1 Scope.

2 Preparations.

3 Procedure.

4 Curing.

5 General Precautions.

6 Safety Precautions.

7 List of Tools & Consumables.

8 Acceptance Criteria.

1 Scope

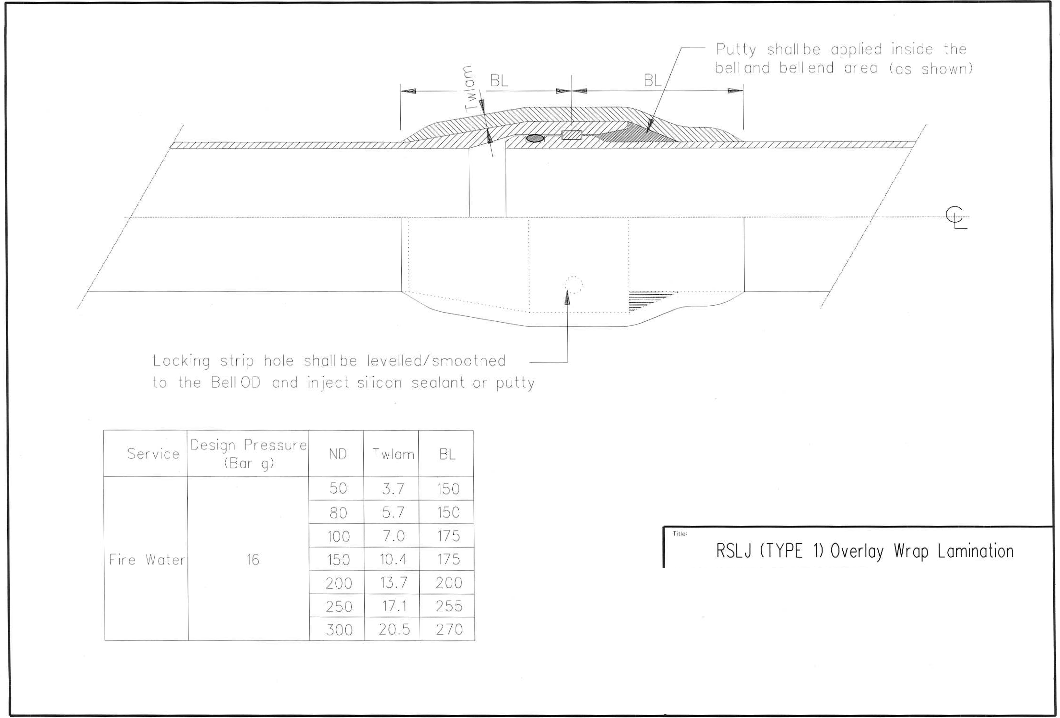

This procedure describes the steps to be followed to carry out field lamination over the RSU (FB/FS} joint. This method statement refers to recipe prepared specifically for this project. The recipe specifies the laminate thickness, the bonding area, the number of layers of each type of glass, the resin type and quantity and the catalyst type and quantity.

Preparations

Take care of a stable support of the pipe parts that are to be joined, excluding movement during the following procedure.

3 FIELD LAMINATION OVER RSLJ JOINT PROCEDURE | METHOD OF STATEMENT

1. Mark the bonding length area of lamination refers to recipe.

2. If any grease or oil noticed on the bonding surface, scuff grind again, wipe with clean dry cloth or brush.

3. Grind the above area to remove the topcoat & surface layer of the pipes by angle grinder with 16 – 24 grit disc until the pipe glass are exposed.

4. Putty shall be applied inside the bell and spigot end area to remove the step & to keep the joint as a one surface.

5. The surfaces are to be laminated have to be clean, dust free and dry.

6. Mix the resin and hardener as per the quantities specified in the recipe to main the right ratio. The temperature of the resin and the hardener during mixing shall be within 20 °C and 30 °C.

7. Wet the above surfaces with resin/ hardener mixture, using a lamb wool roller.

8. Maintain a laminate length of (BL) from both sides of the center of the joint.

9. Impregnate by lamb wool roller the roughened area of the above area with the resin/hardener mixture.

10. Apply woven roving glass 270 using 50% minimum overlap between each two consecutive windings so that wrapping the full surface will end up with two layers of glass.

11. Impregnate by lamb wool roller the above layers with the resin/hardener mixture.

12. Evenly press the surface layers by lamb wool roller to flush/ remove air traps & white marks.

13. Repeat the above three steps until the required number of layers applied as specified on the recipe.

14. Depending on the pipe diameter and pressure class, the type of glass and the number of layers specified in the lamination recipe. If only glass 270 should be used, skip all the below steps except the last one to end up the lamination with two layers of top tape. Otherwise, move to the next step.

15. Apply woven roving glass 360 using 50% minimum overlap between each two consecutive windings so that wrapping the full surface will end up with two layers of glass.

16. Impregnate by lamp woo! roller the above layers with the resin/hardener mixture.

17. Evenly press the surface layers by lamp wool roller to flush/remove air traps & white marks.

18. Repeat the above tree steps until the required number of layers applied as specified in the recipe at stage as “initial winding”.

19. If more layers should be applied, move to the following steps, Otherwise, skips all the below steps except the last one to end up the lamination with two layers of top tape.

20. Apply the specified number of layers of woven roving 580 and 360 alternatively. Each type of glass should be applied in four consecutive layers before changing to the other type.

21. Evenly two layers should be impregnate by lamp wool roller with the resin/hardener mixture before applying the second two layers of the same type.

22. Apply two “sealing layers” of woven roving glass 360.

23. Impregnate by lamp wool roller the above layers with the resin/hardener mixture.

24. Evenly press the surface layers by lamp wool roller to flush/remove air traps & white marks.

25. Wind two layers of top tape glass around the around the laminate to extract the excess quantity of resin and to provide smooth surface.

26. Remove the excess resin on the outside of the laminate with the aid of a (for example) rubber scrapper.

Note: See the attached sketch.

4 Curing

As soon as the laminate is tack free, heat up the lamination following method, Wrap a heating blanket around the lamination and connect the electrical current through a temperature regulator. The blanket will heat the lamination to the required curing temperature, which should be achieved gradually. The curing time@ 90-125 C is two hours.

Note: Curing can be verified by checking the Barco I hardness of the lamination. The Barcol device should show a reading above 30. Once the curing of the lamination is completed, inspection has to be carried out by FPI site representative or client qualified inspector to ensure that the laminated joint is accepted.

5 General Precautions

1. Client qualified technician shall perform the joining of the field joint system.

2. The preparation bond surface area should not have an influence of grease, oil, dust, moisture, waters etc. Clean the surface in accordance with instructions.

3. During the curing process, the assembled joint shall not be disturbed under any circumstances.

4. The resin/hardener mixture will cure too fast if it mixed above 30C and the work shall be carried out within the pot-life after mixing the Resin & Hardener. Never use resin/hardener mixture that has started curing or turned tacky.

5. Adequate precaution shall be taken for the following environment conditions:

6. The weather conditions around the work place are containing high humidity, mist, training, sandstorm etc.

7. Arrange make shift tents to protect the joint lamination directly exposed to the atmosphere.

8. The prepared joint shall be warmed up to avoid moisture contents on the bonding surface. If required.

9. Once the warming process is completed, the joint shall be re-sanded before applying the resin/hardener mixture. 16 – 24 grit disc.

10. The lamination process shall be performed within 1-2 hours, if nor Re-sanding shall be carried out.

6 Safety Precautions

The following safety precautions shall be taken when working with RTR Product.

1. While cutting and grinding the following personal protection shall be used to avoid skin irritation and inhaling dust.

2. Dust mask covering nose and mouth.

3. Safety glass

4. Pair of suitable hand gloves

5. Overalls

6. Safety shoes

7. Safety helmets

8. When working with resin/hardener try to avoid direct contact with skin. If skin has been contact with resin/hardener, wash clean water and soap before it become hard.

7 List of Tools & Consumables

Contents:

1. Work instructions

2. Container Resin

3. Container Hardener

4. Roll Woven Roving 270 g/m2

5. Roll Woven Roving 360 g/m2

6. Roll Woven Roving 580 g/m2

7. Roll polyester fleece

8. Pi tape mm (Diameter: based on project specification)

9. Measuring tape/ Pipe filler’s wrap – around

10. Pipe vise/ rubber strip (for use in chain clamp)

11. Angle grinder/ flexible backing disk

12. Pair of scissors / Digital weighing scale

13. Shelter (depending on the environmental conditions)

14. Dust exhauster

15. Power supply

16. Cutting disks/ Grinding disks/ Emery disks cloth grade P40 to P60

17. Marker pen/ Mixing bucket/ clean rags

8 Acceptance Criteria

During performing lamination joint, all the criteria detailed in the site ITP shall be strictly adhered to. The joint shall be considered accepted only after passing the hydrostatic test.