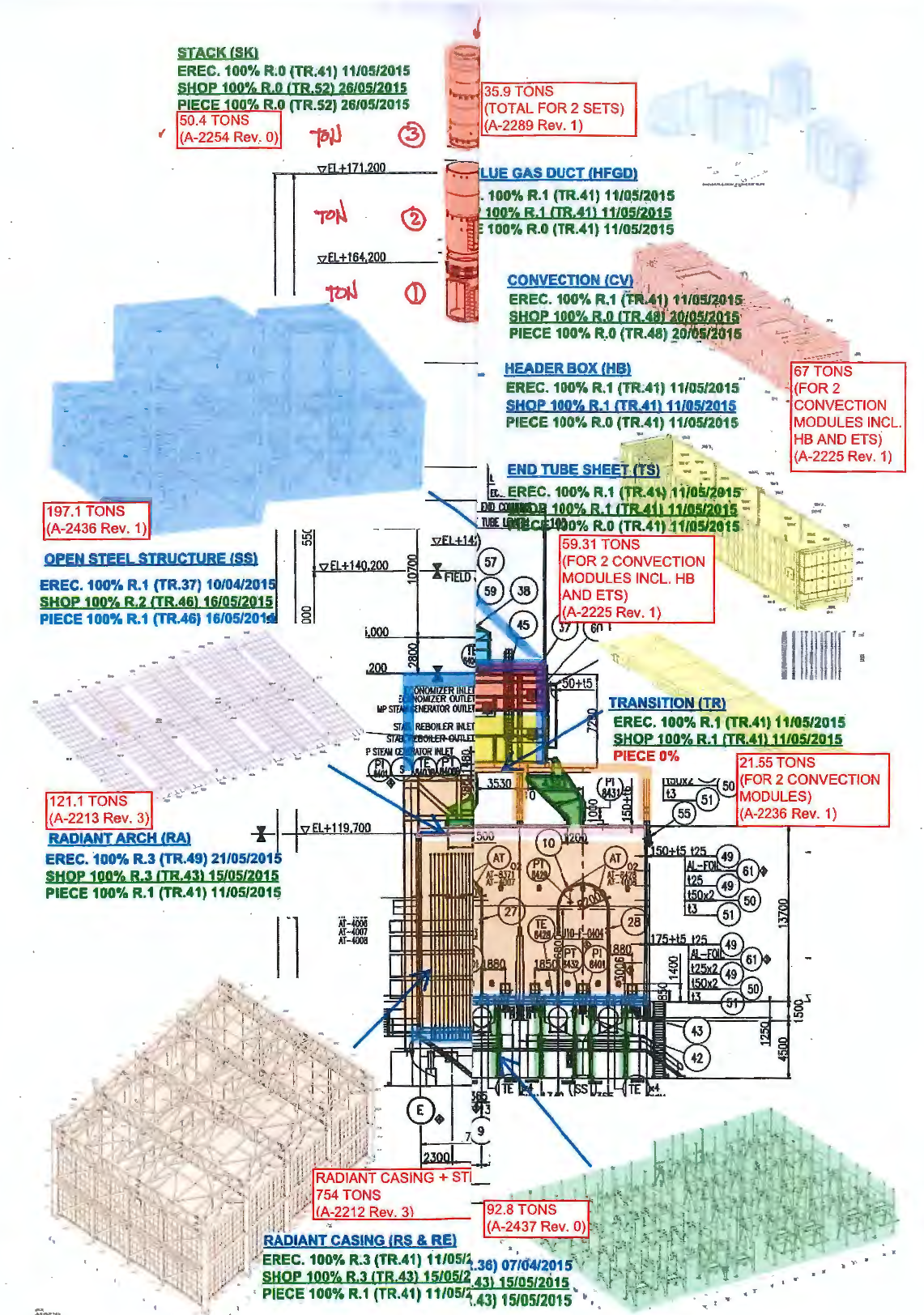

Erection sequence for Reformer Furnaces

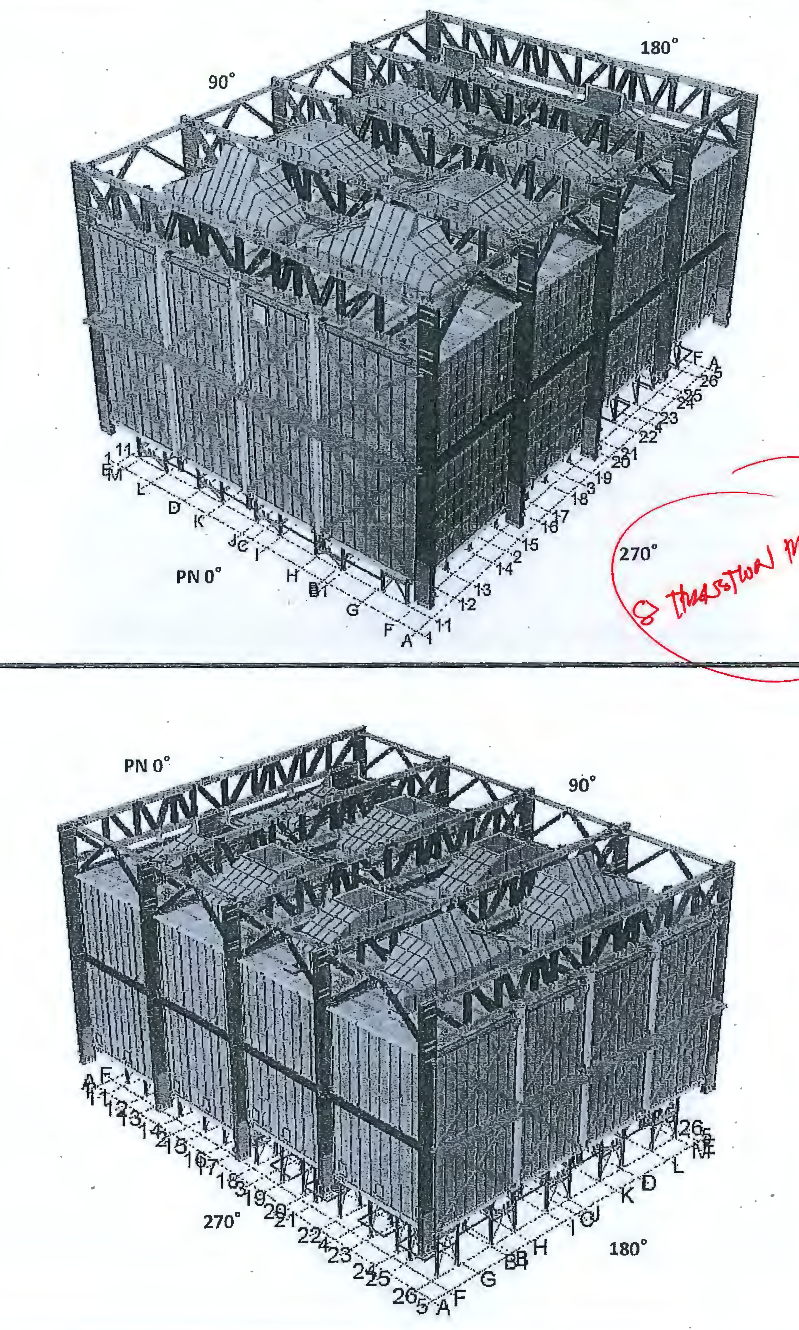

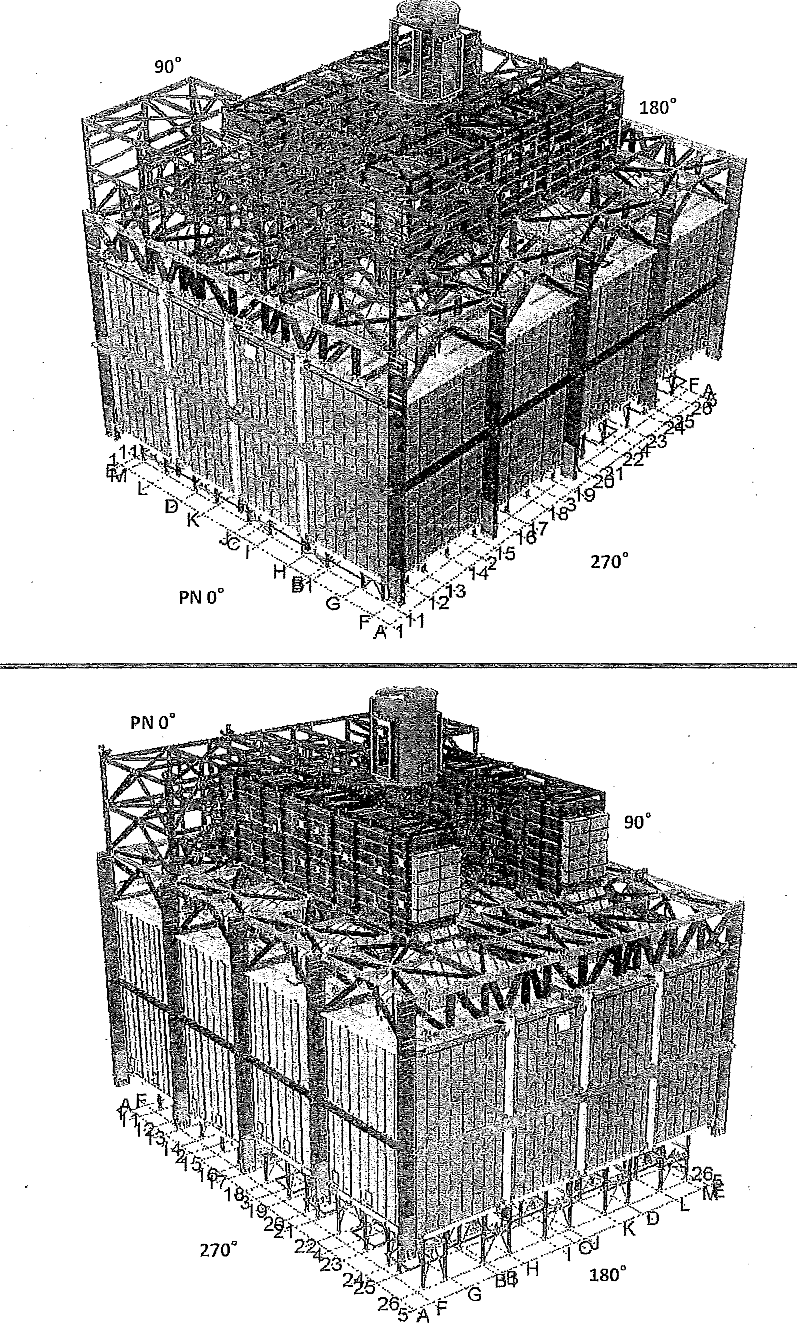

1. After arrival of 1st Shipment.

A) Set of 90 deg. and 270 deg. sides Main columns (A-1-3, E-1-3)

B) Set of Floor beam support stanchion (B-D-1, B-D-2, B-D-3)

C) Installation of 90 deg. and 270 deg. side Beams {between A-1-3, E-1-3)

D) Installation of Floor beam (Line Nos. 1-3)

E) Installation of Reinforcement column & beams of O deg. side

F) Installation of 90 deg. and 270 deg. sides Lower/Upper panels (Total : 24 panels) for J10-F-0401, 0402 Lower panel : 12 panels, Upper panel : 12 panels

G) Installation of O deg. side Lower panels (Total: 16 panels) Lower panel : 8 panels, Upper panel : 8 panels.

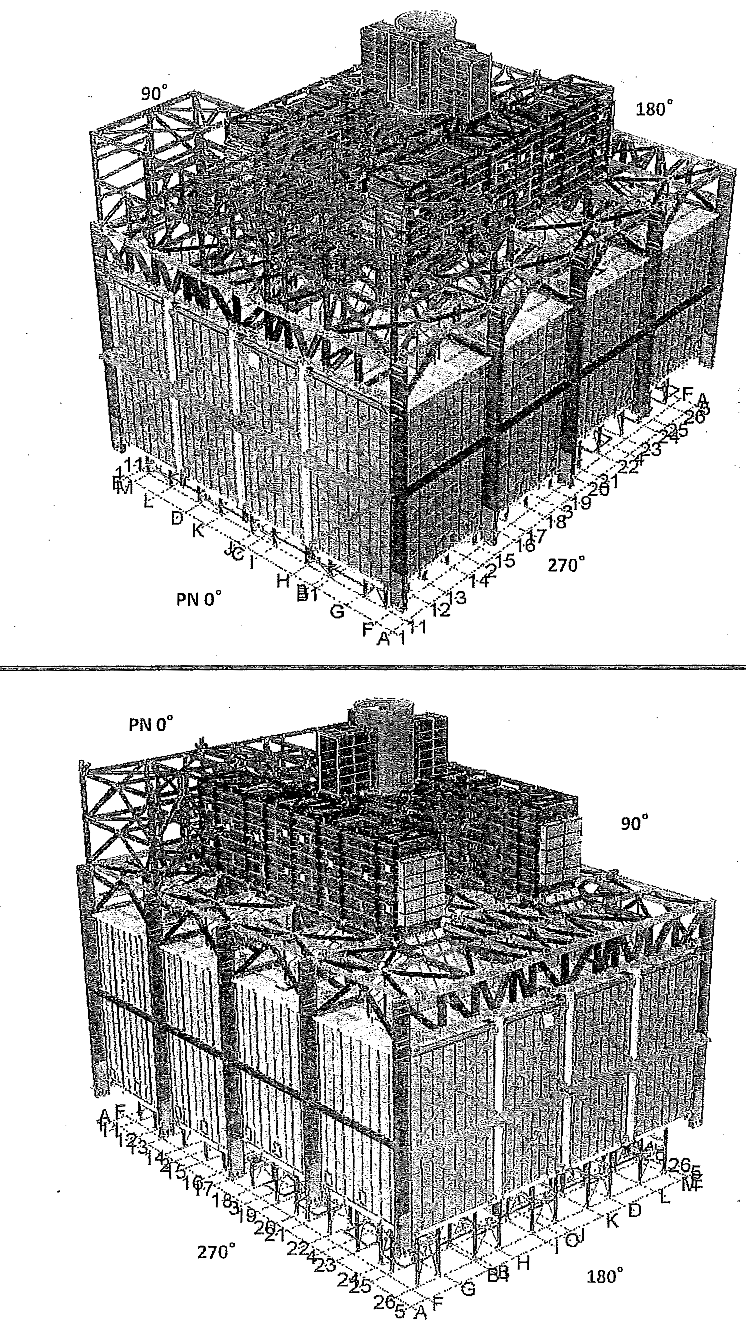

2. After arrival of 2nd Shipment.

A) Set of Main columns (A-4 & 5, E-4 & 5).

B) Set of Floor beam support stanchion (B-D-4, B-D-5).

C) Installation of Floor beam (Line Nos. 4 & 5).

D) Installation of Reinforcement column & beams of 180 deg. side.

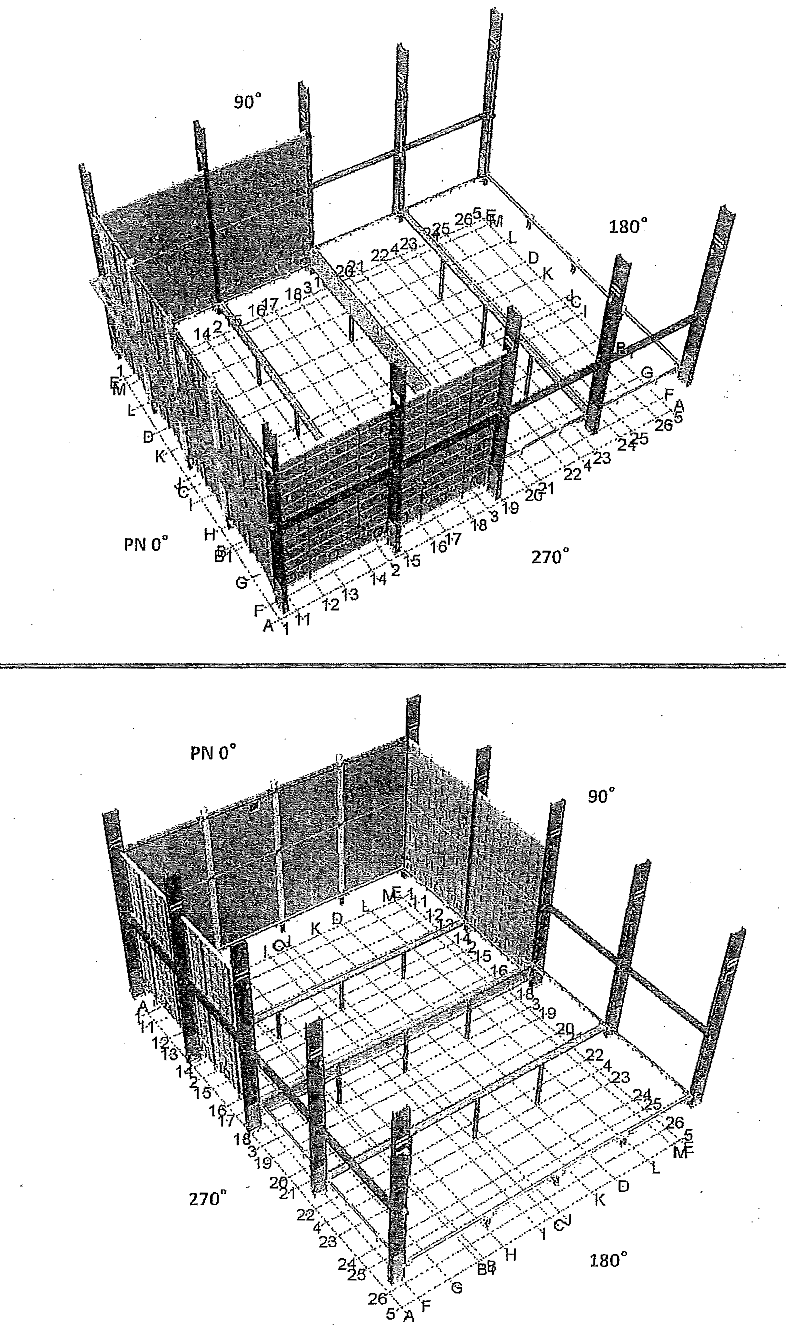

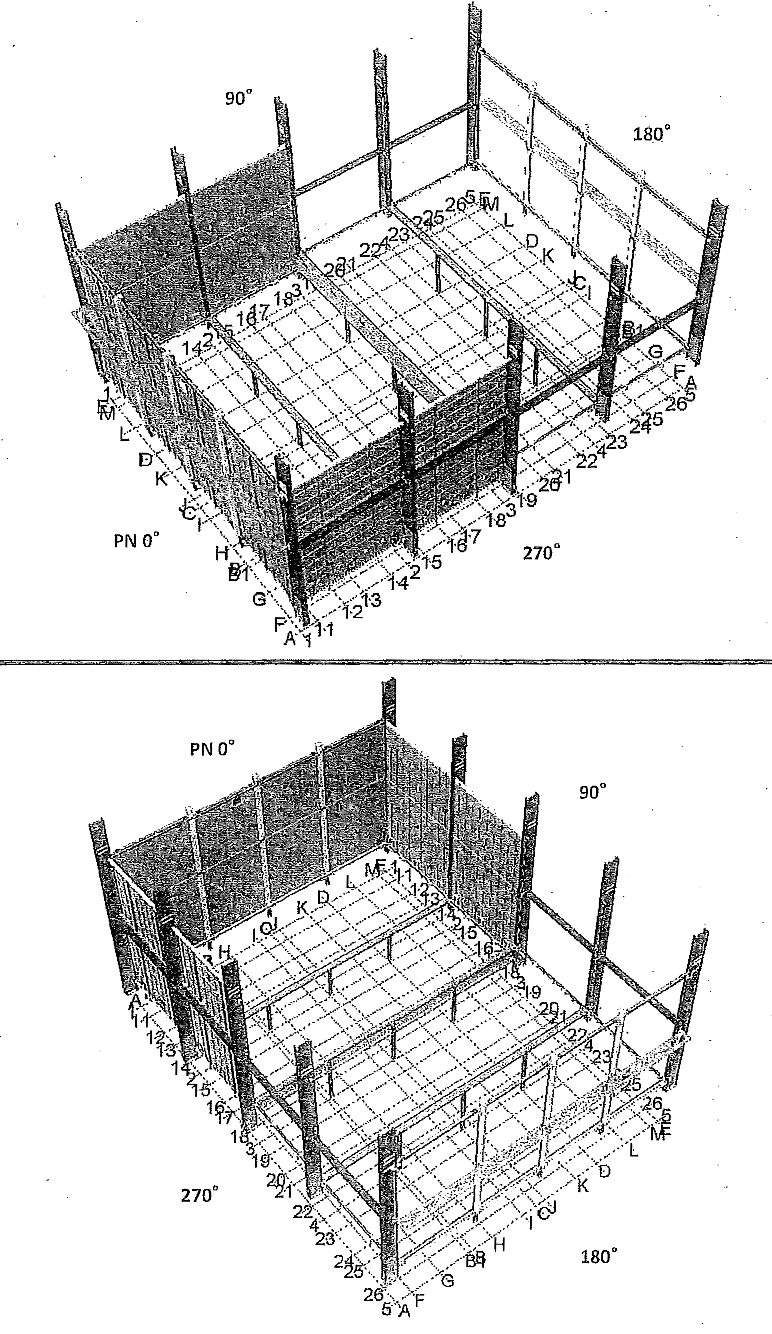

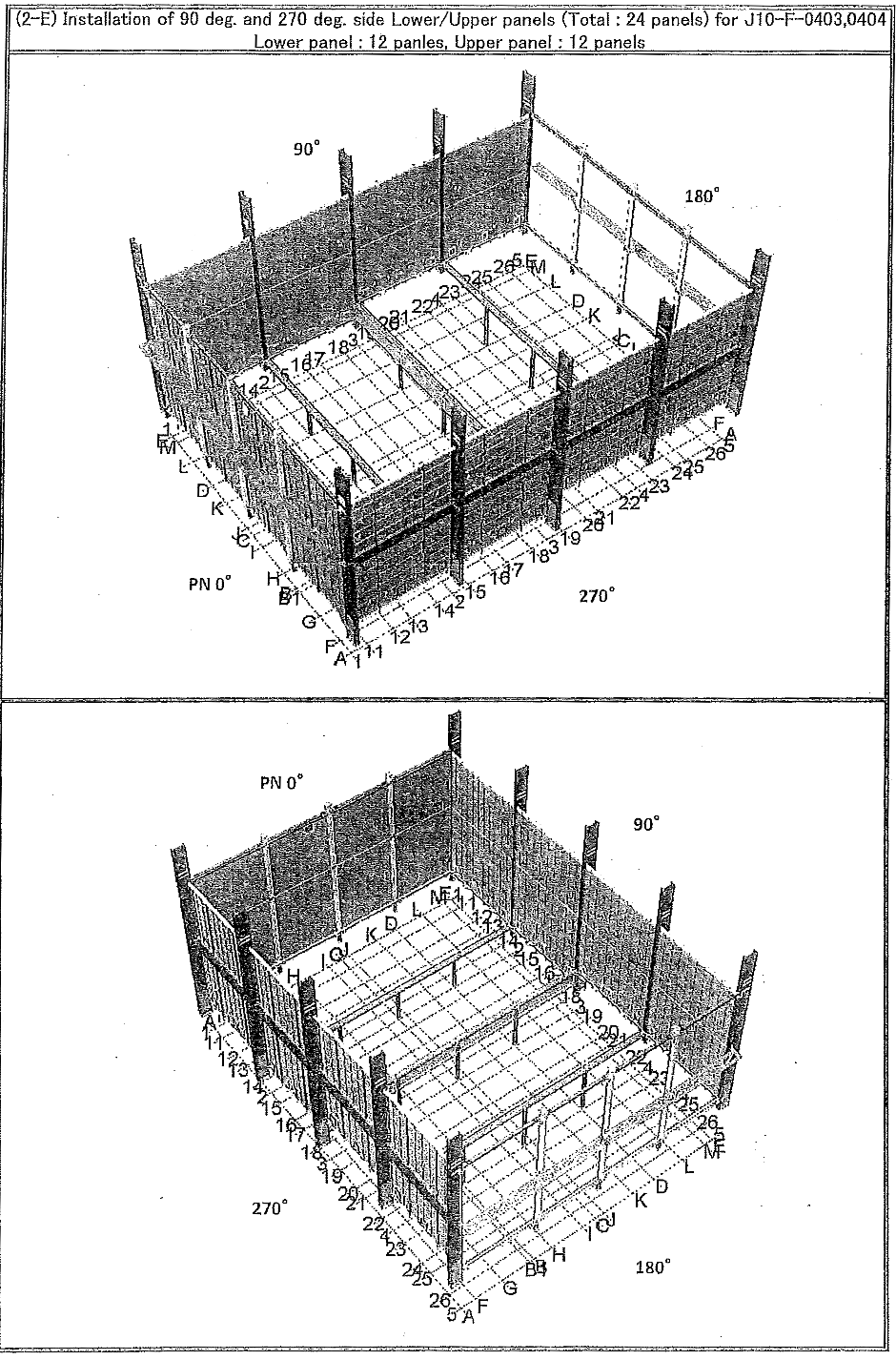

E) Installation of 90 deg. and 270 deg . sides Lower/Upper panels {Total : 24 panels) for J10-F-0403, 0404.

Lower panel : 12 panels, Upper panel : 12 panels

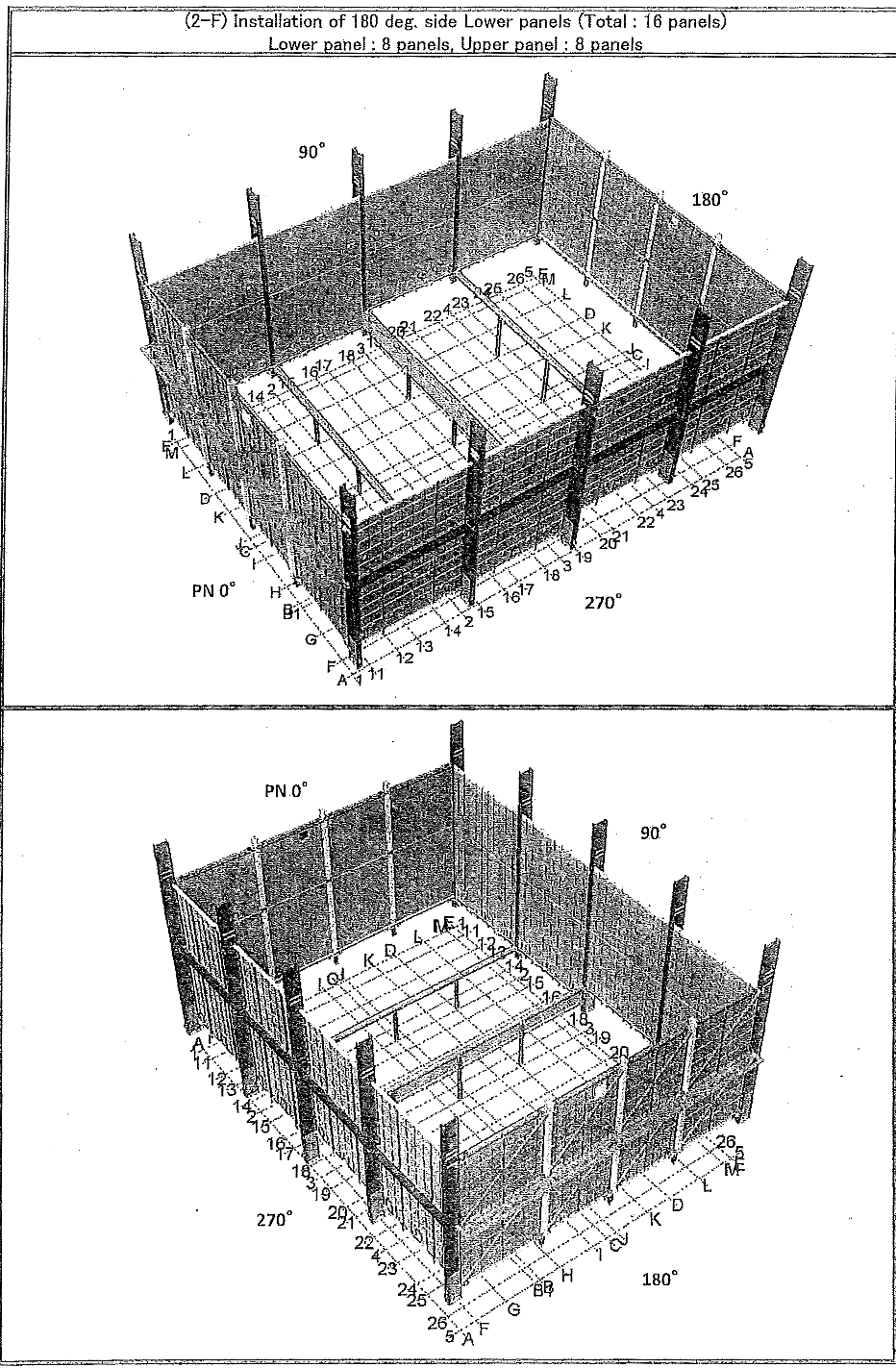

F) Installation of 180 deg . Lower panels {Total: 16 panels).

Lower panel : 8 panels, Upper panel : 8 panels

G) Installation of Header support (B’-11-26, D-11-26, F-11-26, G-11-26, H-11-26, 1-11-26, J-1-26, K-11-26, L-11-26, M-11-26).

H) Installation of Floor Panels ( Inside section of Radiant coil) for J10-F-0410, 0402, 0403, 0404.

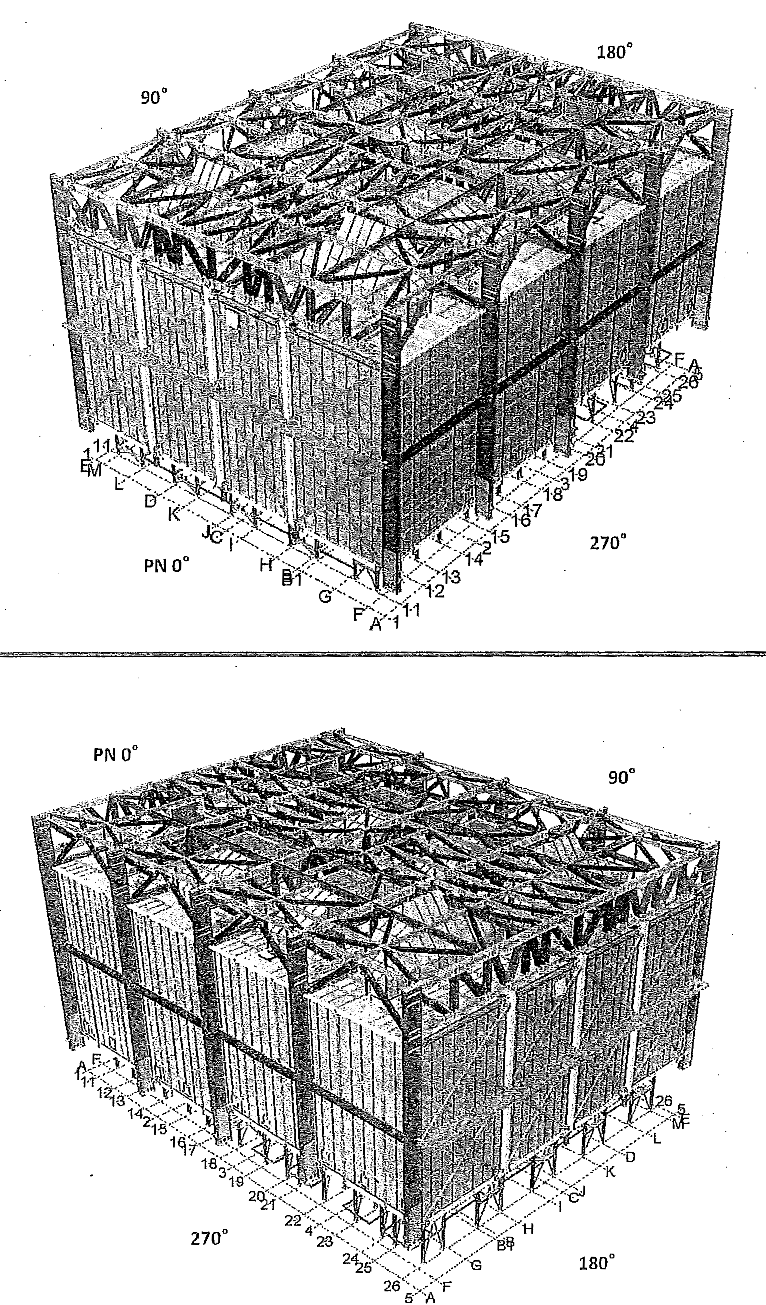

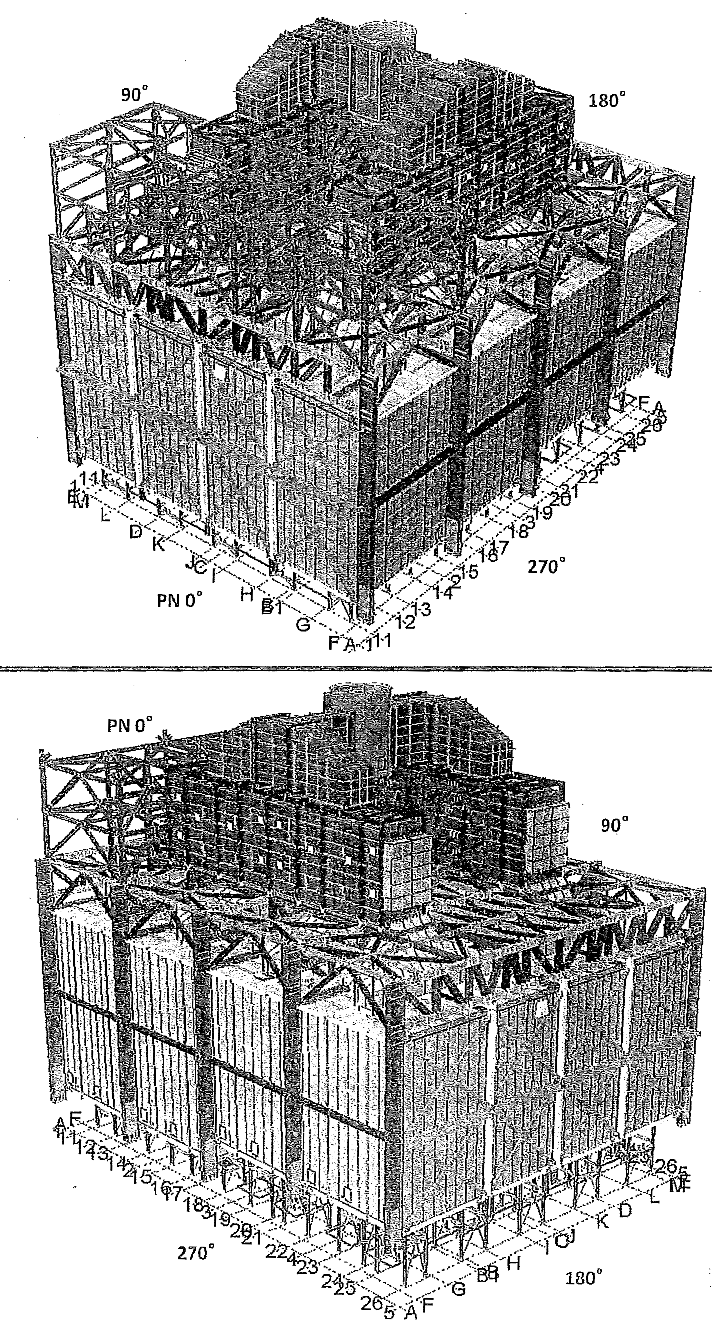

3. After arrival of 3rd Shipment (End of Dec. 2015)

A) Installation and adjustment of Header with Radiant coils for J10-F-0401, 0402

B) Installation of remaining Floor panels for J10-F-0401, 0402

4. After arrival of 4th Shipment

A) Installation and adjustment of Header with Radiant coils for J10-F-0403, 0404.

B) Installation of remaining Floor panels for J10-F-0403, 0404.

C) Installation of Radiant Arch truss frame with radiant arch beams for Column Line Nos. 1-5.

D) Installation of Radiant arch structure for Column Line Nos. A & E.

E) Installation.of Radiant arch panels.

F) Installation of Transition duct block (Refractory lining to be done on the ground).

G) Installation of Radiant arch structure for Column line nos. 81, 82, C1, C2, D1, D2.

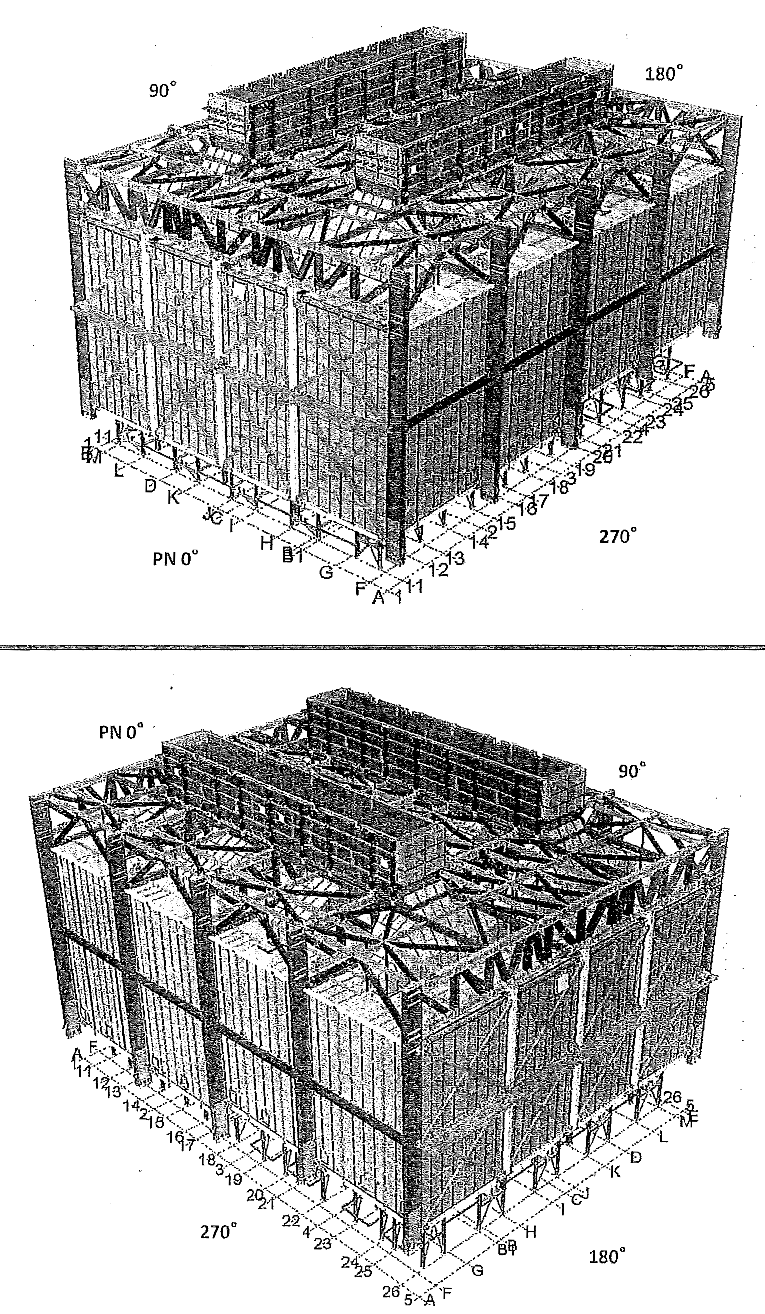

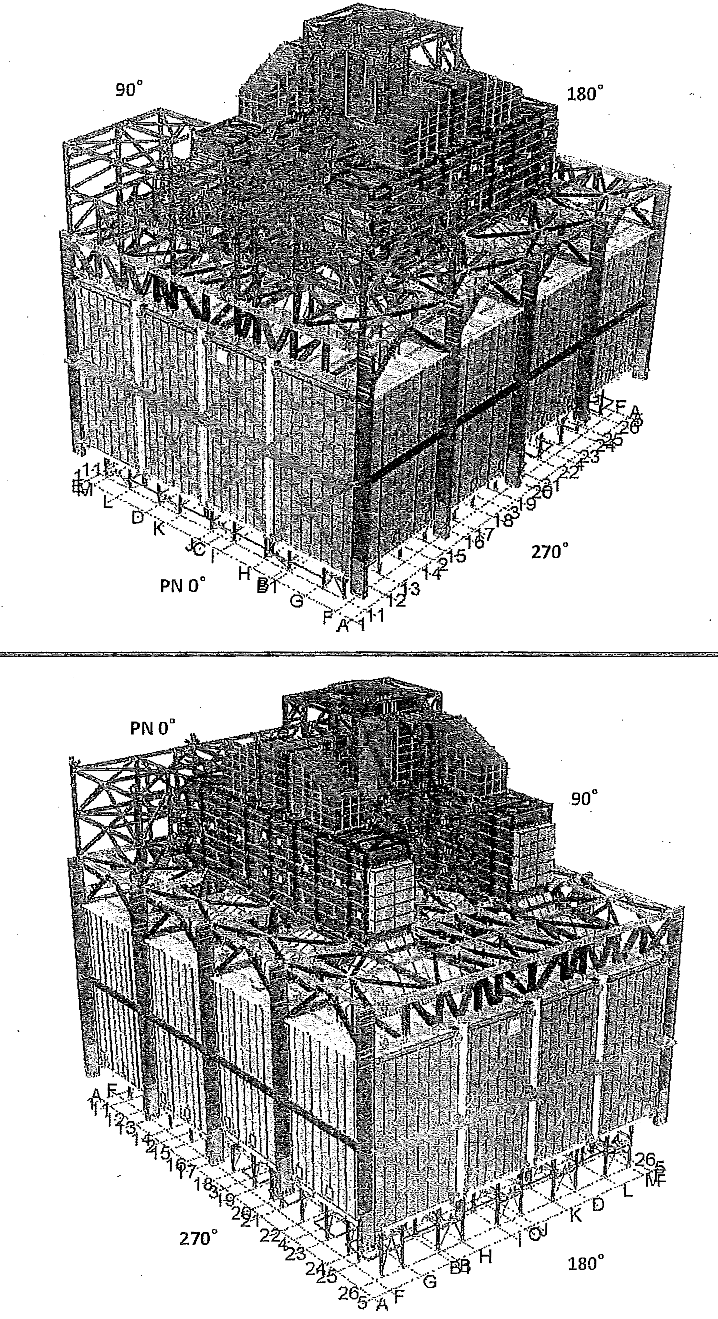

5. After completion of erection until Transition duct and Radiant section

A) Installation of lower convection module.

B) Installation of upper convection module with breeching.

C) Installation of convection and piping structure (to EL +32200 from EL +24200).

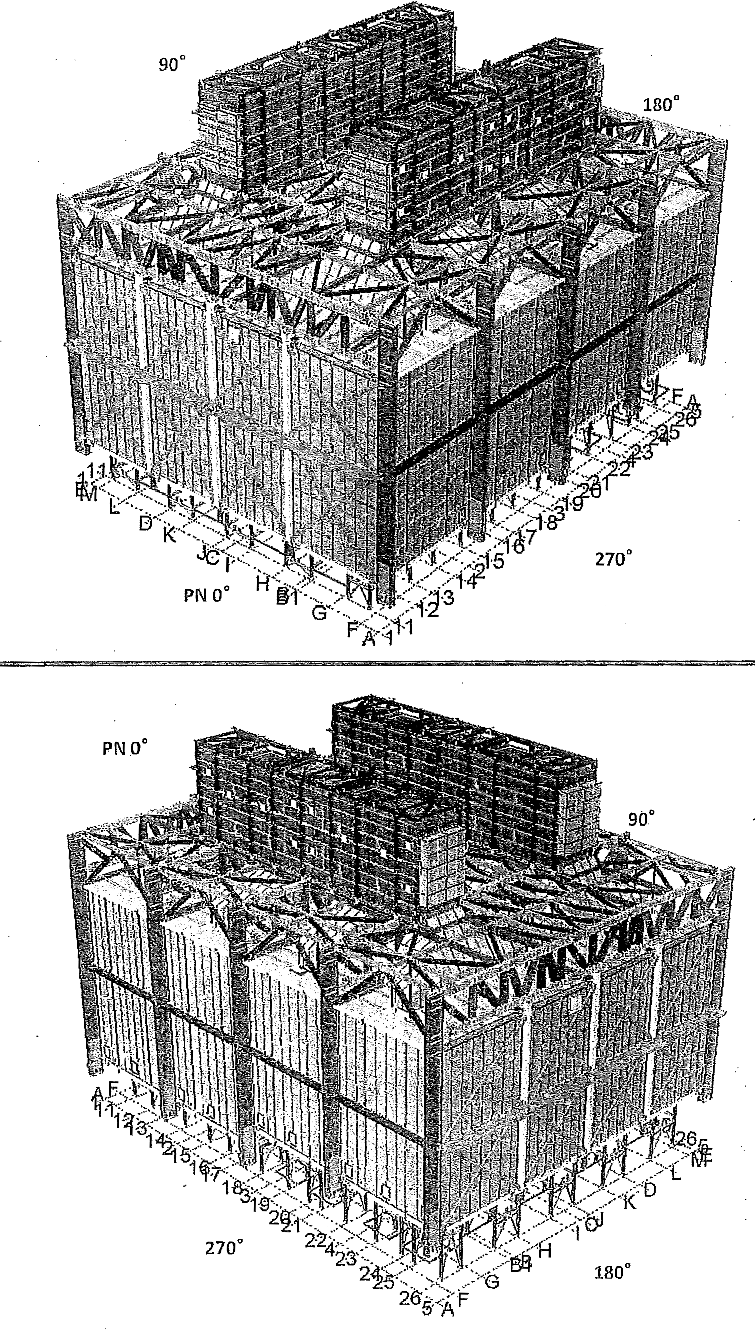

6. After completion of erection for Convection section

A) Installation of Stack bottom duct.

B) Installation of Flue gas outlet duct between Flue gas x-over duct and Stack bottom duct.

C) Installation of Flue gas x-over duct.

D) Installation of Stack structure.

E) Installation of Stack lower block. ( Stack lower/middle sections and the damper unit to be combined on the ground by welding).

F) Installation of Stack upper block.

G) Installation of Piping structure (to EL +43250 from EL +32200).

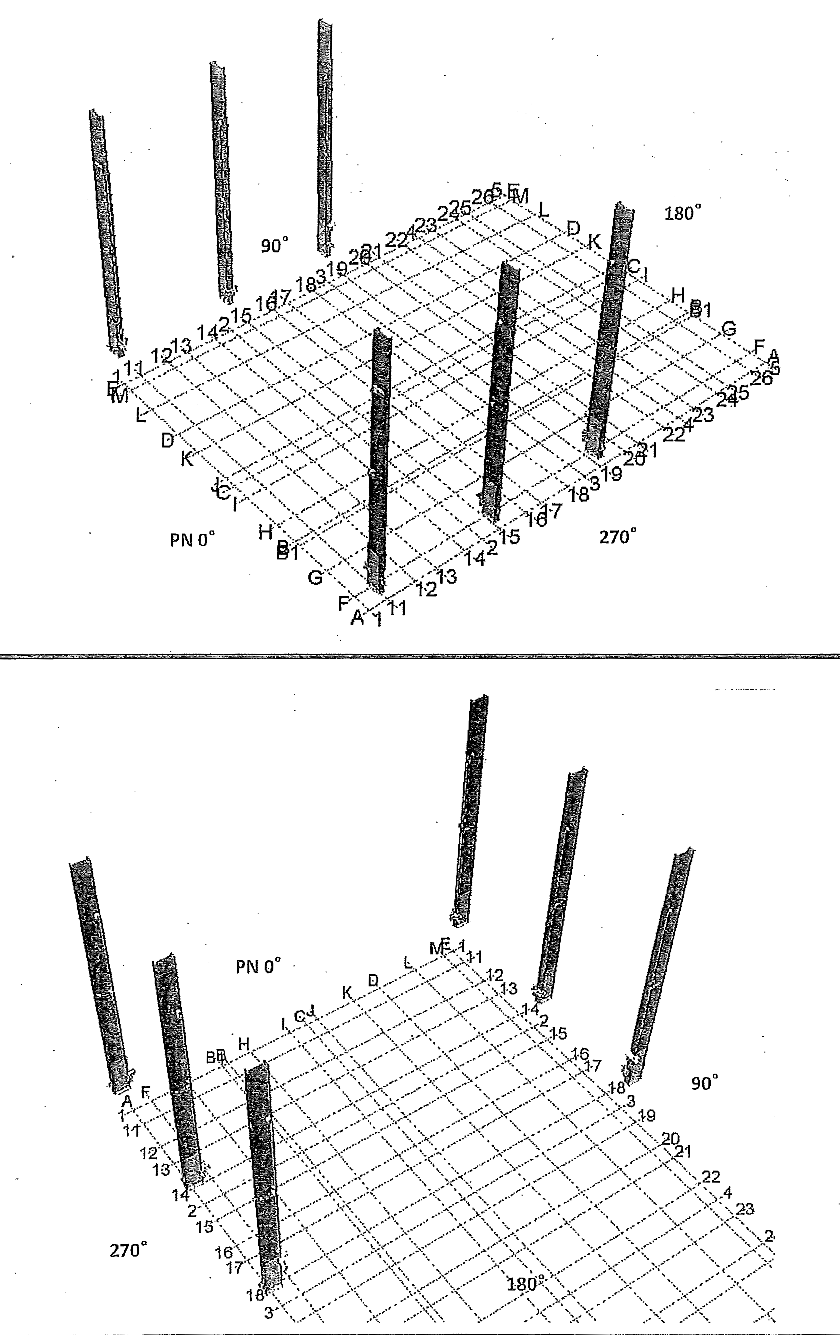

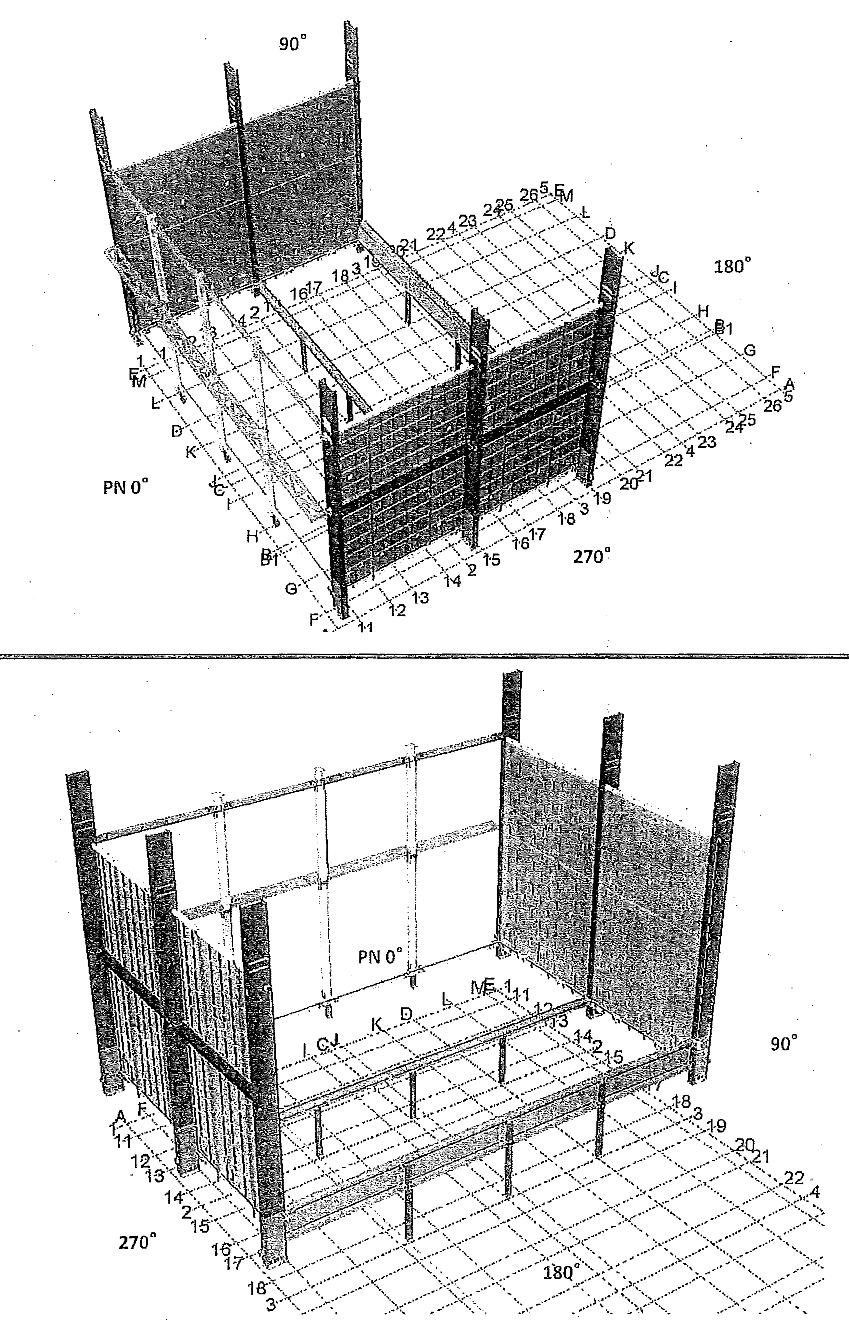

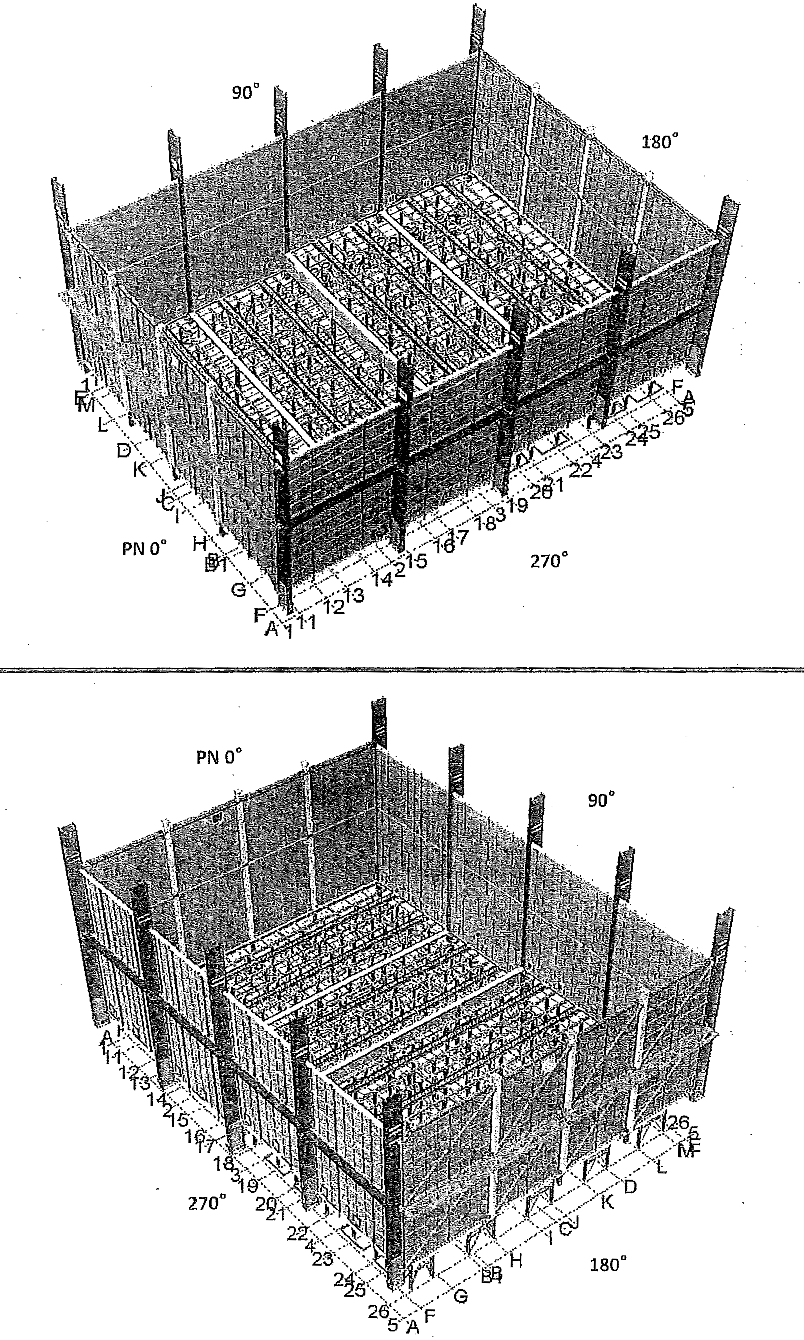

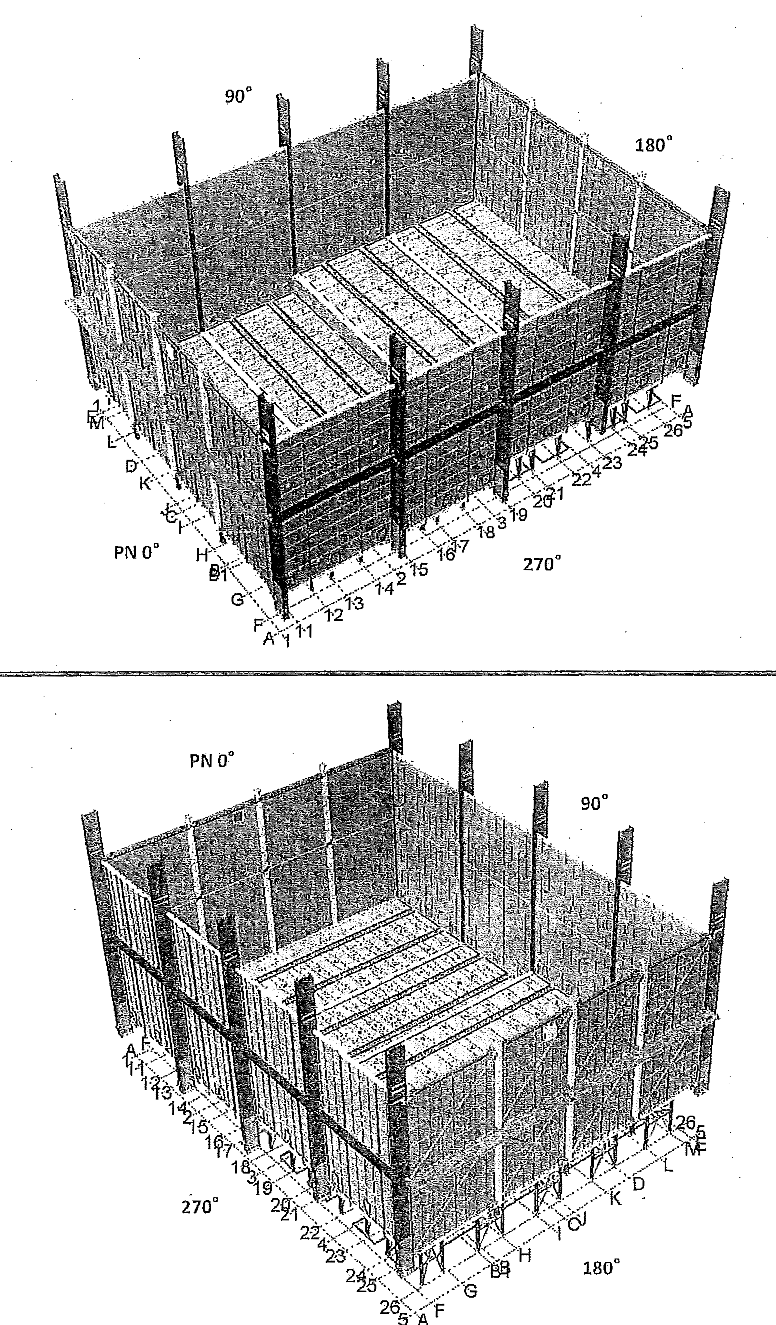

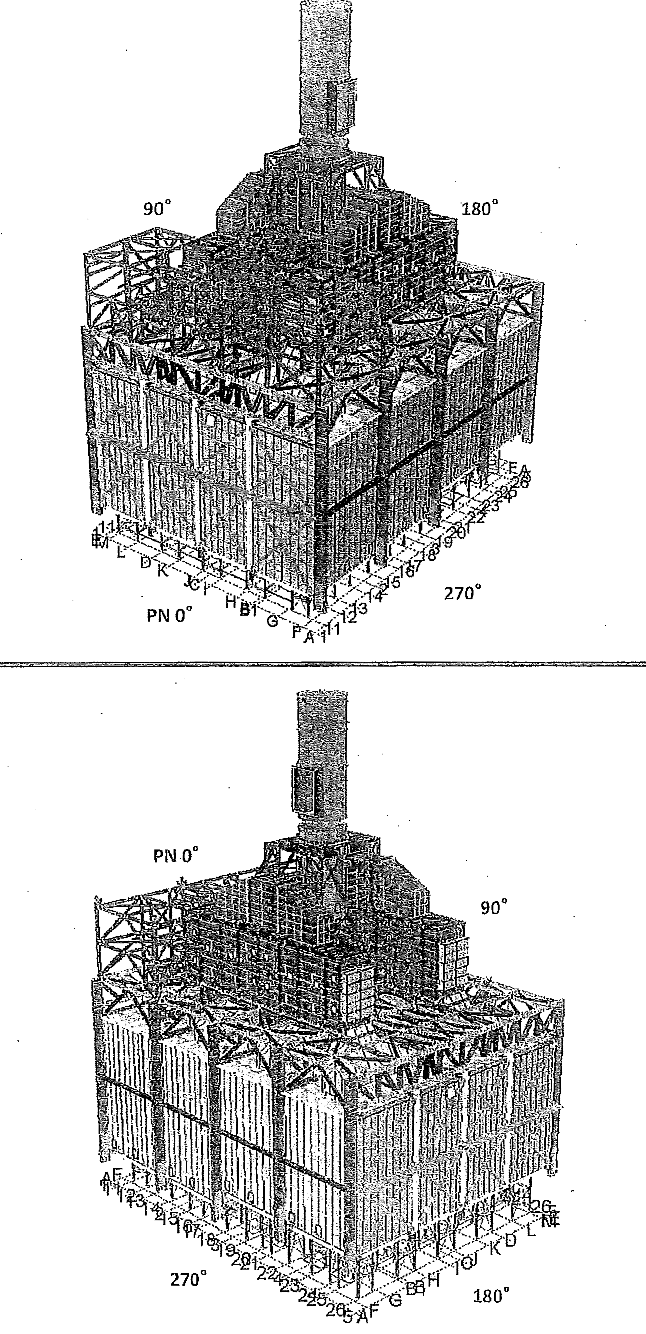

(1-A ) Set Of 90 deg. And 270 deg. sides Main column (A-1~3, E-1~3)

(1-B) Set of Floor beam support stanchion (B∼D-1, B∼D-2, B∼D-3)

(1-C) Installation of 90 deg. and 270 deg. side beams (between A-1 ∼ 3, E-1 ∼ 3) (1-D) Installation of Floor beam (Line Nos. 1∼3)

(1-E) Installation of Reinforcement column & beams of 0 deg. side

(1-F) Installation of 90 deg. and 270 deg. side lower/Upper panels (Total : 24 panels) for J10-F-0401, 0402 Lower Panel : 12 Panels Upper Panel : 12 Panels

(1-G) Installation of 0 deg. side lower panels (Total: 16 Panels) Lower Panels: 8 , Upper Panels ; 8

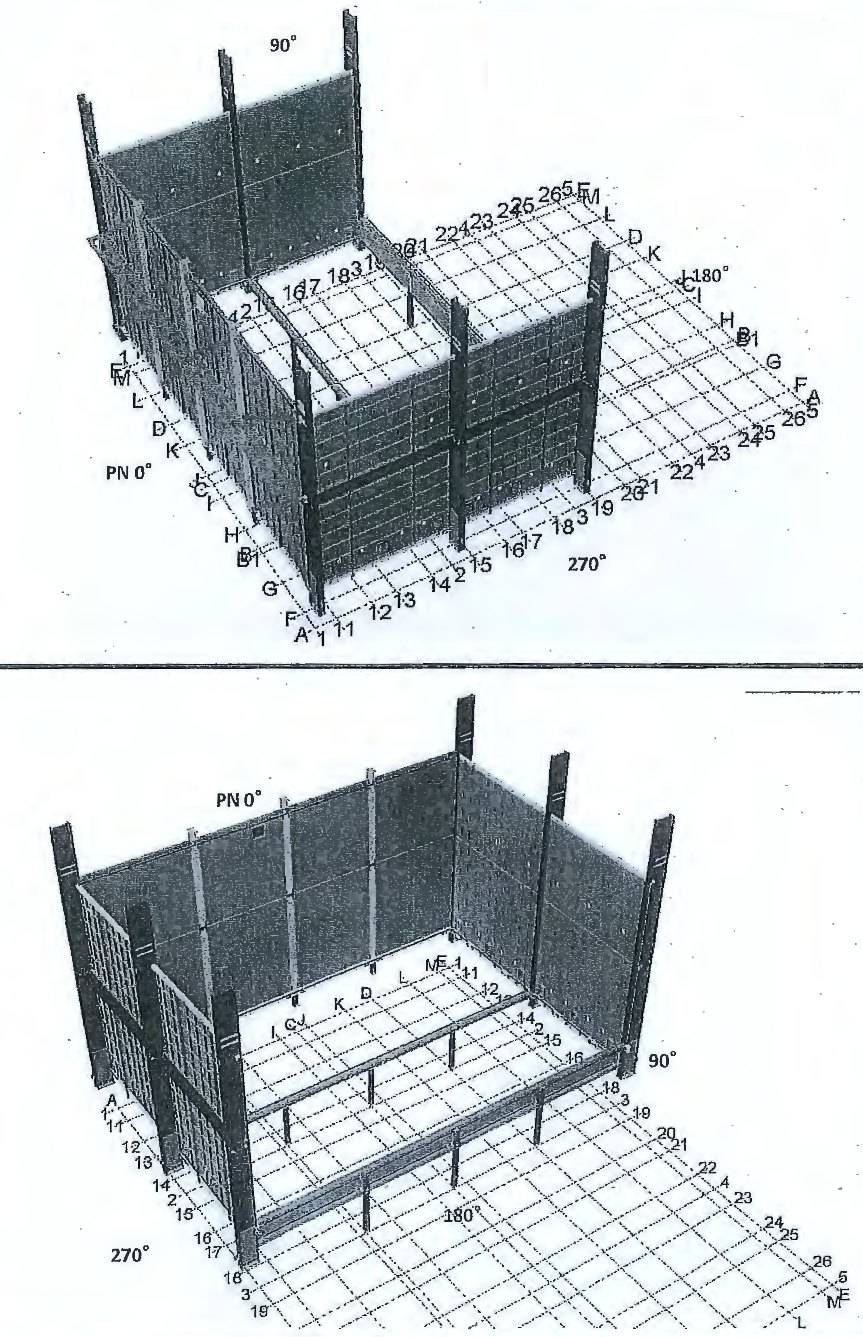

(2-A) Set of Main column (A-4 & 5 , E-4 & 5)

(2-B) Set of Floor Beam Support Stanchion (B ∼ D-4, B ∼ D-5)

(2-C) Installation of Floor beam (Line Nos. 4 & 5)

(2-D) Installation of Reinforcement Column & beam of 180 deg. Side

(2-G) Installation of Header support

(B-11∼26, D-11 ∼ 26, E-11 ∼26, F-11 ∼26, G-11 ∼26, H-11 ∼26, I-11~26, J-11 ∼26, K-11 ∼26, L-11∼26, M-11~26)

2-H) Installation of Floor panels (Inside section of Rad. coil )

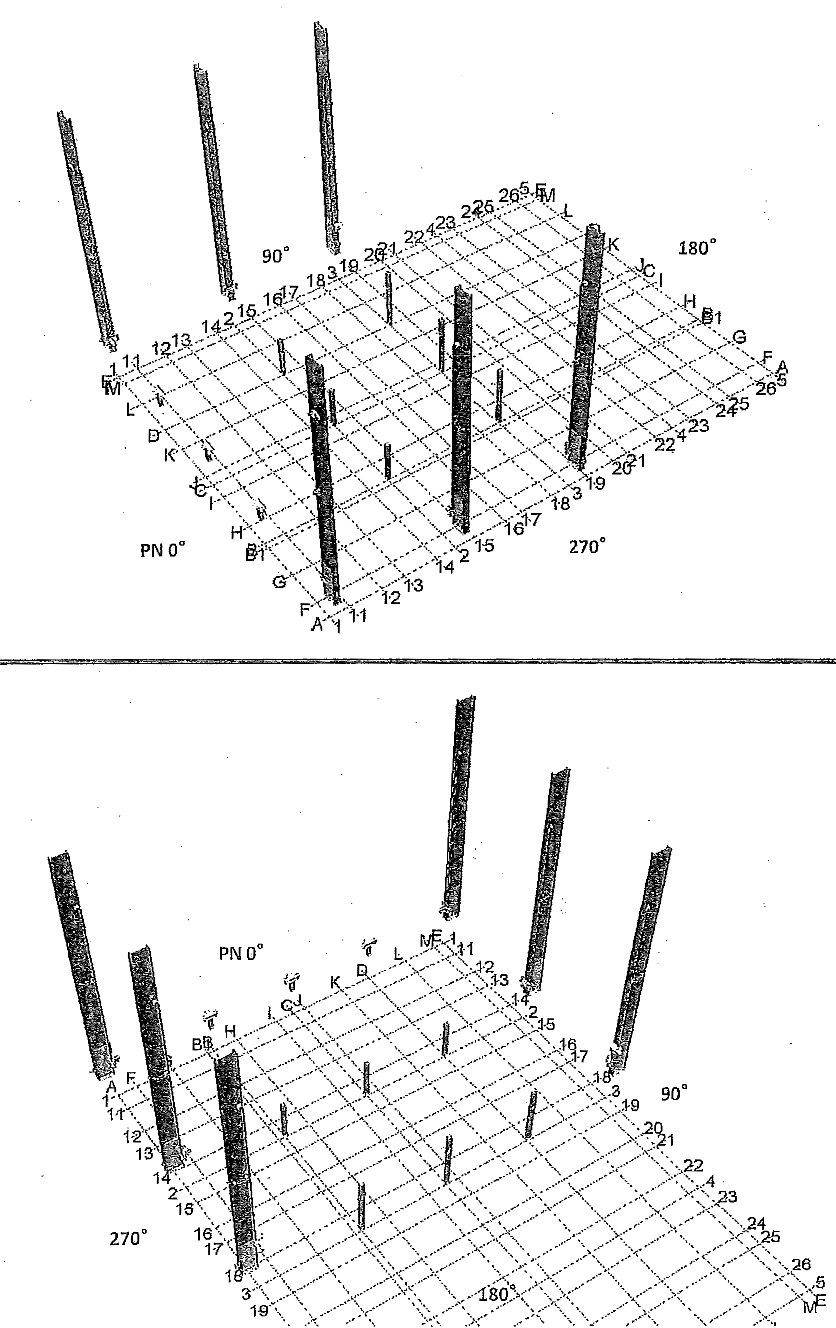

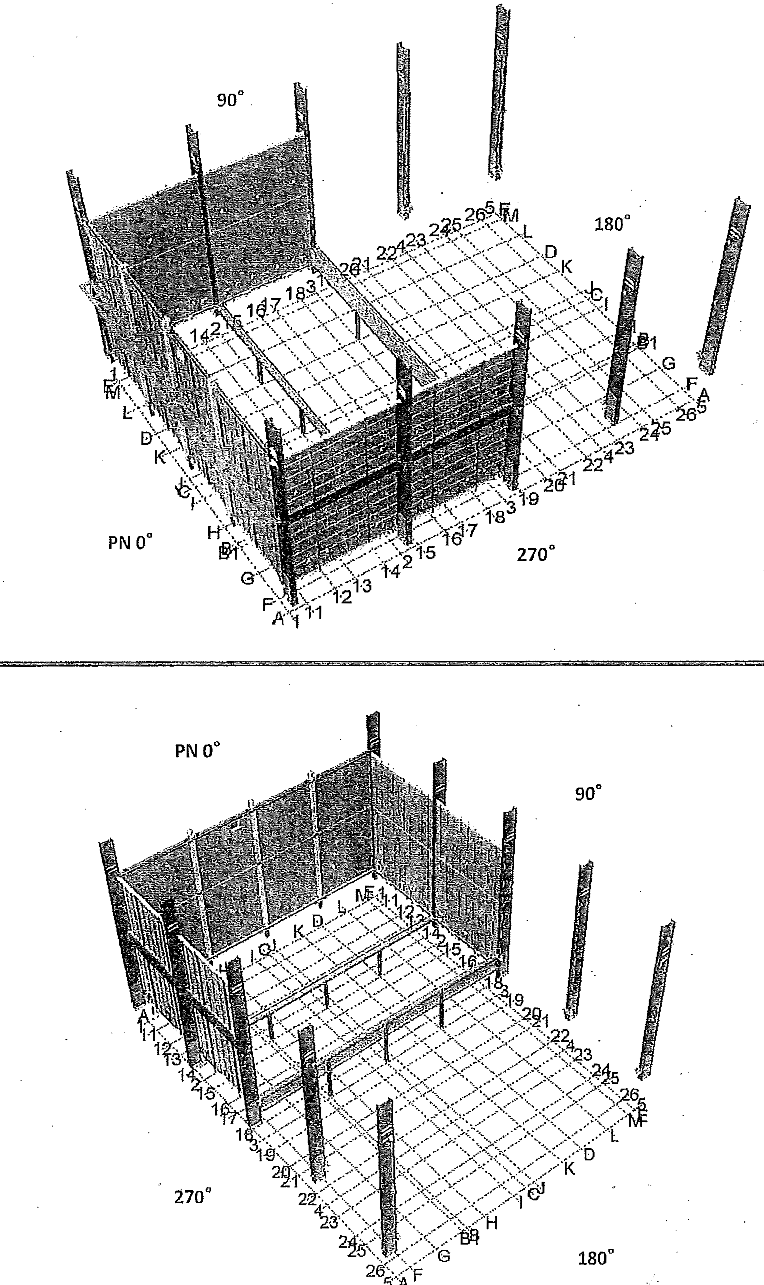

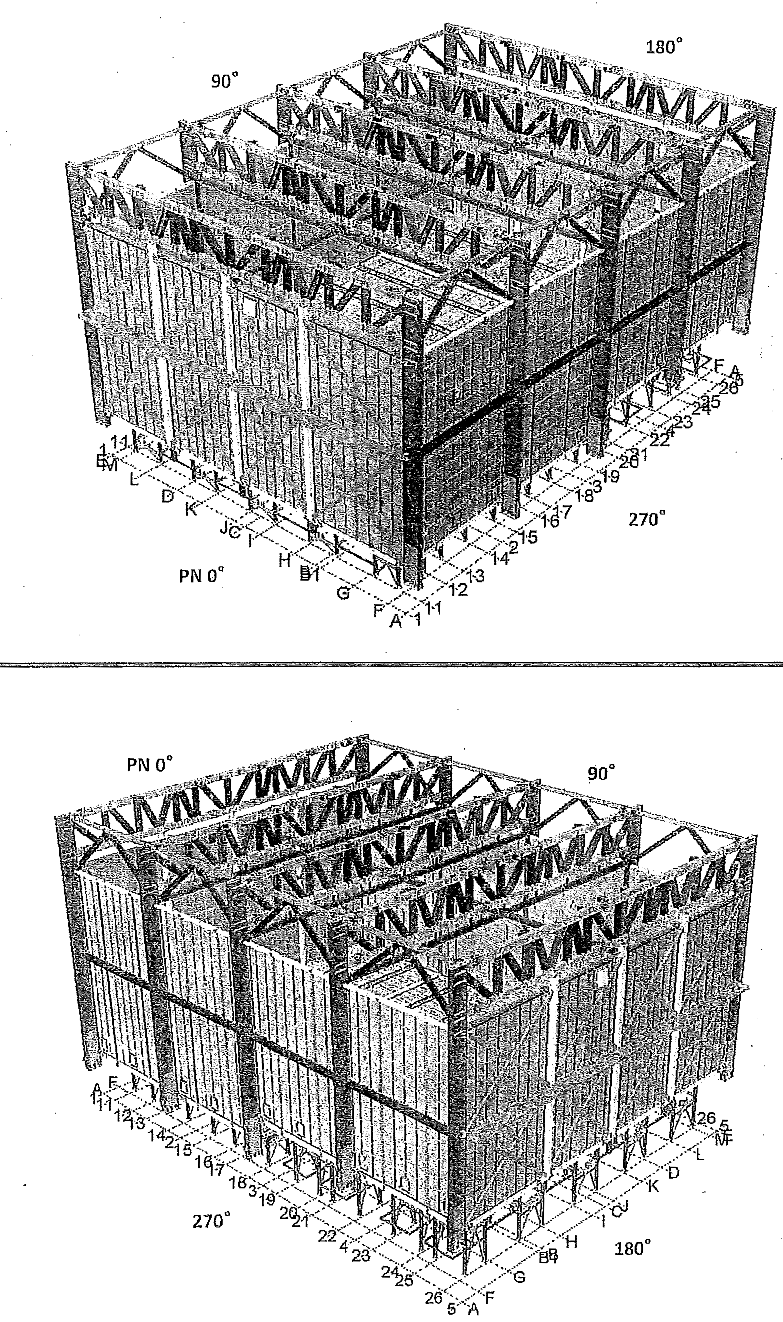

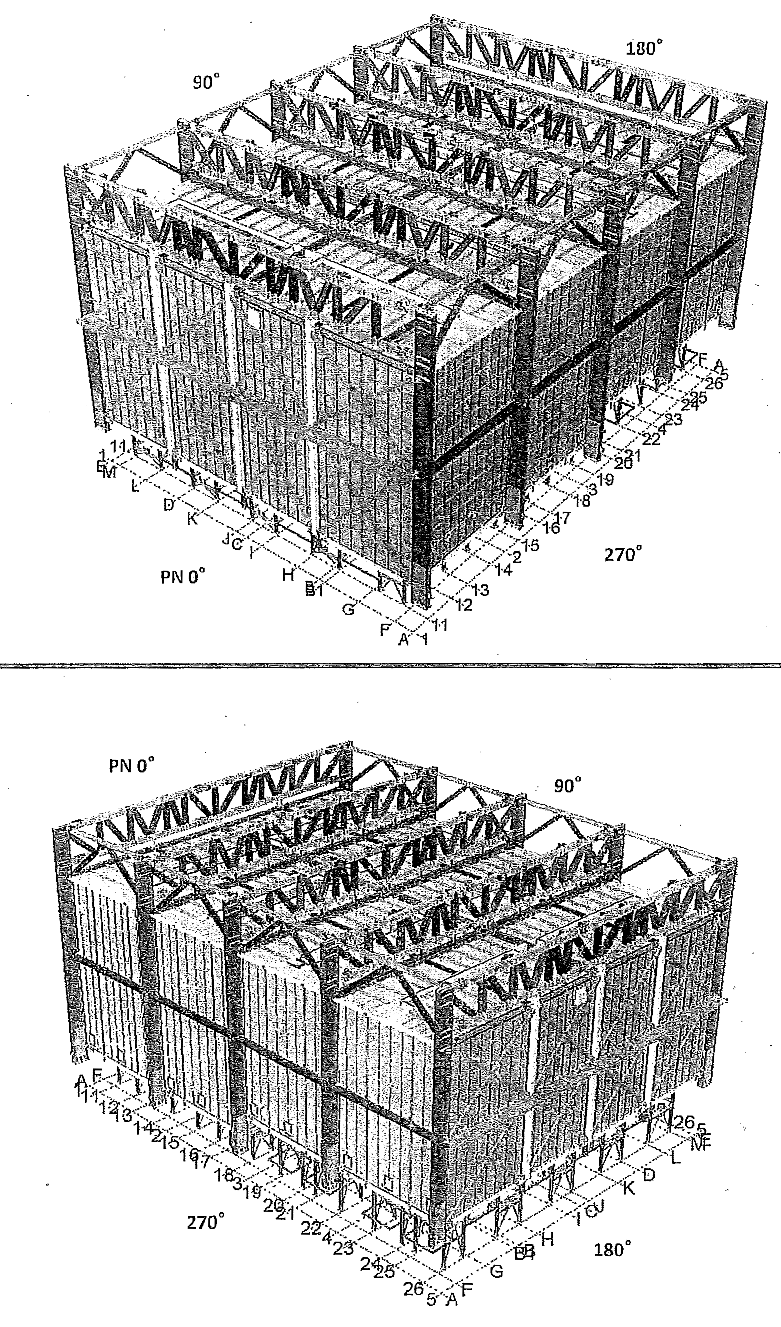

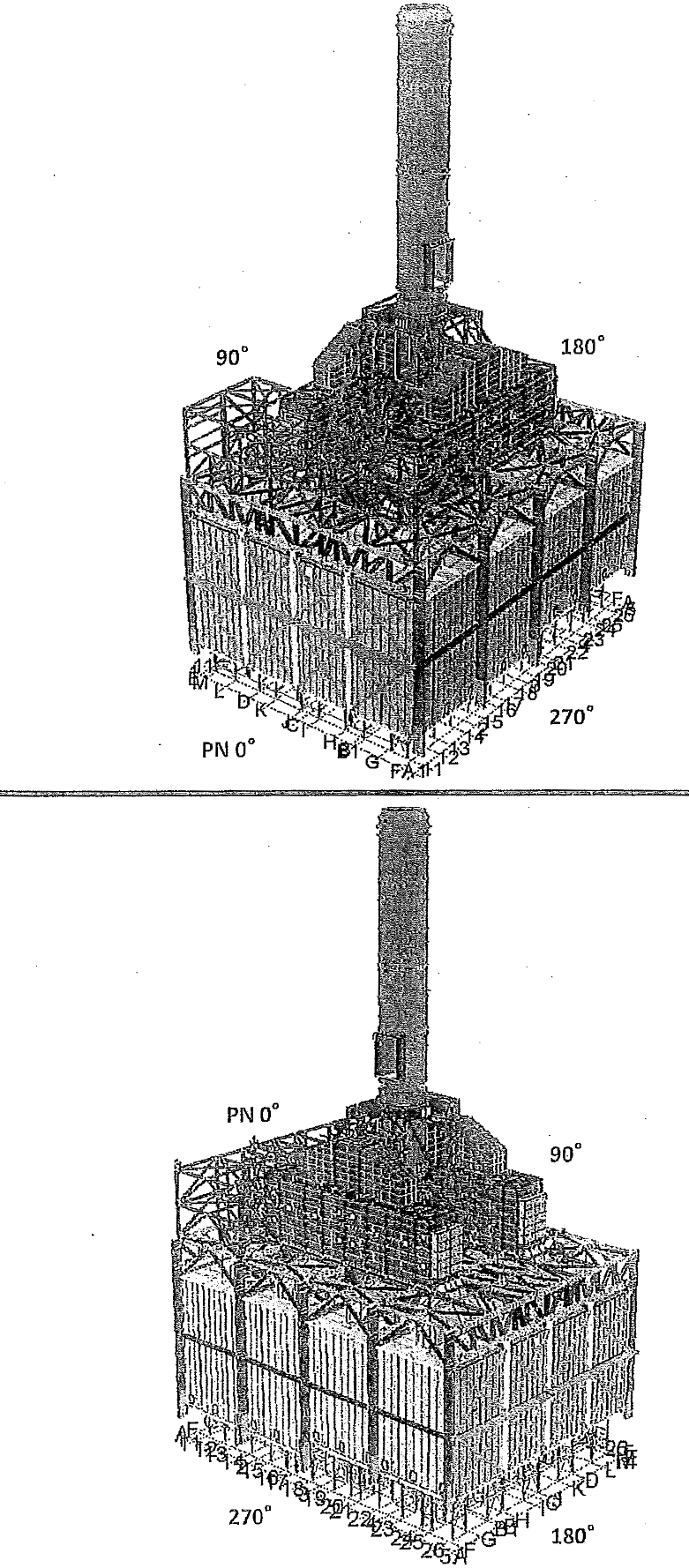

(4-D) Installation of Radiant arch structure for Column Line Nos. A & E

(4-E) Installation of Radiant arch panels

(4-F) installation of Transition duct block ( Refractory lining to be done on the ground)

(4-G) Installation of Radiant arch structure for Column line nos. B1, B2,- C1, C2, D1, D2 —

(5-A) Installation of lower convection module

(5-B) Installation of upper convection module with breeching

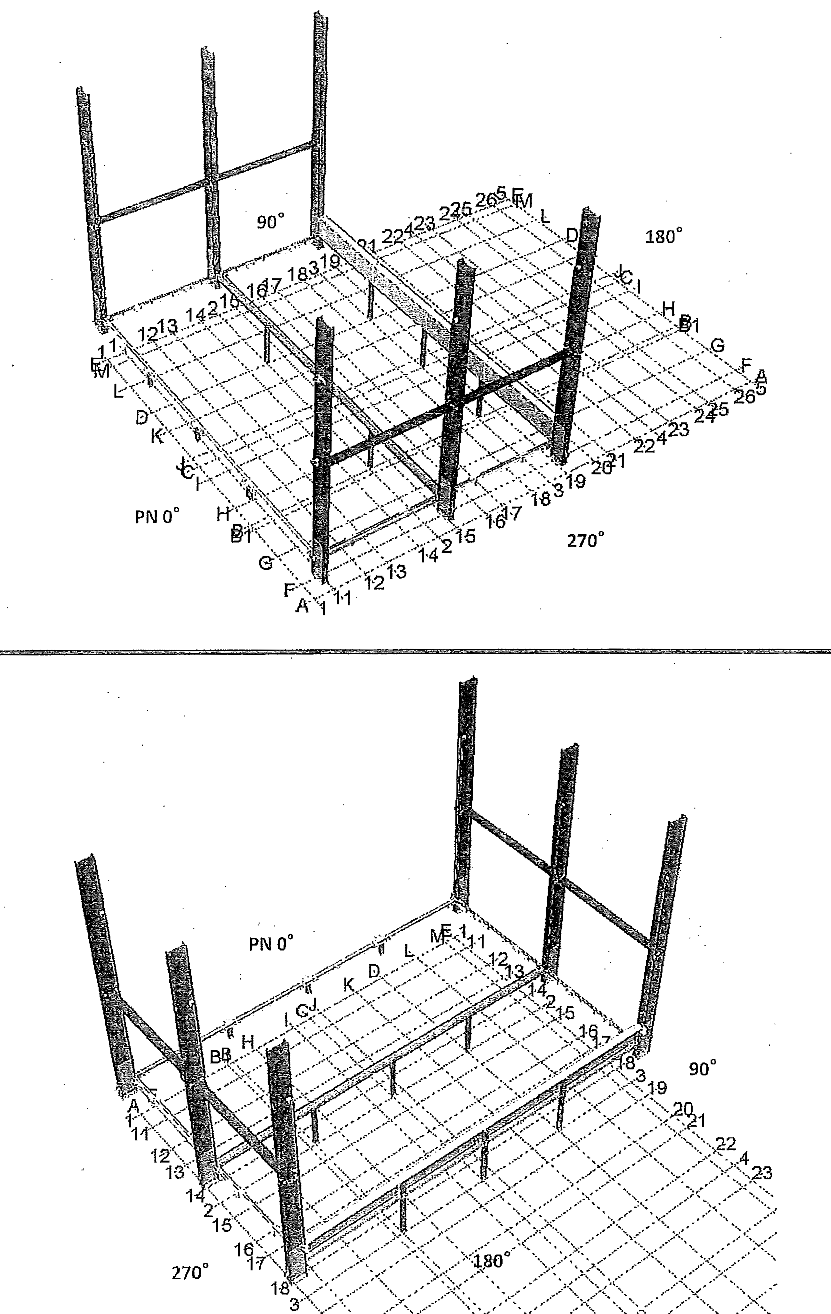

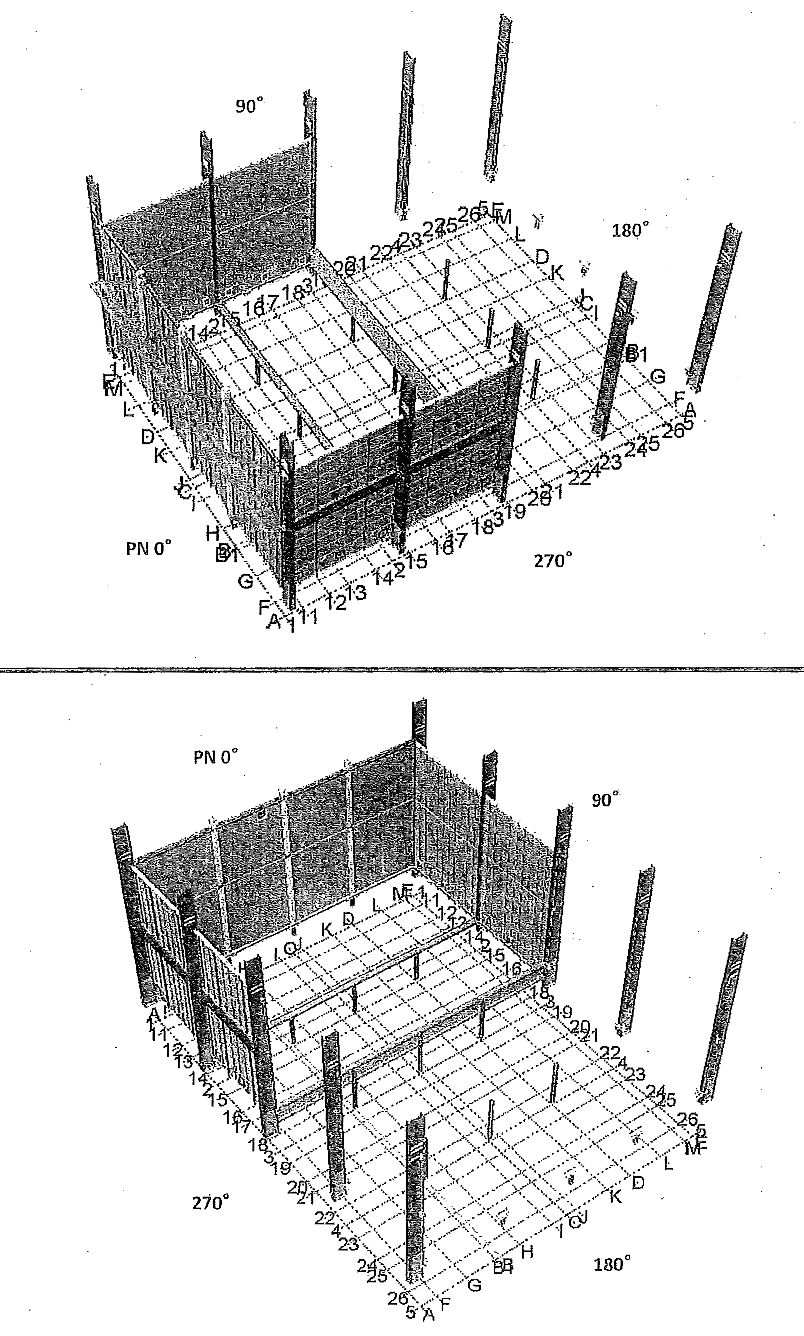

(6-A) lnstallation of Stack bottom duct·

(6-B) Installation of Flue gas outlet duct between Flue gas x-over duct and Stack bottom duct

(6-C) Installation of Flue gas x-over duct

(6-D) Installation of Stack structure

(6-E) Installation of Stack lower block

(Stack lower/ middle sections and the damper unit to be combined on the ground by welding )

(6-F) Installation of stack upper block