This article is about Liquid Tight Flexible Conduit Fittings & Accessories Material Selection Guide & Technical Specification for commercial buildings, plants and refinery projects as per international codes and standards.

LT flex fittings shall be listed as meeting the requirements of UL 514B. [NFPA 70, NEC 110.3 (B)]

Liquid Tight Flexible Conduit Fittings & Accessories Material Technical Requirements

Conduit fittings for outdoor liquidtight flexible metal conduit shall be cast or forged steel, cast iron or malleable iron, either hot-dip galvanized (preferably), or zinc electroplated as supplied by the manufacturer. No aluminum fittings or fitting accessories such as covers, sealing fitting plugs, etc., shall be used outdoor. Only malleable iron sealing fittings shall be used. Gray cast iron split type (EYSR) retrofit sealing fittings may be used if required for repair purposes.

Exception:

Liquidtight flexible metal conduit hubs manufactured from zinc, that are UL or CSA listed (e.g., Myers Scru-Tite hubs) are also acceptable.

Conduit fittings for liquidtight flexible metal conduit used above ground in severe corrosive environments shall be as specified above (Item B1) and, in addition, shall be protected by one of the following methods:

a) Factory-coating with PVC (minimum thickness of PVC: 40 mils) per NEMA RN 1. Internal surfaces of PVC sleeves (boots) and other mating PVC surfaces shall be coated with PVC patching compound (SAMS 15-307-500). Uncoated plugs and other bare metal shall be coated with PVC patching compound, or with SAES-H-101 APCS-22 (offshore), or APCS-26 (onshore).

b) Field-coating prior to installation in accordance with SAES-H-101 APCS-22 (offshore), or APCS-26 (onshore). Light (sweep) sandblasting is required prior to coating so that the zinc is not removed. After installation, any bare metal must be touched up using either of the above coatings, without sandblasting.

c) By heat-shrinkable tubes or wrap-arounds, where the geometric configuration permits it. Exception: Red leaded brass or silicon bronze conduit fittings may be used as an alternative to the above in severe corrosive environments (only above ground).

| Marking: All markings shall be legible. All product markings shall be permanent. The following types of markings or the equivalent are permanent: a) etched b) molded c) die stamped d) paint stenciled [UL 514B Sec. 7.1.2] |

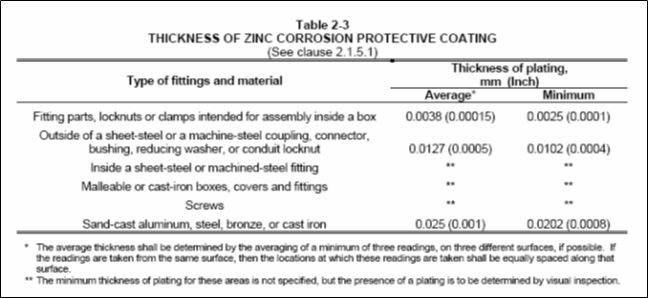

| The minimum thickness of a zinc coating shall be as specified in Table 2-3 (Attachment 1). [NEMA FB1 Sec. 2.1.5.1] |

Marking:

- Unless otherwise stated, a FITTING or cast metal box shall be marked in accordance with the applicable requirements in UL 514A or UL 514B.

- A fitting or cast metal box shall be legibly marked with the name or trademark of the manufacturer. If the catalog number or an equivalent designation is not marked on the fitting or cast metal box, it shall appear on the smallest shipping container in which the product is packaged.

- Other information

The following information shall be provided on the fitting or cast metal box, the smallest shipping container, instruction sheet, or publicly accessible database:

a) Permissive or restrictive information to designate the intended use of the product.

b) Installation instructions for products requiring unique installation techniques including specific identification of components needed that are not supplied with the product.

[NEMA FB1 Sec. 2.1.8]

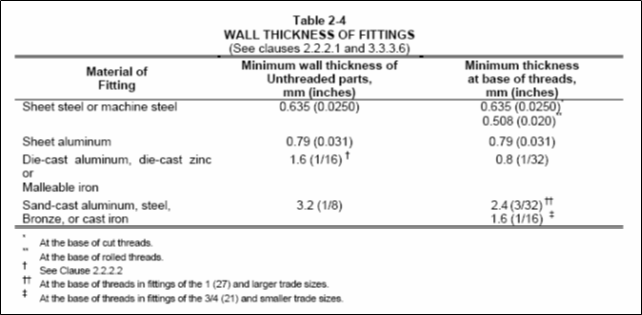

| Wall Thickness: The wall thickness of metallic fittings shall not be less than that specified in Table 2-4 (Attachment 2) when measured at least 3.2 mm (1/8 inch) from the edge of the fitting. If a taper is provided to permit easy withdrawal of the part from the die, the thickness shall not be less than that required at the base of threads when measured 0.8 mm (1/32 inch) from the edge of the fitting. [NEMA FB1 Sec 2.2.2.1] |

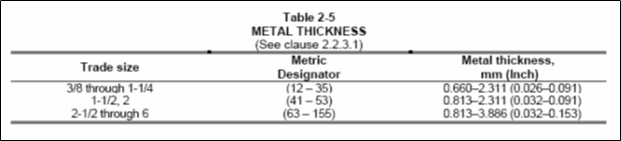

| Connectors: Fittings that are intended to connect to an unthreaded opening in a metal box or enclosure shall provide reliable mechanical and electrical connection, when assembled to various types, and thickness of metal representing the range of boxes and enclosures. The range of metal thickness is specified in Table 2-5 (Attachment 3). [NEMA FB1 Sec. 2.2.3.1] |

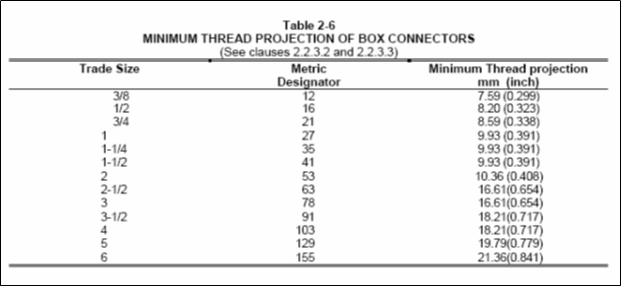

| Connectors: Fittings that are intended to connect to an unthreaded opening in a box or enclosure shall be provided with a securement means. A fitting provided with a locknut shall have a thread projection, when measured from the shoulder stop to the end of the threads along the major axis of the threaded projection, not less than specified in Table 2-6 (Attachment 4). [NEMA FB1 Sec. 2.2.3.2] |

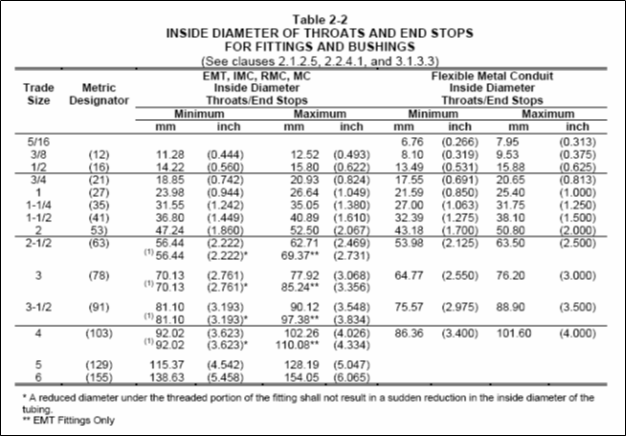

| Assembly and Mechanical Protection: A fitting for use with liquidtight flexible metal conduit shall be provided with a positive end stop that will completely encircle the conduit and has a smooth rounded throat. The throat diameter limits in Table 2-2 (Attachment 5) do not apply to liquidtight flexible metal conduit fittings. The smooth end stop shall be provided by the body of the fitting or by a separate part applied over the cut end of the conduit. [NEMA FB1 Sec. 3.2.6.1.1] |

| New and Unused – Electrical materials shall be new and unused. |

| As Designed – Electrical materials shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents (in particular, raceway type and trade size as shown on electrical BOM and raceway schedules). |

| Free of Damage – Electrical materials shall be free of damage. |

| QC Before Installation – Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. |

| Identification – Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials. |

| Traceability – Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use. |

International Codes & Standards

| 1. NFPA 70 – National Electrical Code, 2008 Edition |

| 2. SAES-P-104 – Wiring methods and Materials. |

| 3. SAES-P-100 – Basic Power System Design Criteria, June 2007 |

| 4. UL 514B – UL Standard for Safety for Conduit, Tubing, and Cable Fittings, February 2004 |

| 5. NEMA FB1 – Fitting, Cast Metal Boxes, and Conduit Bodies for Conduit, Electrical Metallic Tubing, and Cable. |

Table 2-3, Thickness of Zinc Corrosion Protective Coating – NEMA FB1

Table 2-4, Wall Thickness of Fittings – NEMA FB1

Table 2-5, Metal Thickness – NEMA FB1

Table 2-6, Minimum Thread Projections of Box Connectors – NEMA FB1

Table 2-2, Inside Diameter of Throats and End Stops for Fittings and Bushings – NEMA FB1