1. PURPOSE

2 SCOPE

3. REFERENCES

4. RESPONSIBILITIES

5. FILLING GROUT VOID

6. SAFETY INSTRUCTIONS & PRECAUTIONS

7. ATTACHMENT.

METHOD OF STATEMENT FOR FILLING GROUT VOID

1. PURPOSE

The purpose of this Method Statement is for Filling Grout Void. Test & inspection shall be carried out safely, efficiently in accordance with the project requirements of Plants and Refinery Projects.

2. SCOPE

The scope of work under this Method Statement applies to all Filling Grout Void covered under Plants and Refinery Projects.

3. REFERENCE

API 686 Recommended Practices for Machinery Installation and Installation Design.

SAES-0-010 – Cement Based, Non-Shrink Grout for Structural and Equipment Grouting.

SAES-0-011 – Epoxy Grout for Machinery Support.

PIP-STS03600 – Non-Shrink Cementitious Grout Specification.

PIP-STS03601 – Epoxy Grout Specification.

4. RESPONSIBILITIES

Site Manager

Ensure full implementation of this Method Statement and identifies the work and safety requirements including add on resources for the effective accomplishment of the Mechanical Work.

Mechanical Supervisor

Ensure full work and safety compliance by all foremen, erectors and helpers regarding the execution of the work in accordance with the project specification and requirements. Confirm the availability of all materials, tools, equipment and required personnel who will carry out the work.

Quality Control Manager

Ensure full implementation of the required quality control procedures and maintain the required documentation as per the approved inspection test plan for the final acceptance and handover of the system.

Quality Control Inspector

Conducts daily surveillance and inspections in accordance with this procedure and prepares quality control records and final acceptance of documents when required for final handover.

Construction Manager

Check the work areas and monitor from time to time in the implementation of safety procedure and assuring that all safety equipment and tools are present at site and in proper good condition.

Safety Officer

Check the work areas and monitor from time to time in the implementation of safety procedure and assuring that all safety equipment and tools are present at site and in good working condition.

5. FILLING GROUT VOID

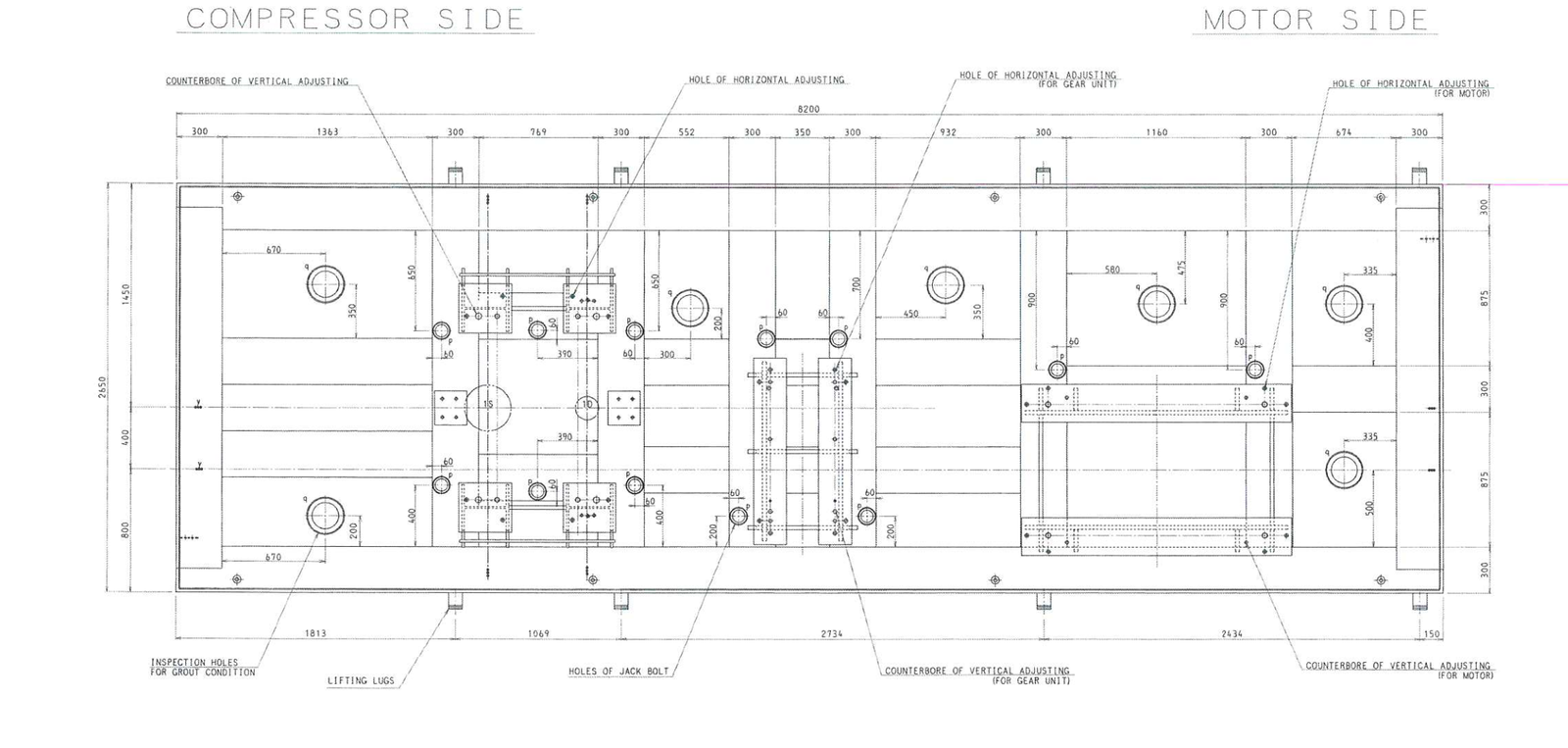

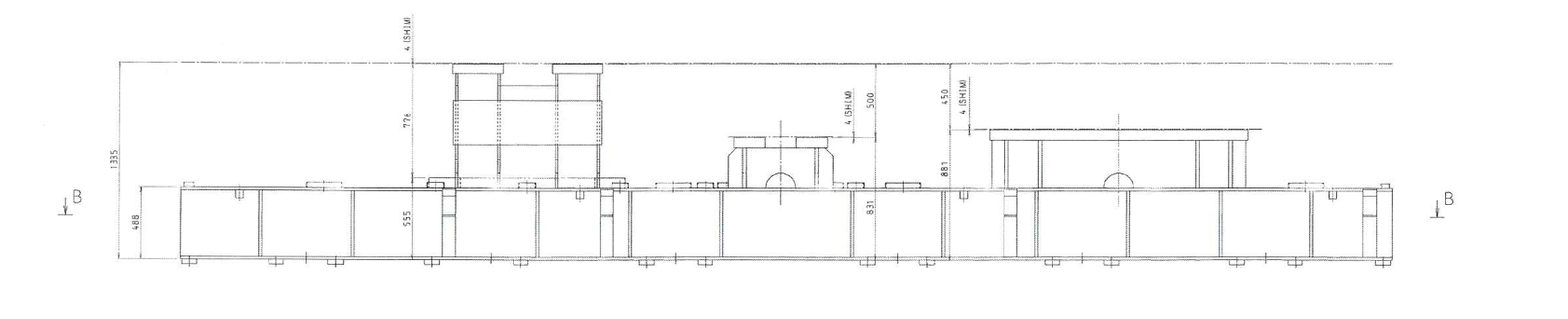

5.1 In case that the base skid has a grouting void, the following steps shall be done:

i. Check for voids by tapping along the top deck of the mounting plate.

ii. Mark the void areas to allow the proper identification when rectifying. A solid sound indicates a good grout area while a drum like hollow sound indicates a grout void and requires filling of grout.

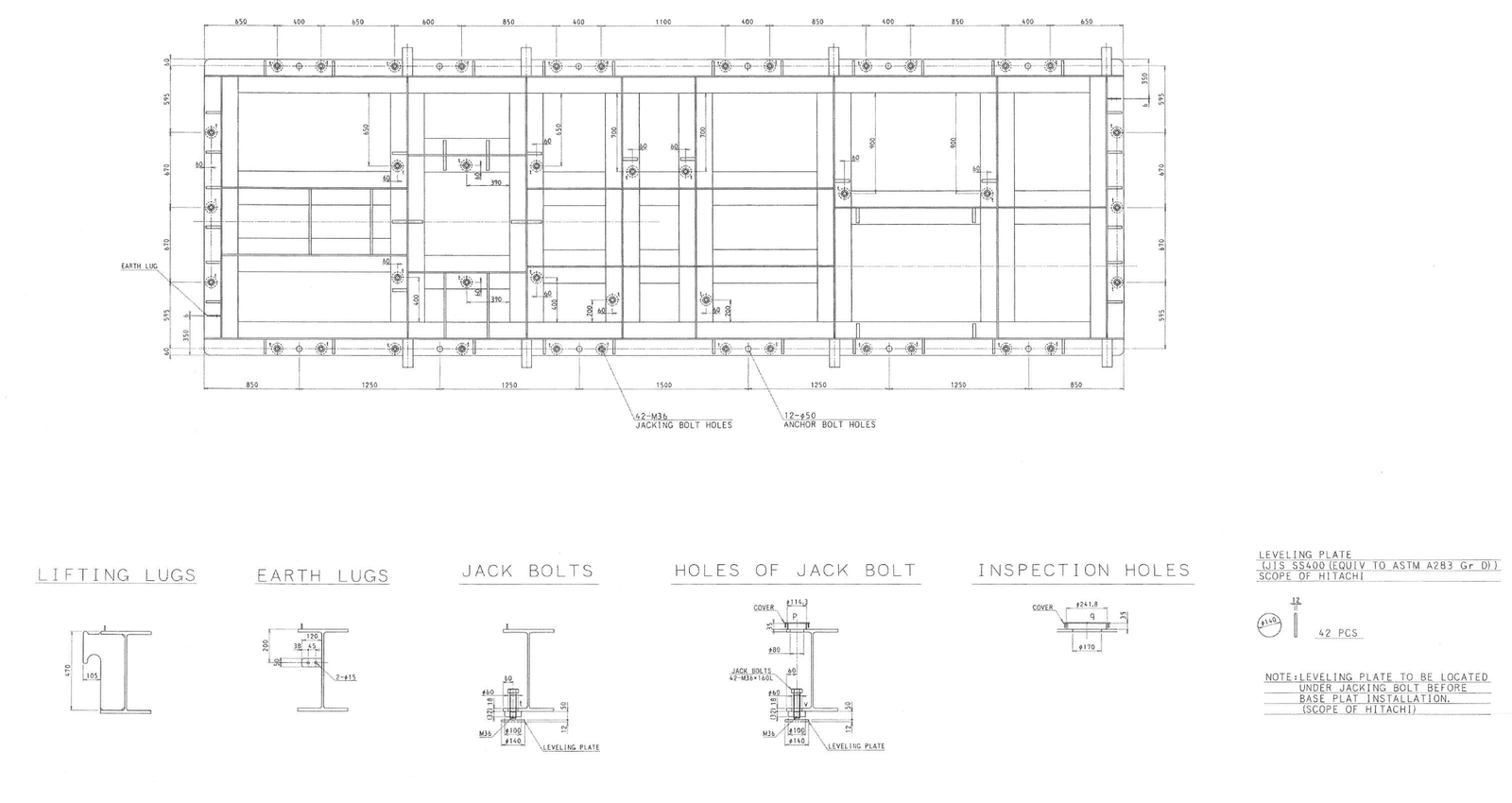

iii. Make the holes by drilling for filling. Diameter of the holes is about 20mm – 30mm. One (1) hole is for the pouring while the other holes will be served as a vent to avoid air trapped during the placement of grout.

iv. Ensure that the mixing of epoxy grout is complied as per manufacturer procedure.

– Void Thickness

– Up to 10mm: Only Base and Hardener can be used.

– More than 10mm: Base and Hardener with three bags Aggregate only(not four bags) can be used. Mix base and hardener then add three bags aggregate (one by one)

v. The third party laboratory to do the sampling and testing of cube samples for grout.

vi. Pour the grout into the hole steadily until it emerges on all vent holes.

vii. Clean all the areas with excess grout before it sets.

viii. Re-check for voids to make sure the filling.

6. SAFETY INSTRUCTIONS AND PRECAUTIONS

6.1 Make sure that all necessary work permits are issued.

6.2 Check all lifting equipment prior to commencing lifting activities.

6.3 Stay away from any suspended load/falling objects

6.4 Wear full body harness when working at elevated platform.

6.5 Ensure that barricades and warning signs are properly installed.

6.6 Ensure that there are no hazardous or combustible gases present in the work area.

6.7 Install flashing lights to traffic.

6.8 Copy of approved JSA to be maintained at work site by Work Supervisor. Conduct daily Tool Box Talk and discuss work methodology prior to commencement of work.

6.9 Implement and monitor safety instruction on site.

7. ATTACHMENT

- JSA (Job Safety Analysis)

- Grout Manufacturer Instruction

- Cementitious & Epoxy Grout Very Good Document with Pictures