Estimation of Paper Deterioration

The two methods below should be used together.

CO2 and CO Accumulated Total Gas Values

IEEE C57.104 Guide for the Interpretation of Gases Generated in Oil-Immersed Transformers gives status conditions based on accumulated values of CO2 and CO. Accumulated dissolved gas levels provide four status conditions: Normal Operation, Modest Concern (investigate), Major Concern (more investigation), and Imminent Risk (nearing failure). The CO2 and CO levels in ppm for each status are given below.

The status from the table above should be at least in the Condition 2 or 3 from one or both gases before a detailed investigation is begun. There is no need to look at the ratios from next section unless a substantial amount of these gases have already been generated. If the transformer is relatively new, CO2 and other atmospheric gases (N2, O2, and even some CO) may be migrating out of the paper into the oil because the paper was stored in air prior to transformer assembly. If the paper was stored in a polluted atmosphere, a considerable

amount of CO may show up in the DGA. This may look like the transformer has a problem and is generating a lot of CO. However, if the transformer has a real problem, H2 and perhaps other heat gases (CH4, C2H6, C2H4) should also be increasing.

CO2/CO Ratio

Experience has shown that with normal loading and temperatures, the rate of generation of CO2 runs 7 to 20 times higher than CO. With a CO2/CO ratio above 7, there is little concern. With some transformers, ratios down to 5 times more CO2 than CO might be considered normal. However, ratio below 7 shall be considered a concern. If H2, CH4, and C2H6 are increasing significantly as well as CO and the ratio is 5 or less, there is probably a problem.

Commentary Note:

After a suspected problem (a substantial increase in the amount of CO), the ratio should be based on the gas generation of both CO2 and CO between successive GA tests and not on accumulated total CO2and CO gas levels.

If a problem is suspected, another DGA sample shall be taken immediately to confirm the problem. The amount of CO2/CO ratio shall be calculated between the DGA tests. An indication of abnormally high temperatures and rapidly deteriorating cellulose insulation is a CO2/ CO under 5. A ratio of 3 or under is an indication of severe and rapid deterioration of cellulose.

Extreme overheating from loss of cooling or plugged oil passages will produce a CO2/CO ratio around 2 or 3 along with increasing Furans. If this is found, deenergization and internal inspection is recommended; the transformer is in mminent danger of failure.

Furans (See Furans Power Transformer Diagnostics for More on Furans)

When cellulose insulation decomposes due to overheating, chemicals, in addition to CO2 and CO, are released and dissolved in the oil. These chemical compounds are known as furanic compounds or furans. The most important one, for our purposes, is 2-furfuraldehyde.

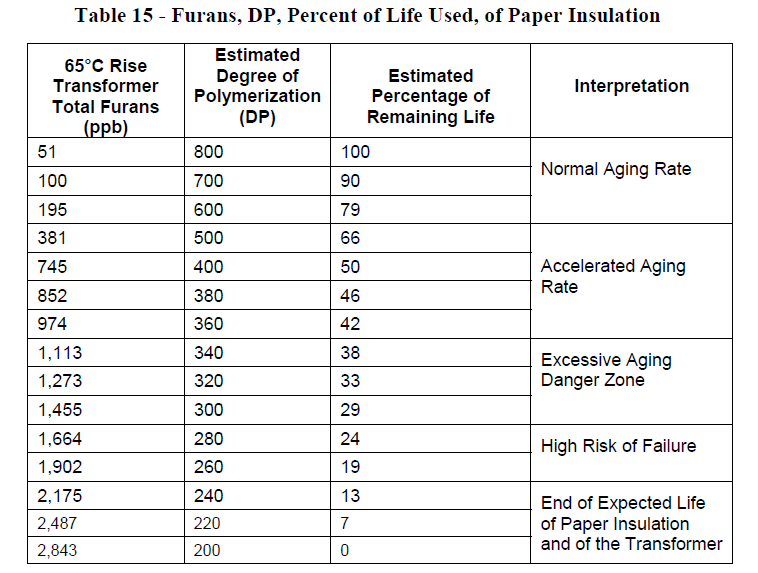

In healthy transformers, there are no detectable furans in the oil, or they are less than 100 ppb. In cases where significant damage to paper insulation from heat has occurred, furan levels have been found to be at least 100 ppb and up to 70,000 ppb. Table 15 is the assessment of Furans. The first column in table 15 is used for transformers with nonthermally upgraded paper, and the second column is for transformers with thermally upgraded paper.

Testing is done for five different furans which are caused by different problems.

The five furans and their most common causes are listed below:

– 5H2F (5-hydroxymethyl-2-furaldehyde) caused by oxidation (aging and heating) of the paper

– 2FOL (2-furfurol) caused by high moisture in the paper 2FAL (2-furaldehyde) caused by overheating

– 2ACF (2-acetylfuran) caused by lightning (rarely found in DGA)

– 5M2F (5-methyl-2-furaldehyde) caused by local severe overheating (hotspot)

Good explanation