The Corrosion Management Program (CMP) is a critical component in ensuring the reliability, safety, and cost-effectiveness of industrial facilities, particularly in the oil and gas sector. The following sections break down the key points and requirements outlined in the provided text:

Understanding Corrosion Management Program (CMP)

The primary purpose of the Corrosion Management Program (CMP) is to systematically manage and mitigate corrosion-related risks throughout the lifecycle of a project or facility. This includes design, construction, commissioning, operation, maintenance, and decommissioning. The CMP aims to reduce the impact of corrosion and materials failure on operational efficiency, safety, and environmental concerns.

Requirements and Elements of CMP

1. Proactive and Integrated Approach

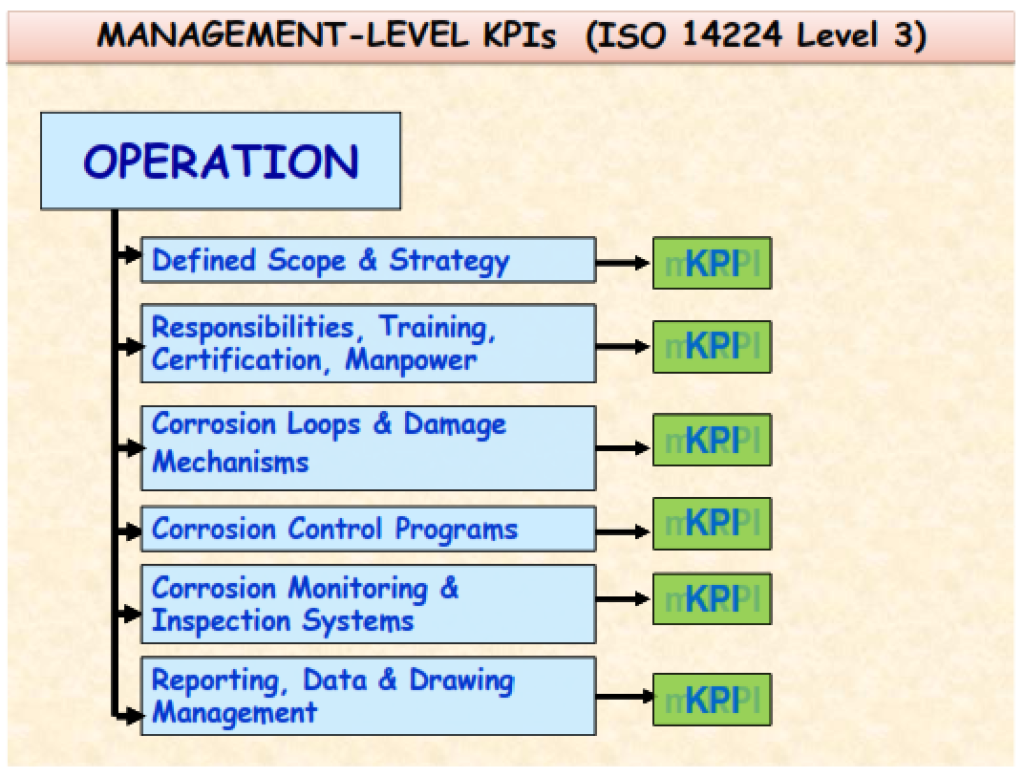

The CMP should follow a proactive, integrated, and structured approach to address various aspects of corrosion management, spanning from design to decommissioning. This approach involves defining roles, responsibilities, and competencies at all levels and establishing benchmarks and key performance indicators (KPIs) for monitoring and assessing corrosion-related issues.

2. Compliance with Standards and Best Practices

The CMP must adhere to relevant international standards, best practices, and metrics related to corrosion control, as referenced in the provided standard. This ensures that the program aligns with industry norms and requirements.

3. Risk-Based Evaluation

A risk-based evaluation is crucial for optimizing the design and planned inspection program. This involves assessing the potential risks associated with corrosion and materials failure and making informed decisions to address these risks effectively.

4. Documentation and Submission

The CMP should be well-documented and submitted for review and approval at various stages of the project. It should address corrosion challenges, materials selection, corrosion control strategies, and inspection programs. The CMP submission should be tailored to the specific stage of the project’s design process.

- The CMP must follow the structure outlined in the United Kingdom Health and Safety Executive requirements published by the Energy Institute.

- It should be documented in a Refinery Instruction Manual (RIM) or an equivalent document for other facilities.

- The program should define roles, responsibilities, and competencies at all levels.

- It should establish benchmarks and key performance indicators (KPIs).

- The CMP should use a risk-based evaluation to optimize design and planned inspection programs.

- International and Saudi Aramco standards, best practices, and metrics should be applied.

5. Design, Construction, and Operation Phases

The CMP must encompass all phases of the project lifecycle, including scoping, design, procurement, construction, commissioning, operation, inspection, major maintenance, and even decommissioning. It should also cover corrosion management for various systems, including structures, utility systems, and process systems.

6. Materials Selection and Approval

Materials selection is a critical aspect of corrosion management. The CMP should involve the development of Materials Selection Tables (MST) and Materials Selection Diagrams (MSD), which document key information related to materials, corrosion mechanisms, corrosion rates, and more. These materials selections must be approved and may require collaboration among various engineering and corrosion control teams.

- Materials Selection Tables (MST) and Materials Selection Diagrams (MSD) should be developed and approved at the Project Proposal stage.

- These tables and diagrams should include details about materials selection, design conditions, expected corrosion mechanisms, corrosion allowances, and more.

- Deviations from the approved materials and corrosion control techniques require specific approvals.

7. Inspection and Monitoring Programs

The CMP should detail the development of corrosion loops, on-stream inspection points, and Equipment Inspection Schedule (EIS) data sheets. These elements help define inspection and monitoring strategies, based on risk-based analysis and industry guidelines.

8. Operation and Maintenance

The CMP must address operational aspects, including monitoring Key Performance Indicators (KPIs) and handling exceptional items related to corrosion. It should also include procedures to prevent corrosion-related damage during startup, operation, and maintenance.

- Procedures for assessing damaged equipment, preserving equipment during downtime, and mothballing equipment should be part of the CMP.

- Preservation procedures for major equipment, including instructions for cleaning and preserving shafts and bearings, should be included.

9. Documentation and Reporting

The CMP should ensure that accurate and up-to-date documentation is maintained throughout the project’s lifecycle. This includes updating drawings, CAD models, and databases to reflect the as-built condition of the plant.

10. Integration of CMP Plans

If a project involves multiple separate budget items (BI), such as offshore pipelines, production facilities, and onshore processing plants, the CMP plans must be integrated to ensure seamless coordination and management of corrosion-related activities across these different components.

In summary, the Corrosion Management Program (CMP) is a comprehensive framework that guides the management of corrosion-related risks in industrial projects and facilities. It spans various phases of a project’s lifecycle and requires careful planning, documentation, compliance with standards, and collaboration among different teams and stakeholders to effectively mitigate the impact of corrosion and materials failure.