1. PURPOSE

2. SCOPE

3 REFERENCES

4. RESPONSIBILITY

5. MANPOWER CATEGORY

6. REQUIRED TOOLS

7. METHOD/PROCEDURE

8. QUALITY CONTROL AND ASSURANCE

9 SAFETY INSTRUCTIONS & PRECAUTIONS

10. ATTACHMENT

1.0 PURPOSE

The purpose of this Method Statement will serve as a minimum guidelines to carry out the Installation of anchor bolts lock nut or Jam nut in order to meet the requirement as per SAES-Q-005 sec.4.8.7, anchor bolts subject to uplift or vibration shall be equipped with as additional nut to serve as a lock nut to ensure against loosening.

2.0 SCOPE

2.1 This method statement will cover the installation works of lock nut or jam nut of anchor bolt for the steel structure of JAZAN REFINERY and TERMINAL PROJECT Package 12-Naptha and Aromatics.

3.0 REFERENCES

3.1 Specification and Standards

3.1.1 Construction Scope of Work.

3.1.2 S000-1520-101 Field QC Procedure

3.1.3 S000-1650-001 Safety Execution Plan

3.1.4 S000-1351-002 Installation Marking Procedure

3.1.5 S000-3150-001 Installation of Static Equipment

3.1.6 FWBS CODE (5000) Equipment Installation

3.1.7 S000-1520-103 Handling Procedure

3.1.8 S000-1630-003 Material & Equipment Protection Program at work site

3.2 ARAMCO Specification and Standards

32.1 SAES-B-014 Safety Requirement for Plant and Operations Support Buildings

3.2.2 SAES-M-001 Structural Design for Non-Building Structure

3.2.3 12-SAMSS-008 Erection of Structural and Miscellaneous Steel

3.2.7 SCHEDULE Q Saudi ARAMCO Project Quality Requirements

3.2.8 Saudi ARAMCO Safety Requirements for Scaffolds

3.2.9 Saudi ARAMCO Construction Safety Manual

3.2.10 Related Vendors Installation and Maintenance Manuals and Specifications.

3.3 Industry Codes and Standards

3.3.1 Steel Design Guide for Baseplate and Anchor Rod Design

3.3.2 AP 686 Recommended practices for Machinery Installation & Installation Design

3.33 ASME B 18.2 Nuts for General Application: Machine screw Nuts, Hex, Square, Hex flange and Coupling Nuts.

3.3.4 PIP STS05130 Erection of Structural and Miscellaneous Steel Specification

3.4 Inspection and Test Plan/ Method Statement

3.4.1 SATIP-M-001-01 Structural Steel- Pipe rack, Steel Supports & Miscellaneous Steel Structures

3.4.2 AA-036322 Standard drawing for Anchor Bolts

3.4.3 SATIP-D-109-01 Typical Inspection Plan shop Fabricated Storage Tank Installation

3.4.4 SATIP-D-001-01 Typical Inspection Plan for Pressure Vessel

3.4.5 AA-036322 Standard Drawing for Anchor Bolts.

4 0 RESPONSIBILITY

Site Manager

Ensure full compliance by all Millwrights, Mechanical Foreman, Labor regarding execution of work and implementation of HSE procedure in accordance with project requirement and specifications. Confirm availability of all materials, tools, equipment and required personnel who will carry out the work.

Quality Control Inspector

Conduct inspection in accordance with this procedure Monitor daily activities and verify compliance to ARAMCO Specifications. Prepares record and final acceptance documentation where required.

Construction Manager

a. Pre-mobilization Inspection and color coding for all tools and equipment used on site. Ensure that all safety requirements have been adequately addressed and the work is carried out in accordance with ARAMCO project safety procedures.

b. Ensure relevant documentation and certifications are submitted for operators, drivers, scaffolding and rigging.

Mechanical Supervisor

Prepare and submit method statement for COMPANY review and approval. Provide latest revision of AFC drawings, procedures, material specifications standards and technical specifications. Provide latest as built drawings for every receive equipment.

Mechanical Foreman

Shall be responsible for the direct work supervision at site to ensure that the work will be performed in accordance with Technical Scope of work and latest approved for construction drawings He shall monitor the availability of materials in line with his required schedule.

QC Inspector

Shall be responsible in monitoring safety aspects and ensuring that the work will be done in accordance with Safety Standard Procedure. He shall give reminders or advise to the workers to do the activity safely.

Safety Officer

Check the work areas and monitor from time to time in the implementation of safety procedure and assuring that all safety equipment and tools are present at site and in good working condition.

5.0 MANPOWER CATEGORY

5.1 Foreman

5.2 Welder

5 3 Mechanical Fitter

5.4 Fabricator

5.5 Helper

5.6 Scaffold er

5.7 Surveyor

5.8 QC Inspector

5.9 Permit Receiver and other involved Manpower

6.0 REQUIRED TOOLS

6.1 Auto Level or Level Machine

6.2 Hammer

6.3 Welding Machine for Tacking of Liners/Wedges

6.4 Wrenches/Leveling Tools/Feelers and Dial Gauges

6.5 Precision Levels/Calibrated Gauge/Torque Wrench/Hand Tools

6.6 Equipment shall be maintained and checked prior to use for safe work assurance

6.7 Equipment shall be approved and certified by SAUDI ARAMCO

6.8 All tools must be calibrated before using.

7.0 JAM NUT INSTALLATION PROCEDURE / METHOD

- Prepare necessary work permit prior to conduct the activity.

- Prepare all tools and equipment needed during installation.

- Provide the necessary Site Instruction to ensure that activity to be done is applicable.

- Provide scaffolding access prior to installation and alignment if required.

- Ensure the availability of Jam nut materials, Contractor will issue Hex. Jam nuts to Subcontractor. The required quantity of Jam nuts will base on the number of anchor bolts detailed in construction drawing of such equipment.

-

Installation of Jam Nuts

- Jam nuts are used as a second nut threaded over a bolt to prevent the first from loosening, or in applications where there is not sufficient space for a standard nut.

- All anchor bolts that are subject to uplift due to vibration shall be equipped with an addition nut to serve as a lock nut to ensure against loosening. Refer to (SAES-Q-005 sect. 4.8.7)

- For thus anchor bolts of mechanical equipment that are short and not meet the requirements of ASME code of standard practice for equipment, thus additional nut cannot be installed.

- With regards to the site condition and for thus anchor bolts were not meet the required projection with a minimum of two (2) thread; therefore, Jam nut shall be installed with a minimum thickness of 10mm, please refer to ASME B18.2.2-2015 page 8 Table-4, Application for this method will be shown in reference drawing( Attachment Ref.1 & 2)

- Method -A 1: Anchor bolts were not meet the required 2 thread bolt projection shall be install with a minimum of 10mm thickness

- Method -A.2: For further evaluation of the actual elevation of foundation, it was found that the projection of anchor bolt was already short and it did not meet the minimum requirements of 2 threads. Therefore, Hex. Jam nut with 15mm thickness shall be installed. But if the minimum of 10mm thickness of Jam nut were installed and the projection is 7.6.1 still less than 2 thread and more shorten, we will apply the other option.

- Method B – If the bolt projection is only one thread or less than 1 and did not meet the required projection, will apply this option. Reduce the thickness of square washer by grinding with the maximum of 6mm to compensate the required bolt projection. See attachment (Ref.3 &4).

8.0 QUALITY CONTROL AND ASSURANCE

8.1 Inspection shall be conducted and recorded in accordance with the Job Specification Inspection and Test Plan.

9.0 SAFETY INSTRUCTIONS AND PRECAUTIONS

9.1 Make sure that all necessary work permits are issued.

9.2 Check all lifting equipment prior to commencing lifting activities.

9.3 Stay away from any suspended load/falling objects.

9.4 Wear full body harness when working at elevated platform.

9.5 Install safety nets when necessary.

9.6 Ensure that barricades and warning signs are properly installed.

9.7 Ensure that there are no hazardous or combustible gases present in the work area.

9.8 Install flashing lights to traffic.

9.9 Copy of approved JSA to be maintained at work site by Work Supervisor. Conduct daily Tool Box Talk and discuss work methodology prior to commencement of work.

9.10 Implement and monitor safety instruction on site.

10.0 ATTACHMENT

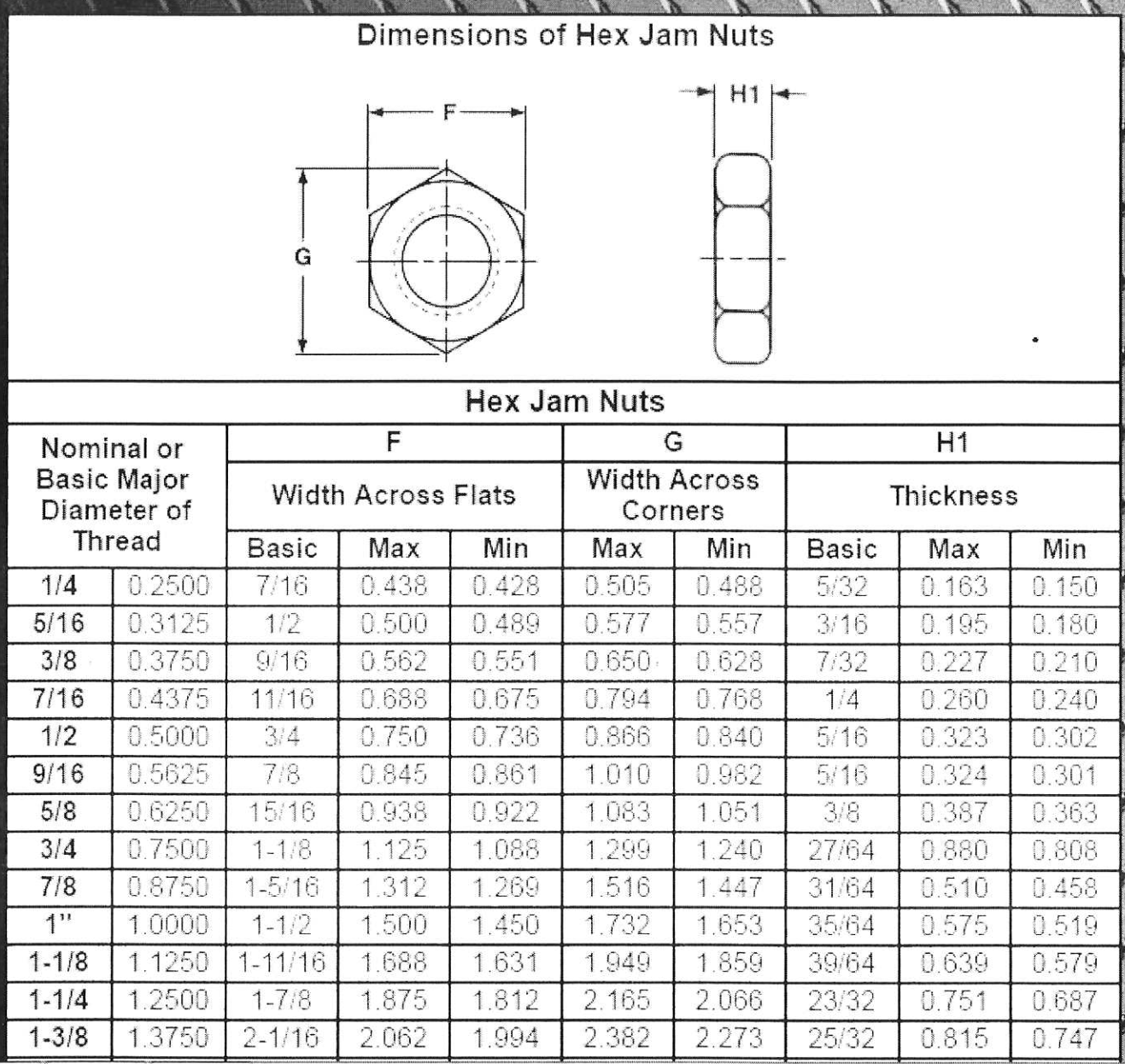

- Table Standard of Hex. Jam Nut Dimension.

- Equipment Anchor bolts and Jam nuts detail for Installation.

- General Arrangement Drawing.

Table Standard of Hex. Jam Nut Dimension.

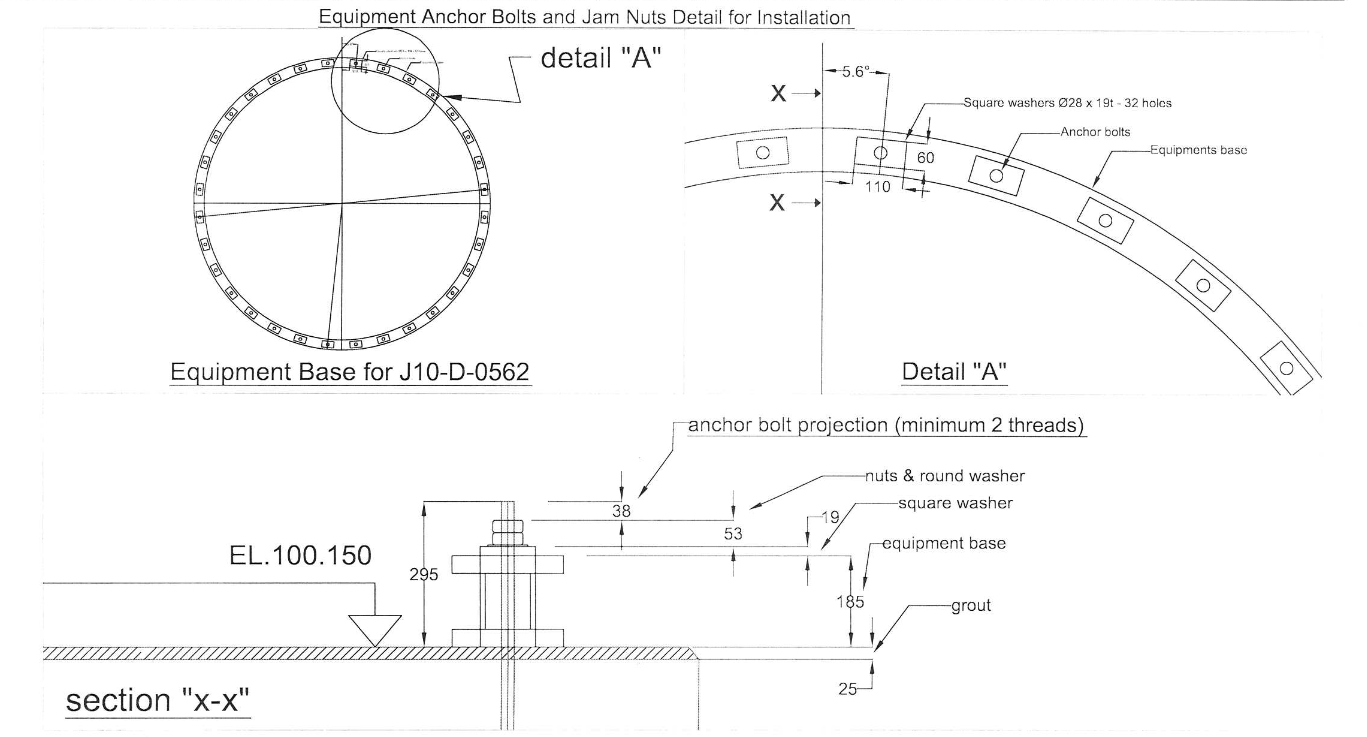

Equipment Anchor Bolts and Jam Nuts Details for Installation

Method A-1: Anchor bolt were not meet the required minimum 2 bolt thread, projection to be installed with jam nuts with minimum 10 mm thickness.

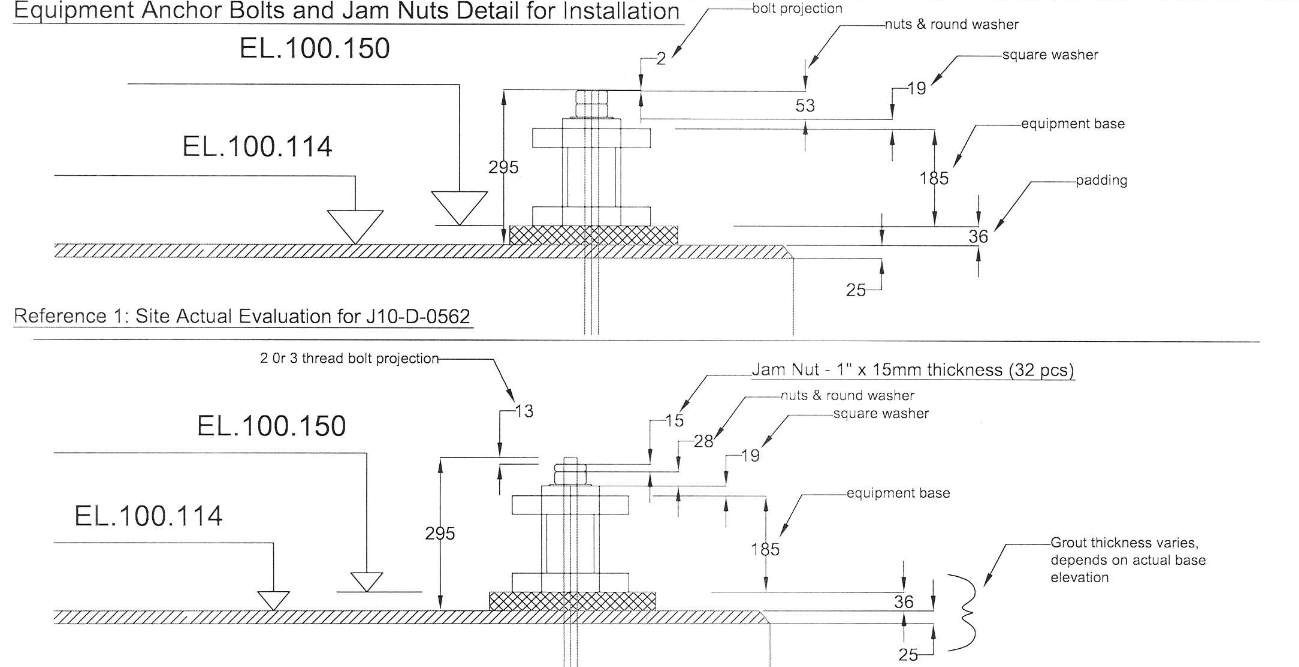

Equipment Anchor Bolts and Jam Nuts Details for Installation

Method A-2: For further evaluation of the actual elevation of foundation, it was found that the projection of anchor bolt was already short and it did not meet the minimum requirements of 2 threads. Therefore 1” Hex. Jam Nut with 15 mm thickness will be installed. The minimum thickness for jam nut should be 10 mm.

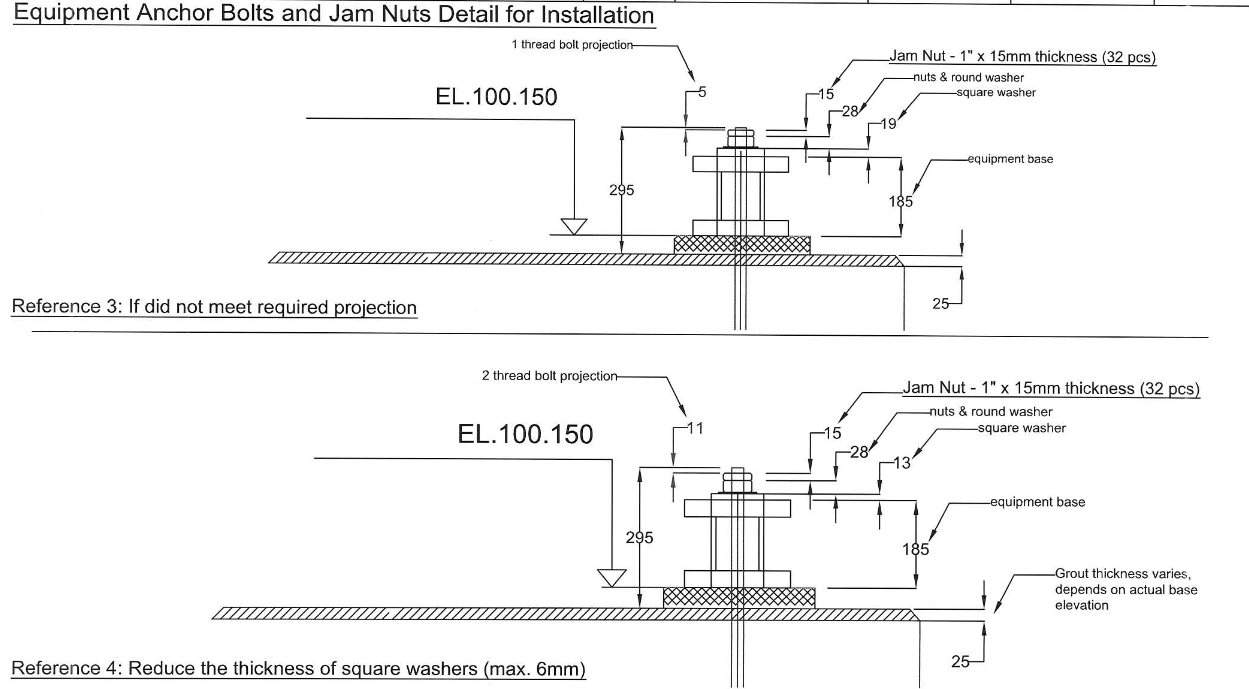

Equipment Anchor Bolts and Jam Nut Details for Installation

Method B : If the bolt projection is only one thread or less than 1 and did not meet the required projection, therefore we will apply this option. Reduce the thickness of square washer by grinding with maximum of – -6 mm to compensate required bolt projection.