Following topics to be discussed here in this article for Soil Improvement for Foundations, Vibro-Compaction, Vibro-Flotation.

1. SCOPE

2. REFERENCES

3. GENERAL

3.1 Vibro-Compaction (Vibro-Flotation)

3.2 Stone Columns

4. SUBMITTALS

4.1 Work Procedures

4.2 Drawings

4.3 Personnel Qualifications

4.4 Data and Records

4.5 Daily Log

5. QUALITY CONTROL

6. MATERIALS

6.1 Stone Backfill for Stone Columns

6.2 Backfill for Vibro-Compaction (Vibro-Flotation)

6.3 Site Backfill

7. EXECUTION

7.1 General

7.2 Pilot and Full Scale Load Tests

7.3 Site Examination

7.4 Equipment and Procedures

7.5 Protection of Facilities / Utilities

8. ACCEPTANCE CRITERIA

Soil Improvement for Foundations | Vibro-Compaction | Vibro-Flotation and Stone Columns

1. Scope

This Article procedure is for soil improvements by vibro-compaction (vibro-flotation) or stone columns.

2. References

Reference is made in this article to the following documents.

American Society for Testing and Materials (ASTM)

C 33 Specification for Concrete Aggregates

D 422 Test Method for Particle Size Analysis of Soils

D 1194 Test Method for Bearing Capacity of Soil for Static Load and Spread Footings

D 3441 Test Method for Deep, Quasi-static, Cone and Friction-cone Penetration Tests of Soil

Occupational Safety and Health Administration (OSHA)

29CFR 1910, Occupational Safety and Health Standards

3. General

3.1 Vibro-Compaction (Vibro-Flotation)

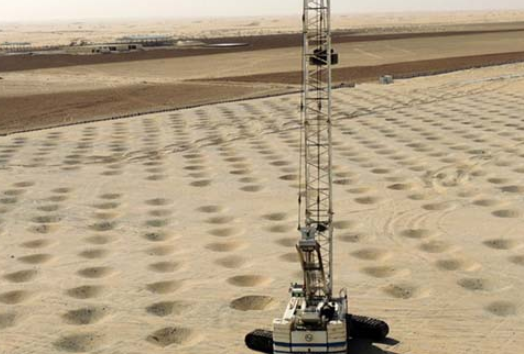

Vibro-compaction (vibro-flotation) is a vibro-densification method for compacting deep granular soils. This site improvement technique uses a specially developed depth vibrator (vibroflot) to direct compactive energy at the required depth. The soil can be penetrated to the required depth by the combined effect of the vibroflot weight, vibration, and sometimes jetting action by air or water, or both.

Improvement is achieved by rearranging the soil matrix to a tighter packing, resulting in an increase in the in-situ density and shear strength of the soil mass. The increase in soil density will result in the lowering of the overall site elevation. The degree to which the elevation will decrease is a function of depth and treatment, initial state

of the soil, and the specified degree of improvement (density). This decrease in elevation is compensated for by either introducing suitable fill material prior to the vibro-densification procedure to raise the initial site elevation above final grade, or by placing engineered fill to raise final grade after completion of treatment.

3.2 Stone Columns

Stone columns are columns of gravel (or crushed stone) constructed in the ground. The stone column technique, typically used in finer grained soils, creates a composite soil structure capable of supporting substantial loads. The level of improvement depends on the column type, column installation technique, relative spacing of the columns, and the column diameter. Stone columns can be constructed by the following methods.

3.2.1 Wet Method (Vibro-replacement). This method involves the use of the vibroflot vibrating weight (mentioned above) in conjunction with the jetting action of water to penetrate the soil to the required depth. Water and disturbed material is flushed from the hole. Coarse gravel or crushed stone is tipped in from the top of the hole in specified increments. The vibroflot is used to compact the gravel or stone. Radial forces produced by the vibrator, force the added material horizontally out against the in-situ soil. The filling/compacting cycle is repeated step by step to the surface resulting in a dense column of granular material interlocking with the surrounding ground.

3.2.2 Dry Bottom Feed Method (Vibro-displacement). With the dry bottom feed method, the stone is installed directly from the bottom of the vibroflot, which is fitted with specially designed stone transport systems. With this method, water is not used and there is no flushing of material. Instead, the existing soil is displaced by the stone.

3.2.3 Alternative Methods. Alternative methods for the construction of stone columns are available.

3.3 A copy of the project geotechnical (soil) report, if available, should be furnished by Company to the contractor for background information only.

3.4 A copy of the related project drawings should be furnished by Company to the contractor.

3.5 The contractor shall furnish all labor, materials, and equipment necessary to monitor and document the soil improvement operations.

4. Submittals

4.1 Work Procedures

4.1 The method of improvement shall be as specified in the contract documents.

4.1.1 The contractor shall submit a detailed written procedure to be followed for performing the soil improvements, and for confirming that the specified results have been achieved. The procedure shall include a detailed description of the specialized equipment to be used.

4.1.2 Contractor shall submit a written quality control program and inspection procedures document that provides details of how compliance with the requirements of the contract documents shall be achieved, with detailed procedures and instructions for the successful inspection, testing, and documentation of the work performed. This document shall also identify the personnel who will conduct the inspection, testing, and documentation during the soil improvement work.

4.1.3 All written procedures shall be submitted to Company for approval prior to the performance of the soil improvement work.

4.2 Drawings

The contractor shall furnish drawings to Company prior to the work indicating the spacing and depth of the proposed vibro points. The drawings shall show the locations of the injection points.

4.3 Personnel Qualifications

Contractor shall furnish resumes, or statements of qualifications and experience, of technical and professional personnel to be assigned to the project, including field personnel. The roles, responsibilities, and degree of involvement of each individual shall be described, as explained in 5.2.

4.4 Data and Records

Data that requires recording, according to the standard test methods specified in the contract documents, shall be obtained, recorded, and if requested, made available to Company. Samples, certifications, and test data of backfill material to be used for construction shall be submitted. Test data shall demonstrate that the backfill material conforms to the contract documents.

4.5 Daily Log

A daily log shall be submitted to Company by the contractor within one day of the work logged, and shall include the probe number, locations, start/finish time of probe, depth of treatment, approximate backfill quantities, and indication of relative amperage readings.

5. Quality Control

5.1 The contractor shall develop a quality control program including test and inspection procedures that will ensure and verify the work performed meets the requirements of the contract documents including inspection, testing, and documentation of the soil improvement work. QC program shall be submitted to Company for approval before the start of the work. Company shall have access to all facilities and records of the contractor for the purpose of conducting performance inspections/audits. During the audit, any inspection and test reports, and engineering analyses and calculations associated with the scope of the work, shall be furnished upon request.

5.2 Contractor performing the work shall have a minimum of five years’ experience of successful execution of vibro-compaction/stone column soil improvements under similar job and subsurface conditions. The key personnel, who shall have a minimum of five years of method specific experience and who shall have been employed by the contractor for a minimum of two years, shall be present at all times during the performance of the soil improvements.

5.3 Contractor shall review data from subsurface investigation(s) provided by Company. Such data shall not be construed to represent subsurface conditions at locations other than the specific boring/sounding location indicated. Contractor may, at contractor’s own discretion and expense, and with Company approval, perform additional investigations as contractor deems necessary. Data from these additional investigations shall be supplied to Company.

5.4 Contractor shall immediately notify Company in writing of any situations detrimental to the proper and timely completion of the work.

5.5 Company shall have the right to make inspections and tests at any time. The contractor shall cooperate with Company in the performance of this work. Work shall not be performed. The presence of Company shall in no way relieve the contractor of the obligation to perform the vibro-compaction and stone column soil improvements in accordance with the contract documents.

6. Materials

6.1 Stone Backfill for Stone Columns

6.1.1 Stone backfill used in the stone columns shall consist of hard, durable, clean, crushed rock, free of vegetation and other deleterious substances. The stone shall meet the requirements of ASTM C 33.

6.1.2 The gradation of the stone shall conform ASTM C 33 or as recommended by geotechnical engineer. The maximum aggregate size, which is dependent on the specific soil improvement process, shall be stated in the detailed written procedures submitted by the contractor to Company for approval.

6.1.3 In lieu of stone backfill, slag aggregate from Hadeed should be considered subject to geotechnical engineer and Company approval.

6.1.4 At least two weeks prior to commencement of the stone column installation, the contractor shall submit to Company a minimum of three 20 kg bags of crushed stone proposed for the backfill, and shall provide Company a written statement regarding the source and quantities of the stone material, and confirmation that the samples supplied are the same material that will be used for the work. The contractor shall provide Company with certifications that the stone materials meet the requirements of the contract documents. The certification shall include appropriate test data, and shall be prepared by a third party.

6.2 Backfill for Vibro-Compaction (Vibro-Flotation)

6.2.1 If required for the vibro-compaction (vibro-flotation) process, backfill shall consist of material well graded as sand or sand and gravel, with less than 10 percent by weight passing the 75 µ m (No. 200) sieve, and containing no clay. The backfill shall meet the requirements of ASTM D 422.

6.2.2 At least two weeks prior to commencement of the vibro-compaction, the contractor shall submit to Company a minimum of three 20 kg bags of material proposed for the backfill, and shall provide Company a written statement regarding the source and quantities of the material, and confirmation that the samples supplied are the same material that will be used for the work. The contractor shall provide Company with certifications that the materials meet the requirements of the contract documents. The certification shall include appropriate test data and shall be prepared by a third party.

6.3 Site Backfill

If the elevation of the site is to be raised above final grade prior to vibro-compaction (vibro-flotation) to compensate for the post-treatment decrease in elevation, the contractor shall provide and install suitable backfill in accordance with the contract documents or SES C02-S01.

7. Execution

7.1 General

7.1.1 Contractor shall comply with OSHA 29CFR, Part 1910 and any additional requirements from SASO SSA 337.

7.1.2 Contractor shall comply with all aspects of Company safety programs and policies.

7.1.3 Contractor shall comply with procedures referenced in the contract documents.

7.1.4 Contractor shall carry out pilot and full scale load test in accordance with 7.2.

7.2 Pilot and Full Scale Load Tests

Pilot and full scale load tests shall be in accordance with ASTM D 1194.

7.2.1 Pilot improvement test shall be carried out to demonstrate the effectiveness of the proposed probe spacing, pattern and other factors influencing soil densification, and to confirm that the required soil parameters could be achieved.

a. At least one pilot test shall be performed for each area as characterized by probe depth advised by the geotechnical engineer (soil investigation consultant).

b. The pilot load test shall be carried out over a minimum of four (4) square meters or minimum six (6) probes.

(i) This area shall be centered on a column.

(ii) The test load shall be equal to the maximum working load multiplied by factor of safety set by geotechnical engineer.

(iii) The column shall be at the center of a group of columns to avoid edge effects.

(iv) Load shall be applied to the ground through a rigid mat to give a uniform bearing pressure and reaction would be provided using concrete or steel blocks as required.

(v) The load shall be applied in at least five increments and each load held until settlement has substantially subsided. Unloading shall be in stages and residual settlement shall be measured.

c. Settlement measurements shall be made at each corner of the mat using remotely supported dial gauges, and also using an optical level.

7.2.2 Static cone penetration tests (CPTs) are recommended in the trial area before and after soil improvement. CPT shall be in accordance with ASTM D 3441. A minimum of one load test shall be performed for each test area and if poor results are obtained, additional tests as required by Company shall be carried out.

7.2.3 Based on results of the load tests and associated cone tests, an acceptance criteria shall be developed to enable cone tests to be used as a control method for soil improvement under proposed structures. Cone test shall be carried out before and after soil improvements, to assess the effectiveness of the work. A minimum of one test before and one test after shall be carried out for each 150 m2. The overall acceptance criteria for soil improvement method shall be either based on actual settlement recorded during load tests on improved soil, or on the decrease in settlement produced by carrying out soil improvement.

7.2.4 The pilot improvement test and final probe pattern and spacing, and overall acceptance criteria shall be submitted to Company for approval.

7.2.5 After the final probes pattern and spacing has been confirmed and approved by Company, work shall proceed accordingly.

7.2.6 Confirmatory test using CPT and full scale load test shall be carried out.

7.3 Site Examination

Prior to submitting a proposal for the soil improvements, the contractor shall examine the site to become familiar with all existing conditions, and to evaluate the conditions with respect to performance of the work.

7.4 Equipment and Procedures

7.4.1 The construction procedures, the specific equipment to be used, and the size and spacing of the stone columns or probe points, or both, shall be determined by the contractor to achieve the acceptance criteria specified in section 8. The procedures and related information shall be subject to Company approval.

7.4.2 The size of the down-hole vibrator and related equipment shall be the responsibility of the contractor. The equipment shall be adequate to achieve the required soil improvement, considering the in-situ soil conditions and groundwater levels.

7.5 Protection of Facilities / Utilities

7.5.1 Contractor shall place and maintain in good condition temporary fences, guardrails, barricades, lights, and other protective measures required for the safety of personnel and the premises, as stated in the contract documents.

7.5.2 All markers, for example reference points, property markers, and benchmarks shall be carefully maintained during execution of the work. Damage to a reference point by the contractor during performance of the work shall be repaired or replaced by the contractor to the satisfaction of Company. Benchmarks shall be located outside of the area of the soil improvements.

7.5.3 Unless otherwise specified, all known utilities within the project limits will be located and marked by Company, or noted in the contract documents prior to the soil improvement work. Other utility locations may become evident as earthwork progresses, which may necessitate work to stop until utilities are identified and specific direction is provided by Company.

7.5.4 During the work, all necessary precautions shall be taken to preserve utilities scheduled to remain. Temporary service lines will be installed by Company when this is impractical.

7.5.5 Existing power supply facilities and utility lines (either overhead or underground) which are designated on drawings provided by Company, visibly apparent, or marked in the field by Company, shall be kept free of damage by the contractor’s operations. If damaged, the utilities shall be restored and repaired at the contractor’s expense. In the event that any utility is damaged, the contractor shall immediately notify Company.

7.5.6 The contractor shall be responsible for establishing and maintaining a drainage system to control the excess water or the water table, or both, during the operations. The means for controlling water shall be included with the written work procedures submitted to Company.

7.5.7 Contractor shall be responsible for preserving and avoiding damage to trees, shrubs, and all other vegetation in the areas beyond the designated excavation area.

8. Acceptance Criteria

8.1 Soil improvement/densification shall be performed in accordance with the vibro-compaction/stone column location layout drawings developed by the contractor and approved by Company.

8.2 Prior to contract award, Company and the contractor shall agree in writing to the criteria for acceptance of the soil improvement work. The acceptance criteria shall be based on post-treatment evaluations of the work conducted. The details of the post-treatment evaluation methods shall be defined in writing prior to contract award. The post-improvement acceptance criteria shall be based on generally accepted standards including one or more of the following tests:

a. Cone penetration testing in accordance with ASTM D 3441.

b. Full scale load test in accordance with ASTM D 1194.

c. Other acceptance criteria defined and agreed to in writing prior to contract award.

8.3 Post-treatment testing shall be performed by contractor through an independent testing contractor approved by Company. The post-treatment test results shall be reviewed and approved by Company to verify compliance of the acceptance criteria.