This article is about Non-Metallic Wireways and Accessories Materials Selection & Requirements of General Boxes and Enclosures for Electrical Power System Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Non-Metallic Wireways and Accessories Materials Selection & Requirements

Certification & 3rd Party Listing – General Purpose Boxes & Enclosures

- Boxes and Enclosure Certification:

In outdoor plant areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA 250/NEMA ICS 6 Type 4; or

(b) NEMA Type 3 manufactured copper free cast aluminum (0.4 of 1% maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP54 or better” - Box and Enclosure Certification:

In outdoor plant areas, outside the perimeter of process units, and other industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3 or 4; or

(b) IEC 60529 Type IP54 or better” - Box and Enclosure Certification:

In outdoor plant and other industrial areas located in severe corrosive environments, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 4X (except galvanized and/or painted or coated carbon steel sheet metal enclosures are not permitted); or

(b) NEMA Type 3 or 4, manufactured of copper free cast aluminum (0.4 of 1% copper maximum), or plastic (including fiberglass); or

(c) IEC 60529 Type IP 54 or better, manufactured of stainless steel (Type 304 or better), copper free cast aluminum, or plastic (including fiberglass).

Commentary Note:

In outdoor plant and other industrial areas located in severe corrosive environments, paragraph 7.3 supersedes paragraphs 7.1 and 7.2.” - Box and Enclosure Certification:

In outdoor non-industrial areas, boxes and enclosures shall be certified by the manufacturer as:

(a) NEMA Type 3R, 3 or 4; or

(b) IEC 60529 Type IP34 or better”

Certification & 3rd Party Listing & Labeling – General Boxes & Enclosures

- Suitability: Suitability of identified equipment shall be determined by one of the following:

(1) Equipment listing or labeling

(2) Evidence of equipment evaluation from a qualified testing laboratory or inspection agency concerned with product evaluation

(3) Evidence acceptable to the authority having jurisdiction such as a manufacturer’s self-evaluation or an owner’s engineering judgment.

[NFPA 70, NEC 500.8(A)] - Cathodic protection junction box enclosures shall be certified, labeled or listed by an approved and recognized testing organization to indicate full compliance with NEMA ICS 6 and NEMA 250 for NEMA Type 4, 4X, 7, 8 or 9 enclosures, as applicable.

- Marking:

All boxes shall be durably and legibly marked with the manufacturer’s name or trademark. [NFPA 70, NEC 314.44] - Marking:

Nonmetallic wireways shall be marked so that the manufacturer’s name or trademark and interior cross-sectional area in square inches shall be visible after installation. [NFPA 70, NEC 378.120]

Material Requirements

- New and Unused – General Boxes, Enclosures and accessories shall be new and unused.

- As Designed – General Boxes and Enclosures and accessories shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated design documents.

- Free of Damage -General Boxes and Enclosures and accessories shall be free of damage.

- QC Before Installation – General Boxes and Enclosures and accessories shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work.

- Traceability – General Boxes and Enclosures and accessories shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use.

- Severe corrosive environments includes:

a) Outdoor offshore locations

b) Outdoor onshore locations within one kilometer from the shoreline of the Arabian Gulf, all of the Ras Tanura Refinery and Terminal, and within three kilometers from the shoreline of the Red Sea

c) Location where chlorine or other corrosive chemicals are being handled (e.g., waste water treatment, water treatment, R.O. facilities)

d) Battery Rooms ”

Locations where chemicals are being handled, enclosures, conduit, fittings and wiring must be resistant to the chemicals present. - Types of Electrical enclosure rated not more than 1000 Volts:

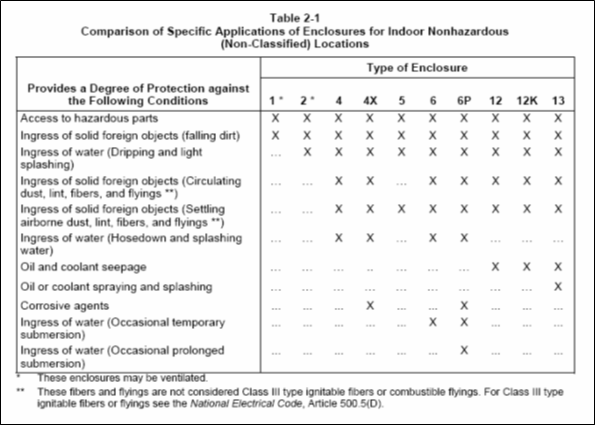

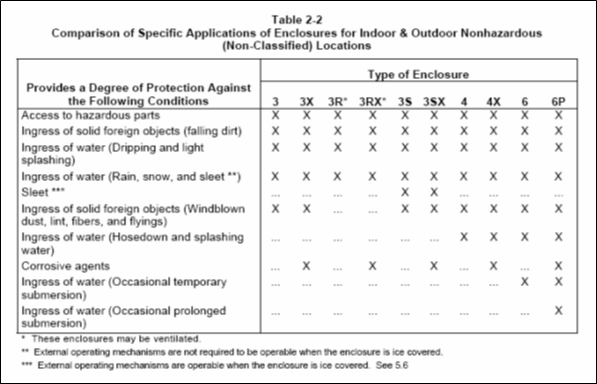

a. Non-hazardous locations

1. Enclosures for indoor locations, Types 1, 2, 5, 12, 12K, and 13; and

2. Enclosures for indoor or outdoor locations, Types 3, 3X, 3R, 3RX, 3S, 3SX, 4, 4X, 6, and 6P.

b. Hazardous locations

1. Enclosures for indoor locations, Types 7 and 9;

2. Enclosures for indoor or outdoor locations, Type 8; and

3. Enclosures for mining applications, Type 10

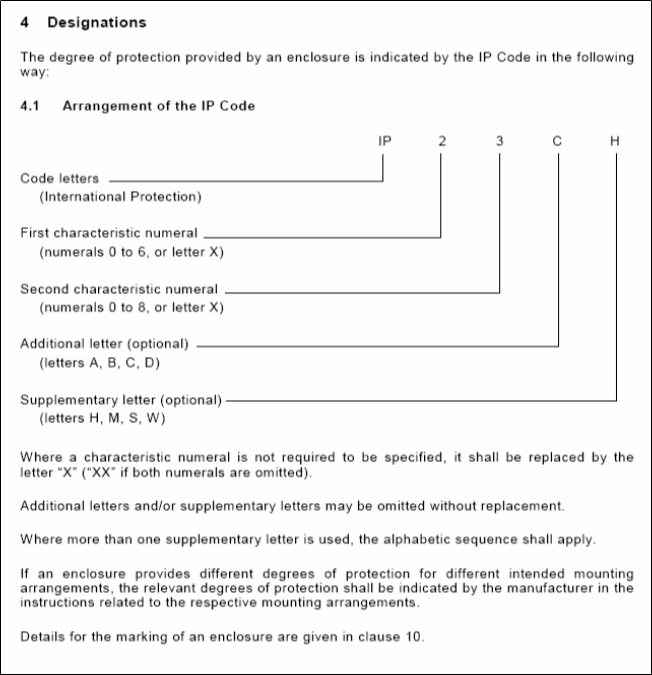

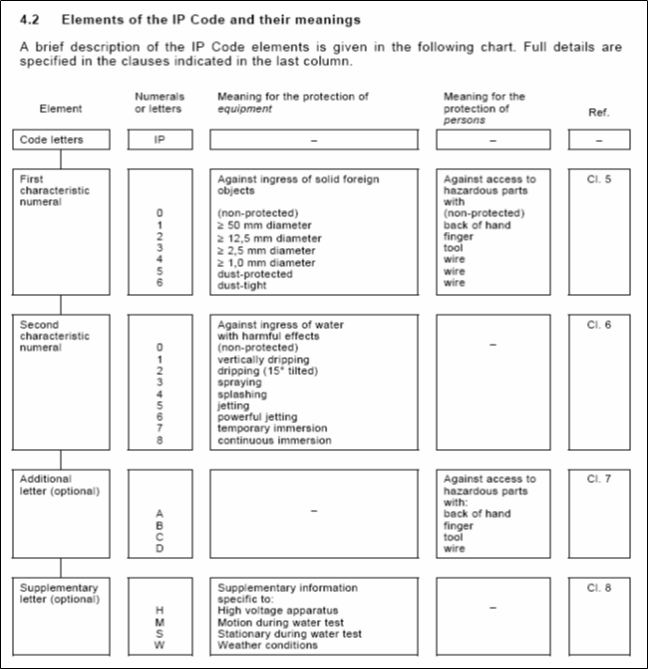

Table 2-1 and 2-2 (Attachment 1) are guides for comparing specific applications of enclosures. [NEMA 250 Sec. 1.1] - The IP Code & Designations:

A coding system to indicate the degrees of protection provided by an enclosure against access to hazardous parts, ingress of solid foreign objects, ingress of water and to give additional information in connection with such protection. Designations of the degree of protection provided by an enclosure is indicated by the IP Code arranged (See attachment 2 & 3) [IEC 60529 Sec. 3.4 and 4] - Drainage Openings:

Type 2, 3R, and 3RX enclosures shall have provisions for drainage. Drainage openings shall not be less than 3.2 mm in diameter (1/8 inch in diameter) or more than 6.4 mm in diameter (1/4 inch in diameter) unless baffled or provided with a drainage fitting.

For Type 2, 3R, and 3RX enclosures that also meet the requirements of other enclosure types, the drainage openings shall be closed by a removable plug. The enclosure shall meet the requirements of the other enclosure types with the plug installed. [NEMA 250 Sec. 3.6.3] - Gaskets: A gasket shall be secured with adhesive or by mechanical means. The gasket and its securing means shall not be damaged when the gasketed joint is opened. [NEMA 250 Sec. 3.14]

- An enclosure shall completely enclose all live parts that may be housed in it. [UL 50 Sec. 6.1.1 and NEMA 250 Sec. 1.2]

- An edge on an enclosure shall not be sufficiently sharp to constitute a risk of injury in normal maintenance or use. [UL 50 Sec. 6.1.4]

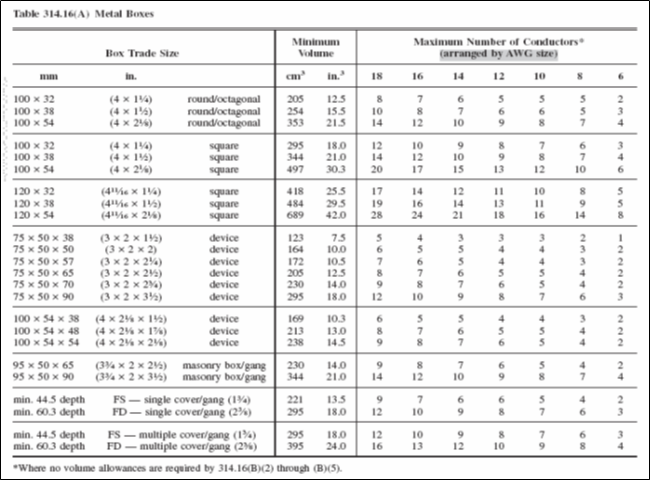

- Verify that all junction boxes, pull boxes, and conduit bodies are correct (size/ type) in according to NEC 314.16 and table 314.6(A) (Attachment 4). [NFPA 70, NEC 314.16]

Metallic Wireways and Accessories Materials Selection & Requirements

Non-Metallic Wireways

- Verify that all Nonmetallic Wireways are flame retardant, nonmetallic troughs with removable covers for housing and protecting electric wires and cables in which conductors are laid in place only after the wireway has been installed as a complete system. [NFPA 70, NEC 378.2]

- Nonmetallic wireways shall not be used in the following:

(1) Where subject to physical damage

(2) In any hazardous (classified) location, except as permitted by other articles in this Code

(3) Where exposed to sunlight unless listed and marked as suitable for the purpose

(4) Where subject to ambient temperatures other than those for which nonmetallic wireway is listed

(5) For conductors whose insulation temperature limitations would exceed those for which the nonmetallic wireway is listed [NFPA 70, NEC 378.12] - Size of Conductors:

No conductor larger than that for which the nonmetallic wireway is designed shall be installed in any nonmetallic wireway. [NFPA 70, NEC 378.21]” - Number of Conductors:

The sum of crosssectional areas of all contained conductors at any cross section of the nonmetallic wireway shall not exceed 20 percent

of the interior cross-sectional area of the nonmetallic wireway. [NFPA 70, NEC 378.22] - Insulated Conductors:

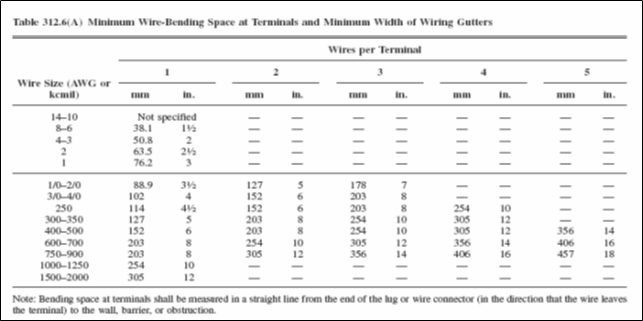

Where insulated conductors are deflected within a nonmetallic wireway dimensions corresponding to Table 312.6(A) (See Attachment 5) shall apply. [NFPA 70, NEC 376.23(A)]” - Horizontal Support:

Nonmetallic wireways shall be supported where run horizontally at intervals not to exceed 900 mm (3 ft), and at each end or joint, unless listed for other support intervals. In no case shall the distance between

supports exceed 3 m (10 ft). [NFPA 70, NEC 378.30(A)] - Vertical Support:

Vertical runs of nonmetallic wireway shall be securely supported at intervals not exceeding 1.2 m (4 ft), unless listed for other support intervals, and shall not have more than one joint between supports. Adjoining nonmetallic wireway sections shall be securely fastened

together to provide a rigid joint.

[NFPA 70, NEC 378.30(B)]” - Expansion Fittings:

Expansion fittings for nonmetallic wireway shall be provided to compensate for thermal expansion and contraction where the length change is expected to be 6 mm (0.25 in.) or greater in a straight run. [NFPA 70, NEC 378.44] - Splices and Taps:

Splices and taps shall be permitted within a nonmetallic wireway, provided they are accessible. The conductors, including splices and taps, shall not fill the nonmetallic wireway to more than 75 percent of its area at that point. [NFPA 70, NEC 378.56] - Dead Ends:

Dead ends of nonmetallic wireway shall be closed using listed fittings. [NFPA 70, NEC 378.58] - Grounding:

Where equipment grounding is required, a separate equipment grounding conductor shall be installed in the nonmetallic wireway. A separate equipment grounding conductor shall not be required where the grounded conductor is used to ground equipment as permitted in 250.142.

[NFPA 70, NEC 378.60] - Extensions from Nonmetallic Wireways:

Extensions from nonmetallic wireway shall be made with cord pendants or any wiring method of Chapter 3. [NFPA 70, NEC 378.70] - Extensions from Nonmetallic Wireways:

A separate equipment grounding conductor shall be installed in, or an

equipment grounding connection shall be made to, any of the wiring methods used for the extension. [NFPA 70, NEC 378.70] - Non-metallic wireway shall be installed as a complete system with removable cover. [NFPA 70, NEC 378.2]

- Metallic wireway shall comply with Purchase Order and Manufacturer’s Catalog description.

International Standard and Codes for Non-Metallic Wireways and Accessories

- METHOD STATEMENT FOR TESTING & COMMISSIONING OF SWITCHGEAR

- Advanced Power and Energy Meters Technical Requirements

3. NFPA 70 – National Electrical Code (NEC), 2008 Edition

4. SAES-P-104 – Wiring Methods and Materials, January 2008

5. SAES-P-100 – Basic Power System Design Criteria, June 2007

6. ANSI/IEC 60529 – American National Standard, Degrees of Protection Provided by Enclosures, 2004

7. NEMA ICS 6 – Industrial Control & Systems Enclosures -1993 (R 2006)

8. NEMA 250 – Enclosures for Electrical Equipment (1000 Volts Maximum), 2008

9. UL 50 – UL Standard for Safety for Enclosures for Electrical Equipment, Non-Environmental Considerations.

1. Attachment 1: Table 2-1 & Table 2-2 – Guides for Comparing Specific Applications of Enclosures – NEMA 250