Magnetic Hysteresis

All ferromagnetic materials have certain magnetic properties that are specific to that material. Most of these properties are described by a magnetic hysteresis curve. The data for the hysteresis curve are collected by placing a bar of ferromagnetic material in a coil and applying an alternating current. By increasing the magnetizing field strength H in small increments and measuring the flux density B at each increment, the relationship between magnetic field strength and flux density can be plotted.

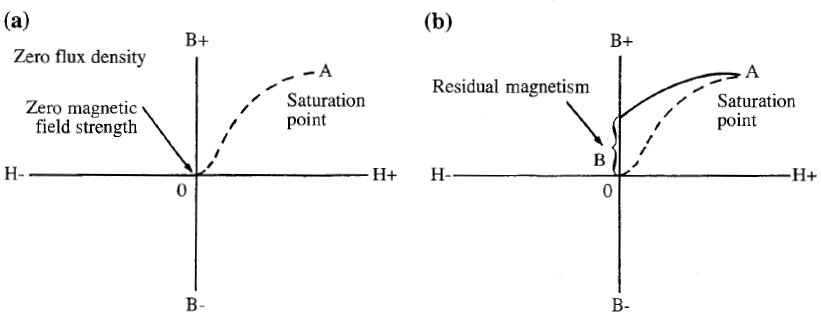

The relationship between magnetic field strength and flux density is not linear for ferromagnetic materials. A specific change in H may produce a smaller or larger change in B, as shown in Figure, the initial curve for an unmagnetized piece of steel. Starting at point 0 (zero magnetic field strength and zero magnetic flux) and increasing H in small increments, the flux density in the material increases

quite rapidly at first, then gradually slows until point A is reached.

At point A, the material becomes magnetically saturated. Beyond the saturation point, increases in magnetic field strength do not increase the flux density in the material. In diagrams of full hysteresis loops, the curve O,A is often drawn as a dashed line because it occurs only during the initial magnetization of an unmagnetized material. It is referred to as the virgin curve of the material.

When the magnetic field strength is reduced to O, the flux density slowly decreases. It lags the field strength and does not reach 0. The amount of flux density remaining in the material (line O,B) is called residual magnetism or remanence. The ability of ferromagnetic materials to retain a certain amount of magnetism is called retentivity.

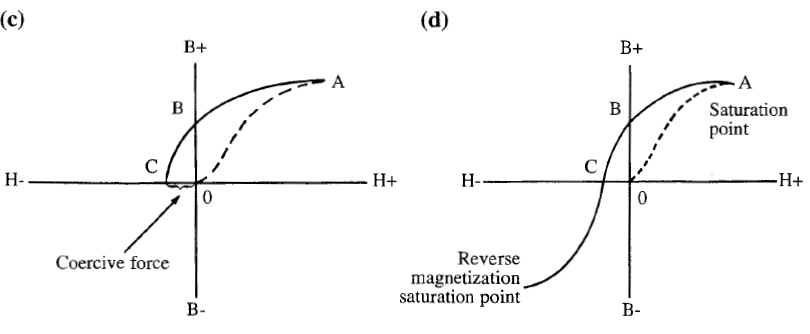

Removal of residual magnetism requires the application of a magnetic field strength in an opposite or negative direction. When the magnetic field strength is first reversed and only a small amount is applied, the flux density slowly decreases. As additional reverse field strength is applied, the rate of reduction in flux density (B ,C) increases until it is almost a straight line where B equals zero.

The amount of magnetic field strength necessary to reduce the flux density to O is called coercive force. Coercive force is a factor in demagnetization, and is also very important in eddy current testing of ferromagnetic materials.

As the reversed magnetic field strength is increased beyond point C, the magnetic flux changes its polarity and initially increases quite rapidly. It then gradually slows until point D is reached. This is the reverse polarity saturation point, and additional magnetic field strength will not produce an increase in flux density.

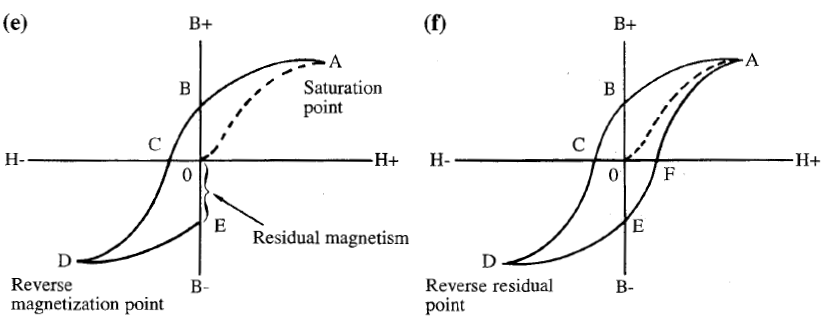

When the reversed magnetic field strength is reduced to O, the flux density again lags the magnetic field strength, leaving residual magnetism in the material (0 ,E). The flux densities of the residual magnetism from the straight and reversed polarities are equal (0 ,B is equal to line O ,E).

Hysteresis data for unmagnetized steel: (a) virgin curve of a hysteresis loop;

(b) hysteresis loop showing residual magnetism; (c) hysteresis loop showing coercive force; (d) hysteresis loop showing reverse magnetism; (e) hysteresis loop showing reverse residual magnetism; and (f) complete hysteresis loop.

Removal of the reversed polarity residual magnetism requires application of magnetic field strength in the original direction. Flux density drops to O at point F with the application of coercive force O,F. Increasing the field strength results in the magnetic polarity changing back to its original direction on the hysteresis

diagram. This completes the hysteresis loop A,B,C,D,E,F (note that the curve C,D,E,F is a mirror image of curve C,B,A,F).