Acoustic imaging, also known as acoustic microscopy or acoustic imaging microscopy, is a non-destructive imaging technique that uses sound waves (acoustic waves) to create detailed images of the internal structure and properties of objects. It is particularly useful for analyzing materials, surfaces, and structures that are not easily accessible using traditional optical or X-ray imaging methods.

What is Acoustic Imaging?

Acoustic imaging involves the generation of sound waves and their subsequent interaction with the object being studied. These sound waves can be transmitted into the object, and their reflections or interactions with the internal features of the object are recorded. By analyzing the patterns of sound wave propagation, reflection, and absorption, acoustic imaging systems create high-resolution images that provide valuable insights into the object’s composition, structure, and other characteristics.

There are different techniques and technologies used in acoustic imaging, including:

- Ultrasound Imaging: This is one of the most common forms of acoustic imaging. Ultrasound imaging uses high-frequency sound waves (typically above the range of human hearing) to produce real-time images of soft tissues within the body. It is widely used in medical diagnostics for examining organs, blood vessels, and pregnancies.

- Acoustic Microscopy: This technique utilizes focused acoustic waves to achieve high-resolution images of small objects or structures, such as microelectronics, materials, and biological specimens. Acoustic microscopy is capable of revealing features that are often not visible with optical microscopes.

- Sonar Imaging: Applied in underwater environments, sonar uses sound waves to map the contours and features of the seafloor, underwater objects, and marine life. It has applications in navigation, marine research, and resource exploration.

- Non-Destructive Testing (NDT): Acoustic imaging is used in NDT to inspect materials for defects, cracks, and structural integrity without causing any damage. It is applied in industries like manufacturing, aerospace, and automotive for quality control.

- Seismic Imaging: In geophysics, seismic imaging uses controlled sources of sound waves to study the Earth’s subsurface. It helps in identifying geological structures, underground resources, and seismic activity.

The process of acoustic imaging involves emitting sound waves into the object and then recording the echoes or reflections using specialized transducers. These transducers can both emit and receive sound waves. By analyzing the time it takes for the sound waves to travel and return, along with their intensity and frequency changes, sophisticated algorithms create visual representations of the object’s internal features.

Acoustic imaging finds applications in various fields, including medical diagnostics, materials science, geophysics, industrial testing, and more. It enables researchers and professionals to gain insights into the structural integrity, composition, and properties of objects without the need for physical contact or invasive procedures.

Acoustic Imaging Explanation

Interest in using acoustic waves for imaging is steadily increasing, largely due to the cost-effectiveness and straightforward design of acoustic transducers. Acoustic imaging has demonstrated its effectiveness in various fields such as medicine, geology, and underwater applications.

However, when applied to mechatronics, there are significant limitations primarily related to the propagation of ultrasonic waves in air, the medium where most mechatronic systems operate. Despite these limitations, as outlined in Chapter 9, ongoing efforts aim to enhance the accuracy and practicality of acoustic measurement systems, particularly for distance measurement and range finding.

One notable drawback of acoustic imaging is the relatively low spatial resolution resulting from the diverging nature of acoustic transducer beams. The directivity of these transducers can be enhanced by increasing the ratio between the transducer’s diameter and the wavelength of the acoustic waves. However, even at medium frequencies (e.g., around 40 kHz), this leads to the creation of relatively large devices. An alternative approach involves employing an array of acoustic elements that are active simultaneously.

Through interference effects, the primary beam (along the acoustic axis) can be narrowed. Moreover, the direction of this beam can be electronically controlled by adjusting the phase shift or time delay between the array elements. This technique, known as phased arrays, is applicable to both transmitters and receivers and enables improved directivity and beam control.

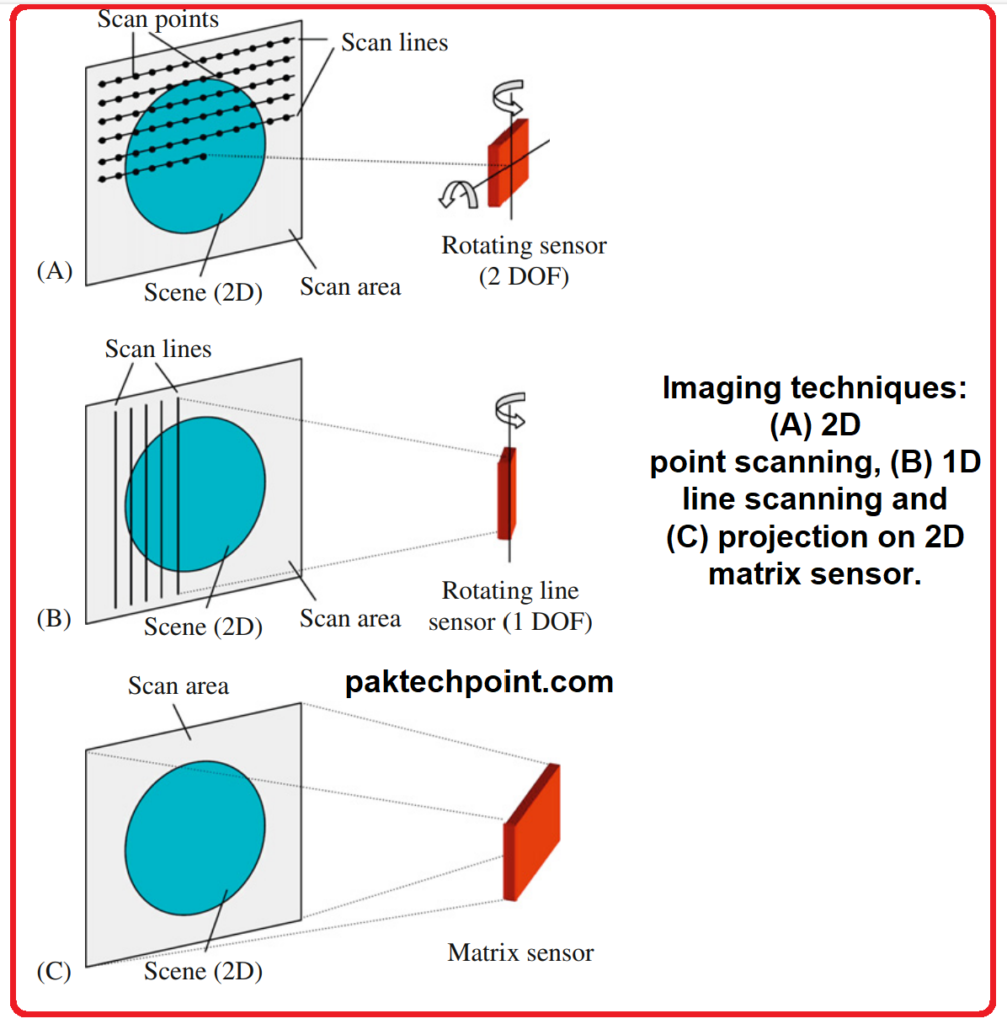

The recognition of shapes often necessitates a set of distance sensors or a scanning process involving a single sensor, based on the principles illustrated in following Figure. The shape of an object can be determined through a series of numerical calculations.

In addition to using geometric models for object recognition, alternative models can also be employed. One such approach is depicted schematically in Figure 1.4. In this method, an acoustic signal (the stimulus) is emitted towards the object. The resulting echo pattern (the response) is influenced by the object’s shape and orientation. During a learning phase, echo patterns from all possible objects are stored in a computer’s memory.

These stored patterns can be regarded as acoustic signatures of the respective objects. Subsequently, the echo pattern generated by a test object (from the trained set) is compared to each of the stored signatures. The process involves applying a minimum distance criterion to determine the best matching candidate. To ensure accurate results, the test conditions must match those of the learning phase, meaning a consistent geometry and a stable stimulus are essential.

The comparison between echo patterns can be carried out in either the frequency domain or the time domain. This straightforward technique enables differentiation between objects with significantly distinct shapes or orientations, such as those in normal versus upside-down positions. By employing an adaptive stimulus and an appropriate algorithm, ultrasonic techniques can even identify minor defects within an object. Under specific conditions, the method can detect extremely subtle differences between sides of an object, such as the faces of a coin [13].