1. GENERAL ……………………………..1.1

Summary

1.2

References

1.3

System Description …………….

1.4

Submittals

1.5 Quality Assurance

2. PRODUCTS …………………………..2.1 Materials

2.2

Fabrication and Manufacture

2.3

Inspection and Tests …………..

2.4

Identification and Tagging

2.5

Preparation for Shipment

3. EXECUTION ………………………….4. ATTACHMENTS

1.1 Summary

1.1.1 Scope of Specification

1.1.1.1 This specification is a supplement to the Item Description shown on the Bills of Material. If the Item

Description differs from or is in conflict with any requirement of this specification, the more stringent

requirement shall govern.

1.1.1.2 When the terms ‘Authorized’ or ‘Authorization’ are used in this specification, they mean authorized

or authorization by Piping Engineering.

1.1.2 Related Specifications. The following specifications prescribe items of related Work:

SES P14-T03 Specification for Piping, Traceability and Certification

Coordinate Work prescribed by this specification with Work prescribed by the above listed specifications.

1.1.3 Supplied by Supplier

1.1.3.1 Supply of Material

a. Supplier’s scope shall include the supply of material as specified in the PO (Purchase Order)

and written clarifications thereto, modifications necessary to meet the requirements of the Item

Description, and additional engineering notes in the PO, examination and testing, preparation of the

material for shipment, suitable packaging, and Manufacturer’s warranty.

b. All piping materials shall be clearly marked with Country of Origin in accordance with applicable

government regulations. In addition, all materials shall be produced by Manufacturers specifically

approved in writing by Contractor, whether on a Project Approved Manufacturers List or Submitted by

Bidders on their quotations. Any materials deviating from these requirements must have prior written

authorization, or they will be subject to rejection or additional verification or testing at the seller’s

expense.

1.1.3.2 Equivalent Manufacturers. Items specified or referenced by Manufacturer and figure number do

not exclude items offered by other manufacturers. Products made by reputable manufacturers and of

comparable type, quality, and characteristics may be submitted for engineering evaluation.

1.2 References

Reference is made in this specification to the following documents. The latest issues, amendments, and

supplements to these documents shall apply unless otherwise indicated.

ASME (American Society of Mechanical Engineers)

B1.1 Unified Inch Screw Threads

B16.1 Cast Iron Pipe Flanges and Flanged Fittings

B16.5 Pipe Flanges and Flanged Fittings

B16.20 Metallic Gaskets for Pipe Flanges – Ring-Joint, Spiral-Wound, and Jacketed

B16.21 Non-Metallic Flat Gaskets for Pipe Flanges

B16.34 Valves – Flanged, Threaded, and Welding End

B16.47 Large Diameter Steel Flanges

B18.2.1 Square and Hex Bolts and Screws

B18.2.2 Square and Hex Nuts

SA193 Alloy and Stainless Steel bolting Materials for High Temperature Service

SA194 Carbon, Alloy, and Stainless Steel Nuts

ASTM (American Society for Testing and Materials)

A193 Alloy and Stainless Steel Bolting Materials for High Temperature Service

A194 Carbon, Alloy and Stainless Steel Nuts

A307 Carbon Steel Threaded Fasteners

A320 Alloy Steel Bolting Materials for Low Temperature Service

MSS (Manufacturers Standardization Society of the Valves and Fittings Industry)

SP-25 Standard Marking System for Valves, Flanges, Fittings, and Unions

NACE (National Association of Corrosion Engineers)

MR-01-75 Sulfide Stress Cracking Resistant Metallic Material for Oil Field Equipment

1.2.5 Precedence of Requirements. Conflicts in technical requirements shall be resolved in the following

order of precedence:

a. Technical requirements specified in the RFQ or PO, as applicable, and identified as additional

technical requirements or engineering notes.

b. The Item Description as shown on the Bills of Material.

c. The requirements of this specification.

d. The requirements of referenced codes or standards (such as ASME B16.5).

1.3 System Description

1.3.1 Design Requirements

1.3.1.1 Bolts and Nuts. Dimensions and tolerances for bolts, heads, and nuts shall be in accordance with

ASME B18.2.1, ASME B18.2.2, and ASME B1.1 (Class 2A & 2B).

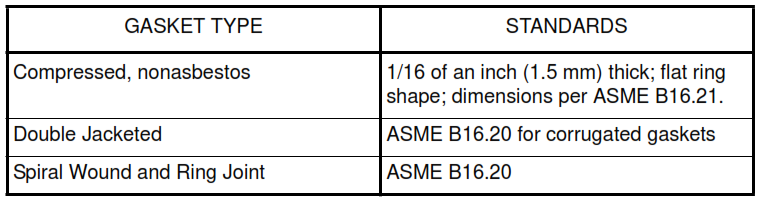

1.3.1.2 Gaskets. Gasket design and tolerances for flanged piping joints shall be in accordance with the

following standards:

1.4 Submittals

1.4.1 The supplier shall furnish manufacturer’s Certification of Compliance with the referenced ASME or

ASTM Specification. The documents shall be identified with Contractor’s PO number and Item Code

number and shall be signed by the manufacturer’s authorized agent.

1.4.2 ASTM materials may be substituted for materials specified as ASME, provided that the ASME

specification is indicated (below the title) to be identical with the corresponding ASTM specification for the

grade, class, or type produced. The manufacturer shall state the dual compliance on the Certification of

Compliance. ASTM specification material substitutions shall be submitted for authorization before

administration of the PO.

NOTE. All submittals shall accompany shipment of materials. Do not send to Contractor’s office.

1.5 Quality Assurance

1.5.1 General. Bolts, nuts, and gaskets used in ASME Code piping shall be in accordance with the criteria

in the applicable piping specification.

1.5.2 Bolt Torques. Gasket manufacturers shall recommend the bolt torque needed to ensure a sufficient

seal.

2. Products

2.1 Materials

2.1.1 Bolts and Nuts. Bolt and nut materials shall be as specified in the Item Description.

2.1.2 Gaskets

2.1.2.1 Gasket materials shall contain no asbestos.

2.1.2.2 Gasket material shall be as specified in the Item Description.

2.2 Fabrication and Manufacture

2.2.1 Bolt and Nuts

2.2.1.1 In accordance with ASME B16.5, the length of bolts shall be measured from the under surface of

the head to the extreme point of the bolt. Stud bolt lengths shall be measured between the extreme

effective threads, exclusive of end points. Length tolerances shall be as specified in ASME B16.5,

Annex F, Table F2, except that positive tolerances of the same values shall also apply.

2.2.1.2 Austenitic stainless steel bolts and nuts shall be furnished in the solution heat treated condition.

2.2.1.3 Strain hardening shall be furnished only when specified in the Item Description.

2.2.1.4 Threads shall be smooth and may be machined, ground, or rolled. Threading shall be in

accordance with ASME B1.1, Class 2A for bolts, and Class 2B for nuts. The coarse thread series for sizes

1 inch and smaller and the 8 pitch (8UN) thread series for sizes above 1 inch shall be used.

2.2.1.5 Studs and stud bolts shall be threaded full length and ends chamfered.

2.2.2 Gaskets

2.2.2.1 Compressed nonasbestos gaskets shall contain an anti-stick release agent or shall be graphited

on both sides and have a minimum tensile strength across the grain of 200 psi (1.38 MPa).

2.2.2.2 The metal windings of spiral wound gaskets shall be type 304 stainless steel unless other materials

are specified in the Item Description.

2.3 Inspection and Tests

2.3.1 Examination and tests may be reviewed and witnessed by Contractor or its authorized agent at

Seller’s and Manufacturer’s facility.

2.3.1.1 A general inspection of the facility for quality control procedures may be made by Contractor’s

Inspector.

2.3.1.2 A visual inspection of the quality and appearance of the product may be made as selected by

Contractor’s Inspector.

2.3.2 Bolts, nuts, or the materials thereof that indicate injurious defects, improper manufacture, or that are

not in accordance with the requirements of this specification shall be subject to rejection by Contractor’s

Inspector, even if such conditions are discovered after acceptance at the manufacturer’s works. Rejected

bolts and nuts shall be replaced by Seller at Seller’s expense.

2.4 Identification and Tagging

2.4.1 Bolting shall be marked to permit positive identification of material. Marking shall be in accordance

with the respective standards to which the items are manufactured unless otherwise specified in the Item

Description.

2.4.2 In addition to being marked with the address, shipping container shall be marked with Buyer’s

complete order number, contract number, and material, size, and quantity of all items therein.

2.4.3 For fluorocarbon polymer coated bolts, seller shall ensure that the stamped markings are visible and

can be verified. If not, the stamped end shall be left uncoated. Alloy verification for such stud bolts shall be

done on the marked end only.

2.5 Preparation for Shipment

2.5.1 The finished product shall be packed in suitable containers for adequate protection of the threads

during shipment.

2.5.2 Bolts and nuts shall be cleaned and greased or oiled before shipment, and nuts shall be shipped

assembled on the bolts.

2.5.3 Austenitic stainless steel bolting and gasket materials shall be protected from chloride attack such as

might occur from exposure to salt water spray, or atmosphere during shipment, cleaning, fabrication,

testing, and storage. Protection shall also be provided when shipping by truck in areas where road salt is

used. Consideration shall be given to enclosing or wrapping in a vaporproof barrier material.

2.5.4 The finished product shall be packed in suitable containers for adequate protection of the threads

during shipment.