SURFACE PREPARATION GUIDELINES FOR PAINT & COATING SYSTEM

Basic Information

No coating system will give optimum performance over a poorly prepared surface. Painting over rust, grease or contaminated surfaces can be wasteful in terms of time and material. All paint systems fail prematurely unless applied over a suitably prepared surface. The purpose of this section is to provide an informative guideline on how to achieve an effective preparation of substrate surface prior to coating application.

Poor Preparation Means Coating Failure:

In marine conditions, a paint system relies on a number of fundamental properties to give and maintain protection. These are:

– Compatibility with the surface to which it is applied.

– Resistance to water penetration.

– Resistance to attack by the elements and other agents in contact with it.

– Resistance to “wear and tear” in service.

What Effects Do Contaminants and Rust Have on those Properties?

Contamination and the products of corrosion, etc., can destroy or seriously impair adhesion. A paint system on an unsuitable surface will not have a secure foundation to resist abrasion or other mechanical stress to which it may be subjected.

Paint systems are not completely impermeable to water; salts in rust or on the steel surface may encourage blistering by osmosis. Contamination trapped between coats can cause adhesion failure and accelerate water penetration or penetration by other aggressive agents.

Corrosion products formed under the film have a larger volume than the steel from which they originated and can cause the film to rupture.

In all methods of preparation, the aim is to remove contamination and corrosion as far as practically possible to provide a sound and clean substrate for paint.

Surface Preparation Specification:

The performance of the coating is dependent upon the proper and thorough preparation and pretreatment of the basic metal. Some of the various methods of surface preparation are listed below, but it should be noted that these are described in a condensed form. For more explicit details, please refer to full specifications such as:

– Steel Structures Paint Council (SSPC), Pittsburgh, PA, USA

– Swedish Standard SIS 05 5900 – Pictorial Surface Preparation Standards for Painting Steel Surfaces

– Shipbuilding Research Association of Japan – Standard for the Preparation of Steel Surfaces prior to Painting

Blast Cleaning

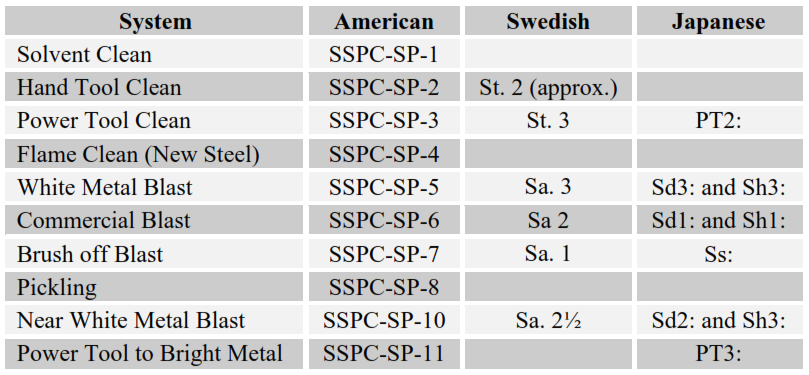

There are four commercial grades of blast cleaning. The recommended grade for a particular painting specification is determined by several inter-related factors, the most important being the coating system selected to protect the steel in the environment in which it is to be used. The

approximate equivalence of the American, Japanese and Swedish Standards are:

Surface Preparation Standards Comparison

How to Specify blast cleaning

Welds

Welds too often receive but scant attention before painting. Surface preparation is most important here. Welding fluxes are strongly alkaline and residues are found after welding on or near the weld area which act as very efficient paint removers. The surface of the weld is usually rough with a

range of high and low spots, and if painted in this condition, an inadequate coating of paint will result. Both welding flux and a rough finish can cause premature rusting and film failure. Correct treatment should include removal of all flux by water washing and grinding of welds and weld

spatter. The use of some shop primers will greatly reduce the problem with weld spatter. It is also good practice to apply an extra coat of paint on weld areas. A stripe coat is also recommended.

The standard of blasting should be to the approved visual standard and degree of roughness. The profile of roughness will depend upon the abrasives used, the air pressure and the techniques employed, such as open blasting, vacuum blasting or automatic methods.

Surface Profile

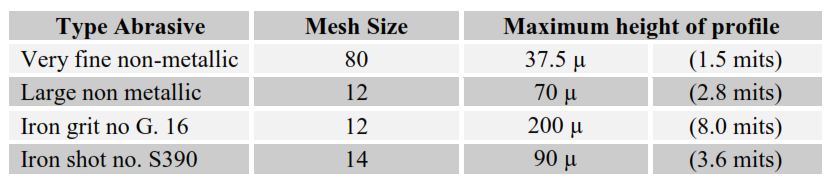

The term surface profile or surface anchor is used to describe the height of the metal that extends from the pit or valley to the peak of the metal after blast cleaning and is influenced by the type of abrasive used, as shown in the following table:

Shop Primed Steel

Because the use of a shop primer is common these days, it is important to have a standard for secondary surface preparation of shop primed surfaces, welds and damages prior to protective painting. The following standards are from the Japanese publication “JSRA – Standard for Preparation of Steel Surfaces Prior to Painting” (SPS 1984):

– Power tool cleaning standards – JSRA PT1, JSRA PT2, and JSRA PT3

– When using power tooling: at new construction, the JSRA Pt standards are more relevant whereas at maintenance and repair, the Swedish St standards are more relevant.

– Shop primers must be treated correctly before over coating to ensure optimum performance.

Non Ferrous Metals

Aluminum

Solvent cleaning, steam cleaning and recognized chemical pretreatments are acceptable methods of

surface preparation. Application of an etch primer is recommended before painting.

Galvanized Steel

Solvent cleaning to remove surface contaminants is necessary before painting new galvanized surfaces. A pre-treatment with an etch primer or a zinc dust based primer is also recommended. Galvanized steel which has been treated with a proprietary chromate or silicate product immediately

after galvanizing must be allowed to weather for several months before pre-treatment with an etch or zinc dust primer. An alternative method is to abrade the surface to remove the surface treatment.

Copper

Solvent cleaning and abrasion or very careful abrasive blasting using low pressure and nonmetallic abrasives are satisfactory methods of preparing the surface.

Other non ferrous metals

Solvent cleaning and an application of an etch primer is recommended before painting.

Technique for Surface Cleaning

Blasting

A corroded or “dirty” steel surface can be very rapidly and effectively cleaned by abrasive blasting. Using a medium (air is most common), abrasive particles (grit, sand, etc.) are propelled at high speed through a nozzle to impact on the surface, removing corrosion and contamination.

A grit size in the range 0.3 – 1.5 mm (12-60 mils) has proven to be the most cost effective in terms of production rates and in achieving specified standards especially when preparing pitted surfaces.

The rate of cleaning using mineral slags (grit) is usually greater than when using sand and reduces the health risk associated with silica.

Spot Blasting

This localized abrasive cleaning is often carried out where patchy corrosion has occurred. It will effectively remove corrosion and yield surfaces cleaned to standards described in the Swedish pictorial booklet. In practice there are some precautions which need to be taken in order to prevent

subsequent breakdown:

The surrounding paint film can be undercut by the abrasive particles and the edges around the blasted patch loosened from the steel surface. If this occurs, the loose edges must be removed by thorough scraping or feathering, using a rotary disc.

The surrounding paint will be peppered by stray abrasive particles and the protective value of the scheme in the vicinity may be destroyed. In making good the protective coating system, it is necessary to treat the area of damage around the blasted patch.

Damage can also occur in the areas between patches if the jet of abrasive particles is played across the surface. Blasting should be discontinued whilst moving from one patch to the next. Any damage which is sustained in this way should be made good as described above.

It is recommended that, whenever possible, the patches to be blasted should be defined by “chalking in” the boundaries.

Grit Blasting

When large areas of tanks are cleaned by grit blasting, a variety of steel surface conditions will be found. Previously coated or superficially corroded steel, can be readily cleaned to Sa2½. However cleaning heavily corroded or pitted surfaces is more difficult and Sa2½ may not be practically

achievable.

The effectiveness of various types and particle sizes of abrasives has been examined in carefully controlled practical trials and the most efficient grit particle size for corroded steel is found to be mineral slag with a range of 0.3 – 1.5 mm (12-60 mils).

After blasting, surface dust must be removed. In open conditions, blowing with dry compressed air from the blasting kettle is satisfactory. Tanks however require careful cleaning; normally using vacuum cleaners to remove all grit and dust particles.

Sweep Blasting

Sweep blasting is the treatment of a surface by the sweeping of a jet of abrasive across the surface. Its effectiveness depends on the nature and condition of the surface, the type and particle size of the abrasive and above all, the skill of the operator.

a) Light sweeping

Rapid sweep blasting will clean the surface of contamination or loose coatings. It may be used to etch the surface of an existing hard and tough coating to improve the adhesion of the following coat. Superficial corrosion such as that found on weathered shop primed steel also responds well to this type of treatment, but more deep seated corrosion is not removed. Where such removal is required, Sa 2½ by “full blasting” is most suitable when the paint

surface under treatment is not to be destroyed (grit or sand particle size -0.2 – 0.5 mm (8-20 mils).

b) Hard/heavy sweeping

The old coating is removed to shop primer or bare steel. The surface standard of steel exposed will vary but all standards, nevertheless, are satisfactory provided rust scale has been removed. Particle size considerations are the same as those described in the sections dealing with blasting/grit blasting.

High Pressure Freshwater Cleaning

The operation consists of directing a high-pressure freshwater jet at the surface. As with sweep blasting, the effect will depend on the nature and condition of the surface and also on the pressure of water. Distance of the nozzle from, and angle of the jet to the surface, will also have an effect.

Pressures as high as 5000 psi (350 kg./sq.cm.) are used when weak or poorly adhering coatings are to be removed. Even at these high pressures, firmly adhering paint will not be damaged.

Hydroblasting

For hydroblasting, abrasive is introduced into the freshwater stream. It can be used for the removal of tenacious and tough coatings and corrosion scale to give satisfactory results. There are various types of equipment on the market which vary in the method of mixing the abrasive and the water.

Normally this method is restricted to pressures up to 3000 psi (210 kg./sq.cm.). By careful selection of abrasive and adjustment of pressure, precise results can be obtained such as removal of loose topcoats without undue damage to the anticorrosive surface. If damage to the underlying coatings

does occur, the broken areas should be made good.

Flash rusting on exposed steel surfaces is normal after hydroblasting. The cleaned surface will oxidize rapidly whilst wet. Some proprietary inhibitors have been used by operators to prevent flash rusting, but at present these are not recommended. Particularly not on under water areas and must

be removed by freshwater hosing prior to coating application. It is recommended that loose deposits produced on the surface should be removed by rotary wire brushing. The remaining firmly bonded ginger coloration provides an acceptable surface for most exterior coatings.

Power Rotary Wire Brushing

The brushes used on this type of equipment consist of steel bristles which bend in contact with the surface. As a result, rust scale is often polished rather than broken away from the surface.

Rust scale is not easily removed and a method such as this fails to give a clean surface. However, it does have some value in the treatment of superficially rusted surfaces, such as the flash rusting present after water blasting and the superficial corrosion on the peaks of shop primed steel where breakdown is still at an early stage.

Rotary Power Discing

This method is effective in producing a surface suitable for the application of most types of coating. The silicone carbide pads will effectively abrade the rust scale from the surface of the steel substrate. To penetrate deep pits, conical carborundum heads must be used. When this method is employed for complete removal of corrosion in localized areas, it can be efficient, but the physical effort required is great, particularly when overhead surfaces are treated. Although theoretically this method can be used for large areas, the operator’s endurance limits its use and constant control is required because effectiveness is so closely allied to operator effort.

Manual Treatments

The term “slicing” refers to manual scraping using a sharp bladed implement. This together with wire brushing and chipping are the traditional, but ineffective methods of removing corrosion.

Scraping has been used for many years to remove the more obvious loose rust scale and loose paint coatings. However, if fails to remove the compacted scale and the salts which are contained within that scale. Chipping can remove scale in small areas but a considerable portion remains fixed to the surface and this layer is probably the most chemically reactive part of the scale. Hand wire brushing will remove loose, powdery, superficial corrosion but is inadequate for the removal of corrosion scale.

Mechanical Chisels

These instruments, usually air-driven, consist of either vibrating needles or chisel edges which pound the surface to break away corrosion scale. This method is more effective than hand cleaning, but a proportion of scale will still be left on the surface and cleaning is only effective at the point of contact.

Points of impact can show as bright points of steel particularly with the chisel edge device, but the areas between these points could still bear a layer of corrosion.

Common Surface Contaminants

Oil and Grease

The presence of even a very thin layer of oil or grease can destroy or seriously impair adhesion of paint. Solvents (e.g., paraffin or mineral spirit) can be used to dissolve the grease, but the problem then becomes one of completely removing the solution of oil in the solvent. Drying with cloths is

only effective if two or three treatments are carried out, each time drying with clean cloths. A single treatment is rarely satisfactory and can aggravate the situation by spreading the oil or grease over an area greater than originally affected.

Commercial chemical cleaners are available but before they are used it must be determined that they will not adversely attack the painted surface. It is usual to apply sufficient cleaner to incorporate the contaminant, leave for a few minutes and then hose down thoroughly with fresh water. It is imperative that all traces of the cleaner should be removed before painting.

Salts

Sea salts are fairly easily dissolved by fresh water. Surfaces should therefore be thoroughly hosed with fresh water.

The major difficulty however, is not the solubility of the salt but surface irregularities and porosity. Fine hair cracks in a paint surface can hold salt quite tenaciously.

For this reason, high pressure freshwater washing should always be used to flush out all the salt from the surface cracks and crevices. If high-pressure freshwater washing is not available then normal fresh hosing with thorough scrubbing should be employed. This is time consuming, but necessary, as to paint over salt residues will certainly lead to detachment or blistering of the fresh paint.

Abrasive Blasting

The subject of abrasive blasting and selection of the abrasives used in this operation is large and complex. Detailed information can be found in special publications such as those issued by SSPC and NACE.

It is an accepted fact that the performance and service life one can expect from high performance coatings is directly linked to the “surface standard” over which they are applied. The most critical areas are the immersed areas such as the underwater areas in tanks, double bottoms, etc. The right

type and size of abrasive must be used along with proper air pressure and blasting nozzle. It is up to the contractor carrying out the job to supply the necessary materials and equipment to achieve the specified standard.

Before blast cleaning takes place, deposits of oil, grease and salt must be removed. It is wrong to think that salt will be removed by the abrasive blasting operation. Clean dry compressed air, free of oil, must be used for blasting. Moisture separators, oil separators, traps or other equipment may be necessary to achieve this requirement. Abrasives used should have the following characteristics:

1. Low soluble salt content 0.05% maximum

2. Low oil content (if applicable) 10 mg/kg maximum

3. Hardness factor 6 – 7 MOHS range

4. Shatter index (low dust) 18-25 Range

5. Low silica content 1% free silica maximum

6. Qualities that offer minimum grit impingement

7. Correct grit size to obtain desired surface profile.

The surface profile produced by a certain grit is not only dependent on the size of the grit but also on factors such as air pressure at nozzle, distance of nozzle from surface, etc. The supplier of the abrasive should furnish all necessary details prior to the start of blasting. The following table, compiled from various sources, may be of some guidance:

Note: Mineral refers to sand or garnet

Hydroblasting

Hydroblasting is increasing in popularity due to several advantages it has over dry abrasive blasting. The term hydroblasting, hydrojetting and water jetting essentially describe the same process. However, there can be confusion over the difference of water washing and hydroblasting. To clarify

the difference, below are listed terms from SSPC/NACE standard.

Low pressure water washing:

Operates at pressures less than 1,000 psi (68 bar)

High pressure water washing:

Operates at pressures between 1,000 – 10,000 psi (68-680 bar) (3,000 psi is recommended for high pressure freshwater wash.)

High pressure hydroblasting:

Operates at pressures between 10,000 – 25,000 psi (680-1,700 bar)

Ultra high pressure hydroblasting:

Operates at pressures above 25,000 psi (1,700 bar) with most machines operating in the 30,000 – 36,000 psi range (2,000 – 2,500 bar)