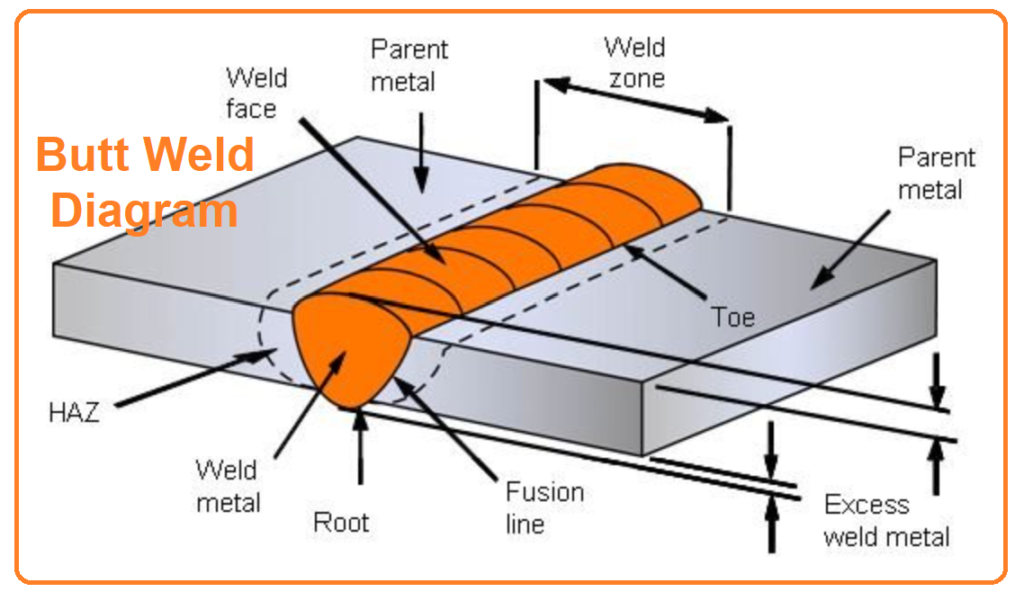

Butt welding is a straightforward yet highly effective welding technique where two pieces of material are aligned and joined along their edges without any overlap. This method is widely used across various industries for its simplicity and strength, making it a fundamental process in welding and fabrication. The key points to remember about butt welding include:

- End-to-End Joining: Butt welding involves aligning the two workpieces so that their ends meet precisely, creating a seam without any overlap.

- Same Plane: The surfaces of the workpieces being joined are on the same plane, ensuring that the weld metal remains within the planes of these surfaces.

- No Overlap: Unlike other types of weld joints, such as lap joints or plug welding, butt joints do not involve overlapping the materials. The workpieces are nearly parallel along the joint.

- Versatility: Butt welding is a versatile technique suitable for a wide range of materials, including metals and plastics.

- Strength: Properly executed butt welds result in strong and durable joints that can withstand various mechanical stresses.

- Common Use: Butt welding is commonly used in construction, manufacturing, pipeline fabrication, and many other industries for its simplicity and effectiveness.

Overall, butt welding is an essential skill in the world of welding and fabrication, allowing for the creation of strong and clean joints in various applications.

Butt Welding Joints

Butt welding is a versatile welding technique used to join two pieces of metal along their edges without overlapping. There are several types of butt welding methods, each suited to specific applications and materials. Here are some common types of butt welding:

- Single-V Butt Weld: In this type, a V-shaped groove is created on one side of each workpiece, and they are then joined along the V-groove. This is often used for thicker materials.

- Single-U Butt Weld: Similar to the single-V butt weld, but a U-shaped groove is created instead of a V-shape. It’s used for materials that are not as thick.

- Single-J Butt Weld: In this case, a J-shaped groove is used, which is often used for thinner materials.

- Double-V Butt Weld: Both workpieces have a V-groove, and they are joined together along these grooves. This provides greater strength and is used for thicker materials.

- Double-U Butt Weld: Similar to the double-V, but U-shaped grooves are used. This is suitable for thinner materials.

- Square Butt Weld: In this method, the edges of both workpieces are squared off and then joined together. It’s often used for sheet metal or thin plates.

- Bevel Butt Weld: Beveling involves cutting an angle on the edges of the workpieces before welding. It’s commonly used for pipes and pressure vessels.

- Compound Butt Weld: This type combines different groove shapes in a single weld joint. For example, it might have a V-groove on one side and a U-groove on the other.

- Backing Strip Butt Weld: A backing strip is often used with thin materials to support the weld joint and prevent burn-through.

- Consumable Insert Butt Weld: Here, a consumable metal insert is placed between the two workpieces, and this insert melts during welding, filling the gap between the workpieces.

- Flare V Butt Weld: In this method, a V-groove is used, but it’s flared outwards on one side, creating a wider weld joint. It’s used for thicker materials.

- V-Groove with Land Butt Weld: This type involves adding a small flat area, called a land, at the bottom of the V-groove to improve alignment and welding control.

The choice of butt welding method depends on factors such as the thickness of the materials, the type of material being welded, the required strength of the weld, and the specific welding process being used (e.g., TIG, MIG, or arc welding). Each method has its advantages and limitations, making it important to select the most suitable type for a given application.

Butt Weld vs Fillet Weld

Following is comparison table for Butt Weld vs Fillet Weld.

| Aspect | Butt Weld | Fillet Weld |

|---|---|---|

| Joint Type | Connects two pieces of metal along their edges. | Joins two pieces of metal at right angles or a tee joint. |

| Weld Strength | Generally stronger because it joins full thickness of the materials. | Weaker compared to butt welds but often adequate for many applications. |

| Welding Techniques | Requires precise edge preparation and alignment. | Tolerates more variation in joint fit-up. |

| Thickness Suitability | Suitable for thicker materials. | Commonly used for thinner materials, including sheet metal. |

| Material Types | Suitable for various materials, including alloys. | Versatile but may not be suitable for very thick materials. |

| Weld Appearance | Usually results in a flush, smooth joint. | Typically forms a triangular cross-section. |

| Fillet Size Control | Fillet size can be controlled to some extent. | Fillet size is primarily determined by the weld size and angle. |

| Inspection Ease | Easier to inspect for complete penetration and fusion. | May be more challenging to inspect for complete fusion. |

| Distortion Control | Prone to distortion due to shrinkage; controlled through pre-heating and successive passes. | Distortion can occur but may be less severe; controlled through successive passes. |

| Weld Preparation | Requires edge preparation and precise fit-up. | No preparation required as fillet welds are made on existing surfaces. |

| Cost | Can be costlier due to the need for precise preparation and fit-up. | Generally more cost-effective due to simpler preparation and tolerances. |

Practical Example of Butt Weld included Pictures

The preparation of V-butt weld specimens is designed for thinner plates, which are meant for testing using 4 mm thick plate specimens with dimensions of 600 mm in length and 1200 mm in width.

The steel was supplied by US Supplier.

Table 1 provides an overview of the mechanical properties of the steel, while Table 2 presents the chemical composition of the material.

Preparing the specimens according to the design outlined in the document involves working with thinner plates with a thickness of 4 mm.

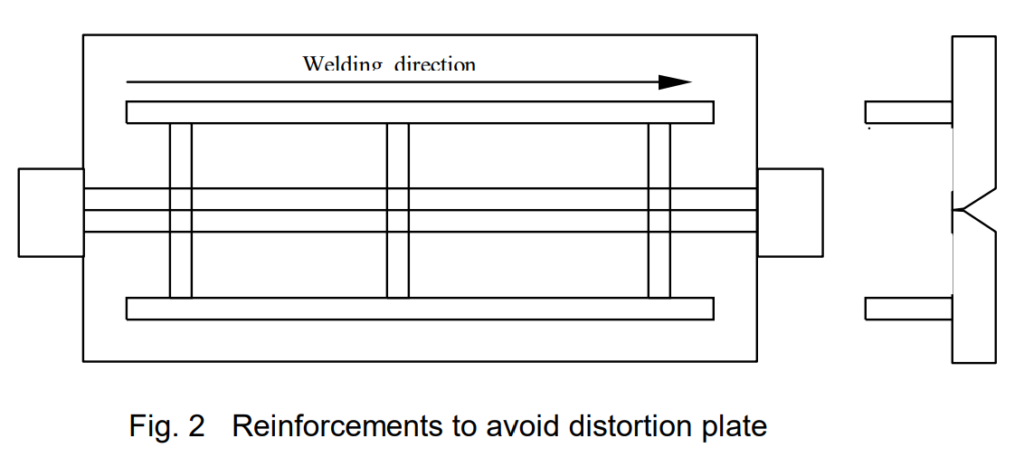

The plates used for creating the specimens were cut using a steel cutting machine, and grooves were meticulously prepared by grinding, employing an automatic machine. To prevent any distortion of the plates during the welding process, temporary reinforcements were strategically placed, as illustrated in Figure 2 below.

Following the welding process, the temporary reinforcements were eliminated, and the surfaces underwent a grinding procedure to ensure their smoothness. Subsequently, a Magnetic Particle Inspection (MPI) was conducted to detect any potential small cracks. Fortunately, no unacceptable indications or flaws were detected during this inspection.

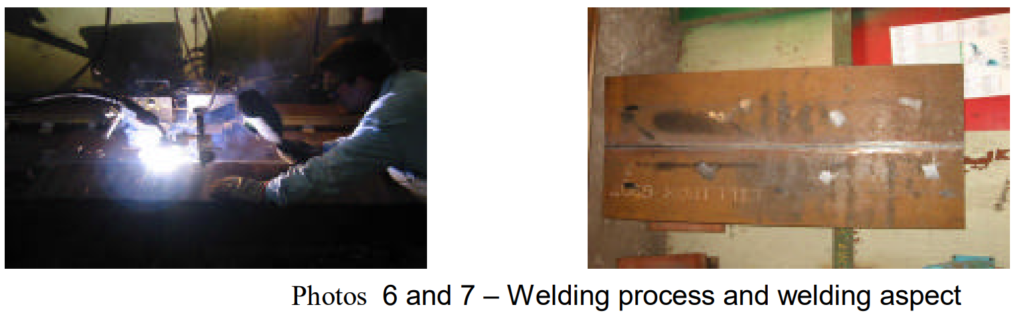

The welding process was automated and executed by a machine, as depicted in photos 3 and 4. The welding technique employed was the MAG process, which involves the use of a constant current and flux-cored wire for welding the specimens. A rutile wire with a diameter of 1.2 mm was consistently utilized for all the specimens.

For tack welding, the identical welding process and wire were employed. Welding was performed in the flat position (PA) for all the specimens. To mitigate the occurrence of start and stop defects, run-on and run-off plates were incorporated for all specimens, as illustrated in photos 5 and 6.

Filler Metals: Chemical composition and mechanical properties

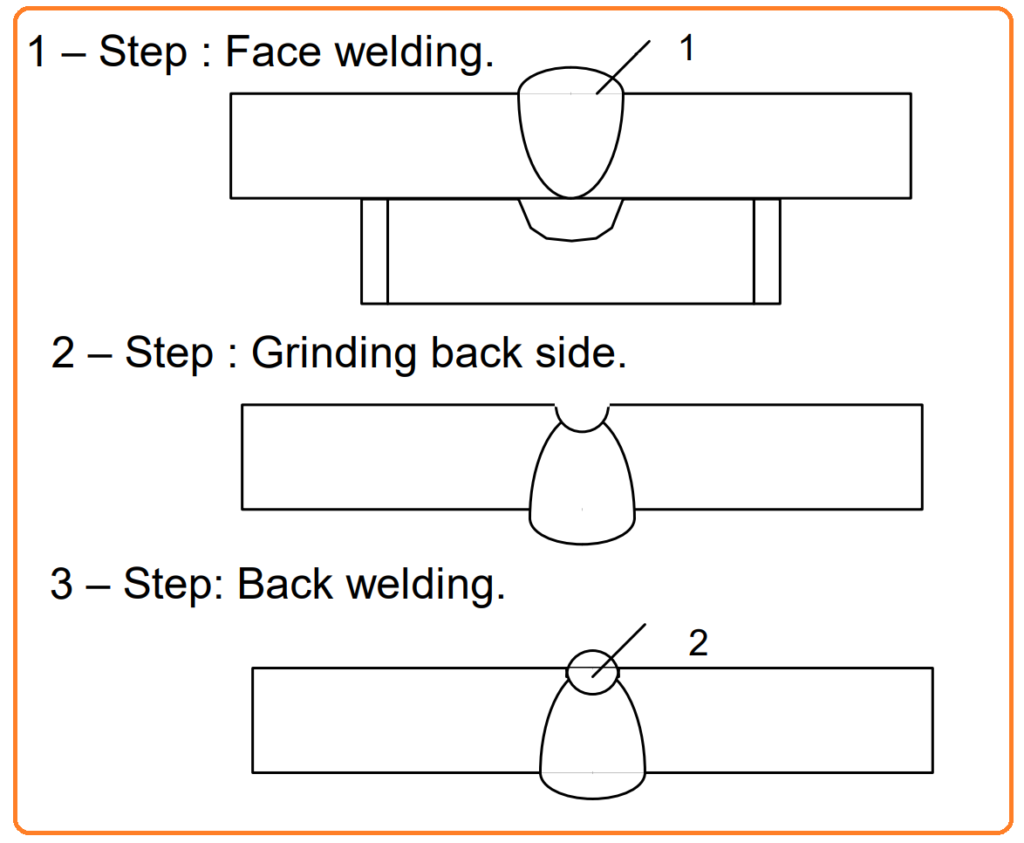

Welding sequence

Butt Weld Uses:

Butt welding is a widely-used technique in the welding industry, applicable to steel, and even copper pieces when brazing is used. Its primary purpose is to join two pieces of metal, like pipes, framework in factories, and flanges. Flanges are components that strengthen a material, either internally or externally. In manufacturing, butt welding has demonstrated its cost-effectiveness, especially when constructing structures from metal.

The process of butt welding can involve heating the two metal pieces, applying pressure, or both. Ensuring proper penetration during welding is essential. While it’s relatively straightforward with thin metals, thicker pieces might require edge preparation to prepare the metal for welding. The strongest butt welds have minimal imperfections, and this is achieved by controlling the heat input, which, in turn, reduces the size of the weld. In commercial welding, this not only saves costs but also maintains the weld’s strength, often through double butt welds.

In butt welding, there are two primary types used to achieve specific welds, along with various joint configurations considered as butt joints.

MIG and TIG welding applications are commonly used in butt welding due to their excellent ability to connect two metal pieces. The type of welding electrodes used affects the weld’s properties, including its corrosion resistance and strength. Electrodes serve as conductors of current through the metal being welded and are chosen based on the metal type. Electrodes can be heavily or lightly coated, with heavily coated electrodes preferred for structural welding due to their superior strength and corrosion resistance.

Butt welding is usually performed with the welder held at a slight angle when the weld lays flat. This helps minimize porosity in the weld and enhances its strength. Fillet welding is a common technique, accounting for around 80 percent of connections, even though it’s weaker than butt welds. Fillet welds are popular because they offer more room for error, thanks to larger tolerances. It’s important to note that fillet welding, despite its similarities, is not considered a type of butt weld.

FAQs about Butt Weld:

1. What is the primary advantage of using a butt weld over other types of welds?

2. Can you explain the key differences between a full penetration butt weld and a partial penetration butt weld?

3. What factors influence the selection of welding electrodes for butt welding, and how do they affect the weld’s properties?

4. How can distortion in butt welds be minimized, and what techniques are commonly employed for this purpose?

5. Are there specific applications or industries where butt welding is preferred over other welding methods, and why?

This article is sourced from international code and standard of EN.1993-1-8.