1. SCOPE

2. PURPOSE

3. OBJECTIVE

4. DEFINITIONS

5. REFERENCE

6. RESPONSIBILITIES

7. MATERIALS

8. MATERIAL STORAGE

9. PROCEDURE

10. QUALITY CONTROL AND INSPECTION PLAN

RAISED ACCESS FLOOR SYSTEM INSTALLATION PROCEDURE | METHOD STATEMENT

1. SCOPE

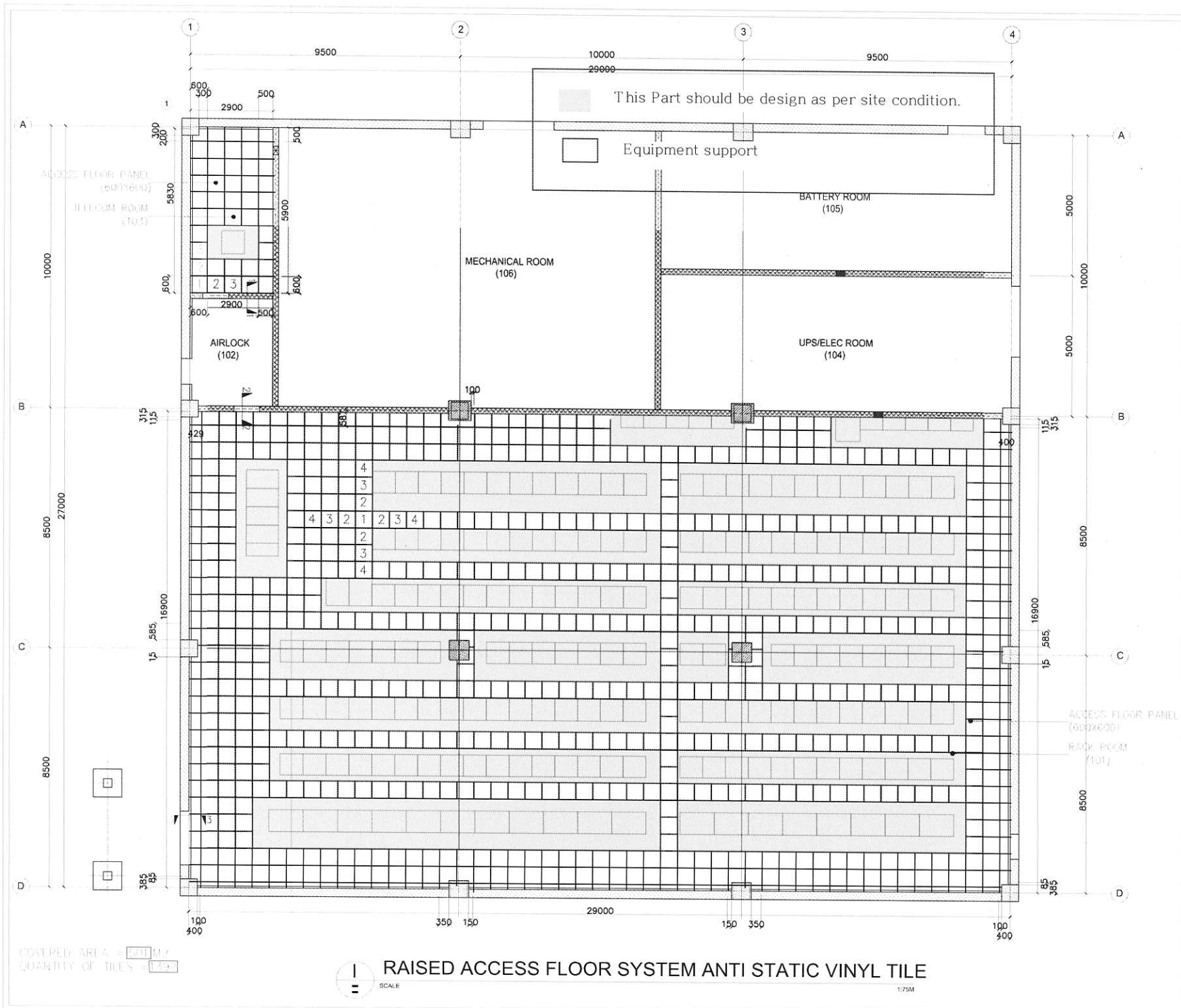

Raised Access Floor System for buildings for Rack Room, Air lock Room, and Telecom Room. Accordance with the requirements of CONTRACTOR/COMPANY drawings, specifications & standards.

2. PURPOSE

The purpose of this Method Statement is to describe in detail the appropriate requirement for Raised Access Floor System for buildings for Rack Room, Air lock Room, and Telecom Room.

3. OBJECTIVE

To ensure execution of Raised Access Floor System for PIB 010, PIB014 buildings for Rack Room, Air lock Room, and Telecom Room are meeting with all quality and safety requirements under the above Referenced project.

4. DEFINITIONS

Method Statement : A written document that gives specific instructions on how to perform a work related task safely or safe operation plan using tools and equipment.

5. REFERENCES

The latest revision of COMPANY’s Project Specifications shall be used as references and shall be the part of this Method of Statement during work execution.

a) SAUDI ARAMCO ENGINEERING STANDARDS (SAES)

SAES-M-100 Saudi Aramco Building Code

SAES-J-801 Control buildings

SAES-B-014 Safety Requirements for Plant& operation support buildings

b) MANUFACTURER’S CATALOGUE

c) SHOP DRAWING (submittal copy)

d) IFC DRAWINGS

e) SAUDI ARAMCO INSPECTION TEST PLAN OF CHECK LIST

a) SATIP-M-100-11 SATIP for Raised Equipment Floor System

b) SAIC-M-1075 SAIC for materials receiving & storage inspection

c) SAIC-M-1055 SAIC for raised equipment system installation & final installation

6.0 RESPONSIBILITIES

6.1 Site Manager

The Site Manager shall ensure compliance by all foremen, labors and other craftsmen to the requirements of this procedure. He shall observe and implement proper execution of the work and responsible for implementation of HSE on the site.

6.2 Site Engineer

The Site Building Engineer has the overall responsibility for the implementation of work as per Approved drawings. He shall arrange the manpower, equipment and materials required for the Implementation of the works, coordinate with HSE Officer and QA/QC Site Manager involved in the tasks in accordance to the method statement.

6.3 Safety Supervisor

The Safety Supervisor shall ensure that all workers are in compliance with the requirements of the safety manual. He is responsible for monitoring the work area for any unsafe conditions and make corrective actions where necessary.

6.4 Site Supervisor / Foreman

The Site Supervisor and/or Foreman are solely responsible in assuring that all materials installed permanently and works being implemented are in conformance with specifications and manufacture’s recommendation.

6.5 QC Manager

He will ensure all the material & method statement is approved prior to start of work. He will explain QC requirement for installation of raised floor to PM, site representative & QC supervisor/inspector by coordination with them. He will ensure that raised floor installers are trained and skilled & if required he will arrange training for them. He will ensure that all work is inspected and accepted as per Aramco requirement & SATIP. He will identify any potential nonconformance & suggest preventive action to eliminate occurrence of nonconformance.

6.6 QC Inspector

The QC Inspector is responsible to conduct daily surveillance and inspections as necessary in accordance with this procedure and project quality requirement. Prepare quality control records and documentation to secure completion of activity for final acceptance and handover.

7.0 MATERIALS

a) Raised Floor System / With Accessories

1) Hot dip galvanized adjustable pedestals height @600mm.

2) Fixing bolts.

3) Hot Dip galvanized stranger.

b) Access Raised Floor Tiles

Tile Size (600*600) mm Anti-Static Vinyl Tile & Composition Vinyl Tile.

– For Access Raised Floor System and Tiles, Refer To Approved MAR (AL-MAR-092, T-ALDW-0335)

– For Fixing Bolts, Refer To Approved MAR (AL-MAR-097, T-AL-DW-0343).

8.0 MATERIAL STORAGE

Materials shall be stored in original packing in accordance with manufacturer’s instructions

and recommendations and Saudi Aramco standards requirements.

9.0 RAISED ACCESS FLOOR SYSTEM INSTALLATION PROCEDURE

9.1 Pre-installation

9.1.1 The areas and conditions shall be examined under which raised flooring is to be installed.

9.1.2 Surface shall be smooth and level at the required finish elevation.

9.1.3 If required as per approved design drawings, requirements for dust proof epoxy coating as approved shall be applied. Refer To Approved MAR (AL-MAR-054, T-AL-DW-0210)

9.1.4 Gypsum Board System should be applied under raised floor system where it is required as per design drawings.

9.1.5 Door frame should be installed prior to start installation of raised floor system. But if due to site condition door frame installation is not possible prior to raised flooring, care should be taken for top surface level marking of raised flooring.

9.2 Under Structure Installation

9.2.1 As per approved shop drawing layout, all the pedestal locations shall be laid-out on the floor and marked. Refer to approved shop drawings (T-AL-DW-0333). If required additional “L” support for side of wall and panels should be installed as per approved IFC drawing.

9.2.2 Utilizing manufacturer/supplier’s recommended adhesive, entire pedestal base shall be firmly fixed on the floor and shall be left overnight for drying.

9.2.3 Once after the entire pedestal base adhesive has dried, all the accessories of understructure shall be installed leveled and squareness shall be checked & if required adjustment shall be made.

9.2.4 Where-ever openings are required, steel base structure shall be installed and anchored firmly to the concrete slab for future panel board installations.

9.3.1 All tiles shall be laid symmetrically about axis line, and toward outside edges, both directions. Tile shall be laid in straight line, in perfect alignment, without offsets in joints and as per manufacturer’s instructions & recommendations. All joints shall be tight, closed and evened.

9.3.2 All surfaces shall be in true, level plane, with no raise corners or edges. Marbleized pattern shall run in short direction of each room, unless noted otherwise.

9.3.3 Edges of all tiles shall be cut to fit accurately at walls vertical surfaces, offsets and at jointing of tile and other floor finishes. Holes for pipes shall be cut neatly so that floor plates or flanges cover same.

9.4 Post-Installation

9.4.1 Installed flooring shall be protected from damage by use of heavy Kraft paper or other covering.

9.4.2 After completion of the project and just prior to the final inspection of the work, floors and accessories shall be thoroughly cleaned.