Sensors can be categorized based on the amount of information they provide: binary sensors, analogue sensors, and image sensors.

Binary Sensors: These sensors offer only one bit of information, either 0 or 1. Despite their simple output, they are essential in mechatronics. Binary sensors are used as end stops, event detectors, and safety devices. They initiate, terminate, or interrupt processes based on their output. Their binary nature makes them resistant to electrical interference.

Analogue Sensors: These sensors acquire metric information related to quantities such as distance (position, velocity, and acceleration), force (pressure, gripping force, and bending), and other properties (thermal, optical, mechanical, electrical, or magnetic) of an object. A wide range of industrial sensors falls into this category, serving various purposes.

Image Sensors: Image sensors capture information about structures and shapes. They provide data related to one, two, or three-dimensional images, depending on the application. While their accuracy requirements are often less stringent compared to other sensors, the information content of their output is much larger. Consequently, data acquisition and processing for image sensors are more complex and time-consuming.

These categories provide a general overview of sensors and sensing systems. The subsequent chapters delve into specific types of sensors, discussing their physical principles, specifications, and typical applications. This overview highlights the differences in approach and underscores how these differences impact their usability in mechatronic systems.

Sensors Types based on Information

1. Binary Sensors

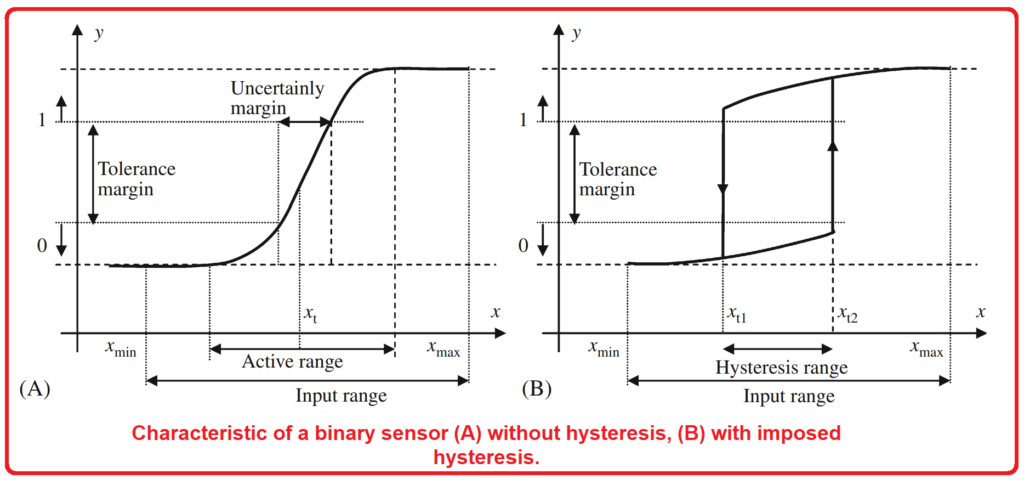

Binary sensors, also known as switches or detectors, have an analogue input and a two-state output (0 or 1). They convert an analogue input quantity into a one-bit output signal. Binary sensors utilize a fixed or adjustable threshold level, often with hysteresis to reduce noise-induced bouncing (Figure A, B).

Mechanical switches are commonly used as binary sensors to detect position or proximity. They respond when a moving object reaches a specific position. Two main types exist: mechanically controlled and magnetically controlled switches.

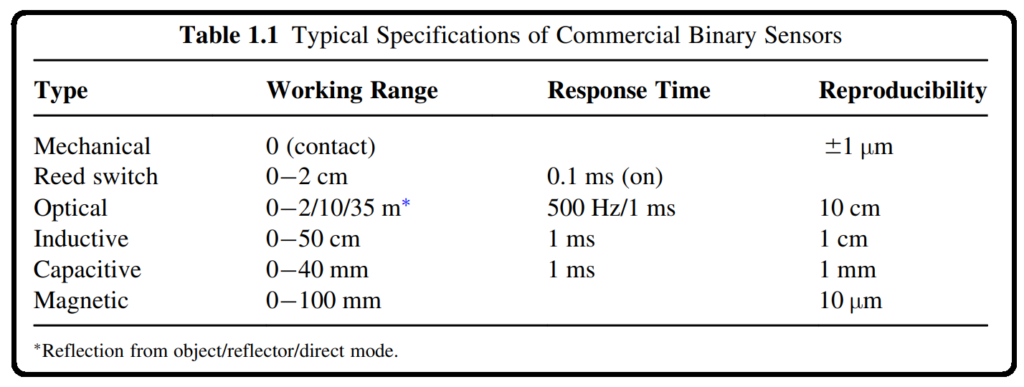

Mechanical Switches: These touch sensors come in various sizes and designs, including waterproof and explosion-proof variants. They have high precision (inaccuracy < 1 µm) and guaranteed hysteresis over temperature ranges. Mechanical switches are applied in systems where reliability (around 10^6 cycles) and precision are crucial, such as end-of-motion detectors, touch sensors, and safety devices.

Reed Switches: These magnetically controlled switches contain magnetizable tongues enclosed in a sealed capsule filled with gas. A permanent magnet triggers them. Reed switches have high reliability (over 10^7 cycles) and are used in various systems, from cars to electronic devices.

The limitations of mechanical switches include a relatively slow switch-on time and wear. This has led to the popularity of electronic switches like optically controlled semiconductors and Hall plates. Binary displacement sensors come in a range of distances and performance levels. Optical, inductive, and capacitive sensors, which offer adjustable threshold levels, operate contact-free.

In particular, optical sensors have a broad distance range, while the mechanical ones have a relatively short response time and wear over time. Table 1.1 provides an overview of specifications for various binary displacement sensors, including interface and read-out electronics, response time, and accuracy data.

2. Analogue Sensors

The market offers a wide array of analogue sensors that operate based on various physical principles and measure almost any physical quantity. In the field of mechatronics, key measurement parameters include linear and angular displacement, along with their derivatives (velocity and acceleration), as well as force (including torque and pressure). These and many other analogue sensors will be covered in greater depth in subsequent chapters.

3. Image Sensors

Imaging is a potent approach for extracting information about the intricate geometrical attributes of complex-shaped objects. By translating a 3D object or an entire scene into data points, it conveys specific characteristics like position, orientation, dimensions, shape, and identity. Yet, maintaining the integrity of essential information is challenging due to the inherent loss of data when translating a 3D world into 2D images.

Three Fundamental Strategies for Image Acquisition

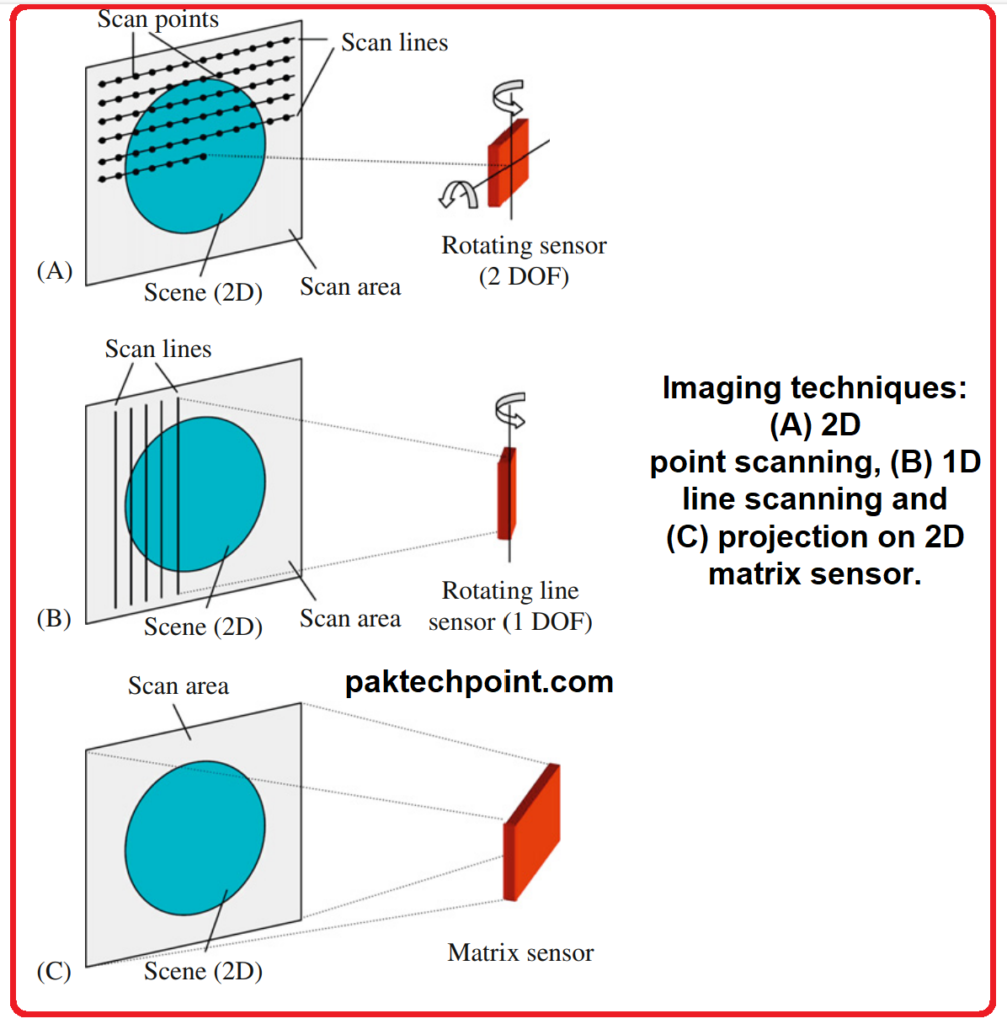

Figure 1.3 illustrates three fundamental strategies for image acquisition:

- The first method involves systematically scanning the scene point by point using mechanical mechanisms (e.g., a motorized mirror) or electronic means (like phased arrays). Referred to as a range finder, this approach provides distance information across an angular span determined by the scanning mechanism’s limitations. The outcome is a sequential data stream offering 3D insights into the scene, combining depth data from the scanning sensor with angular data from the mechanism. However, this method only captures information about the surface boundary range that’s directly visible to the sensor system, leading to data sometimes termed as 2.5D.

- In the second method (depicted in Figure B), the image acquisition process involves scanning the scene line by line using a mechanical scanning device. Each line obtained through this scanning is then projected onto an array of sensors, which could be a diode array within the optical domain. The sensor array might also incorporate electronic scanning to efficiently process the collected data. The mechanical scanning mechanism operates in a single direction, enhancing the speed of image formation and simplifying construction compared to point-wise scanning.

- The third method (shown in Figure C) revolves around projecting the unknown image onto a 2D matrix of individual point sensors. This matrix is electronically scanned for sequential processing of the data. As all scanning is carried out in the electronic realm, the acquisition time is notably short. The CCD matrix camera (Charge Coupled Device) stands out as the most widely recognized imaging device within this category. It boasts the highest spatial resolution among all matrix imagers, making it a prevalent choice for various applications.

Three primary information carriers—light, (ultra)sound, and contact force—are employed in both scanning and projection modes. While CCD cameras are often used to explore and analyze mechatronic system workspaces, the choice of imaging method depends on the specific application.

Image acquisition serves as the initial step; efficient data processing is crucial. For vision-based data, the challenge lies in filtering out irrelevant information and identifying objects based on their contours. Non-vision imaging tools often grapple with low resolution, requiring the extraction of meaningful data. In all cases, model-driven data processing is key to deriving accurate insights about object features or scenes.

Image Sensor Considerations

When it comes to capturing images, there are three primary contenders for information carriers: light, (ultra)sound, and contact force. All three can be utilized in both scanning and projection modes. Among these, the CCD camera stands out as a popular choice for imaging, especially for exploring and analyzing the workspace of mechatronic systems or a robot’s environment. However, it’s important to note that there are situations where the camera might not be the most suitable option.

Acquiring an image is just the initial step in obtaining the necessary information; data processing plays a crucial role as well. There’s a notable distinction between vision-based data processing and non-vision data processing. For CCD cameras, one of the main challenges is dealing with the excess data generated. Consequently, the first step in image processing involves filtering out irrelevant data from the image.

For example, sometimes a mere contour is enough for accurate object identification. However, many non-vision imagers suffer from relatively low resolution. In such cases, the main hurdle is extracting meaningful information from these low-resolution images. This challenge is compounded in scanning systems, where data must be integrated from various sensors. Regardless of the approach, model-driven data processing is essential to draw accurate conclusions about the features of objects or scenes being examined.