6. HVAC Ductwork Installation | Ductwork Design

6.1 Materials

6.1.1 Galvanized steel sheets shall be of lock forming quality, having zinc coating of 1.25 ounces per square foot conforming to ASTM A653/A653M, G-60 coating designation for each side. Common use for majority of ductwork applications.

6.1.2 Carbon steel sheets shall be of commercial quality, conforming to ASTM A366/A366M.

6.1.3 Stainless steel sheets shall be Type 304 with no. 1 finish conforming to ASTM A480/A480M for battery rooms, laboratories containing corrosive emissions.

6.1.4 Fasteners shall be by use of rivets and bolts throughout; sheet metal screws shall be acceptable on low pressure ducts.

6.1.5 Sealants shall be water resistant, fire resistant, compatible with mating materials. Ductwork shall be sealed per SMACNA Seal class B, minimum.

6.1.6 Exterior ductwork shall be hot dip galvanized 16 Ga, seal weld sheet metal.

6.1.7 Reinforcement shapes and plates shall be galvanized steel reinforcement where installed on galvanized sheet metal ducts; compatible materials shall be used on stainless steel ducts.

6.2 Ductwork Fabrication

6.2.1 Duct fabrication shall be in accordance with SMACNA , HVAC Duct Construction Standards-Metal and Flexible

6.2.2 Metal ducts shall be completed within themselves with no single partition between ducts, unless shown on the drawings. Where width of duct exceeds 457 mm, duct shall be cross broken for rigidity. Open corners shall not be acceptable.

6.2.3 Metal ducts shall be lapped in direction of air flow. Edges and slips shall be hammered down to leave smooth duct interior.

6.2.4 Rectangular tees, bends, and elbows shall be constructed with a minimum radius of not less than 1 1/2 times width of duct. Where not possible and where rectangular elbows used, airfoil type turning vanes shall be provided. Where acoustical lining is required, turning vanes of perforated metal type with fiberglass inside shall be provided.

6.2.5 Duct sizes shall be increased gradually, not exceeding 15 degrees divergence wherever possible. Maximum divergence upstream of equipment shall be limited to be 30 degrees and 45 degrees convergence downstream.

6.2.6 Metal duct shall be rigidly with joints mechanically tight, substantially airtight, braced and stiffened so as not to breathe, rattle, vibrate, or sag. Duct joints and connections shall be caulked with sealant as ducts are being assembled and cover with tape.

6.2.7 Laboratory fume hood exhaust duct system shall be constructed with fabricated seams and joints liquid tight with continuous external welds.

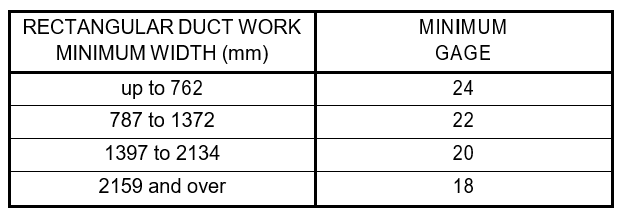

6.3 Duct Gages in HVAC

6.3.1 Static pressure in duct less than 500 Pag and velocities less than 10 m/s.:

Table I – Duct Gages (500 Pa)

6.3.2 Static pressure in duct up through 1.5 kPag and velocities greater than 10 m/s.:

Table II – Duct Gages (1.5 kPa)

6.4 Ductwork Execution

6.4.1 Ductwork shall be constructed and fabricated in compliance with SMACNA – HVAC Duct Construction Standards-Metal and Flexible and the requirements of this standard.

6.4.2 Welding procedures and welding personnel shall be qualified to perform processes according to AWS D1.1 for hangers and supports and AWS D9.1 duct joint and seam welding.

6.4.3 Work shall comply with NFPA 90A and 90B.

6.4.4 Comply with NFPA 96 for cooking range hoods.

6.4.5 Openings shall be provided in ductwork where required to accommodate thermometers and controllers. Pilot tube openings shall be provided where required for testing of systems, complete with metal can with spring device or screw to ensure against air leakage. Where openings are provided in insulated ductwork, insulation material shall be installed inside a metal ring.

6.4.6 Duct systems shall be cleaned with high power vacuum machines before final acceptance. Equipment that may be harmed by excessive dirt shall be protected with filters or bypassed during cleaning. Adequate access into ductwork shall be provided for cleaning purposes.

6.4.7 Ducts shall be located with sufficient space around equipment to allow normal operating and maintenance activities.

6.4.8 Air handling units and exhaust fans shall be connected to ductwork with flexible connections.

6.4.9 Ducts passing through partitions shall be sealed around the ductwork with non- combustible material.