When it comes to managing and monitoring liquid levels in large tanks and vessels, having a dependable and accurate measurement system is crucial. One such solution, widely used in various industrial applications, is the Flat Board Float Type Level Gauge. In this article, we’ll explore the fundamentals of this mechanical level measurement device and its significance in industrial processes.

What is a Flat Board Float Type Level Gauge?

The Flat Board Float Type Level Gauge is a time-tested instrument designed to provide precise and straightforward liquid level measurements. It is particularly well-suited for applications involving large tanks where the reliable tracking of liquid levels is paramount.

Components of the Flat Board Float Type Level Gauge

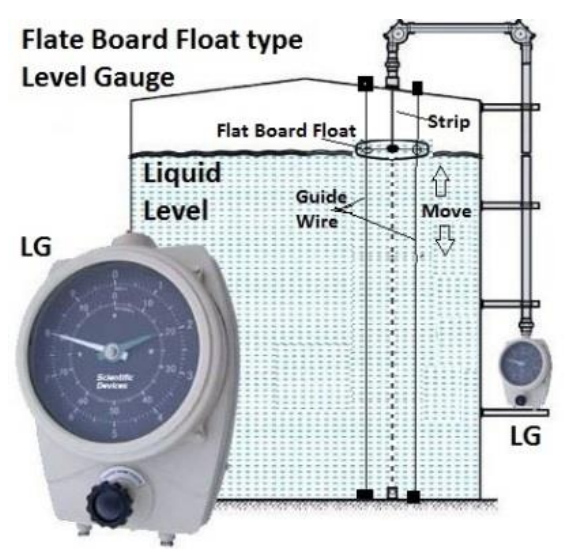

This level gauge consists of several key components:

- Float: The heart of the system, the float, is a buoyant object that moves along with the liquid inside the tank. Typically, it is connected to two guide wires to ensure stability.

- Steel Strip and Rollers: The float is linked to a steel strip, which, in turn, is guided by two rollers. These rollers allow for smooth vertical movement of the float as the liquid level changes.

- Level Gauge Display: The level gauge features two needles or pointers. The larger needle moves along a meter-scale, while the smaller needle tracks a centimeter (CM) scale.

How Does It Work?

The functioning of the Flat Board Float Type Level Gauge is elegantly simple yet effective:

- Float Movement: As the liquid level within the tank rises or falls, the float responds by moving up or down. The float is carefully designed to be buoyant, ensuring it remains on the liquid’s surface.

- Steel Strip Mechanism: The movement of the float is transmitted through the steel strip, which rolls on the two guiding rollers.

- Needle Indication: This mechanical movement of the steel strip is translated into the rotation of the two needles on the level gauge display. The big needle provides a coarse measurement in meters, while the smaller needle offers a finer measurement in centimeters.

- Reading the Levels: To determine the liquid level precisely, an operator can simply read the position of the needles on their respective scales. This allows for an accurate assessment of the liquid’s depth inside the tank.

Advantages of the Flat Board Float Type Level Gauge

- Reliability: This type of level gauge is known for its reliability. It operates without the need for electricity or complex sensors, making it a robust and consistent choice for level measurement.

- Simplicity: Its straightforward design makes it easy to install, use, and maintain. It doesn’t require intricate calibration procedures.

- Applicability: The Flat Board Float Type Level Gauge can be employed across a wide range of industries, including chemical processing, petrochemicals, pharmaceuticals, and water treatment.

- Cost-Effective: It offers a cost-effective solution for accurate liquid level measurement, especially in scenarios where electrical instrumentation might not be suitable.

Maintenance and Calibration

To ensure the continued accuracy of measurements, routine maintenance and occasional calibration are essential. Regularly inspecting the gauge for any signs of wear, damage, or corrosion is crucial. Calibration should be performed according to the manufacturer’s guidelines to maintain its precision.

In Conclusion

The Flat Board Float Type Level Gauge has proven its worth as a reliable and cost-effective solution for liquid level measurement in large tanks and vessels. Its simple yet effective design, independence from electrical power, and versatility in various industries make it a valuable asset in industrial processes where precise liquid level monitoring is paramount. Whether in chemical plants, refineries, or water treatment facilities, this time-tested instrument plays a vital role in ensuring the smooth operation and safety of industrial processes.

Read Full Course on Instrumentation and Control Engineering.