An overload relay is a protective device used in electrical systems to protect motors and other equipment from damage due to excessive currents. It monitors the current drawn by the motor and detects when it exceeds a predetermined threshold, indicating an overload condition. When triggered, the overload relay interrupts power to the motor, preventing overheating and potential damage.

Overload relays are special devices used in motor control circuits to protect motors from damage caused by excessive currents. They serve three main functions:

- Allow harmless temporary overloads, such as during motor starting, without shutting down the circuit.

- Trip and open the circuit if the current exceeds safe levels for an extended period, which could damage the motor.

- Can be reset after the overload condition is resolved, restoring normal operation.

Before to understand overload relay working. You need to to understand about What is an electrical overload and overload protection.

What is Overload Relay?

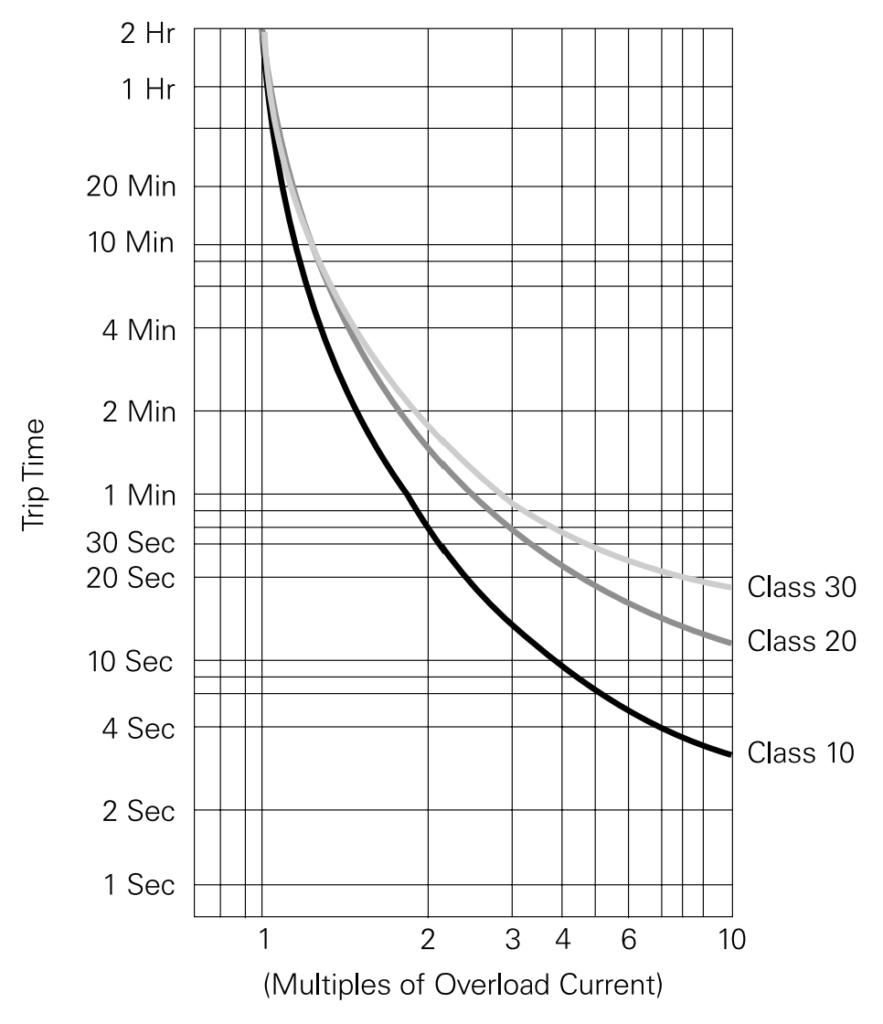

Overload Relay Trip Class

Overload relays come with a trip class rating, which indicates how quickly the relay will trip during an overload situation. The most common trip classes are Class 10, Class 20, and Class 30. For instance, in Class 10, the relay must trip the motor offline within 10 seconds or less when the current reaches 600% of the full load amps. This timeframe is usually sufficient for the motor to reach its full speed. Class 30 is often used for industrial loads, especially those with high inertia. Siemens standard overload relays typically offer Class 10 or Class 20 ratings, with Class 30 available for some starters.

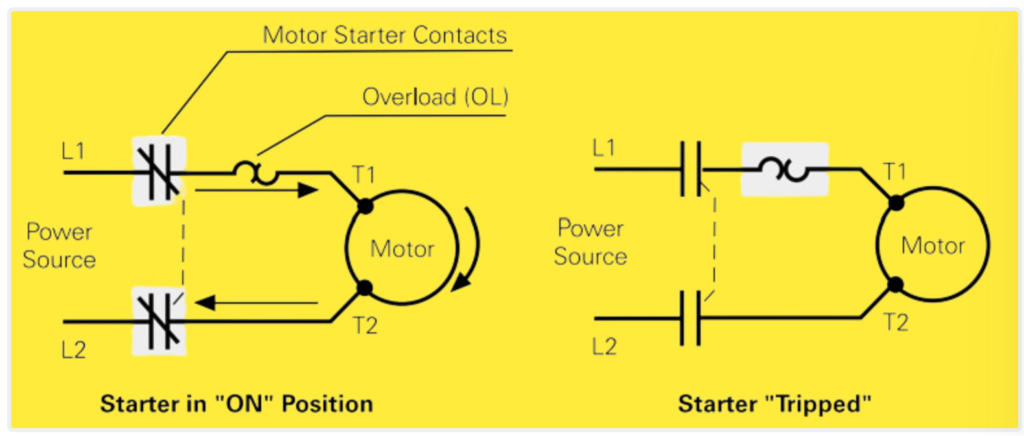

Overload Relay in Motor Circuit

In this motor circuit setup, there’s a manual Motor Circuit starter equipped with overloads. As the motor operates, the current passes through these overloads. If the current exceeds a set limit, the overload will trip, breaking the circuit between the power source and the motor. After a specific time period, the starter can be reset. Once the cause of the overload is fixed, the motor can be restarted safely.

Overload Relay Types

There are three types of overload relay.

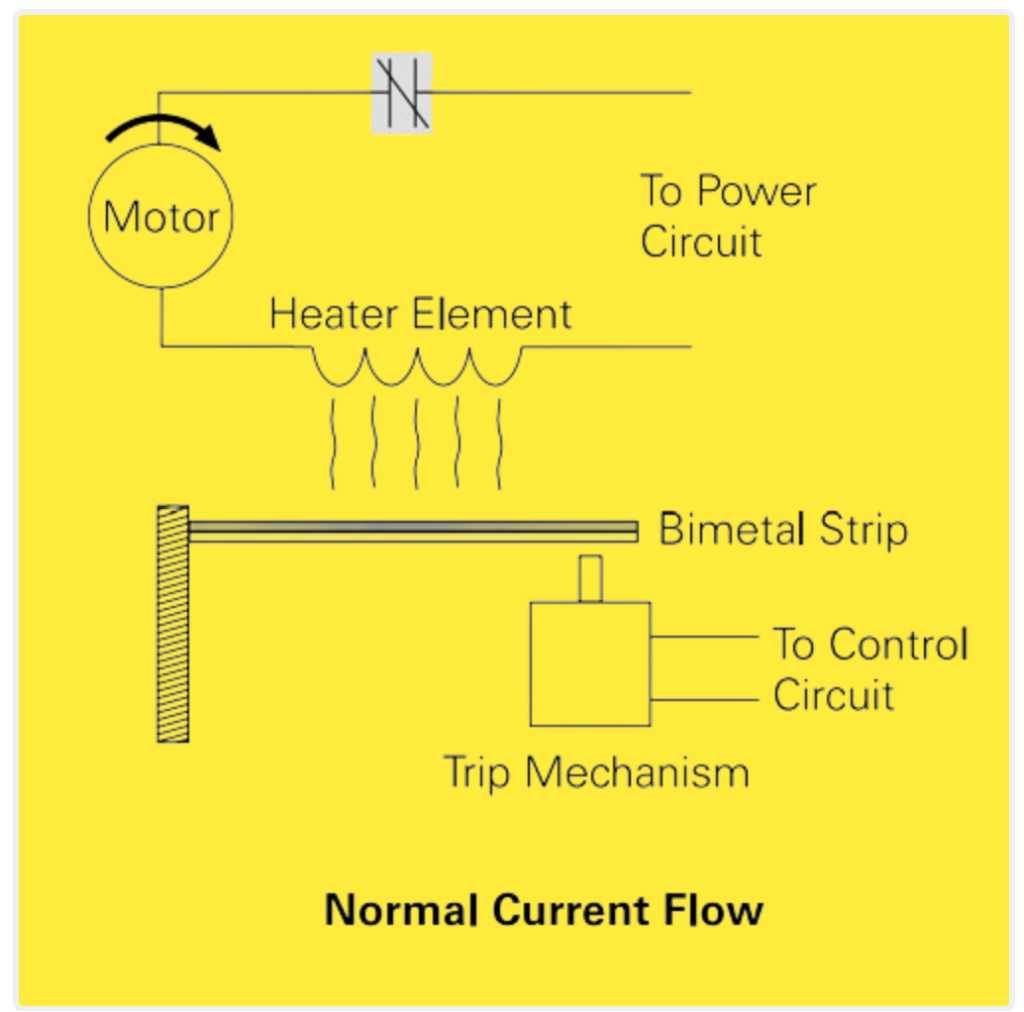

1. Bimetal Overloads or Thermal Overload Relay

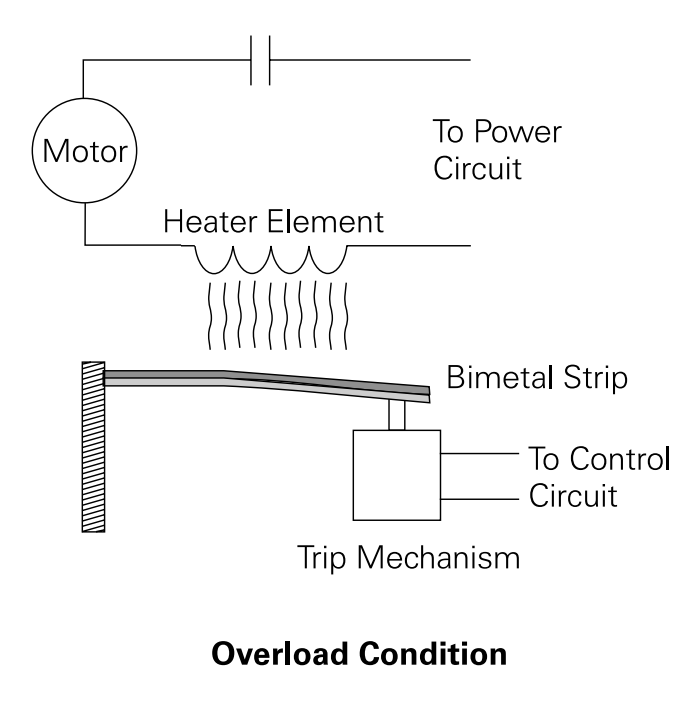

Overload protection relies on a bimetal strip, which includes a tiny heater element wired alongside the motor and the bimetal strip itself, acting as a trip lever. This strip is composed of two different metals bonded together. Because these metals expand at different rates when heated, the bimetal strip bends when heated. During regular operation, the heat produced by the heater element isn’t enough to bend the bimetal strip significantly to trigger the overload relay.

As the current increases, the bimetal strip heats up more. The hotter it gets, the more it bends. During an overload situation, the heat generated by the heater causes the bimetal strip to bend until it triggers the mechanism, stopping the motor.

Certain overload relays equipped with a bimetal strip are designed to automatically reset the circuit once the bimetal strip has cooled down and returned to its original shape, allowing the motor to restart. However, if the cause of the overload persists, the motor will trip again and reset at specified intervals. It’s important to be cautious when selecting this type of overload relay because repeated cycling can eventually harm the motor.

2. Ambient Compensated Overload Relay

In some situations, like with a submersible pump, the motor might be placed in a spot where the temperature stays the same, while the motor control and overload relay could be in an area where the temperature changes. This can cause the overload relay to trip unexpectedly due to temperature fluctuations and the current going through the motor.

To address this issue, ambient compensated overload relays are used. These relays have two bimetal strips: one primary and one compensated. When the surrounding temperature changes, both bimetal strips bend equally, ensuring the overload relay doesn’t trip unnecessarily. However, if there’s an overload, only the primary bimetal strip, affected by the current flow and heater element, will trigger the relay to protect the motor.

3. Electronic Overload Relays

Electronic overload relays provide an alternative method for protecting motors. They come with various features and advantages, but they share some common traits. One notable benefit of electronic overload relays is their heaterless design. This lowers installation expenses and eliminates the requirement to keep multiple heaters in stock to match different motor ratings. Electronic relays also offer phase loss protection, which is crucial because motor windings can be damaged rapidly if a power phase is lost. Unlike mechanical overload relays, electronic ones can detect a phase loss and disconnect the motor from the power source, providing an extra layer of safety.

Electronic Overload Relay Example

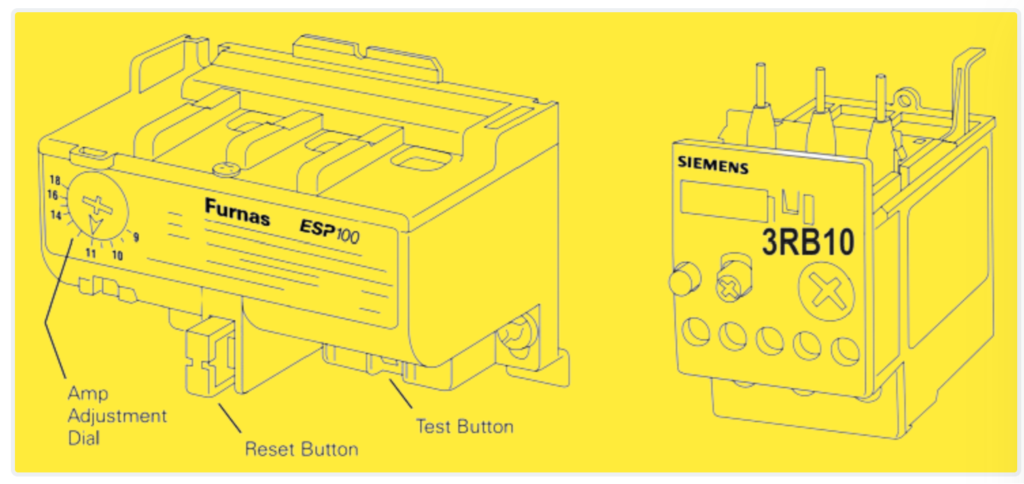

The ESP100 overload relay is a versatile solution that replaces multiple heater sizes. Instead of using heaters, you can simply adjust the full-load amperes (FLA) of the motor using a dial. For instance, the ESP100 shown below can be adjusted from 9 to 18 amperes. It offers NEMA Class 10, 20, and 30 trip curves to suit various applications. You can choose between manual or self-resetting versions, and auxiliary contacts are available as an option.

The Siemens SIRIUS 3RB10 is an electronic overload relay similar to the ESP100. It comes with Class 10 or Class 20 trip options and offers adjustable current settings and ambient compensation. The 3RB10 features both manual and automatic reset functionalities. Additionally, it includes a switch-position indicator with a test function for simulating a tripped overload relay. Each unit comes with a normally open and normally closed auxiliary contact.