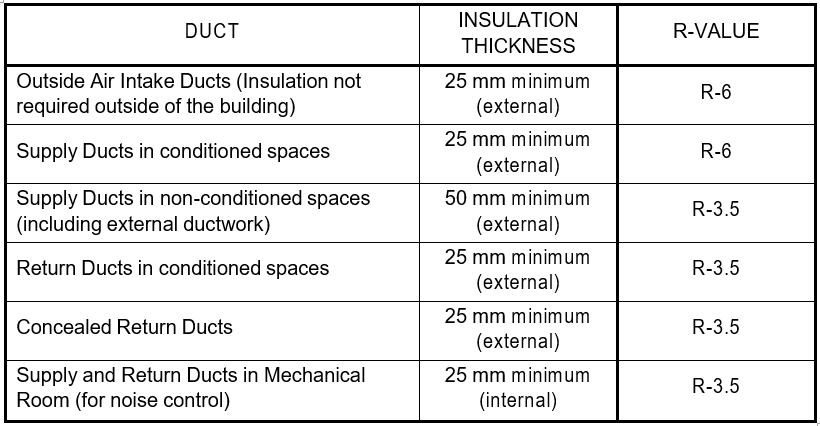

- Insulation Thickness Schedule

Table III – Duct Insulation