This article is about Checklist and General Instrumentation Requirements for Mechanical Equipment Skid Division 2 Locations of Instrumentation and Control Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Instrumentation Requirements for Mechanical Equipment Skid Division 2 Locations

- Contractor shall produce certification that Instruments and control systems shall operate continuously under the following ambient air temperatures without any degradation of the manufacturer’s guaranteed performance:

(1) Indoor Air conditioned, 10°C(50°F) to 35°C(95°F)

(2) Outdoor sheltered, 0°C (32°F) to 55°C (32°F)

(3) Outdoor unsheltered conditions, 0°C (32°F) to 65°C (149°F)” - Vendor to provide certification that the equipment complies the following: Humidity

(1) Indoor humidity design basis shall be 20% to 80% relative humidity.

(2) Outdoor design basis shall be 5% to 95% relative humidity (non-condensing).” - Contractor to provide certification that the equipment meets the severe dust and contaminants requirements detailed below:

Onshore Environment: Usual airborne dust concentration is 1 mg/m³. During sandstorms, dust concentrations may reach 500 mg/m³. Particle size distribution is as follows:

(1) 95% of all particles are less than 20 micrometers

(2) 50% of all particles are less than 1.5 micrometers

Elements present in dust include compounds of calcium, silicon, magnesium, aluminum, potassium, chlorides and sodium. When wetted (high humidity conditions) these compounds function as electrolytes and can result in severe corrosion. Other pollutants present in the atmosphere under the most extreme conditions are:

H2S — 20 ppm (vol/vol)

Hydrocarbon — 150 ppm (vol/vol)

SO2 — 10 ppm (vol/vol)

CO — 100 ppm (vol/vol)

NOx — 5 ppm (vol/vol)

O3 — 1 ppm (vol/vol)

Read Also: Material Receiving General Checklist for Instrumentation & Control

Storage, Handling, and Preservation

The manufacturer’s storage, handling and preservation instructions to be followed.

General Requirements

- All materials shall be suitable for the specified service, and the Vendor shall obtain a written approval from the Buyer for all selected materials in severe process services. All wetted parts in sour service shall conform to SAES-A-301.

- The Vendor shall submit a list of all selected instrument manufacturers, instrument model numbers and specification sheets for approval by the Buyer.

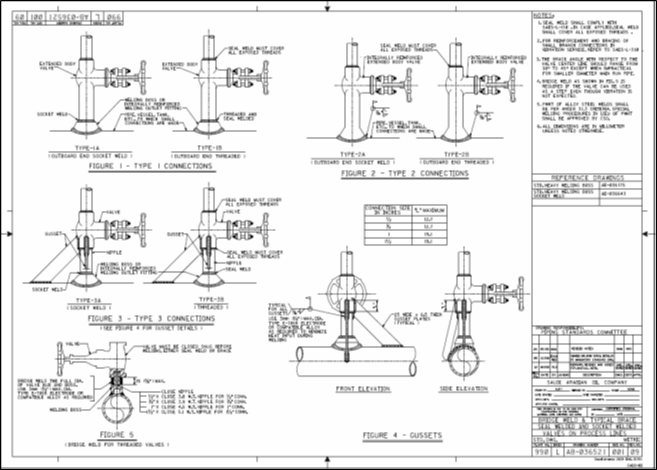

- Electrical Requirements: All Electrical equipment intended for operation in locations classified under the requirements of NFPA 70, Article 500, shall be listed or labeled by any of the agencies listed in appendix 2 (Attachment 3 and 4)

- Conduit sealing fittings shall be labeled or listed by UL, FM or CSA.

Material Requirements for instruments, piping and tubing/ Fittings

- Purchase Order and Instrument specification sheet criteria shall be confirmed and compared with instrument stainless steel tags / labels and nameplates, and shipment checked for damage, prior to acceptance of the shipment

- All process-connected instruments shall be cast or forged steel, stainless steel or a suitable corrosion resistant alloy equal to or better than the ASTM specifications.

- Cast iron shall not be used for hydrocarbon service, or for any flange-mounted instrument.

- Instrument enclosures shall be steel or copper free aluminum, and shall be rated as NEMA Type 4X or IEC Type IP 65. All junction boxes shall be 316 Stainless Steel

- Enclosures for instruments in outdoor plant areas shall be NEMA Type 4 in accordance with NEMA ICS 6 and NEMA 250 or IEC 60529 Type IP 65. Enclosures in severe corrosive environments shall be NEMA Type 4X or IEC 60529 Type IP 66.

- The field junction box, in a Class I, Zone 2 location and in non-hazardous areas, shall be a single door NEMA Type 4X or IEC 60529 Type IP 66 box. The box construction shall meet the following requirements: 7.2.1 Type 316 stainless steel body, door and hardware.

7.2.2 Continuously welded seams, finished smooth.

7.2.3 Stainless steel hinge.

7.2.4 Stainless steel captive clamps.

7.2.5 Data/Print pocket on inside of door.

7.2.6 External mounting brackets.

7.2.7 Collar studs for mounting inside panel.

7.2.8 Ground stud for terminating A/C safety ground wire.

7.2.9 Removable door” - Instrument enclosures and junction boxes having an internal volume exceeding 2,000 cm³ shall be provided with Type 300 Series stainless steel breather and drain fittings, or a combination breather and drain fitting.

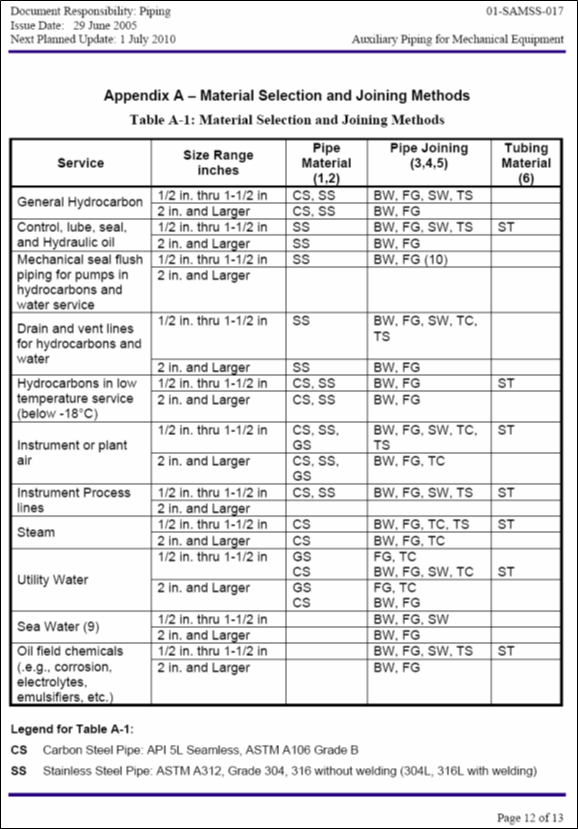

- Instrument Piping and Tubing: Process connections up to and including the first block valve (the root valve) shall comply with 01-SAMSS-017, Table A-1 (See Attachment 1).

- Piping and tubing materials downstream of the first block valve shall comply with check list items C16 to C18.

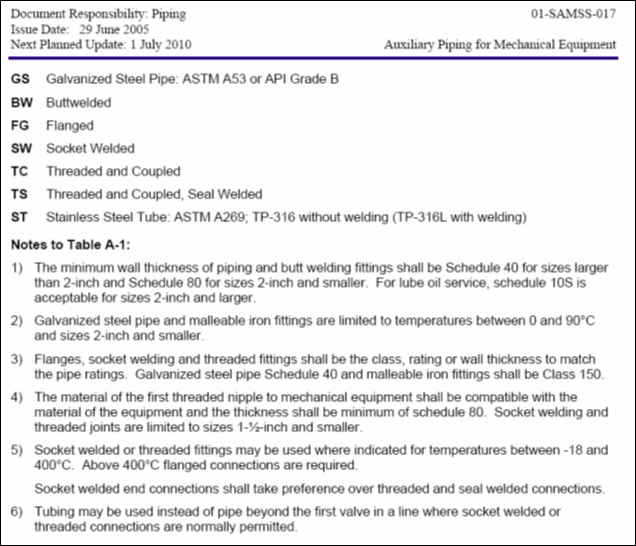

- All threaded fittings shall be forged carbon steel or stainless steel per ASME B16.11, and be Class 3000 for systems rated up to and including ANSI Class 900, and Class 6000 for systems rated ANSI Class 1500.

- All threaded connections shall be tapered per ASME B1.20.1.”

- The minimum size of auxiliary piping and tubing for mechanical equipment shall be 1/2-inch NPS with the exception of air compressor packages which shall be 3/8-inch NPS.

- All piping, tubing and valves shall be adequately supported and fastened in a manner which facilitates replacement, prevents vibration, and damage due to incidental loads which may occur during operation or maintenance work. Refer to Drawing AB-036521 for valve bracing (See attachment 2)

Unions are not permitted in pressurized lines carrying flammable or toxic fluids unless they are required for removal or assembly of the equipment and cannot otherwise be substituted by flanges. - All piping systems shall be provided with vent valves at high points and drain valves at low points. Horizontal runs in pressure piping shall slope gradually towards drain points. The minimum slope of drain lines shall be 1:50.

- A block valve, 3/4-inch NPS minimum, shall be installed in each instrument take-off connection and shall be located as close as feasible to the line, vessel, or mechanical equipment. Exception: thermocouples and thermometers are excluded from the 3/4-inch NPS minimum requirement.

- Pipe may be bent where necessary to achieve the desired configuration. Bending of the pipe shall conform to the following: Pipe bends shall have surfaces free of cracks and buckles. Flattening of the cross section of bends shall not exceed 8 percent of the nominal pipe diameter. Bending procedures and required heat treatment shall be in accordance with ASME B31.3.

- Tubing: Stainless steel tubing shall be seamless, annealed, minimum wall thickness 1.24 mm, per ASTM A269, Grade TP-316L. Instrument air tubing shall be ¼ inch, 3/8 inch, or ½ inch OD stainless steel. Wall thickness shall be 0.75 mm or larger.

- Fittings: 316 stainless steel compression fittings shall be either Crawford Swagelok, Parker Hannifin A-Lok, Parker Hannifin Corp. CPI or Hoke Gyrolock. Any proposal to use fittings other than those listed above shall be reviewed by Supervisor, Instrumentation Unit, Process Instrumentation Division, P&CSD.

- Flexible hoses shall be stainless steel armored, with integral connectors. The hose length shall not exceed 600 mm. The hose lining shall be suitable for the process and operating conditions.

- Valves and Manifolds: Forged carbon steel valves shall conform to ASTM A105, Grade 2. Forged stainless steel valves shall comply with ASTM A182, Grade F316.

- Gate Valves (Excluding the Root Valve): Gate valves shall be forged steel, with ratings as required, but at least Class 800 at 454°C. Gate valves shall have 316 stainless steel trim and stem, solid wedge, reduced bore, renewable stellited seat, and a hand wheel. Furthermore, they shall be suitable for repacking under pressure. Gate valves shall have internal screw rising stems for services below 175°C. An outside screw and yoke design is required for services at and above 175°C.

- Needle Valves: Needle valves shall be bar stock steel, with ratings as required, but at least Class 3000.

- Needle valves shall have 316 stainless steel trim, integral seat, and welded bonnet.

- Manifolds: Manifolds for flow meter service shall have a rating Class 6000 at 95°C, or Class 4000 at 260°C. Manifolds shall have 316 stainless steel body, bonnet, stem and seat, and teflon packing. Connections shall be ½ inch NPT female at oval flange surface.

Instrumentation Requirements

- General power wiring, for circuits up to 600 V to ground and a maximum current rating of 15 A, shall be stranded copper; flame retardant PVC, XLPE or XLPO insulated; size 14 AWG; have an insulation minimum temperature rating of 90°C and shall comply with NFPA 70 or IEC 60502-1.

- Instrumentation signal wiring shall be stranded copper; flame retardant PVC, XLPE or XLPO insulated and shall have an insulation minimum temperature rating of 90°C. The minimum wire size shall be:

(a) 16 AWG single twisted pair/triad from instruments to the nearest skid mounted junction box. Cables carrying analog signals shall also be shielded.

(b) 18 AWG for multi-twisted pair/triad cables from junction boxes to other junction boxes or marshalling cabinets

(c) 22 AWG for multi-conductor cable inter-cabinet wiring. - Specialty cables (e.g., High Temperature, communication, network cables) shall be certified by any of the agencies listed in Appendix 2 (See attachment 3)

- Pair/triads of multi-twisted pair/triad control cables shall be numbered.

- Except for thermocouple wiring, black and white are the preferred colors for pair conductors and black, white and red for triad conductors unless otherwise specified in the purchase order. Blue color insulation or jacket shall only be used for intrinsically safe installation.

- Splices are not permitted in wiring. When wiring must be extended, connections shall be made via terminal blocks.

- Terminals: Wiring connections shall be made to channel (rail) mounted terminal blocks. These terminal blocks shall have tubular box clamp connector and compression bar or yoke for wire termination. More than two connections per terminal point are not allowed. If open screw type terminals are used, terminal lugs shall be ring tongue, compression type, with insulated sleeves.

- Fused terminals shall be used for power distribution, alarm and shutdown systems.

- All packaged unit wiring, intended for interface with plant wiring, shall be terminated in junction boxes.

- Wire Tagging: Interconnecting wires between skid mounted components and between skid mounted instruments and the skid termination panel shall be tagged. Each tag shall identify the device to which the opposite end of the wire is connected. Heat shrink or ferrule type wire tags with permanently embossed identification markings shall be used.

- Grounding: Provision for grounding the skid structure shall be made at diagonally opposite corners. The skid structure shall be designed to accommodate two-hole compression connector, for (2/0 AWG) copper conductor, at each corner.

- An identification tag or nameplate of 316 stainless steel shall be attached securely to the equipment with SS or Monel fasteners. The tag shall be marked with raised alphanumeric or die stamped with the following information:

● Saudi Aramco Purchase Order number

● Manufacturer

● Part/Model Number

● Serial Number

● Date of Manufacture

● Mark/Tag Number - The tag or nameplate shall be located so that the information can be read after installation of the equipment or components.”

- Class I, Division 2. In Class I, Division 2 locations, meters, instruments, and relays shall comply with 501.105(B)(1) through (B)(6).

- That is all meters, instruments, and relays, including kilowatt-hour meters, instrument transformers, resistors, rectifiers, and thermionic tubes, shall be provided with enclosures identified for Class I, Division 1 locations. Enclosures for ClassI, Division 1 locations include explosion proof enclosures and purged and pressurized enclosures.

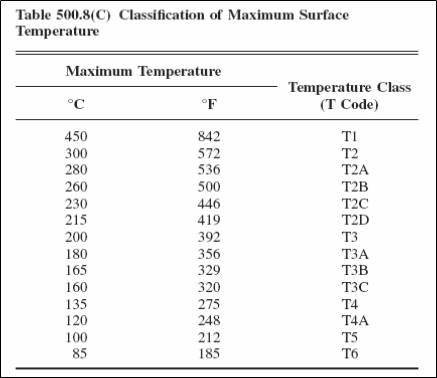

Alternatively, equipment shall be permitted to be marked to indicate the temperature class for which it is suitable, using the temperature class (T Code) of Table 500.8(B).- See Attachment 4″ - Wiring Methods: In Class I, Division 2 locations, the following wiring methods shall be permitted:

(1) All wiring methods permitted in NEC Art. 501.10(A).

(2) Threaded rigid metal conduit, threaded steel intermediate metal conduit.

(3) Enclosed gasketed busways, enclosed gasketed wireways.

(4) Type PLTC cable in accordance with the provisions of Article 725, or in cable tray systems. PLTC shall be installed in a manner to avoid tensile stress at the termination fittings.

(5) Type ITC cable as permitted in 727.4.

(6) Type MI, MC, MV, or TC cable with termination fittings, or in cable tray systems and installed in a manner to avoid tensile stress at the termination fittings.

(7) In industrial establishments with restricted public access where the conditions of maintenance and supervision ensure that only qualified persons service the installation and where metallic conduit does not provide sufficient corrosion resistance, reinforced thermosetting resin conduit (RTRC), factory elbows, and associated fittings, all marked with the suffix -XW, and Schedule 80 PVC conduit, factory elbows, and associated fittings shall be permitted. - Where seals are required for boundary conditions as defined in 501.15(A)(4), the Division 1 wiring method shall extend into the Division 2 area to the seal, which shall be located on the Division 2 side of the Division 1–Division 2 boundary.”

- Flexible Connections: Where necessary to employ flexible connections, as at motor terminals, flexible fittings listed for Class I, Division 1 locations or flexible cord in accordance with the provisions of NEC Art. 501.140 shall be permitted.

- Flexible Cords, Class I, Divisions 1 and 2: A flexible cord shall be permitted for connection between portable lighting equipment or other portable utilization equipment and the fixed portion of their supply circuit. The length of the flexible cord shall be continuous. Flexible cords are used shall be as follows:

(1) Of a type listed for extra-hard usage

(2) Contain, in addition to the conductors of the circuit, a grounding conductor complying with NEC Art. 400.23

(3) Connected to terminals or to supply conductors in an approved manner

(4) Supported by clamps or by other suitable means in such a manner that there is no tension on the terminal connections

(5) Provided with suitable seals where the flexible cord enters boxes, fittings, or enclosures of the explosion proof type.

Local Control and Alarm Display Cabinet Requirements

- Finish: The cabinet finish shall be per manufacturer’s standard unless stated otherwise. The color of the coating shall be as specified in the Purchase Order.

Design: Vortex coolers, heat pumps or air conditioners may be used to reduce internal cabinet temperature with the prior approval of Supervisor, Instrumentation Unit, Process Instrumentation Division, P&CSD. - Drawings: Vendor shall provide wiring diagrams or wiring list showing termination strips and all electronic interconnections, with names and equipment/terminal identification. All spare terminals, terminal strips and wires shall appear on the vendor wiring drawings or list.

- Indication Lights, Pushbuttons and Switches: Indication lights, pushbuttons and switches shall be of the oil tight, heavy duty type. Long-life type dated lamps or LED cluster lamps shall be used. Indication lights and pushbuttons shall have the following color:

Red – abnormal, trip, shutdown, off, closed, emergency

Yellow – (pre-) alarm

Green – normal, on, open, permissive start “ - Controllers and Instrumentation: The vendor shall ensure that all equipment, including digital controllers and displays are suitable for operation in the ambient conditions specified in Specification sheet.

- Controllers and displays shall be installed in locations where vibration is negligible. Digital displays shall be screened from direct sunlight.

- Alarm and Shutdown Systems: Alarm and shutdown systems shall be of fail-safe design.

- Solenoid valves and relays shall be energized during normal operating conditions.

- All contacts of direct process-operated, manual shutdown and equipment status switches shall be closed during normal operating conditions.

- Initiating devices for shutdown systems shall be independent, dedicated primary elements having their own individual process connections. Primary elements in control or indicating loops shall not be used to initiate shutdowns.

- Each shutdown signal shall have an alarm.

- Switch contacts shall be single-pole, double-throw (SPDT) as a minimum. Unless otherwise specified, the minimum contact rating for disconnecting inductive loads shall be:

• 0.4 A @ 125 V DC

• 5.0 A @ 120 V AC/60 Hz “ - Shutdown logic shall be designed to incorporate test facilities to permit initiating devices and output devices to be tested on line.

- Inlet and outlet bypass switches shall be provided as necessary. Password protected software bypass switches are acceptable. The implementation of an input or output bypass shall be alarmed.

- Solenoid valves shall have Code HT high-temperature molded coils, suitable for 180°C, with silicone rubber insulated coils and connection wires. Viton elastomers shall be used, for seating and other resilient, unless otherwise specified.

- Control Valves: Refer to SATIP-700-01 for requirements of control valves.

- All control Valves shall be flanged. Threaded control valves (size 1½”and smaller) shall only be used with prior approval of Supervisor, Instrumentation Unit, Process Instrumentation Division, P&CSD.

- The minimum flange rating shall be ANSI Class 300, RF for valve sizes up to and including 16-in.

- Self acting thermostatic control valves shall not be used without prior approval of Supervisor, Instrumentation Unit, Process Instrumentation Division, P&CSD.

- The application, sizing, design and installation of safety relief valves (PZV) shall meet the requirements of ASME SEC I, ASME SEC IV, ASME SEC VIII D1, and ASME SEC VIII D2; API RP 520, Parts I and II; API RP 521; API STD 526, and/or API STD 527, as applicable.

Installation Requirements

- Mounting : All instruments shall be mounted as close to the process connection as possible.

- Impulse lines shall be as short as possible.

- The location of instruments shall be so that direct drainage of condensate, water or process fluids from adjacent equipment has no adverse effect.

- Instruments shall be mounted in locations where vibration is negligible.

- All local instrumentation and associated control equipment shall be readily accessible from grade, platform, fixed walkway, or fixed ladder.

- Local indicating instruments shall be visible from where related equipment is operated or primary instruments are tested or calibrated.

- Pressure and D/P instruments in liquid or condensable vapor service shall be self-venting (i.e., mounted below the process connections) with all impulse lines sloping downward approximately 1:10 minimum toward the instrument.

- Pressure and D/P instruments in gas service shall be self-draining (i.e., mounted above the process connections) with all lines sloping downward approximately 1:10 minimum toward the process connection.

- Pressure transmitters in gas service may be mounted on panels below their process connections provided that the process connections are located on the top of the process lines, low point drains are provided, and the impulse lines slope toward the low point. For other applications refer to API RP 551.

- Impulse tubing shall be made with metallurgy compatible to process and ambient conditions. Threaded fittings shall be used.

- Cables between skid mounted instruments and junction boxes shall be routed in conduits. The conduit installation shall be in accordance with NFPA 70 and 17-SAMSS-515 . Refer to SATIP-P-104-05.

- Different instruments signals shall be segregated from each other and from power wiring.

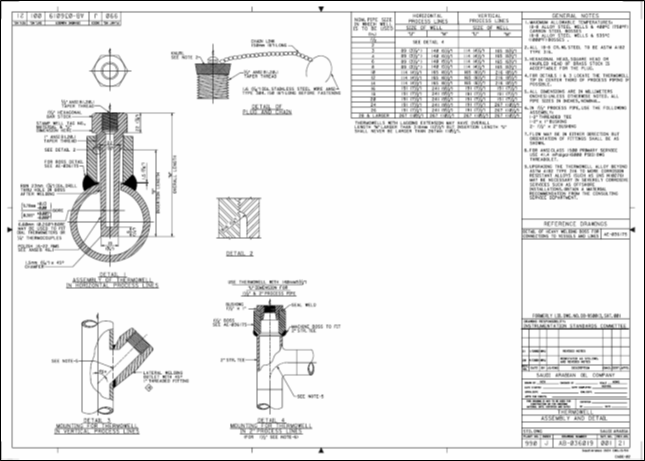

- Temperature sensors shall be fitted with terminal heads and installed in thermowells. For details, see Standard Drawing AB-036019. (Attachment 5)

- Tagging: Instruments shall have permanently attached engraved phoenolic / laminate or plastic nameplates, showing instrument tag numbers. Phoenolic nameplates shall be installed with two stainless steel screws.

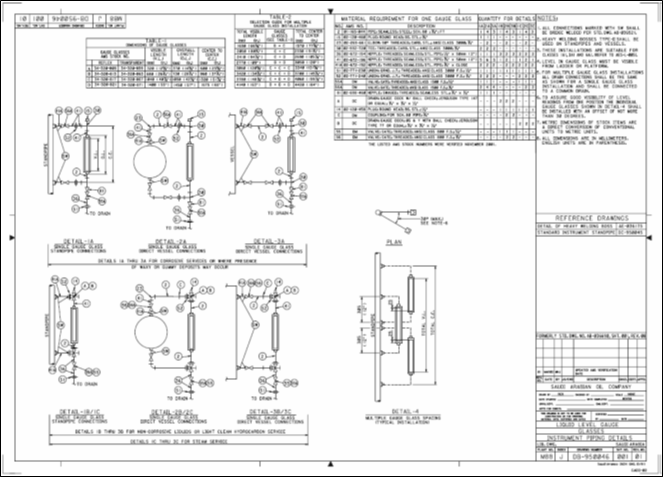

- Level Gauge Glasses Refer to Library Drawing DB-950046 (See attachment 6) for typical liquid level gauge glasses installations. Weld pad type level gauges are acceptable for lube oil tanks. Refer to SATIP-J-300-01 for different types of installations

- Orifice Runs, Venturi Tubes and Flow Nozzles The minimum required lengths of straight and unobstructed pipe upstream and downstream of the primary element shall be based on a beta ratio of 0.7, and be in accordance with Standard Drawing AA-036197 (See attachment 7)

- The pipe sections upstream and downstream of the primary element shall be round and smooth to obtain optimal metering accuracy. In vertical lines the flow shall be downward for wet gases and saturated steam, and upward for liquids containing vapor.

- Process Connections: All threaded process connections shall be tapered per ASME B1.20.1. All threaded process connections to vessels, standpipes and lines, except thermowells, shall have heavy welding bosses per Standard Drawing AE-036175, and threaded gate type block valves as close to the vessel, standpipe or line as possible. Fittings between the block valve and the welding boss, other than the pipe nipple, are not allowed. The two threaded connections between the welding boss, pipe nipple and block valve shall be seal or bridge-welded per Standard Drawing AB-036521. Table 1(Attachment 2) shows the type of welding (e.g., seal or bridge) for each application, but does not apply to thermowells and flanged connections. Commercially available forged steel branch outlets of Class 6000 rating are considered equivalent (Thredolets or Socklets of Bonney Forge or equal). Couplings or half couplings shall not be used, unless provision is made for a full penetration weld.

- Instrument Piping and Tubing: The instrument piping and tubing installation shall ensure the reliable and accurate operation of the instrument(s) involved, and allow sufficient access for maintenance, calibration and testing. It shall be possible to test all alarm and shutdown initiating devices, without interfering with the process operation of the packaged unit.

- Instrument tubing shall be adequately supported to eliminate any vibration transmission to the instruments or excessive load to the piping connection, process line or vessel. Tubing to and from non-indicating instruments shall have a plugged tee or equivalent test point for calibration and testing purposes. All threaded connections shall be tapered per ASME B1.20.1.

- All incoming and outgoing interconnection lines shall terminate in bulkhead fittings. The lines shall be marked with the tag numbers of the corresponding instruments. Bulkhead fittings shall be installed with adequate spacing to ensure that any connection can be removed without the need to remove other fittings.

International Standard and Codes for Instrumentation Requirements for Mechanical Equipment Skid

Copper Tubing, Brass Fittings, and Valves for Instrument Service

3. SAES-J-902 – Electrical Systems for Instrumentation.

4. 34-SAMSS-831 – Instrumentation for Packaged Units.

5. 01-SAMSS-017 – Auxiliary Piping For Mechanical Equipment.

6. NFPA 70 – National Electrical Code.

1. Attachment 1A: Sheet 1 of 2 – Material Selection and Joining Methods, 01-SAMSS-017

2. Attachment 1B: Sheet 2 of 2 – Material Selection and Joining Methods, 01-SAMSS-017

3. Attachment 2: Valve Bracings Std DWG AB-036521 Sheet 1

4. Attachment 3: Approval Agencies for Equipment in Hazardous Area

5. Attachment 4: Electrical Equipment Temperature Class NEC Table 500.8©

6. Attachment 5: Temperature sensors in Thermowells, STD. Dwg. AB-036019 Sheet 1

7. Attachment 6: Liquid Level Guage Glasses, Instrument Piping Details Lib. Dwg DB-950046

8. Attachment 7: Straight Pipe Requirements for Orifice, Venturi and Flow Nozzles Std. Dwg AA-036197