Diaphragm valves, a vital component in fluid control systems, have become a fundamental choice for numerous industries due to their unique design and versatile applications. From pharmaceuticals and food processing to chemical manufacturing and water treatment, diaphragm valves offer precise control, reliable shut-off, and exceptional durability. In this article, we delve into the technical aspects of diaphragm valves, exploring their construction, working principles, types, advantages, and applications.

Diaphragm Valve: An Introduction

A diaphragm valve is a specialized type of control valve that utilizes a flexible diaphragm or membrane to regulate the flow of fluids. The diaphragm is placed within the valve body and acts as the separation element between the flow stream and the valve actuation mechanism. This unique design provides several distinct advantages over traditional valve types, making diaphragm valves a preferred choice in various demanding applications.

Diaphragm valves, also known as membrane valves, are specialized flow control devices that offer unique advantages in various applications. These valves comprise several essential components, including a valve body with multiple ports, a flexible diaphragm, and a seat or weir against which the diaphragm seals the valve. The choice of materials for the valve body depends on the specific application and requirements, ranging from plastics and metals to even wood in certain cases.

The fundamental design of a diaphragm valve involves the interaction of its key components to regulate the flow of fluids. The valve body contains inlet and outlet ports, allowing for the controlled passage of fluids. The flexible diaphragm, often made of elastomeric materials, acts as a barrier between the valve body and the fluid. When the valve is open, the diaphragm remains relaxed, permitting fluid flow through the valve. Conversely, when the valve needs to be closed, the diaphragm is pressed against the seat or weir, effectively stopping the flow.

The seat or weir provides the sealing surface against which the diaphragm makes contact. This design ensures a reliable shut-off, preventing any leakage or backflow. Diaphragm valves are known for their exceptional ability to create a tight seal, making them suitable for a wide range of applications, including those involving corrosive or abrasive fluids.

The choice of valve body material depends on factors such as the type of fluid being handled, the pressure and temperature conditions, and compatibility with the surrounding environment. Plastic diaphragm valves are often used for handling corrosive chemicals or in applications where non-metallic components are preferred. Metal bodies are chosen for applications requiring higher pressure and temperature tolerances. Wood, while less common, may be employed in specialized situations where its properties are advantageous.

Read Also: What is Plug valve? Types, Components, Working Principle, Pros & Cons

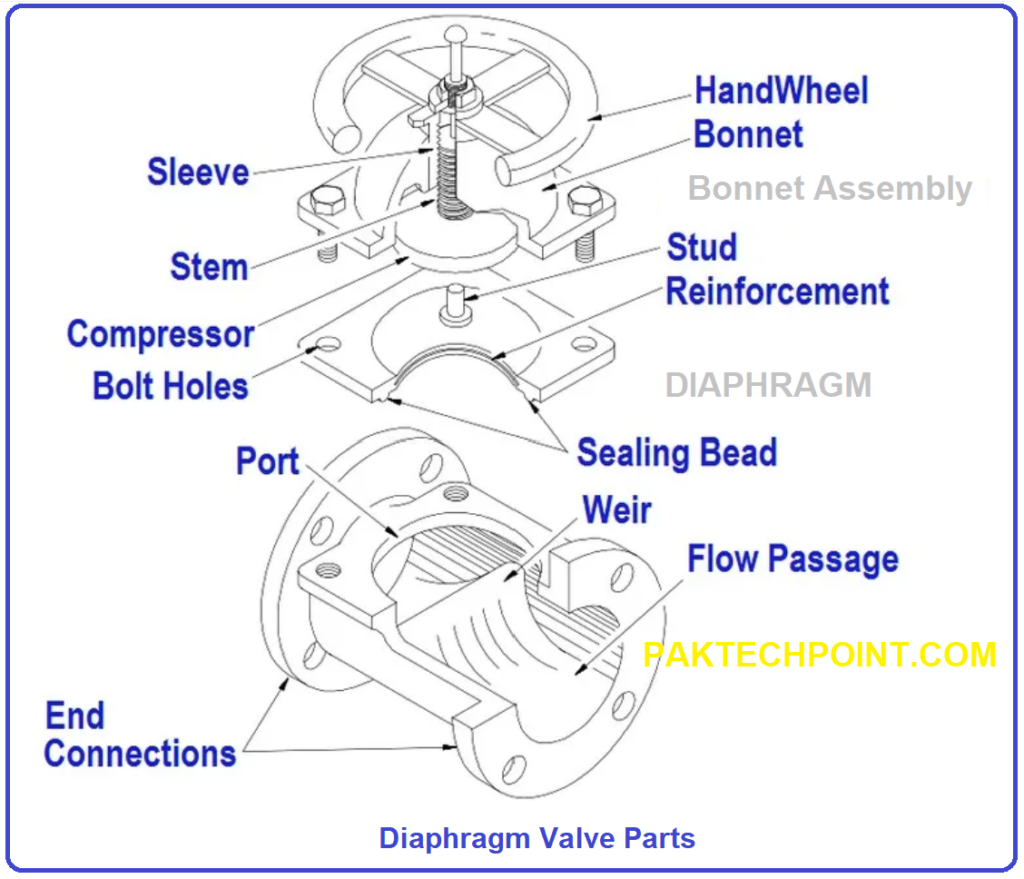

Diaphragm Valve Components or Parts

A diaphragm valve consists of several key components that work together to achieve precise fluid control:

- Valve Body: The valve body houses the diaphragm and other internal components. It provides the primary structural support for the valve assembly.

- Bonnet: The bonnet encases the stem and provides a protective cover for the valve’s internal components. It helps prevent contamination and damage to the stem and actuator. Bonnets can come in different designs, such as bolted, threaded, or clamp type, based on the valve’s construction.

- Weir or Seat: In weir-type diaphragm valves, the weir or saddle serves as the sealing surface against which the diaphragm closes to regulate flow. It’s a critical part for achieving effective shut-off and flow control.

- Diaphragm or Disc: The diaphragm or disc is the flexible component that moves to open or close the valve. It is made from elastomeric or fabric-reinforced material, allowing it to flex and create a tight seal against the seat. Diaphragms can vary in design, such as straight or weir, to accommodate different flow requirements.

- Stud: The stud secures the diaphragm in place, holding it against the seat. It ensures that the diaphragm maintains proper alignment and provides consistent sealing performance.

- Plunger: The plunger is attached to the stem and is responsible for moving the diaphragm. As the stem moves up or down, the plunger imparts the motion to the diaphragm, allowing it to open or close the valve.

- Stem: The stem connects the actuator to the diaphragm and plunger. It transmits the actuator’s force to the diaphragm to control the valve’s position. Stems can be driven by manual handwheels, electric actuators, pneumatic actuators, or hydraulic actuators.

- Actuator: The actuator is the mechanism that drives the stem to move the diaphragm and control fluid flow. Actuators can be manual, pneumatic, hydraulic, or electric, depending on the application’s requirements. They provide the force needed to open, close, or modulate the valve.

Read Also: Ball Valve: Types, Design, Working Principle, Ball Sealings, Diagram

Diaphragm Body of Valve

The design and dimensions of a diaphragm valve’s body play a crucial role in its performance and compatibility with various industrial applications. In many cases, diaphragm valve body dimensions adhere to the Manufacturers Standardization Society (MSS) SP-88 standard. However, it’s important to note that the standards for diaphragm valves can differ from those of other industrial valves.

While most industrial valves follow the ANSI/ASME B16.10 standard, diaphragm valves often have their own set of specifications due to their unique design and function. This can sometimes make it challenging to directly substitute diaphragm valves for other types of industrial valves in certain applications. However, to address this challenge, some manufacturers offer diaphragm valves that are designed to conform to the ANSI B16.10 standards. This approach allows these diaphragm valves to be used interchangeably with various types of valves, including solid wedge, double disc, and resilient wedge gate valves, as well as short pattern plug and ball valves.

By offering diaphragm valves that align with ANSI B16.10 standards, manufacturers aim to provide a more versatile solution for fluid control systems. This compatibility with other industrial valves allows for greater flexibility in valve selection and installation, making it easier for industries to integrate diaphragm valves into their existing setups or replace other valves with diaphragm valves when needed.

Read Also: Globe Valve : Types, Working Principle, Parts & Trim Characteristics

Working Principle of Diaphragm Valves

The operation of a diaphragm valve is straightforward yet effective. When the actuator applies force to the diaphragm, it flexes and moves away from the valve seat, allowing fluid to flow through the valve. Releasing the actuator causes the diaphragm to return to its original position, closing off the flow.

This unique mechanism offers several advantages:

- No Contact with the Process Fluid: The diaphragm acts as a barrier, ensuring that the process fluid does not come into contact with the actuator or other internal components. This is crucial for applications involving corrosive or abrasive fluids.

- Precise Flow Control: The linear response of the diaphragm allows for accurate and proportional control of flow rates. This makes diaphragm valves suitable for applications requiring precise dosing or regulation.

- No Packing or Stuffing Box: Unlike traditional valves that may require packing or sealing arrangements, diaphragm valves eliminate the need for these components, minimizing maintenance and potential leak points.

Types of Diaphragm Valves

Diaphragm Valves Categories

Diaphragm valves, distinguished by their unique design and versatile applications, are categorized based on their sealing mechanism and port configurations. These categories offer different functionalities and suit various operational needs in industries. Let’s delve into the main categories of diaphragm valves:

- Weir or Saddle Type Diaphragm Valves: This category features a diaphragm that seals against a raised ridge or weir in the valve body. The weir provides a controlled flow path, and the diaphragm closes against it to stop or regulate the flow. Weir type diaphragm valves excel in applications requiring precise control and throttling. They are commonly employed in industries where accurate flow modulation is vital.

- Straight-Through or Full-Bore Diaphragm Valves: This category encompasses diaphragm valves that seal over a seat, providing a straight and unobstructed flow path when open. The diaphragm lifts away from the seat, allowing fluid to flow without significant hindrance. Straight-through diaphragm valves are typically used in on-off applications, where quick opening and closure are required. They are ideal for scenarios where minimal pressure drop and unimpeded flow are essential.

While diaphragm valves predominantly come in two-port configurations (known as 2/2-way diaphragm valves), they can also be designed with additional ports. Three-port diaphragm valves (3/2-way diaphragm valves or T-valves) and even multi-port block valves offer expanded functionality for specific applications. In cases involving more than three ports, multiple diaphragm seats may be incorporated, with specialized dual actuators enabling the management of multiple ports using a single membrane.

Diaphragm valves can be operated manually or in an automated manner. Automation options include pneumatic, hydraulic, or electric actuators, complemented by accessories like solenoid valves, limit switches, and positioners. Automation enhances precision and efficiency in fluid control processes.

Beyond the traditional two-way shut-off and throttling diaphragm valves, various specialized types cater to specific industrial needs:

- Three-Way Zero Deadleg Valve: Designed to eliminate dead spaces in piping systems, preventing fluid accumulation and contamination.

- Sterile Access Port Valve: Facilitates aseptic sampling and fluid injection in pharmaceutical and biotechnology applications.

- Block and Bleed Valve: Combines isolation and venting functions in a single unit, ensuring safe maintenance and system integrity.

- Valbow: A combination of a ball valve and a diaphragm valve, offering both on-off and throttling capabilities.

- Tank Bottom Valve: Installed at the bottom of tanks or vessels, enabling draining, sampling, and cleaning operations.

These diverse categories showcase the adaptability and versatility of diaphragm valves in fulfilling various process requirements across industries. Each category serves a specific purpose, allowing industries to select the most suitable diaphragm valve for their fluid control needs.

Read Also: Butterfly Valve: Design, Working Principle, Types, Applications, and Diagram

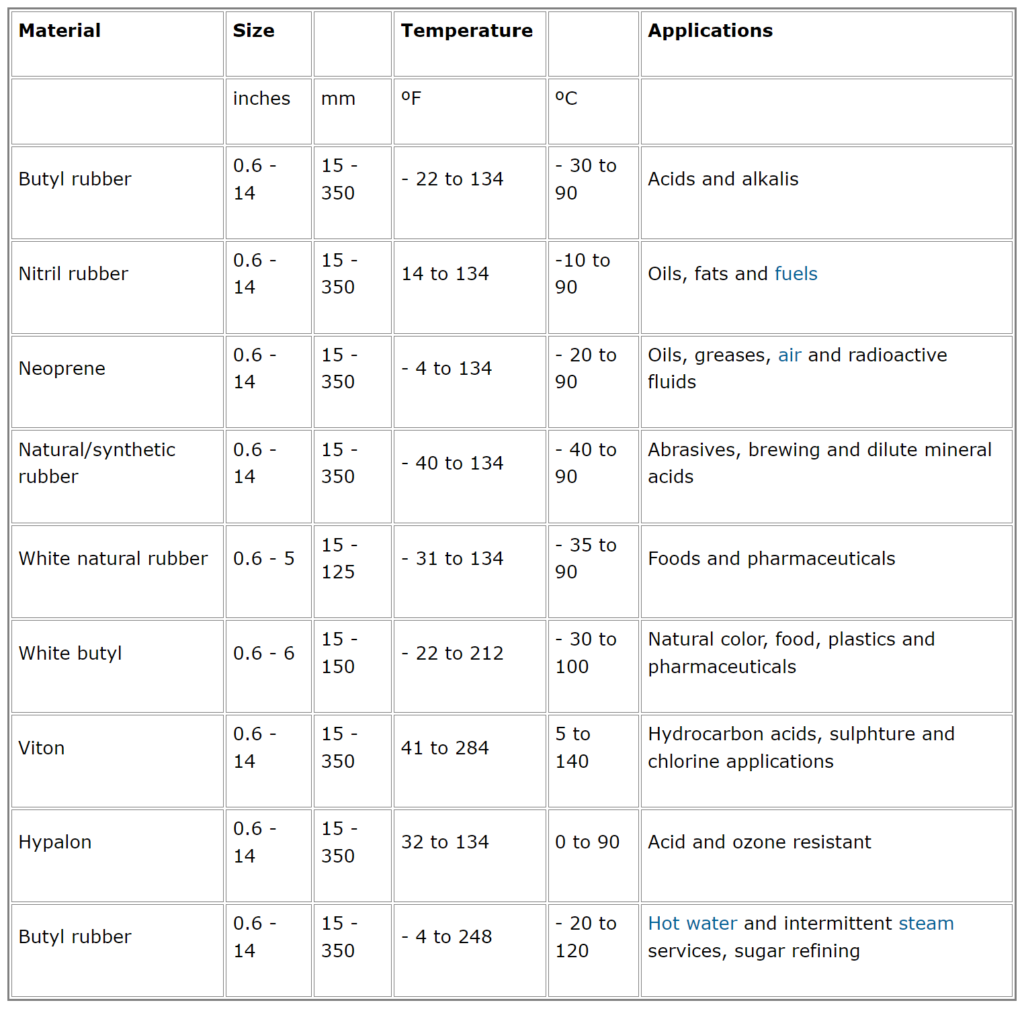

Material for Construction of Diaphragm Valves

The choice of material for diaphragms in diaphragm valves is a critical aspect that directly impacts the valve’s performance, durability, and compatibility with the fluid being handled. Various factors, including the nature of the material, temperature, pressure, and operational frequency, influence the selection of diaphragm materials. It’s essential to choose a material that can withstand the specific conditions of the application to ensure efficient and reliable valve operation.

Elastomeric diaphragm materials are commonly used due to their chemical resistance and flexibility. However, it’s important to consider their limitations, especially when dealing with high temperatures and pressures. Here are some key considerations for selecting diaphragm materials based on different factors:

- Nature of Material Handled: Different materials have varying chemical compatibility. For aggressive or corrosive fluids, diaphragm materials with excellent chemical resistance should be chosen to prevent degradation and ensure a longer service life.

- Temperature: Elastomeric diaphragm materials are suitable for moderate temperatures, but their mechanical properties can weaken at elevated temperatures (typically above 150°F or 65°C). In high-temperature applications, metal or PTFE diaphragms may be preferred.

- Pressure: High pressure can damage elastomeric diaphragms. In such cases, metal diaphragms that can withstand higher pressures might be a better choice.

- Media Concentration: The concentration of the fluid being handled can affect the corrosion resistance of the diaphragm material. Materials should be selected based on their compatibility with the specific concentration and temperature of the media.

- Frequency of Operation: The frequency of valve operation can impact the wear and tear on the diaphragm. Consider materials that offer durability and resistance to fatigue, especially in applications with frequent cycling.

- Fluid Purity: In applications where fluid purity is critical, diaphragm materials that are non-reactive and have low extractables are preferred to avoid contamination.

- Special Applications: Some applications may require specialized diaphragm materials, such as those with FDA approval for food and pharmaceutical industries or materials designed for cryogenic conditions.

To assist in material selection, manufacturers provide compatibility charts that outline the suitability of different diaphragm materials for various chemicals and conditions. It’s crucial to consult these charts and work with experts to ensure that the chosen diaphragm material aligns with the application’s requirements.

Here are some examples of diaphragm materials and their specifications:

- Natural Rubber: Offers good resilience and flexibility but may have limitations in temperature and chemical compatibility.

- EPDM (Ethylene Propylene Diene Monomer): Provides excellent resistance to weathering, ozone, and aging. Suitable for water, steam, and some chemicals.

- PTFE (Polytetrafluoroethylene): Exceptional chemical resistance, high-temperature capability, and low friction. Suitable for corrosive and high-purity applications.

- Neoprene: Offers good resistance to oil, ozone, and weathering. Suitable for applications involving hydrocarbons and refrigerants.

- Buna-N (Nitrile): Good oil and solvent resistance. Suitable for applications involving petroleum-based fluids.

- Viton (Fluoroelastomer): Excellent chemical resistance to a wide range of fluids, including high-temperature applications.

- Metal: Provides high-pressure capability and is suitable for corrosive and abrasive fluids.

- Teflon-Coated: Combines the benefits of PTFE with enhanced flexibility and durability.

The proper selection of diaphragm material is essential for achieving optimal performance, longevity, and safety in diaphragm valve applications. It requires a comprehensive understanding of the application’s conditions and the chemical compatibility of different materials. Consulting with valve experts and referring to compatibility charts provided by manufacturers can help in making informed decisions about diaphragm material selection.

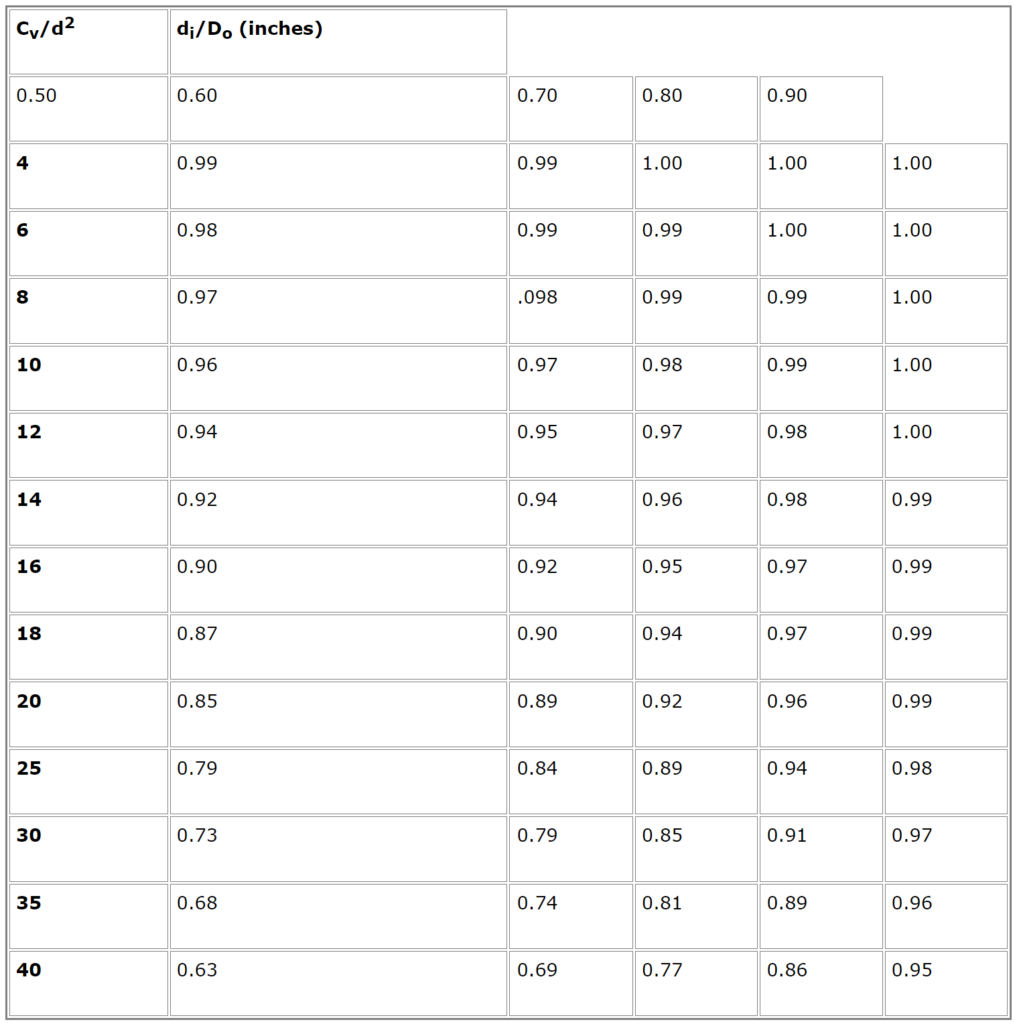

Diaphragm Valve Sizing

Diaphragm valve sizing plays a critical role in ensuring optimal performance and efficient flow control. When selecting a diaphragm valve for throttling applications, proper sizing is essential to achieve accurate control of fluid flow. Unlike open/close systems, diaphragm valves are used for regulating flow, making it important to consider various factors when determining the appropriate valve size.

Here are the key considerations and steps involved in diaphragm valve sizing:

- Inlet and Outlet Port Size: In most cases, diaphragm valves have inlet and outlet ports of the same size. The valve size is determined based on the required flow rate and the flow coefficient (Cv value).

- Media Type and Properties: The type of fluid being controlled is a crucial factor. The specific gravity (density) and viscosity of the media influence the flow rate and pressure drop across the valve.

- Flow Coefficient (Cv): The Cv value represents the flow capacity of the valve and is a measure of how much flow a valve can pass with a given pressure drop. It is essential to calculate the required Cv value based on the desired flow rate and the application’s parameters.

- Maximum Inlet and Outlet Pressure: The maximum pressure at the inlet and outlet of the valve needs to be considered. This includes both the inlet pressure and the outlet pressure (pressure drop) under maximum load conditions.

- Temperature: The temperature of the fluid being controlled affects its viscosity and, consequently, its flow characteristics. Extreme temperatures may require special considerations for material selection.

- Maximum Capacity: Determine the maximum flow rate (capacity) that the valve needs to handle. This helps ensure that the selected valve can accommodate the required flow without causing excessive pressure drops.

- Maximum Pressure Drop: Consider the maximum pressure drop that the valve must close against. This is particularly important to prevent issues like cavitation or excessive backpressure.

- Pipe Geometry Factor: The pipe geometry factor adjusts the Cv value based on the pipe’s configuration (straight pipe, elbows, reducers, etc.). This factor ensures that the calculated Cv value is appropriate for the specific installation.

To assist with the sizing process, manufacturers often provide sizing software or charts that help calculate the appropriate valve size based on the given parameters. These tools consider various variables to determine the most suitable diaphragm valve size for a particular application. It’s essential to accurately input the relevant data to obtain accurate sizing results.

Advantages of Diaphragm Valves

- High Purity Applications: Diaphragm valves are widely used in industries like pharmaceuticals and food processing due to their ability to maintain fluid purity by preventing contamination.

- Corrosion Resistance: The separation of the actuator from the process fluid eliminates the risk of corrosion and ensures a longer service life.

- Precise Flow Control: The linear flow response and accurate dosing capability make diaphragm valves suitable for applications requiring precise control.

- Minimal Maintenance: The absence of packing and stuffing boxes reduces maintenance requirements and potential leakage points.

- Versatile Applications: Diaphragm valves find applications in industries ranging from chemicals and petrochemicals to water treatment and biotechnology.

Applications of Diaphragm Valves

- Pharmaceutical Industry: Diaphragm valves are essential in pharmaceutical manufacturing to ensure sterile conditions and prevent contamination.

- Food and Beverage Industry: They are used to control the flow of ingredients and maintain hygiene standards in food and beverage production.

- Chemical Processing: Diaphragm valves handle corrosive and aggressive fluids, making them suitable for chemical manufacturing.

- Water Treatment: They play a crucial role in water treatment plants, controlling the flow of chemicals and ensuring safe water supply.

- Biotechnology: Diaphragm valves are used in bioprocessing applications where purity and precision are critical.

In conclusion, diaphragm valves offer a unique combination of precise flow control, durability, and versatility, making them a reliable choice for various industries. Their innovative design and ability to maintain fluid integrity position them as an essential component in modern fluid control systems. As technology continues to advance, diaphragm valves are likely to find even more applications, driving efficiency and reliability across industries.

If still confused please check out following video.

Manufacturer of Diaphragm Valves

There are several reputable manufacturers of diaphragm valves that are widely recognized for their quality and reliability. Here are some leading diaphragm valve manufacturers in the USA:

- DFT Inc. (DuraValve):

- Asahi/America

- Plast-O-Matic Valves, Inc.

- Aquasyn LLC

- Magnatrol Valve Corporation

- Val-Matic Valve & Manufacturing Corp.

- Crane Engineering

- Assured Automation