Pump Cavitation is a significant concern in the operation of centrifugal pumps. It occurs when the liquid pressure falls below its vapor pressure, leading to the formation and subsequent collapse of vapor bubbles, which can cause severe damage to the pump components, primarily the impeller, and decrease the pump efficiency.

What is Pump Cavitation?

Cavitation happens within the pump when the liquid’s pressure drops below its vapor pressure, causing vapor bubbles to form in the liquid. These bubbles are created in low-pressure areas and are transported to high-pressure areas within the pump. When the bubbles reach high-pressure regions, they collapse, releasing shock waves and creating high temperature in small areas. This phenomenon usually occurs near the impeller’s eye and is manifested by a characteristic pinging or crackling noise.

Causes of Pump Cavitation:

The two main causes of cavitation in a centrifugal pump are:

- Low Inlet Pressure: When the inlet pressure falls below the design inlet pressure, it reduces the liquid pressure in the pump, leading to cavitation.

- High Flow Rate: Operating the pump at a flow rate higher than the design flow rate can also induce cavitation by altering pressure conditions within the pump.

Implications of Cavitation:

Cavitation can have several effects on pump operation:

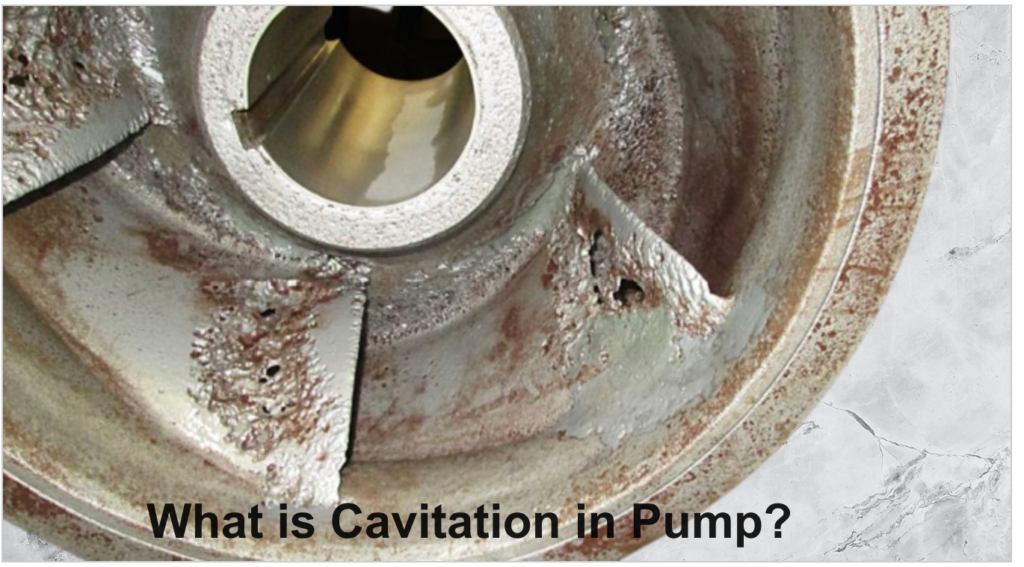

- Impeller Damage: The impeller is subjected to the shock waves emitted by the collapsing bubbles, leading to pitting on its surface and eventually shortening its service life.

- Noise and Vibration: The collapse of the bubbles causes a distinctive noise and can create vibrations, affecting the pump’s performance and structural integrity.

- Decreased Efficiency: The damage to the impeller and the disruptions due to vibrations can lead to a considerable decrease in pump efficiency.

Identifying Pump Cavitation:

- Noise Observation: The distinct pinging or crackling noise that occurs during cavitation is often the first indicator for operators that something is amiss.

- Visual Inspection: Regularly inspecting the impeller for any signs of pitting or wear can also indicate the occurrence of cavitation.

- Monitoring Pressure and Flow: Keeping a close eye on the pump’s inlet pressure and operating flow rate can help in early detection and prevention.

Mitigation and Prevention:

Cavitation can be mitigated or prevented by addressing its root causes:

- Maintaining Adequate Inlet Pressure: Ensuring that the inlet pressure doesn’t fall below the design inlet pressure is crucial. This can be achieved by avoiding high suction lifts and keeping the suction line free of obstructions and air leaks.

- Operate within Design Parameters: It is essential to operate the pump within the designated flow rate and pressure parameters to avoid creating conditions conducive to cavitation.

- Regular Monitoring and Maintenance: Regular checks and maintenance of pump components, particularly the impeller, and monitoring of pressure and flow rate can prevent cavitation and its detrimental effects.

- Proper Pump Selection: Selecting a pump with the right specifications and design for the application is critical. A well-chosen pump will operate efficiently under the given conditions, reducing the risk of cavitation.

Final Thoughts:

Cavitation is a complex but straightforward phenomenon: when liquid pressure falls below its vapor pressure, causing vapor bubbles to form and collapse on reaching higher-pressure areas causing damage, noise and decreased efficiency. To manage cavitation effectively requires understanding its causes: low inlet pressure and high flow rate – then taking steps such as running your pumps properly with regular maintenance checks as well as monitoring for adverse effects such as cavitation resulting from low flow rate or inadequate inlet pressure or selecting an inappropriate pump ensuring long term efficiency performance from any future applications that might arise from cavitation-ensuring its continued existence!

Although cavitation may appear intimidating, its preventive measures are straightforward – simply focus on maintaining optimal pump operation and maintenance practices. Cavitation serves as a reminder of the necessity of vigilantly overseeing and maintaining pump systems, placing special emphasis on monitoring pressure levels, flow rates, and components’ overall condition. Regular inspection combined with an understanding of the operating conditions and parameters can go a long way toward preventing cavitation in centrifugal pumps and ensuring their smooth operation. While identifying and preventing cavitation may appear simple, its complexity highlights the significance of proactive management for upholding their efficiency and integrity.

FAQs about Pump Cavitation:

Q1: What is cavitation in pumps?

Q2: How does cavitation occur in pumps?

Q3: What are the implications of pump cavitation?

Damage and pitting of the impeller due to the impact of shock waves from collapsing bubbles.

Noise and vibration, impacting the pump’s structural integrity and operational stability.

Decrease in pump efficiency due to the disruption in fluid flow and damage to pump components.

Q4: How can cavitation be identified in pumps?

Q5: How can cavitation be prevented?

Maintaining adequate inlet pressure to avoid pressure falling below the liquid’s vapor pressure.

Operating the pump within the designated flow rate and pressure parameters.

Regularly inspecting and maintaining pump components.

Selecting pumps with appropriate specifications and design for the intended application.

Q6: What is the significance of vapor pressure in pump cavitation?

Q7: Can cavitation occur in all types of pumps?

Q8: How does flow rate affect pump cavitation?

Q9: Can cavitation affect the pump’s efficiency?

Q10: How does regular maintenance help in preventing pump cavitation?

Read Also: Water Pump Types: Technical Complete Guide