Pressure gauges and pressure transmitters are often employed in level measurement applications to indirectly determine the level of a liquid or material in a tank, vessel, or container. This method relies on the principle that the hydrostatic pressure at a specific depth within a fluid is proportional to the liquid’s density and the height of the liquid column above that point.

Here’s how pressure gauges and pressure transmitters are used in level measurement:

Pressure transmitters are commonly used to measure liquid level head pressure between two altitude points and convert this head pressure into an electrical signal, typically a 4-20 mA current signal. This setup is widely employed in various industries for accurate and reliable liquid level measurement and control.

Here’s how pressure transmitters work in such level measurement applications:

- Installation: The pressure transmitter is installed in a way that it is connected to the tank or vessel at the lower altitude point (typically at the bottom) and exposed to the liquid. Another reference point is established at the higher altitude point (the desired level measurement point).

- Hydrostatic Pressure Measurement: As the liquid level rises or falls within the tank, it exerts pressure on the pressure transmitter’s sensing element. The pressure transmitter accurately measures this hydrostatic pressure at the lower point.

- Pressure-to-Electrical Signal Conversion: The pressure transmitter converts the hydrostatic pressure into an electrical signal, which is typically a 4-20 mA current signal. The signal is proportional to the liquid level difference (head pressure) between the two altitude points.

- Signal Transmission: The 4-20 mA current signal is then transmitted from the pressure transmitter in the field to a control room or a central monitoring system. This signal can travel over long distances without significant signal degradation, ensuring accurate and real-time level measurement.

- Data Interpretation: In the control room or central monitoring system, the received electrical signal is interpreted to determine the liquid level within the tank or vessel. The control system can use this information to trigger alarms, control pumps or valves, or display the level on a user interface.

Advantages of Using Pressure Transmitters for Liquid Level Measurement:

- Accuracy: Pressure transmitters provide precise and highly accurate level measurements, making them suitable for critical applications.

- Remote Monitoring: The electrical signal generated by pressure transmitters can be easily transmitted over long distances, enabling remote monitoring and control.

- Digital Communication: Many pressure transmitters offer digital communication protocols such as HART, Modbus, or Profibus, allowing for advanced features and integration with control systems.

- Minimal Maintenance: Pressure transmitters often require less maintenance compared to mechanical alternatives like float-operated devices.

- Compatibility: Pressure transmitters can be used with a wide range of liquids, including corrosive and hazardous substances.

Hydrostatic Pressure Principle Role:

The fundamental principle behind this method is the hydrostatic pressure law. It states that the pressure at a specific depth within a liquid is directly proportional to the height of the liquid column above that point and the density of the liquid. Mathematically, it can be expressed as: [P = ρ * g * h] Where:

- (P) is the pressure at depth (h),

- (ρ) is the density of the liquid,

- (g) is the acceleration due to gravity, and

- (h) is the height of the liquid column above the point of measurement.

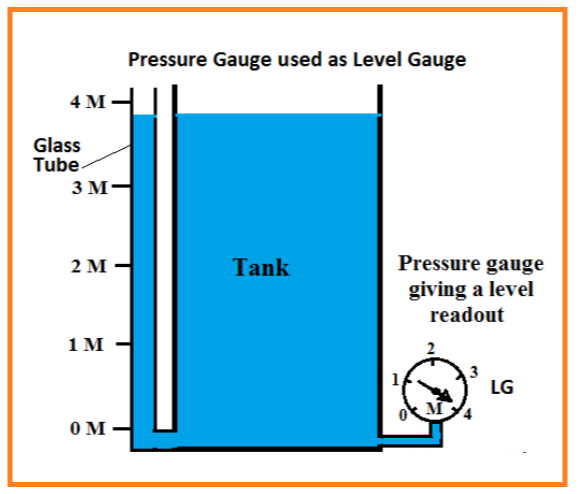

Pressure Gauge: A pressure gauge is a mechanical device used to measure and display pressure. In level measurement applications, a pressure gauge is installed at the bottom of the tank or vessel, and a tube or pipe connects it to a specific point within the tank at the desired measurement depth. As the liquid level rises or falls, it exerts pressure on the gauge through the connected pipe. The pressure gauge’s display indicates the pressure, which can then be converted into a level measurement based on the hydrostatic pressure principle.

- Advantages of Pressure Gauges: Pressure gauges are relatively simple and cost-effective instruments for level measurement. They are suitable for applications where high accuracy is not critical.

- Limitations: Pressure gauges may require manual reading, and they do not provide remote monitoring or data logging capabilities. Additionally, they may not be suitable for corrosive or harsh environments.

Pressure Transmitter: A pressure transmitter is an electronic device that converts pressure into an electrical signal, typically a 4-20 mA current signal or a digital output. In level measurement applications, a pressure transmitter is installed similarly to a pressure gauge, with a connection to the tank at the desired depth. As the liquid level changes, the pressure transmitter converts the hydrostatic pressure into an electrical signal, which can be transmitted to a remote control system or data acquisition device for real-time monitoring, recording, and control.

- Advantages of Pressure Transmitters: Pressure transmitters offer high accuracy and precision in level measurement. They provide remote monitoring capabilities, can be integrated into control systems, and offer digital communication options for enhanced functionality. They are also suitable for use in harsh or corrosive environments.

- Limitations: Pressure transmitters are typically more expensive than pressure gauges and require electrical power for operation. Additionally, they may require calibration and maintenance to ensure accuracy over time.

In summary, pressure gauges and pressure transmitters are valuable instruments in level measurement applications based on the hydrostatic pressure principle. While pressure gauges are simple and cost-effective, pressure transmitters offer greater accuracy, remote monitoring, and integration capabilities. The choice between the two depends on the specific requirements of the application, including accuracy, remote monitoring needs, and environmental conditions.

Read Full Course on Instrumentation and Control Engineering.