This article is about Instrument Cable Installation, Termination, Identification and Commissioning of Instrumentation and Control Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Instrument Cable Installation, Termination, Identification and Commissioning

Material Receiving General Checklist for Instrumentation & Control

- Copper data link cables shall be specified per system manufacturers’ recommendations. In plant fiber optic data link cables shall be specified and installed per SAES-Z-020. If these cables are routed in aboveground conduit, the conduit shall be specified and installed per this standard and SAES-P-104.

- All in plant process automation networks shall be redundant and shall be routed in separate cables. The primary cable shall follow a different route from the backup cable. Primary and backup data link cables shall preferentially enter cabinets or consoles from opposite sides. Data link cables shall not be routed in the same conduit, duct, or tray with other instrument cables.

- Exception: Fiber Optic data link Cables may be routed with other instrumentation cables – in existing trays or ducts with prior approval of the Supervisor, Instrumentation Unit/PID/P&CSD.

- Fiber Optic cables installed in trays shall be routed in PVC conduit and shall meet ANSI/ISA-TR12.21.01 if installed in classified areas.

- A conduit outlet box (e.g., GUAT) shall be installed within eighteen (18) inches of the field device. The cable to the instrument shall be looped one or more times within this fitting; the sizing of the conduit outlet box shall take into account the bending radius of the cable.

- Flexible conduit shall be used at the instrument end of the conduit to provide isolation from vibration, protection against thermal expansion of the rigid conduit systems and for ease of maintenance.

- All field junction boxes shall be mounted vertically i.e., the door shall open from left-to-right or from right-to-left.

- Precast 50 mm thick red concrete tiles, red plastic tiles (12 mm minimum thickness), or PVC coated steel fence fabric shall be placed 300 mm above direct buried cable or direct buried conduit, in accordance with Standard Drawing AD-036874. In addition, a yellow warning tape shall be installed over the tiles or fence fabric. This paragraph does not apply to ground grid conductors and connections to ground grids or grounding electrodes, when paragraph 10.2 configurations are used, or under elevated substations. [SAES-P-104, Sec. 10.3]

Cable Trays – Installation Requirements

- Cable tray installation shall be per NEMA VE 2 and SAES-P-104, Section 9 and SATIP-104-03.

- Cable Trays shall be grounded as required in SAES-P-111, SATIP-P-111-01.

- In new grass root projects, cable trays extending between the process area and the control room or process interface building, or trays installed beneath raised computer floors, in control rooms or PIB shall be sized for a minimum of 20% spare space for future expansions. This spare capacity is in addition to the installed 20% spare cabling.

- Cable tray fill shall comply with NEC Article 392.

- Cable tray supporting armored cables extending between field instruments and junction boxes shall be ventilated bottom, channel cable tray. The channel cable tray shall be designed, manufactured, and marked in accordance with NEMA VE-1. In addition to the requirements in section 9.1 and 9.5, the channel cable tray system shall meet the following:

(a) The channel cable tray material shall be copper-free aluminum (aluminum with a maximum of 0.4% copper).

(b) Channel cable tray width shall be 3, 4, or 6 inches with a minimum loading depth of 1-¼ inch.

(c) The channel cable tray system shall be installed with the manufacturers standard fittings, clamps, hangers, brackets, splice plates, reducer plates, blind ends, connectors, and grounding straps.

(d) The channel cable tray system shall be installed with flanged covers.

(e) The ventilated strait sections shall have slots (approximately 3/16″” x ½””) to facilitate the use of cable ties to secure the cable (s). The slots shall repeat every 12-18 inches.

(f) The ventilated strait sections shall have splice holes, repeating every 12-18 inches to simplify field modifications.

(g) All fasteners (i.e., nuts, bolts, washers, etc.) used to connect and assemble the channel cable tray system shall be 304 SS. In severe corrosive environments, 316 SS fasteners shall be used.

(h)The channel cable tray system shall be free from burrs or other sharp projections that could cause damage to the cable jacket during installation.

Installation Requirement of Fiber Optic Cables

- Nonconductive optical fiber cables shall be permitted to occupy the same cable tray or raceway with conductors for electric light, power, Class 1, non–power-limited fire alarm, Type ITC, or medium-power network-powered broadband communications circuits, operating at 600 volts or less. NEC Article 770.133(A)

- Conductive optical fiber cables shall not be permitted to occupy the same cable tray or raceway with conductors for electric light, power, Class 1, non–power-limited fire alarm, Type ITC, or medium-power network-powered broadband communications circuits. NEC Article 770.133(A)

- Optical fibers in composite optical fiber cables containing only current-carrying conductors for electric light, power, Class 1 circuits rated 600 volts or less shall be permitted to occupy the same cabinet, cable tray, outlet box, panel, raceway, or other termination enclosure with conductors for electric light, power, or Class 1 circuits operating at 600 volts or less.NEC Article 770.133(A)

- Nonconductive optical fiber cables shall not be permitted to occupy the same cabinet, outlet box, panel, or similar enclosure housing the electrical terminations of an electric light, power, Class 1, non–power-limited fire alarm, or medium power network-powered broadband communications circuit. NEC Article 770.133(A)

- Conductive and nonconductive optical fiber cables shall be permitted in the same cable tray, enclosure, or raceway with conductors of any of the following:

(1) Class 2 and Class 3 remote-control, signaling, and power-limited circuits in compliance with Article 725

(2) Power-limited fire alarm systems in compliance with Article 760

(3) Communications circuits in compliance with Article 800

(4) Community antenna television and radio distribution systems in compliance with Article 820

(5) Low-power network-powered broadband communications circuits in compliance with Article 830. NEC Article 770.133(B) - Hazardous (Classified) Locations. Cables installed in hazardous (classified) locations shall be any type indicated in Table 770.154(E). Cables shall be sealed in accordance with the requirements of 501.15, 502.15, 505.16, or 506.16, as applicable. (See Attachment 1). NEC Article 770.154(F)

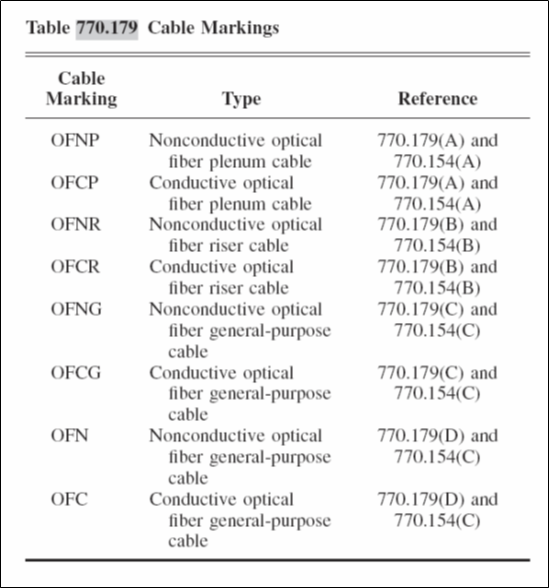

- Cable Trays. Optical fiber cables of the types listed in Table 770.179 shall be permitted to be installed in cable trays.

FPN: It is not the intent to require that these optical fiber cables be listed specifically for use in cable trays. (see Attachment 2) NEC Article 770.154(D) - Grounding or Interruption of Non–Current-Carrying Metallic Members of Optical Fiber Cables. Optical fiber cables entering the building or terminating on the outside of the building shall comply with 770.93(A) or (B). NEC Article 770.154(D)

Communications Wires and Cables Installation Requirements

- Communications circuits and equipment installed in a location that is classified in accordance with 500.5 and 505.5 shall comply with the applicable requirements of Chapter 5. NEC Article 800.3 (A).

- Grounding or Interruption of Metallic Sheath Members of Communications Cables. Communications cables entering the building or terminating on the outside of the building shall comply with 800.93(A) or (B). NEC Article 800.93.

- Installation of Communications Wires, Cables, and Equipment. Communications wires and cables from the protector to the equipment or, where no protector is required, communications wires and cables attached to the outside or inside of the building shall comply with following:

(A)(1)(b) Separation from other conductors: class 2 and class 3 circuit. Class 1 circuits shall not be run in the same cable with communications circuits.

(A)(1)(c) Communications conductors shall not be placed in any raceway, compartment, outlet box, junction box, or similar fitting with conductors of electric light, power, Class 1, non–power-limited fire alarm, or medium-power network-powered broadband communications circuits.”

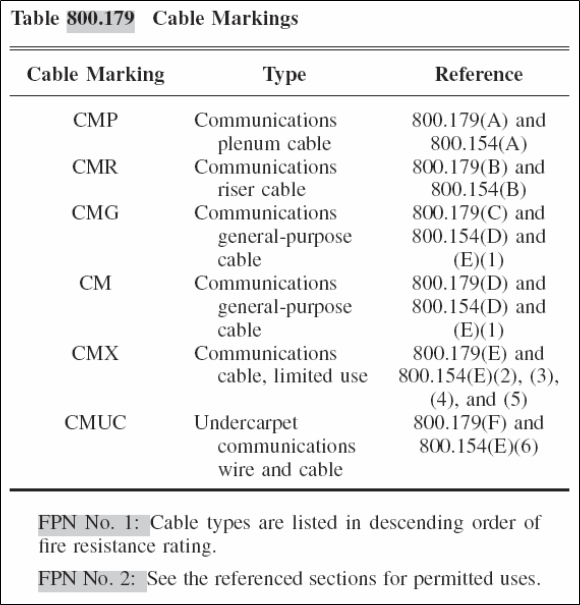

Other Applications. Communications wires and cables shall be separated at least 50 mm (2 in.) from conductors of any electric light, power, Class 1, non–power-limited fire alarm, or medium power network-powered broadband communications circuits. NEC Article 800.133(A) - Communications Wires and Cables: Communications wires and cables shall be listed in accordance with 800.179(A) through (I) and marked in accordance with Table 800.179. Conductors in communications cables, other than in a coaxial cable, shall be copper. NEC Article 800.133(A)(2)

- The cable voltage rating shall not be marked on the cable or on the under carpet communications wire. Communications wires and cables shall have a temperature rating of not less than 60°. NEC Article 800.179

- Equipment: Communications equipment shall be listed as being suitable for electrical connection to a telecommunications network. NEC Article 800.170

- Cable Trays. Types CMP, CMR, CMG, and CM communications cables shall be permitted to be installed in cable trays. Communications raceways, as described in 800.182, shall be permitted to be installed in cable trays. NEC Article 800.154(D)

Routing Requirements of Instrument and Control Cables and Data Highways

- Aboveground Routing: Instrument to Field JB, Cable and Conduit: Single twisted pair/triad cables, per Table-2, shall be installed in steel conduits from the field instruments to the field junction boxes. Low-point drains and breathers shall be provided as required on all conduits. Conduit installation shall be per Section 8.

- Aboveground Routing: Armored Cable and Tray

a) Armored instrumentation cable shall be routed on a cable tray per Section 9.8.

b) The armored cable shall be routed independently of existing overhead tray systems used for “”home-run”” cables.

c) The unsupported end of the cable at the instrument shall be looped; this loop shall take into account the bending radius of the cable. The unsupported length of cable at the instrument shall be the minimum length required to provide the service loop.

Commentary Note: This unsupported loop in the armored cable is required to provide sufficient slack for cable gland make-up and for easy removal of the cable from the device for future instrument change-out.

d) The cable shall be either galvanized steel wire armor or galvanized steel interlocking armor, per 34-SAMSS-913.” - Routing: Field Junction Box to Control Room Marshaling Cabinets. Cables between field junction boxes and marshaling cabinets may be routed in conduits, on trays, or direct buried. For direct burial, the trench shall be constructed per SAES-P-104. Twisted, multi-pair/triad cables per Table 2 shall be used. The use of armored cables for homerun application is not recommended. However, if they are used, the cables shall be terminated using glands per paragraph 6.2 at both ends. In addition, the armor shall be grounded at both ends.

- All signal wiring from field cables shall terminate in dedicated ‘marshaling cabinets’. Marshaling cabinets shall comply with 34-SAMSS-820, Instrument Control Cabinets – Indoor.

Exception: Wiring for millivolt, microamp, pulse, and frequency signals under one Volt such as thermocouples, vibration elements, load cells, thermistor elements and transmitters with pulse outputs may be directly connected to the I/O unless otherwise specified.”

Each cable or group of cables carrying similar signals shall contain a minimum of 20% spare pairs or triads. The number of pairs/triads in a given cable shall be dictated by usage and spare requirements and the manufacturers’ standard offerings. - All spare pairs/triads of a multi-pair/triad cable shall be terminated at both the field junction box and the marshaling cabinet. Drain wires for spare shielded pairs/triads shall also be individually terminated at these locations.

- Cables entering the marshaling cabinet shall be cut to the appropriate lengths. Coiling extra cable length or spare pairs/triads beneath the marshaling cabinet is not acceptable. Exception: For wiring directly connected to the I/O, per the exception item in section 13.1.2.2, the spare pairs/triads may be neatly coiled & taped beneath the cabinet.”

All conductors/pairs, from each field cable, shall be terminated adjacent to each other on the same terminal strip in the marshaling cabinet. - Routing: Cables connecting marshaling cabinet terminals to control room instrumentation and control systems shall conform to the requirements of Section 13.1.2, above. Where possible and practical, pre-assembled cables with plug-in type connectors shall be used for interconnections. Wiring lists identifying pin connections shall be required for each pre-assembled cable.

- Control room cabling/wiring must conform to NEC Articles 725-61 and 725-82 (2005 edition). Wiring requirements for distributed control systems (DCS) are detailed in 23-SAMSS-010.

Cable Entry Requirements in Control Buildings and Hydrocarbon Processing plants

- Penetration of the wall of the building basement or underfloor space shall be via short horizontal sections of PVC conduits (sleeves) that will be encased or grouted into the wall. [SAES-P-104, Sec 15.4.1]

- The inside of the sleeves shall be sealed with 3M Scotchcast Brand 4416 Cable Duct Sealing Kits, with an additional layer of 3M Brand Fire Barrier CP 25N/S Caulk to provide fire retardancy on the building interior side. [SAES-P-104, Sec.15.4.2]

- The cables outside the building shall be direct buried for a distance of at least 2 meters. [SAES-P-104,Sec 15.4.3 (see also paragraph 10.14)]

- Multi-conductor cable penetrations shall be made with intact cable jackets. If individual conductors are required to be sealed by other Saudi Aramco standards, the sealing shall be done at the most convenient location inside the building using Raychem CBK cable blocking kits, Raychem DWBS water blocking system kits, or equivalent. [SAES-P-104, Sec 15.4.4]

Commentary 15.4: If cables or conduits entering buildings are required to be sealed by the NEC, sealing must meet requirements of the NEC and paragraphs 15.1, 15.2 and/or 15.3 above. [ SAEP-P-104, Sec.15.4.4]” - Emergency shutdown system (ESD) wiring shall have dedicated cabling, junction boxes and marshaling cabinets.

Exception: For offshore platforms only, ESD system wiring may be terminated in the same junction box as general instrumentation wiring. Terminals shall be segregated and clearly labeled. - Wiring for intrinsically safe (IS) systems shall be segregated and installed in dedicated conduit or cable tray and terminated in dedicated junction boxes. For additional details refer to SATIP-J-903-01.

Terminations / Connections at Field Instruments and Junction Boxes

“Connections at Field Instruments (1) All connections at the field instrument shall be made on screw type terminal blocks. Wire nuts and spring type terminals shall not be used. Instruments with integral terminal blocks shall be connected directly to the field cable.

(2) If the instrument is fitted with factory sealed fly leads then they shall be connected to a screw type terminal block installed in a GUA conduit fitting. A typical installation arrangement is shown in Library Drawing DC-950043 as attachment 4″

The outer jacket of shielded twisted single pair/triad cables shall be left intact up to the point of termination. Drain wires and mylar shields on shielded cables shall be cut and insulated with heat shrink sleeve at the field instrument unless otherwise specified by the instrument manufacturer.

Connections at Field Junction Boxes (1) Conduit and cable entries to field junction boxes shall be through the bottom. Top entry is allowable provided a drain seal is installed on the conduit within 18” of the enclosure. Side entry (within six inches of the bottom) shall be permitted only when space limitations dictate. The number of conduit entries shall be kept to a minimum. All unused entry ports shall be fitted with approved plugs.

Conduit entries shall be through gasketed hubs, except in explosion-proof installations where the connection shall be through threaded connections.

In severe corrosive environments, cable glands shall be protected against corrosion, either by a heat shrink sleeve, anti corrosion tape or PVC shroud with anti-corrosion compound. Gasket materials shall be oil resistant.

All connections and entries shall comply with the electrical area classification.

Low point conduit drains shall be provided as needed.

Twisted, multi-pair/triad cables shall be cut to the appropriate length to minimize looping and flexing of the cable within the junction box.

For twisted shielded single pair/triad cables the outer jacket shall be left intact up to the point-of-termination (approximately three to four inches from terminal blocks). The shield drain wire shall be insulated from jacket end to terminal. Approximately, one inch of heat shrink tubing shall be applied over the jacket end.

For individually shielded twisted multi-pair/triad cables each pair/triad shall be heat shrink sleeve insulated from the cable-jacket-end up to the point-of-termination to keep the foil shielding intact and free from accidental grounds. The shield drain wire shall be insulated from foil end to terminal. Approximately, two inches of heat shrink tubing shall be applied over the jacket end.

Terminations / Terminal Block Requirements

Terminal blocks shall be channel (rail) mounted, strip type, with tubular box clamp connector and compression bar or yoke for wire termination. As a minimum, the thickness of the terminals shall be 5 mm or higher. Multi-deck and spring type terminal blocks are not acceptable.

Terminals and terminal block accessories (e.g., DIN rail mounting brackets for electrical insulation, busbar support blocks, end brackets, etc.) shall be made of fire retardant, halogen free, high strength material such as polyamide or equivalent in accordance with UL 94, V0. Brittle materials such as melamine shall not be used.

The termination shall be channel (rail) mounted, strip-type terminal blocks, with tubular box clamp connector and compression bar or yoke, as detailed above.

When screw-type terminals are provided, solder less crimp/compression connectors shall be used for connecting stranded copper conductors. Screw-type terminals are defined as those in which the termination method involves the direct compression of the conductor by the underside of the screw head, and which do not contain the conductor within a clamp or yoke. Insulated ring lugs or locking fork connectors, specifically designed to hold the connector on the terminal in the event of loosening of the terminal screw, shall be used on all such connections. Exposed electrical connections at signal lamps and pushbuttons shall be completely shrouded by removable, insulating covers.

Fused terminals shall be equipped with blown fuse visual indication. The disconnect levers for fused terminals and knife- switch terminals shall be hinged.

Wires terminated on these terminal blocks shall not have the bare ends coated with or dipped in solder (“tinned”). However, termination of wiring that has individual strands of the copper conductor tinned during manufacture (typical of shield drain wires or for corrosion protection) is acceptable. Direct termination of the bare wire end is acceptable. No more than two bare wire ends shall be connected to each side of a single terminal block.

The use of crimp-on ferrules for this type of termination shall follow manufacturer’s guidelines. Ferrules shall be provided with plastic insulating collars. Two-wire ferrules are acceptable. However, the use of ferrules to daisy chain is not acceptable. Only one ferrule shall be connected to each side of a single terminal block.

Terminal strip spacing shall allow ample room for plastic wire ducts and permit training and lacing of cables, and fanning of individual wires to termination points. Each terminal strip shall be labeled above or below with the terminal strip number, as shown on wiring diagrams.

Terminals for similar (AC or DC) current service shall be grouped together and physically separated from terminals for different service by means of dividers, separate mounting rails or separate enclosures.

Terminals for 120 VDC and 120 VAC power for field contacts shall be segregated from other systems.

Terminal strips for ESD wiring shall be completely separate from all other wiring including power, control and instrumentation.

Identification – Wire Tagging – Requirements

All wiring shall be tagged at each end. Each wire tag shall have two labels. The first label (closest to the end of the wire) shall identify the terminal number to which the wire is physically connected. The other label shall be the terminal number of the connection of the opposite end of the wire.

Wire tag information shall be permanently marked in block alpha numeric or typed on tubular, heat-shrinkable, slip-on sleeves. Wrap-around, snap-on or self-adhesive wire markers shall not be used. Handwritten wire tags are not acceptable.

A clear heat shrink sleeve shall be installed over the wire tag for all instruments that use rust preventive grease on its threaded wiring access cover.

Spare pairs/triads in multi-pair/triad cables shall be labeled “Spare” in addition to the destination and source terminal numbers. The “Spare” designation shall be on a separate wire tag installed on the twisted pair and not part of the source/destination tag.

Cable Tagging: All cables shall be tagged, at each end, with a cable-tag.

Homerun cables shall be tagged with the assigned “IC” cable number.

Cable-tags outside junction boxes and marshalling cabinets shall be 316 SS with permanently marked alphanumeric characters i.e., raised or stamped characters. The cable-tag shall be securely attached to the cable with stainless-steel cable ties. Where cable tags are required inside junction boxes or marshalling cabinets (i.e. cables extended in conduits), weather resistant, high quality plastic cable tags secured using cable ties per Paragraph 5.7.2 may be used.

Terminal Reference: Each row of terminals shall be uniquely identified alphanumerically, e.g., TS-101, TS-102, etc.

The terminals in each row shall be sequentially numbered starting at number one (1).

Proceed this article with following link.

Instrumentation and Control Earthing & Grounding Technical Requirements

International Codes and Standards for Thermowells Material

- Flow Nozzle Material Selection Criteria Design & Flow Measurement

- Venturi Tube Material Selection Criteria Design & Flow Measurement

3. SAES-J-902 – Electrical Systems for Instrumentation, 11 May 2008

4. 34-SAMSS-913 – Instrumentation and Thermocouple Cable, 31 July 2005

5. NFPA 70 – National Electric Code 2008

6. SAES-P-104 – Wiring Methods & Materials, 13 Jan 2008

1. Attachment 1: Figure 770.154(E) Cable Substitution Hierarchy

2. Attachment 2: Optical Fiber Cables Listing Requirements in Accordance with Table 770.179

3. Attachment 3: Communications Wires and Cables Marked in Accordance with Table 800.179

4. Attachment 4: Electrical Connections for Field Mounted Instruments – Lib. Dwg. DC 950043