- PURPOSE

- SCOPE

- APPLICABLE DOCUMENTS

- RESPONSIBILITY

- MANPOWER

- TOOLS & EQUIPMENT

- METHODS/PROCEDURES

- QUALITY CONTROL

- SAFETY PRECAUTION

- ATTACHMENTS.

METHOD STATEMENT FOR BOLT HOLES OF LOWER COLUMN BASE

1.0 PURPOSE

This method statement shall provide minimum guidelines to carry out the rectification of bolt holes of lower column base for Plants and Refinery Projects to ensure that the work is carried out in accordance with Project Drawings and Project Specifications.

2.0 SCOPE

This method statement will cover the rectification of bolt holes of lower column base at Plants and Refinery Projects.

3.0 APPLICABLE DOCUMENTS

3.1 ARAMCO Project Specification and Standards

3.1.1 SAEP-302 Instruction for Obtaining a Waiver of a Mandatory Saudi ARAMCO Engineering Requirements

3.1.2 SAES-M-001 Structural Design for Non-Building Structure

3.1. 3 12-SAMSS-007 Fabrication of Structural and Miscellaneous Steel

3.1.4 12-SAMSS-008 Erection of Structural and Miscellaneous Steel

3.1.5 SCHEDULE Q Saudi ARAMCO Project Quality Requirements

3.1.6 Saudi ARAMCO Safety Requirement for Scaffolds

3.1.7 Saudi ARAMCO Construction Safety Manual

3.2 Industry Codes and Standards

3.2. 1 AISC AISC Code of Standard Practice, Specification for Structural Joints Using ASTM A325 or A490 Bolts

3.2.2 PIP STS05130 Erection of Structural and Miscellaneous Steel Specification

3.3 Inspection and Test Plan I SA Inspection Checklist

3.3.1 SAT I P-M-001 -01 Structural Steei-Piperack, Steel Supports & Miscellaneous* Steel Structures (* Incl. Piping Supports per Specification)

3.3.2 SAIC-M-2008 Repair/Correction of Errors of Structural Alignment

4.0 RESPONSIBILITY

4.1 Construction Manager is responsible for implementing HSE and shall study, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources required for the successful implementation of the construction work activities. Study all aspects of work procedure as per Technical Scope of Work.

4.2 Structural Supervisor shall study and review all necessary documents for the rectification work in his area. He shall monitor the availability of materials in accordance with the schedules and construction analysis. He shall report directly to the Construction Manager. He shall coordinate with other disciplines to visualize possible conflicts in the drawings as well as in the schedule to provide alternative options to prevent unnecessary delays or obstructions.

4.3 Structural Foreman shall be responsible for direct work supervision at site and shall ensure that the work is performed safely by monitoring the activity.

4.4 Surveyor shall study and analyze if the location where the structure should be installed satisfies the condition or restriction of erection works on site. He shall coordinate with other disciplines to visualize possible conflicts in the drawings as well as in the schedule to provide other options to prevent unnecessary delays or obstructions.

4.5 QC Inspector shall be responsible for the monitoring and inspection of the work and ensure that the work is performed in accordance with Technical Scope of Work and Standards.

4.6 Safety Engineer/Supervisor shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with Safety Standard Procedure. He shall discuss with the field supervisor’s the characteristics of related materials and status of work area giving reminders on any additional points to work safely.

5.0 MANPOWER

5.1 Manpower will consist of the following, but not limited to as listed to as below:

• Structural Supervisor

• Structural Foreman

• Steelworkers

• Structural fitters

• Helper

• Surveyor

• Safety Engineer/Supervisor

• QC Inspector

6.0 TOOLS AND EQUIPMENT

6.1 Tools and equipment needed shall be in good condition and must be checked by Structural Supervisor I Safety Officer prior to use. These includes but are not limited to below items:

• Pencil Grinder

• Carbide

• Total Station

7.0 METHODS I PROCEDURES

7.1 Preparation Work

7.1.1 Secure work permit from concerned personnel prior to start of work/activity.

7.1.2 Prepare all materials, tools and equipment needed for the job.

7.1.3 Provide visual inspection on bolts.

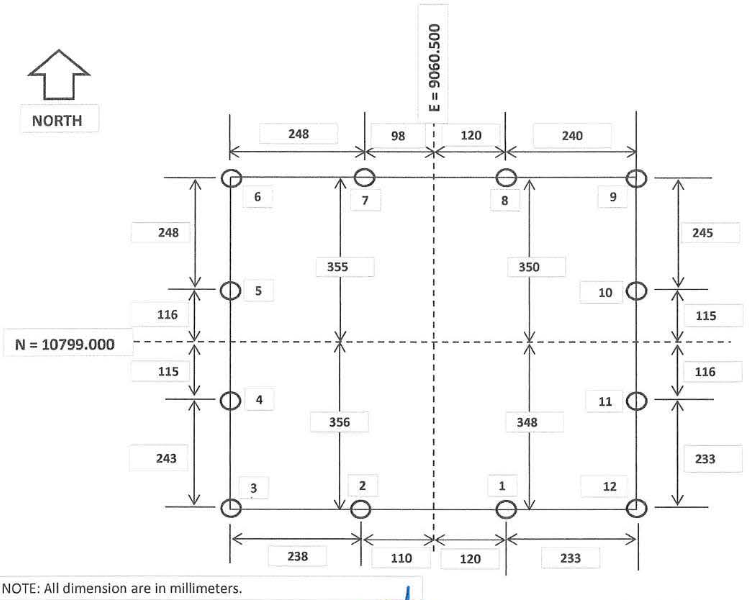

7.1.4 Provide survey report of anchor bolt top elevation and bottom elevation to determine the discrepancy.

7.2 Method/Procedure

7.2.1 Gather all the surveyed data as per actual condition of bolt.

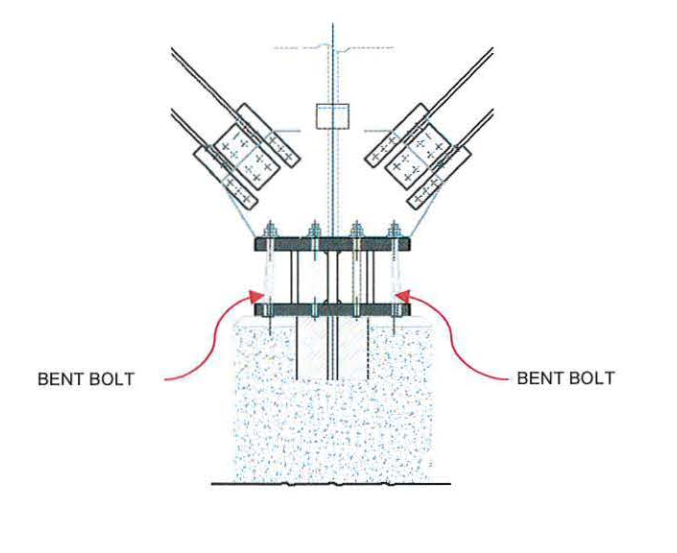

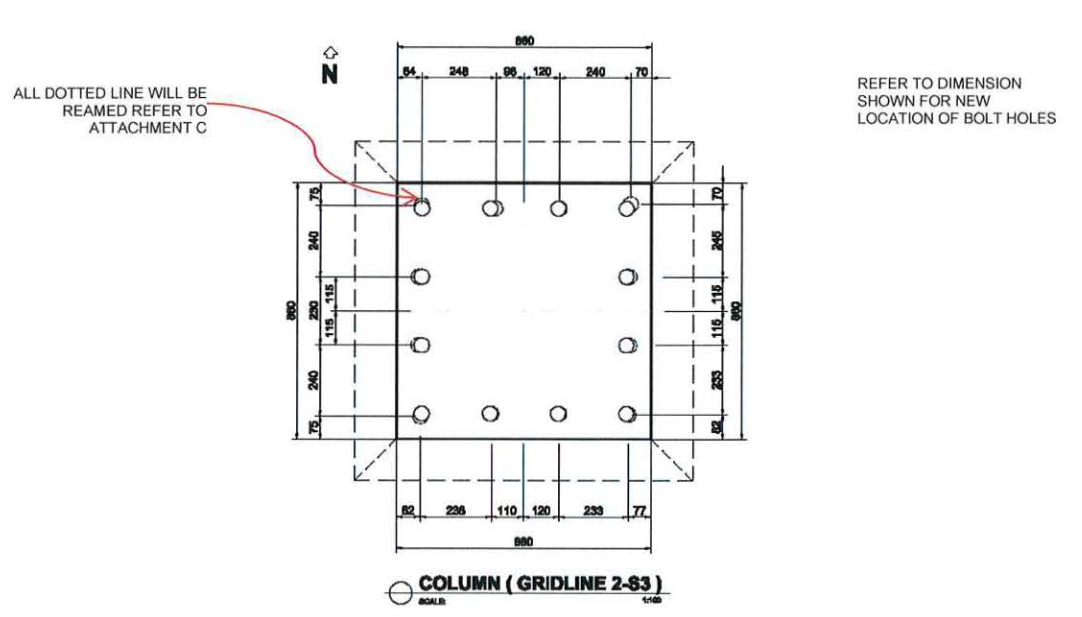

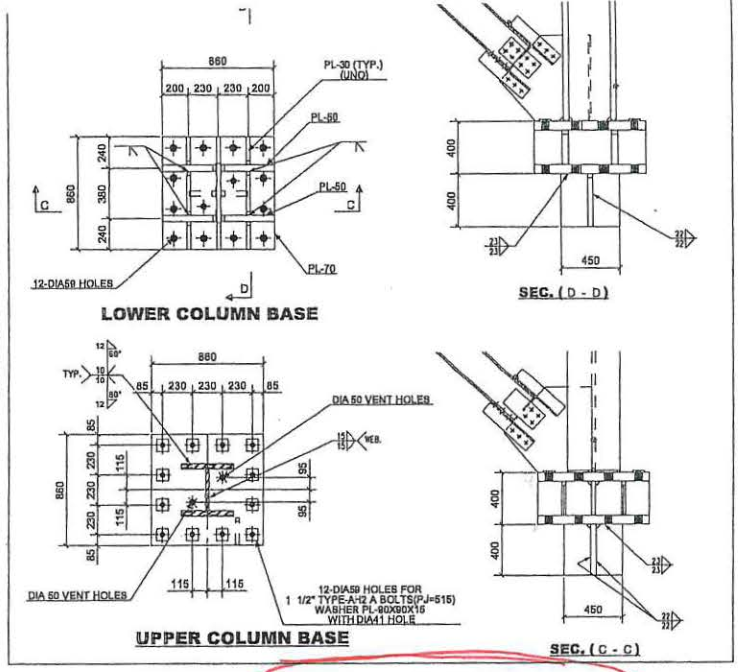

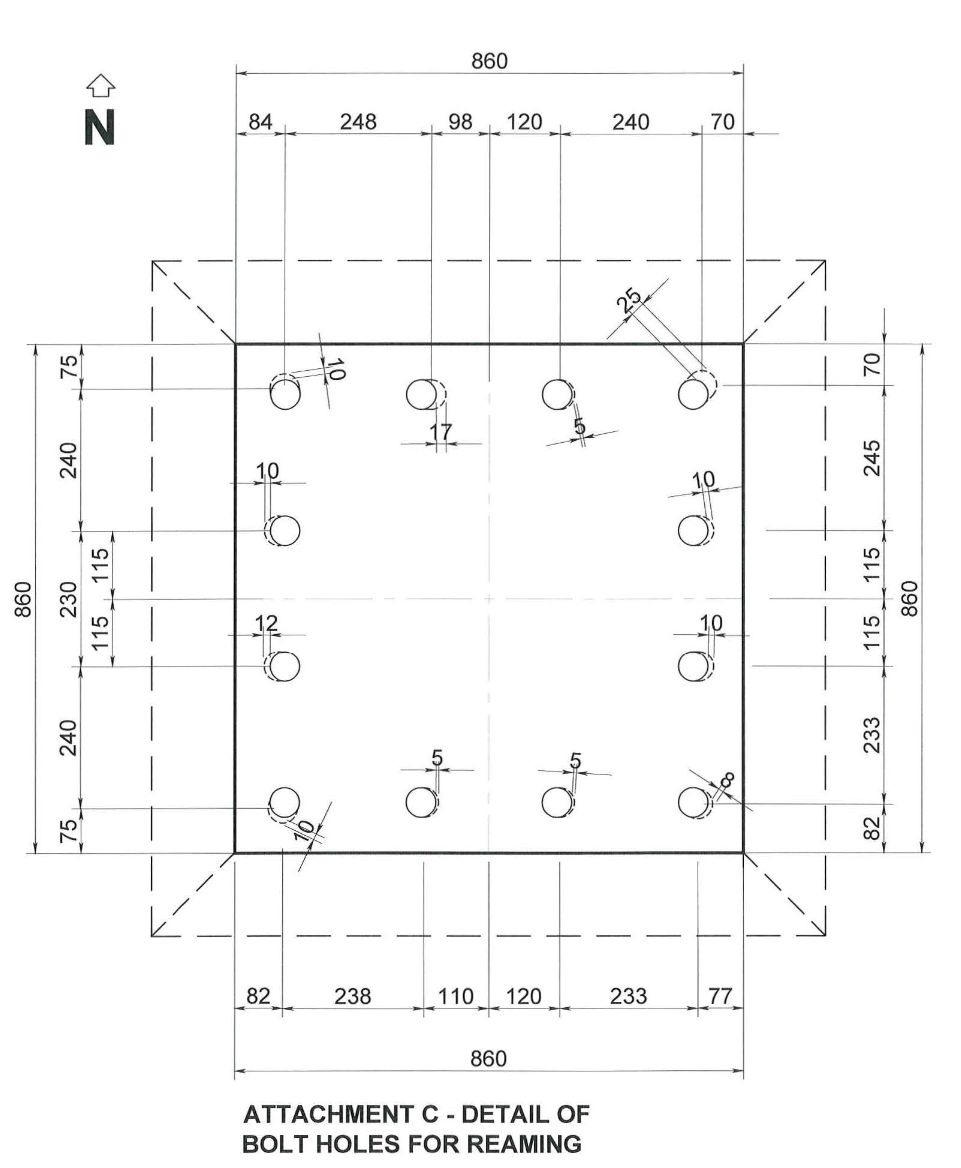

7.2.2 Reflect actual bolt condition on lower column base prior for reaming , see illustration below.

7.2.3 After reaming touch-up paint the damaged portion.

8.0 QUALITY CONTROL

8.1 QC Inspector will be present at site during the activity to ensure that the activity will be done as required.

8.2 QC Inspector wi ll produce all the documents attesting to the acceptability of the work and submit to JGC/DAEWOO.

8.3 QC Inspector has to uti lize the appli cable SATIP’s & SAIC’s for every activity.

9.0 SAFETY PRECAUTION

- Approved work permit should be obtained by concerned personnel prior to start any activities.

- Work execution shall be carried out in accordance with this method of statement.

- The necessary manpower inclusive of supervisory staff, tools, equipment, materials, and other resources required must be made available and ready to use.

- During the activity, close supervision shall be done by field supervisor.

- All workers shall wear as a minimum PPE required below.

- Safety Helmet

- Safety glasses

- Safety Shoes

- Gloves

- Sufficient lightings shall be provided if work is done at night time. Work at night shall be approved by client.

- Good housekeeping must be maintained throughout duration of works.

- Safety Supervisor/Engineer shall monitor compliance of entire working crew until the work is fully completed.

- Contractor shall endeavor to make sure that all workers shall be incident and injury free.

- The area shall be blocked by physical barricade or warning tape during activities to be done to ensure safety.

10.0 ATTACHMENTS

Job Haza rd and Risk Assessment (JHRA)

Survey Data Report

Detail of bolt holes for reaming

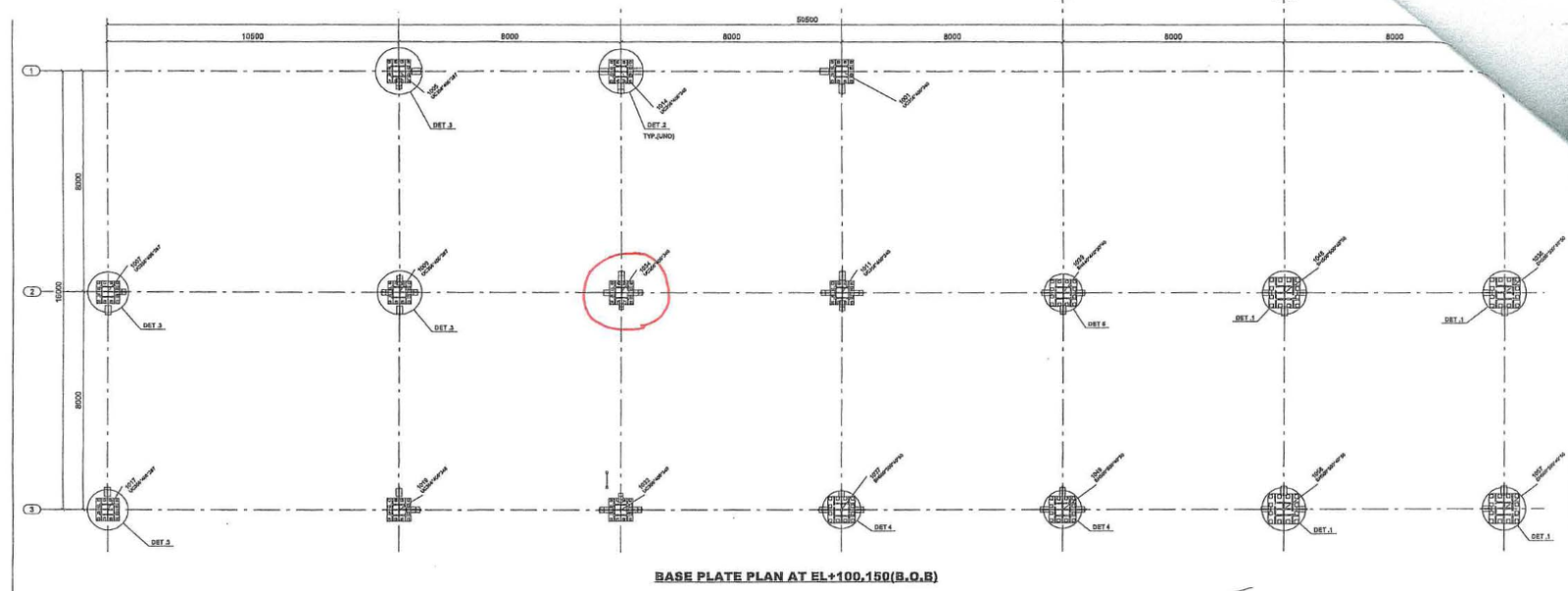

SURVEY DATA REPORT

Base Plate Plan

Details of Bolt Holes for Reaming