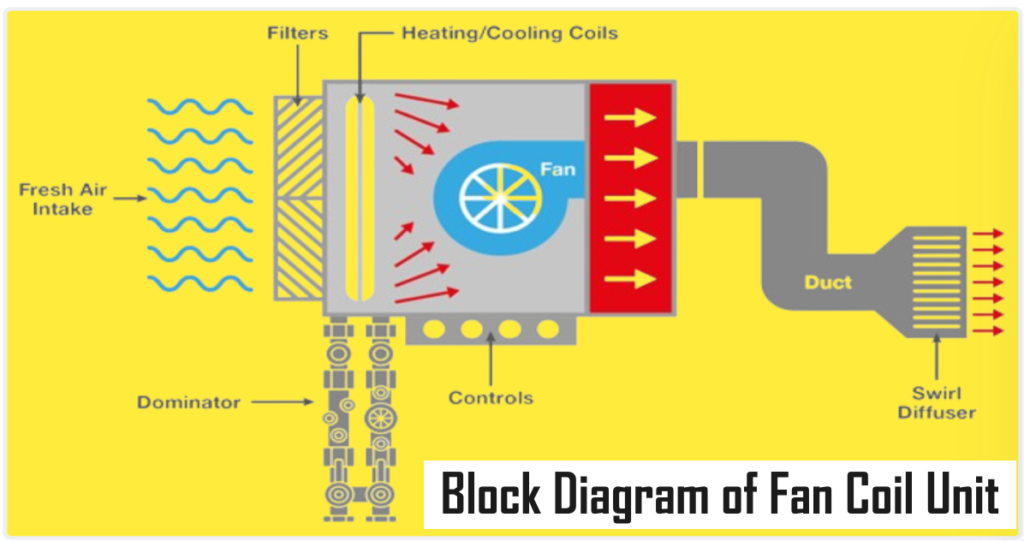

A Fan Coil Unit (FCU) is a fundamental component of Heating, Ventilation, and Air Conditioning (HVAC) systems used in residential, commercial, and industrial buildings. It plays a crucial role in regulating indoor air quality and temperature by circulating air through a building’s ductwork. Below picture showing block diagram of fan coil unit (FCU) for HVAC system.

This article is about the minimum requirements for fan coil units, their accessories and controls.

Functionality.

The primary function of a Fan Coil Unit is to condition air by either heating or cooling it before distributing it throughout a building. This is achieved through a combination of heating or cooling coils, a fan, and air filters (which is discussed later in this article). FCUs are versatile units that can be configured for various HVAC applications, including individual room climate control, zone cooling/heating, or centralized air handling.

FCU Components:

Following main components are used in fan coil unit (FCU) of HVAC.

1. Coils:

FCUs contain two types of coils – heating coils and cooling coils. Heating coils, typically heated by hot water or electric resistance, raise the temperature of the air passing through them. Cooling coils, chilled by refrigerant or cold water, lower the air temperature.

2. Fan:

A fan is used to draw air through the coils and push conditioned air into the building’s ductwork. The fan speed can be adjusted to regulate airflow and maintain desired comfort levels.

3. Air Filters:

Air filters are installed to remove dust, allergens, and other contaminants from the air before it enters the FCU. Clean air filters improve indoor air quality and protect the unit’s internal components.

4. Controls:

FCUs are equipped with control systems, such as thermostats or Building Management Systems (BMS), to monitor and adjust temperature settings, fan speed, and operating modes based on occupant preferences and building requirements.

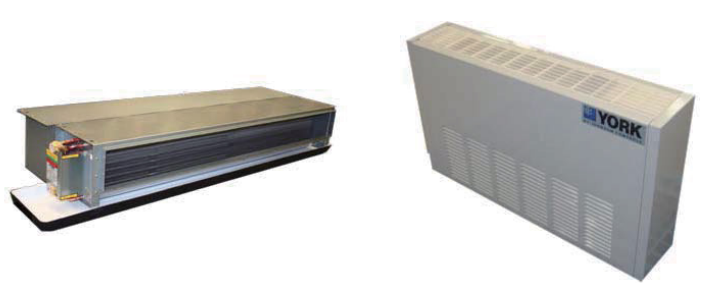

Fan Coil Unit System for HVAC

A fan coil unit (FCU), also known as a Vertical Fan Coil Unit (VFC), is a simple device consisting of a heating and/or cooling heat exchanger or ‘coil’ and fan. It is part of an HVAC system found in residential, commercial, and industrial buildings. Source By Wikipedia.

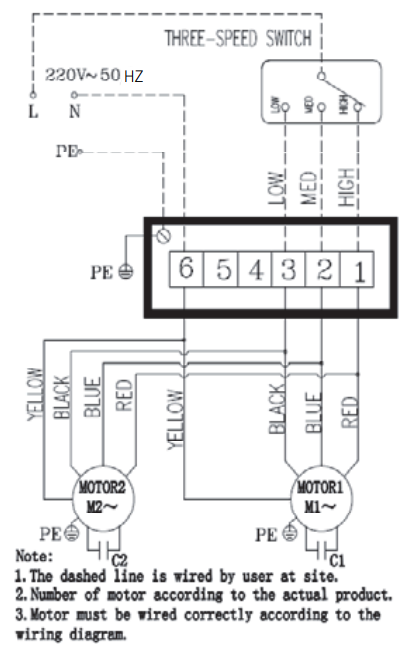

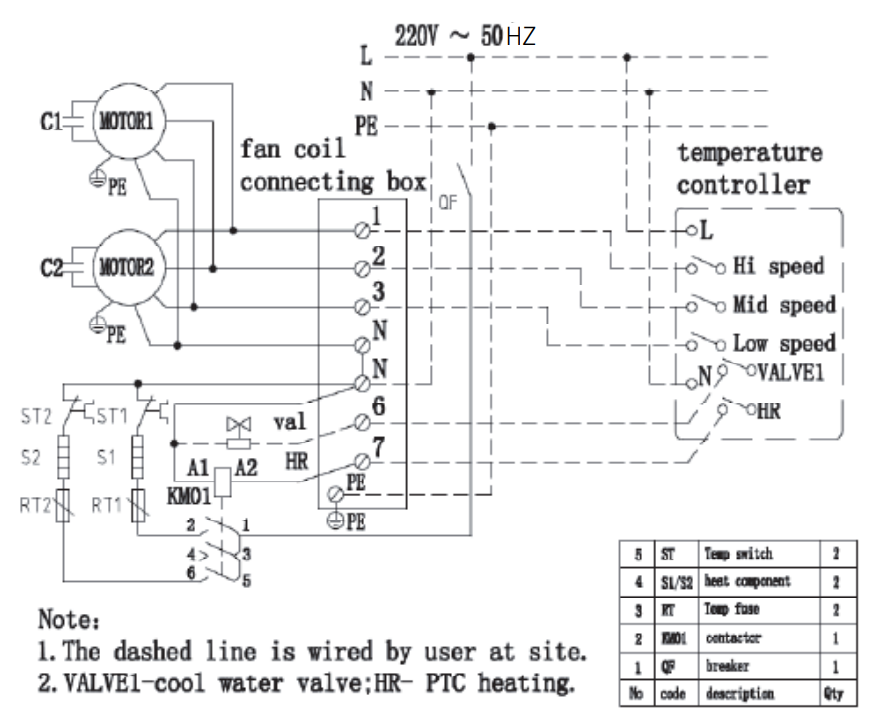

FCU Wiring Diagram (Control Circuit).

Creating a wiring diagram for a Fan Coil Unit (FCU) and control panel wiring involves illustrating the electrical connections between the components of the unit.

Below picture of FCU Control Circuit Electrical Heating and Special Terminal Box With Relays and Fuse.

What should be included in FCU documents?

- Product data shall include certified dimension drawings, specialties and accessories for each unit type and configuration.

- Shop drawings shall be submitted the following for each fan-coil unit type and configuration:

- Wiring diagrams indicating power, signal and control wiring. Wiring diagrams shall differentiate between manufacturer installed and field installed wiring.

- Equipment schedules shall include rated capacities; shipping, installed, and operating weights; furnished specialties; and accessories.

- Operation, installation and maintenance data shall be submitted for fan coil units to including operation, installation and maintenance manuals.

How to make assure quality as per international codes?

Following is technical specification for fan coil unit as per international codes and standards.

1. Electrical components, devices, and accessories shall be listed and labeled as defined in NFPA 70, Article 100, by a testing agency acceptable to authorities having jurisdiction, and marked for intended use.

2. Fan coil units shall be tested and rated in accordance with ARI 440.

3. Fan coil units coils shall be tested in accordance with ASHRAE 33.

FCU Technical Casing Guidelines.

- Fan coil chassis shall be galvanized steel, with flanged edges.

- Cabinet shall be galvanized steel with removable panels.

- Vertical unit front panels shall be removable, galvanized steel, with integrally stamped or galvanized steel discharge grilles and channel formed edges and with insulation on back of panel.

- Horizontal unit bottom panels shall be fastened to unit with cam fasteners and hinge and attached with safety chain with integrally stamped or cast aluminum discharge grilles.

- Cabinet finish shall be bonderized, phosphatized, and flow coated with baked on primer with manufacturer’s standard paint unless project requirements dictate an alternate finish.

- Drain pans shall be galvanized steel, with connection for drain. Drain pan shall be insulated with polystyrene or polyurethane insulation. Drain pan shall be formed to slope from all directions to drain connection.

FCU Coils

Coil section insulation shall be 25 mm duct liner complying with ASTM C 1071 and attached with adhesive complying with ASTM C 916. Insulation and adhesive fire hazard classification shall have a maximum flame spread rating of 25 and smoke developed rating of 50 when tested according to ASTM E 84.

Water Coils

Hot and chilled water coils shall be copper tube, with mechanically bonded aluminum fins spaced no closer than 2.5 mm and with manual air vent. Coils shall be rated for a minimum working pressure of 2068 kPa and a maximum entering water temperature of 135° C.

Direct Expansion Refrigerant Coils

Refrigerant coils shall be copper tube, with mechanically bonded aluminum fins spaced no closer than 2.5 mm and rated for a minimum working pressure of 2068 kPa.

Electric Resistance Heating Elements

a. Heating elements shall be nickel chromium heating wire, free from expansion noise and 60 Hz hum, embedded in magnesium oxide insulating refractory and sealed in high mass steel or corrosion resistant metallic sheath with fins no closer than 4 m Element ends shall be enclosed in terminal box. Fin surface temperature shall not exceed 288° C at any point during normal operation.

b. Circuit protection shall be provided by one time fuses in terminal box for overcurrent protection, air flow switch and limit controls for overtemperature protection.

FCU Fan.

Fan coil fans shall be centrifugal, with forward curved, double width wheels and fan scrolls made of galvanized steel or thermoplastic material; directly connected to or V belt driven from motor.

Fan motors for direct drive units shall be shaded pole or permanent split capacitor, multispeed with integral thermal-overload protection and resilient mounts.

Motors for belt drive units shall be open drip proof with hinged mount and adjustable motor pulley.

Filters

Refer to SES H01-E01 for filter media requirements.

Benefits.

- Energy Efficiency: FCUs can be energy-efficient, especially when equipped with variable-speed fans and advanced control systems that optimize energy usage based on occupancy and ambient conditions.

- Flexibility: FCUs offer flexibility in installation and configuration, allowing for customizable solutions tailored to specific building requirements and space constraints.

- Quiet Operation: Modern FCUs are designed for quiet operation, making them suitable for noise-sensitive environments such as offices, hotels, and residential buildings.

- Improved Indoor Air Quality: By filtering and conditioning air, FCUs help improve indoor air quality by removing pollutants, allergens, and airborne contaminants.

In summary, Fan Coil Units are essential components of HVAC systems, providing efficient and effective air conditioning for a wide range of residential, commercial, and institutional buildings. With their versatility, performance, and comfort-enhancing features, FCUs contribute to creating healthy, comfortable, and productive indoor environments.

Central Station Air Handling Units

What is Packaged Air Conditioner? Types of Packaged Air Conditioners