Ultrasonic and Sonic Fault Detection

This test should be applied when hydrogen is increasing markedly in the DGA. High hydrogen generation indicates partial discharge occurring inside the transformer. Other gases such as methane, ethane, and ethylene may also be increasing. Acetylene may also be present if arcing is occurring and may also be increasing.

Ultrasonic contact (in contact with the tank), fault detection can detect partial discharge

(corona) and full discharge (arcing) inside the transformer. This test can also detect loose parts inside the transformer. Partial discharges emit energy in the order of 20 kHz to 200 kHz. These frequencies are above levels that can be detected audibly. The test equipment receives the signals and converts them electronically into audible signals. Headphones are provided to eliminate spurious noise from the power plant and other sources. The equipment logs data for future reference. A baseline test should be conducted and compared with future test data.

This test method has some limitations; if a partial discharge is located deep within the

windings, external detectors may not be sensitive enough to detect and locate the problem. However, partial discharges most often occur near the top of the transformer in areas of high voltage stress which can readily be located by this method. These defects can sometimes be easily remedied extending transformer service life.

Magnetic piezoelectric crystal transducers, sized and tuned to the appropriate frequencies, are placed on the outside of the tank, and signals are recorded. If discharges are detected, the location is defined so that during an internal inspection, the inspector will know the general area to search for a problem. Refer to IEEE 62, section 6.1.8.4, for more information.

Vibration Analysis

Vibration analysis by itself cannot predict many faults associated with transformers, but

it is another useful tool to help determine transformer condition. Vibration can result from loose transformer core segments, loose windings, shield problems, loose parts, or bad bearings on oil cooling pumps or fans. Extreme care must be exercised in evaluating the source of vibration. Many times, a loose panel cover, door, or bolts/screws lying in control panels, or loose on the outside have been misdiagnosed as problems inside the tank.

There are several instruments available from various manufacturers and the technology

is advancing quickly. Every transformer is different; therefore, to detect this, baseline

vibration tests should be run and data recorded for comparison with future tests.

For a normal transformer, vibration data is normally 2 times line frequency (120 Hz) and also appears as multiples of 2 times line frequency; that is, 4 times 60 (240 Hz), 6 times 60 (360 Hz), etc. The 120 Hz is always the largest and has amplitude of less than 0.5 inch/second and greater than 0.1 inch/second. The next peak of interest is the 4 times line frequency or 240 Hz. The amplitude of this peak should not exceed 0.5 inch/second. None of the remaining harmonic peaks should exceed 0.15 inch/second in amplitude.

Turns Ratio Test

This test only needs to be performed if a problem is suspected from the DGA, Doble testing, or relay operation. The turns ratio test detects shorted turns which indicate insulation failure by determining if the correct turns ratio exists. Shorted turns may result from short circuits or dielectric (insulation) failures.

The voltage ratio obtained by the test is compared to the nameplate voltage ratio. The

ratio obtained from the field test should agree with the factory within 0.5%. New Transformers of good quality normally compare to the nameplate within 0.1%.

DC Winding Resistance Measurement

If generation of ethylene, ethane, and perhaps methane in the DGAs indicates a poor connection, winding resistances should be checked. Turns ratio, SFRA, Doble tests, or relay operations may give indications that dc testing is warranted. Winding resistances are tested in the field to check for loose connections on bushings or tap changers, broken strands, and high contact resistance in tap changers. Results are compared to other phases in wye connected transformers or between pairs of terminals on a delta connected winding to determine if a resistance is too high.

Resistances can also be compared to the original factory measurements or to identical transformers. Agreement within 5% for any of the above comparisons is considered satisfactory. If winding resistances are to be compared to factory values, resistance measurements will have to be converted to the reference temperature used at the factory. To do this, use the following formula:

Rs = Rm [ Ts + Tk / Tm + Tk]

Where Rs is the resistance at the factory reference temperature (found in the transformer

manual), Rm is the resistance actually measured, Ts is factory reference temperature

(usually 75°C), Tm is the temperature at which you took the measurements, and Tk is a

constant for the particular metal the winding is made from: 234.5°C for copper; 225°C

for aluminum.

It is difficult to determine actual winding temperature in the field, and, normally, this is

not needed. The above temperature corrections are necessary only if resistance is going

to be compared to factory values. Normally, phase resistances are compared to each other or to identical transformers at the same temperature, and actual winding temperatures and corrections are not needed. The most accurate method is to allow the transformer to sit de-energized until temperatures are equalized. This test can reveal serious problems. If the DGA indicates this test is necessary, it’s worth the effort.

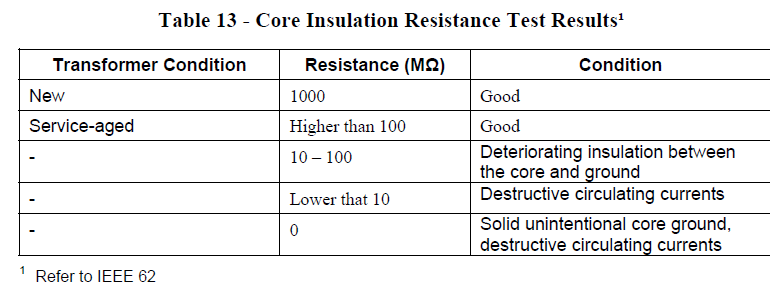

Core Insulation Resistance and Unintentional Core Ground Test

Core insulation resistance and core ground test is used if an unintentional core ground is

suspected; this may be indicated by the DGA. Key gases to look for are ethane and/or

ethylene and possibly methane. These gases may also be present if there is a poor

connection at the bottom of a bushing or a bad tap changer contact. Therefore, this test

is only necessary if the winding resistance test above shows all the connections are good

and if tap changer contacts are in good condition.

The intentional core ground must be disconnected. This may be difficult, and some oil

may have to be drained to accomplish this. On some transformers, core grounds are

brought outside through insulated bushings and are easily accessed. A standard dc

Megger (1,000-volt Megger is recommended) is then attached between the core ground

lead (or the top of the core itself and the tank [ground]). The Megger is used to place a

dc voltage between these points and the resistance measured.