CALIBRATION OF VALVES WITH ACTUATOR AND ACCESSORIES

Note:Valve calibration will be carried out at warehouse up to 2” (inch) without transportation and the 3” (inch) above are carried Site calibration.

· TSO Valves shall be calibrated after the seat leakage test. Hand wheel test as the part of calibration, manual operation of the hand wheel shall override the automatic operation.

Self-Actuating Valves (i.e., pressure regulator)

Visual checking shall be carried out to ensure that there is no damage on the body.

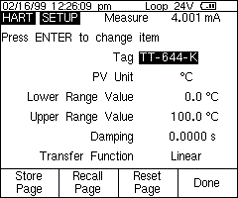

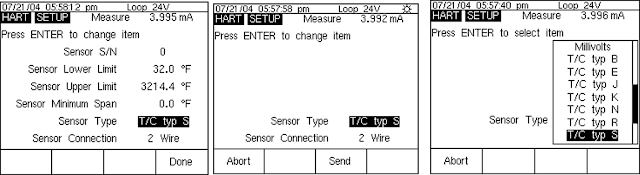

Tag no., range, & type shall conform to the data sheet.

If required, detailed calibration procedure for self-actuating valves shall adhere to manufacturer’s manual and shall be confirmed.

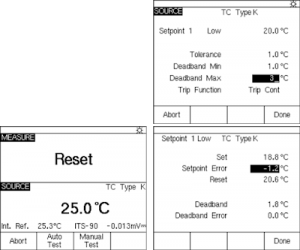

Final set point adjustment is required during start-up operation in order to make it suitable with process variables.

Note: No such confirmation (final set point) is required for pressure regulator with internal relief feature (i.e., air filter regulator for CV, I/P, etc.).

Diaphragm Actuator, Spring Adjustment (Bench Set)

The following items shall be checked:

· Size and type

· Stroke range

· Spring range

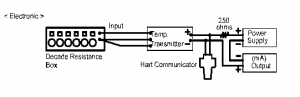

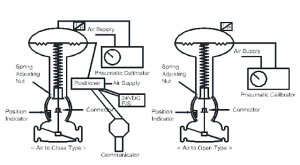

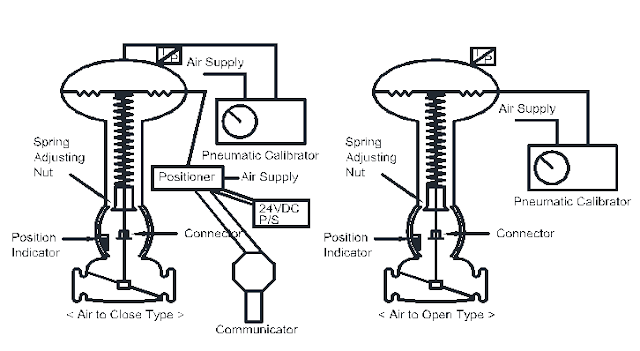

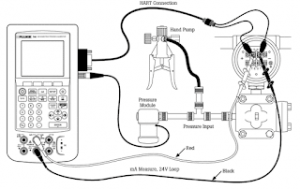

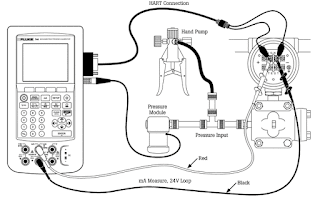

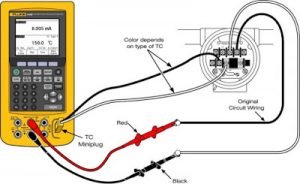

Hook up testing equipment as illustrated below:

Procedure for Valve calibration With Pneumatic Calibrator:

1. Adjust pneumatic signal so that the valve closes slowly, and stop when the valve fully closed.

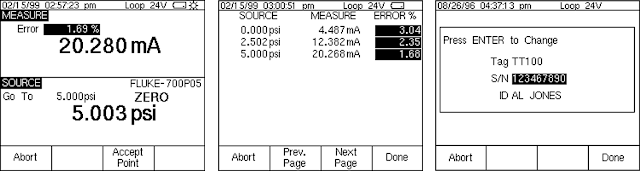

2. Dynamic error band, which is the difference between upscale and downscale plots at any given input signal, shall be less than 3.0% which valve travel. If the desired value cannot be obtained with spring

adjustment, change stem length by adjusting connector assembly.

3. Adjust pneumatic signal so that the valve opens slowly, and stop when the valve fully opened.

4. Read the pneumatic signal value and compare it with the actuator’s range. If the difference is greater than 3.0%, change spring and recheck closing and opening.

5. Adjust position indicator scale so that the indication works correctly.

6. Inject pneumatic signal 0%, 25%, 50%, 75% and 100% of its range and read valve position with signal rising and falling.

7. Check air failure action by disconnecting air supply.

8. Check power failure action by disconnecting power supply.

9. Speed of stroking time from full open to full close shall be checked, if required. Note down in form and compare with datasheet.

Other Type Actuator

The actuators other than diaphragm type shall be checked for the following items before the stroke check

(positioner calibration).

Piston Type Actuator

· Size and type

· Stoke range

· Leakage

Electrical Actuator

· Electrical insulation of motor and other electrical parts

· Limit switches and/or torque switches

· Positioner assembly

· Power requirement

· Local open/close/stop switch

· Hand wheel operation

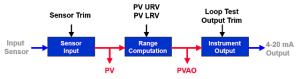

Positioner (Stroke check) Procedure Calibration:

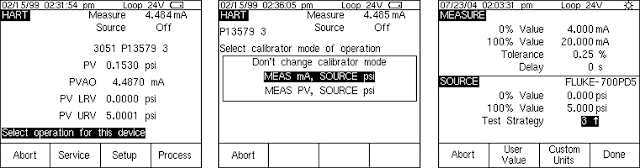

II. Determine signal range and characteristics curve through full stroke of valve. Before calibration curve shall be provided.Select proper travel character cam if provided.

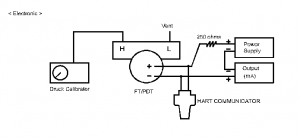

III. Connect Power Supply and and/or air supply to the positioner and actuator.

IV. Connect proper input signal source (4-20mA) to the positioner.

V. Adjust input signal so that the valve closes slowly, and stop when the valve is fully closed.

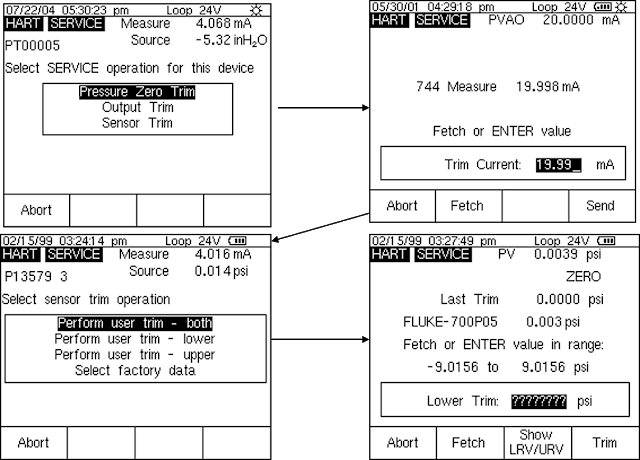

VI. Read the input signal and adjust zero adjustment when error is found. Repeat steps until the valve corresponds with closing signal within error limit.

VII. Adjust input signal so that the valve opens slowly, and stop when the valve fully opened.

VIII. Read the input signal and adjust zero adjustment when error found. Repeat step until the valve corresponds with closing and opening signal within error limit.

IX. Inject signal 0%, 25%, 50%, 75%, and 100% of its range and read valve position with signal rising and falling. Action of the positioner shall be checked (direct or reverse).

X. Analyse the stroke characteristic curve and figure out the reproducibility which includes dead band and hysteresis.

XI. If the character or the reproducibility is not acceptable, check feedback cam style and/or mechanical condition of all moving parts and correct existing deficiencies.

XII. Mechanical stops shall be checked as per data sheet.