Very Low Frequency (VLF) testing is an important diagnostic method for assessing the condition of medium and high-voltage cables. Operating at frequencies between 0.1 and 0.01 Hz, VLF testing is particularly effective for detecting insulation defects and ensuring the reliability of cable systems.

What is VLF Testing?

VLF testing involves applying a sinusoidal voltage at very low frequencies to a cable system. Unlike traditional DC tests, VLF tests can reveal more comprehensive information about the insulation condition because they more closely simulate the stresses experienced by cables during normal AC operation.

Importance of VLF Testing

- Condition Assessment: Identifies insulation defects such as voids, water trees, and other aging-related issues.

- Preventive Maintenance: Helps in proactive maintenance by identifying potential failures before they occur, thus reducing the risk of unexpected outages.

- Regulatory Compliance: Many industry standards, such as IEEE 400.2, recommend VLF testing as part of routine maintenance for medium and high-voltage cables.

How VLF Testing Works

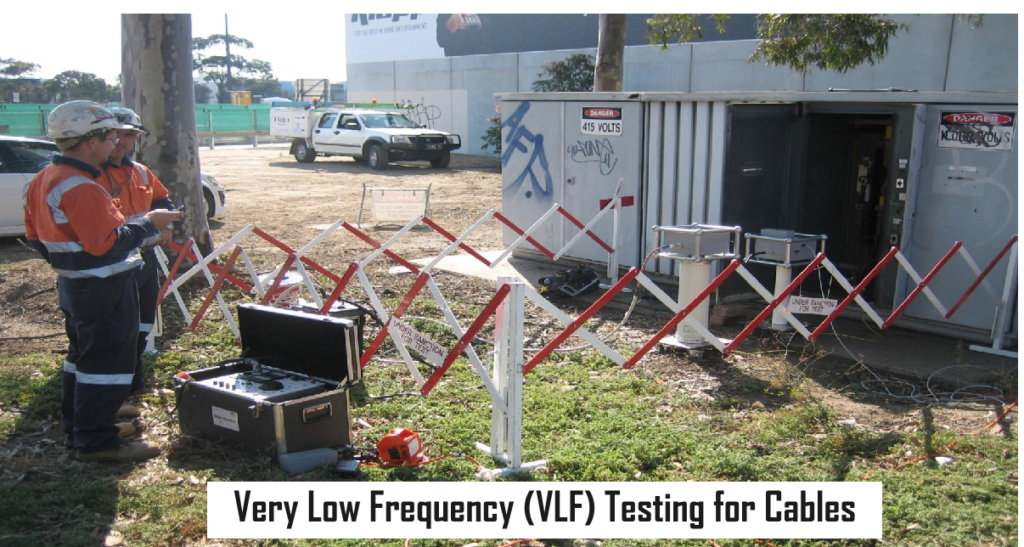

- Preparation: The cable is disconnected from the network and connected to the VLF test equipment.

- Voltage Application: A sinusoidal voltage is applied at a very low frequency, usually in the range of 0.1 Hz.

- Monitoring: The cable’s response to the applied voltage is monitored. Key parameters include leakage current, dissipation factor, and partial discharge activity.

- Analysis: The data collected is analyzed to determine the insulation condition. High leakage current, elevated dissipation factor, or significant partial discharge activity indicates potential insulation problems.

Advantages of VLF Testing:

- Service-like Stress: Mimics actual service conditions.

- Lightweight and Cost-Effective: Portable and affordable.

- Ease of Use: Simple to perform and interpret results (Go-No Go test).

- Compatibility: Sine wave output can be used with diagnostic equipment.

Disadvantages of VLF Testing:

- Waveform Limitations: Some designs (trapezoidal waveform) do not support Partial Discharge (PD) or Tan Delta diagnostics.

- Potential Destructiveness: The cable may fail during the test.

Applications

- New Installations: Ensures the quality and integrity of newly installed cables before they are put into service.

- Maintenance Testing: Periodic testing to monitor the condition of cables in service.

- After Repairs: Verifies the effectiveness of repairs and ensures the cable is safe to return to service.

VLF testing is a crucial tool in the maintenance and assessment of medium and high-voltage cables. By providing a reliable indication of insulation condition, it helps prevent unexpected failures and ensures the long-term reliability of cable systems. Regular VLF testing, as part of a comprehensive maintenance program, can significantly enhance the safety and performance of electrical infrastructure.

Why Use 0.1 Hz in VLF Testing?

Key Points:

Efficiency: Lower frequency reduces power needs.

Standardization: 0.1 Hz was established as the standard frequency.

Flexibility: Standards allow 0.1 Hz to 0.01 Hz, with 0.1 Hz and 0.05 Hz preferred for cables, and 0.1 Hz required for motor and generator coils.

VLF testing ensures thorough and cost-effective assessment of electrical insulation.

What Is The Math Behind VLF Testing?

Ohm’s Law: I=V/R – Current (I) is the voltage (V) divided by resistance (R).

Capacitive Reactance (Xc): In AC circuits, resistance (R) is replaced by capacitive reactance, calculated as: Xc = 1/2πfC.

Example Calculation:

Cable Specs: 15 kV, 5000 ft, 0.5 µF capacitance.

At 60 Hz: Xc=5300 ohms, requiring 4.2 amps at 22 kV, equating to 91 kVA (large and impractical).

At 0.1 Hz: Xc=3.2 megohms, drawing only 7 mA at 22 kV, equating to 0.154 kVA (much more practical).

By lowering the frequency to 0.1 Hz, the capacitive reactance increases, significantly reducing the current and power requirements for testing, making it more practical for field use.

What are Applications of VLF Testing?

AC Field Testing of Medium and High Voltage Cables:

Ensures installation quality and prevents in-service failures. Governed by IEEE 400.2-2013 standard.

Testing Rotating Machinery (Motors and Generators):

Used in rewind, repair shops, and field maintenance due to its practicality. Governed by IEEE 433-2012 standard.

Other High Capacitance Loads:

Includes large insulators, arrestors, and bus ducts, although no recognized standards exist for these applications yet.

How to Perform a VLF Test?

Connect Equipment:

Attach the high voltage output lead of the VLF tester to the conductor.

Connect a common ground to the cable shield.

Apply Test Voltage:

Set the VLF tester to the required voltage level. Apply the voltage for the specified duration.

Basic Withstand Test:

Monitor for any insulation breakdown or failure during the test period.

VLF testing is straightforward, involving isolation, connection, and application of test voltage to assess cable integrity.

What are Test Voltages and Duration for VLF Testing?

IEEE 400.2-2013: Specifies test voltages for medium and high voltage cables.

General Range: 1.7 to 3 times the normal line-to-ground voltage (1.7 Uo – 3 Uo).

Duration: 30 to 60 minutes.

European Standard: Mandates 3 Uo rms for 60 minutes for any cable.

Example Test Voltages:

15 kV Cable:

Maintenance Test: 22 kV peak.

Acceptance Test: 30 kV peak.

35 kV Cable:

Maintenance Test: 47 kV peak.

Acceptance Test: 62 kV peak.

These values ensure the integrity and safety of the cables under test conditions.

Is the VLF Test Destructive?

Non-Destructive Nature: VLF testing does not degrade good insulation or exacerbate minor defects.

Partial Discharge: Severe defects may be triggered into partial discharge (PD) under test voltage, causing them to fail during the test.

Controlled Failure: Identifying and repairing defects during testing prevents future in-service failures.

Appropriate Voltage: VLF uses AC voltage, matching the cable’s design and operating conditions. Cables are factory-tested at higher AC voltages than VLF test levels.

In essence, VLF testing helps ensure cable reliability by identifying and allowing for the repair of significant defects.

Could My Cable Fail During a VLF Test?

Purpose: VLF testing is an AC withstand test designed to apply over-voltage stress to identify weak points.

Outcome: The cable either withstands the test voltage or fails, revealing significant insulation defects.

Diagnostic Alternatives: If the possibility of failure is unacceptable, diagnostic tests that assess cable insulation without causing failures are available.

These tests help ensure that only reliable cables are used in service by exposing and allowing for the repair of any defects.

What are Alternatives to VLF Withstand Testing for Cables?

50/60 Hz Power Frequency AC Withstand Test: Not practical for field use due to the large, heavy, and expensive equipment required.

DC Testing: Outdated and unreliable as it can cause future cable failures and provides little information about cable quality.

Diagnostic Tests:Tan Delta Testing: Measures the integrity of cable insulation by assessing dielectric losses.

Partial Discharge Testing: Detects and locates insulation defects by identifying discharge activity within the cable.

These diagnostic tests are valuable for assessing cable insulation quality without the risk of causing immediate failures.

What is Tan Delta (Tan δ) Testing?

Benefits:

Effective Assessment: Identifies insulation condition and prioritizes replacement or repair needs.

Ease of Use: Requires minimal training and is straightforward to perform.

Common Practice: Widely used and easy to interpret.

Tan Delta testing provides valuable insights into cable health, making it a popular choice for insulation diagnostics.