Following topics to be discussed for step by step to cover this article of HVAC System Design Criteria.

This article defines criteria for the design of Heating, Ventilating and Air Conditioning (HVAC) systems.

HVAC General Requirements.

- Safety code analysis shall be conducted to determine area and occupancy classifications. All specific safety requirements shall be described and incorporated in design documents.

- Special HVAC system design parameters and conditions related to HVAC system and plant process shall be defined in early stages of the design either provided by plant Licenser or specified in the basic design package.

- HVAC system design shall consider energy conservation, durability, and ease of maintenance shall be emphasized consistently with required performance characteristics and at the same time delivering a cost-effective system to maintain throughout its useful life of selected HVAC equipment and materials.

- Other objectives to be reflected in HVAC design are flexibility and adaptability to accommodate future modifications or expansions, mitigation of equipment corrosion, occupant safety, occupant comfort, acceptable indoor air quality and acceptable noise level.

- Energy conservation HVAC equipment such as heat recovery units, thermal storage tanks..etc shall be utilized in maximum extend as possible in HVAC system design.

- All values maximum or minimum mentioned in this standard when used in design shall be provided with 10 % tolerance.

- The HVAC systems shall be designed and sized to maintain summer and winter operating condition limits.

- Power supply shall in accordance to NEC Electrical System Design Criteria in Process Industry requirements.

HVAC Design Conditions.

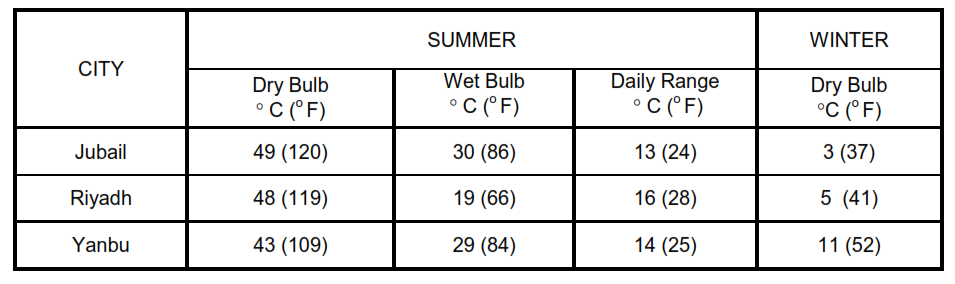

HVAC Outdoor design conditions

- In the absence of meteorological weather data design criteria, outdoor design conditions shall use data from ASHRAE Fundamentals Handbook for design criteria under 2 percent cooling dry bulb and mean coincident values shall be used for cooling load calculations, and 99.6 percent heating dry bulb shall be used for heating load calculations.

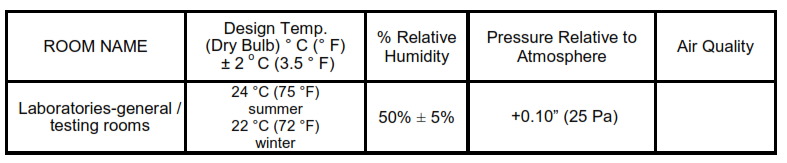

HVAC Indoor design conditions

- Table II contains the minimum indoor conditions to be used for the design of HVAC systems in selected rooms/spaces.

- HVAC system shall be capable of maintaining dry bulb and relative humidity within the performance range given in Table II.

- Design conditions shall comply to values in the ASHRAE Handbooks, applicable health and safety codes, equipment manufacturer condition and plant Licensor for HVAC system related to process.

Note: In the case a room or space name is not included in above table, then the selection of design conditions shall consider the space/room with nearest similar function from above with the approval of Company.

Key: DB – Dry bulb RH – Relative humidity

HVAC Ambient Air Quality

HVAC systems shall be designed for the ambient air quality and will be defined on a project location basis.

HVAC Ventilation

- Ventilation requirements for various specific applications shall be in accordance with the latest ASHRAE Standard 62.1 (Ventilation for Acceptable Indoor Air Quality) and based on ventilation rate procedure calculation method. For rooms/spaces with specified ventilation rates requirement exceeding either the amount required for cooling or exhaust, whichever is greater shall be used in HVAC design.

- Unless otherwise specified, all ventilation systems shall be mechanically operated.

HVAC Load Calculations (Click Here)

HVAC Air-Conditioning System:

Packaged equipment shall be used to the greatest extent possible if appropriate for the application/facility, in order to simplify the specifying, purchasing, installation, and maintenance of equipment. Equipment selected shall include provisions for minimum cycling of equipment on part-load operation.

Air and Water Balance Requirements: The heating, ventilating and air conditioning systems shall be designed to facilitate ease of balancing both by (1) selecting supply fans for 5% over required air, to allow for air leakage and for maximum operating efficiency based on system pressure drop calculations; and (2) providing means of balancing the air and water flows.

District Cooling or Central Chiller Plant:

Utilization of such HVAC system shall be decided based on Life Cycle Cost study comparing between other HVAC systems such as individual direct expansion package units. The selection of chilled water pumping arrangement (primary variable vs. primary-secondary) shall consider overall load profile, individual building load and the use of modern variable frequency drives in order to enhance the system efficiency. Chilled water storage tanks shall be selected in most extent to save on initial cost and operation cost of package water chiller. In addition careful attention shall be on high noise levels generated from the refrigeration system or chilled water pumps and the transmission of noise to adjacent sensitive buildings, means of reducing the noise level thru studying the location of the central plant that minimize the noise transmission or the using sound absorbing barriers or providing sound attenuator on the package water chillers shall be highly considered.

HVAC Cooling (Refrigeration) System

- All cooling (refrigeration) systems using vapor compression refrigeration cycle shall be selected.

- The package units direct expansion or water chiller shall be complete package unit with all refrigeration system major components evaporator, compressor, expansion valve, condenser and complete package unit instrumentation/electrical components.

- Selection between water chiller and Direct expansion refrigeration system shall be based on life cycle cost analysis.

- Refrigeration package units shall be selected from among commercial products of approved manufacturers to provide refrigeration load under site ambient conditions and capable of supplying spare parts for the normal operating life of the equipment. If manufacturer’s published performance data does not include data at the design temperature for the project location, manufacturer shall be consulted for performance data.

- Refrigeration media (refrigerant) shall not use chlorinated fluro carbon (CFC’s) or other ozone depleting compounds. Proposed refrigerants shall require prior company approval considering Montreal Protocol refrigerant phase-out schedule.

- All refrigeration equipment shall be electric motor driven and variable refrigeration system is preferred.

- Local Direct Digital Control controller installed on the refrigeration package unit displaying operating parameters to assist local monitor of package unit during maintenance as an addition to DDC control panel for the HVAC system.

- See PAKTECHPOINT.COM for HVAC equipment specification.

HVAC Air System (Click Here)

HVAC Redundancy (Back-up) systems

- Essential space such as control rooms/buildings, Remote Instrument Building (RIB), substations, communication rooms and analyzer houses shall be provided with back-up air conditioning unit(s), to provide air conditioning redundancy in case of a primary air condition unit failure.

- Control systems shall be designed to energize the back-up air condition unit(s) on the detection of primary air condition unit(s) failure.

- The control philosophy shall incorporate switch over from primary air condition unit(s) to back-up unit(s) once every four months for a period of one week. During switchover period the primary unit(s) shall be in function as the back-up unit(s).

- Backdraft Dampers shall be provided as required in the main supply ductwork to isolate the back-up unit(s) from the primary unit(s). Backdraft dampers shall be install in common main plenum box to prevent air flow from either primary or back-up unit(s) from entering the other unit(s).

- Motorized Volume Dampers shall be install in unit(s) supply, return and outside main ductwork or wherever required to assist in shifting the operation from primary and back-up unit(s) by HVAC DDC control system.

Air conditioning unit redundancy guidelines:

- Where a single air conditioning unit (DX or Chilled Water) is proposed, a minimum of two independent compressor/condenser circuits shall be provided.

- Where 50 % or 75 % redundancy requirements are specified by project criteria, four (3) or three (2) air conditioning units respectively, each selected for 50 % or 75 % of system load shall be provided correspondingly.

- In all redundancy configurations, one chiller water pump shall be selected to match, and discharge piped individually to the respective chill

- Redundancy configurations mentioned above shall compared using life cycle cots analysis study on 25 year span.

- Refer to NEC Electrical System Design Criteria for requirements on emergency power supply.

HVAC Noise Control.

- HVAC equipment shall be selected which do not generate noise within the occupied space. The noise control curve limits and decibel ranges shall not be in excess of the recommendations values.

- Sound attenuator shall be used to maintained targeted sound criteria mentioned below or specified in ASHRAE Applications Handbook.

HVAC Vibration Control

Special attention shall be given to eliminate the transmission of vibration to the building structure. Vibration isolation shall be provided for equipment, ductwork, and piping. No rigid connections between rotating/oscillating equipment and the building structure shall be permitted. Vibration isolators shall be selected in accordance with the weight distribution and the manufacturer recommendations to produce uniform deflection. The selection shall consider selection guideline in sound and vibration control chapter of ASHRAE Application Handbook.

HVAC Heating System

Electrical heaters shall be provided for those areas requiring heat or humidity control see Table II. See Duct Insulation in HVAC | Insulate HVAC Heating and Cooling DuctWork for electric heater specifications. Energy waste thru heating shall be permitted as space zoning.

HVAC Humidification / De-Humidification

Humidifiers shall be installed rooms/spaces where inside condition required strict humidity control such as control room or as defined by individual project requirements. Where required by specific projects, de-humidification shall be provided through the use of the cooling coil, with re-heat as required to maintain room design conditions. See Humidifier For HVAC System | Air Conditioning Systems for information on humidity control systems.

HVAC Filtration (Click for Details)

HVAC Ventilation System (Click for Details)

HVAC Exhaust Air System (Click for Details)

HVAC Air Purge System

Rooms/space served by fire suppression system shall be equipped by air purge system capable to extract the fire extinguishing agent from the room/space.

The portion of the HVAC system intended to run during the air purge operating mode, shall be sized, selected and constructed to meet the requirements of area hazard classification where it is installed.

Ductwork and dampers shall be configured so that during smoke evacuation operating mode, the return air damper is fully closed while the exhaust and outside air dampers are fully open to enable smoke from the space(s)/zone(s) to be purged and replenished with outside air in case of fire. All dampers and set to their normal operation settings after the completing smoke purging.

HVAC Smoke Management Systems

Requirements of smoke management system shall conform to IBC, NFPA 92 and associated codes and standards. Smoke management system for warehouse, basements and atrium shall be installed to prevent the spread of smoke within the corridors and stairways used for emergency evacuation.

HVAC Duct Design (Click Here)

HVAC Hydronic (chilled water) system

HVAC Refrigerant Piping

See Piping and Equipment Insulation for refrigerant piping, liquid line dryer, moisture indicator and liquid refrigerant sight glass requirements.

HVAC Insulation

Building exterior walls and roof shall be thermally insulated to achieve thermal transmittance values mentioned in ASHRAE 90.1 for commercial buildings and 90.2 for residential building.

Air duct located outdoor shall be cover by aluminum cladding and internal insulated with internal insulation (acoustic lining) to nearest diffusion devise. For ducts installed indoors wrap insulation shall be installed.

See Duct Insulation in HVAC | Insulate HVAC Heating and Cooling DuctWork for insulation requirements and thickness for the ductwork and chilled water pipe.

HVAC control system

- A detailed control philosophy shall be developed to describe different operating modes and HVAC system action and interaction with related building systems such as fire alarm control panel, elevators, audio and visual warning signals …etc..

- The HVAC control system shall be direct digital type (DDC) with a central control panel and communicating with all sensors, transmitters, terminal units controllers and other systems interlocking and interfacing panels. Control system shall meet the requirements of Engineering Standards.

- HVAC DDC system technology shall not be more than 5 year old from the date the documents are submitted for approval.

- Provide HVAC control system to operate and adjust the system operating parameters (temperature, humidity …etc) for the comfort of the occupancy or space requirements for unoccupied space/rooms.

- The Direct Digital Control (DDC) for each unit, system or zone shall report the operating parameters or fault to terminal or shall be linked to Distributed Control Systems (DCS) or Plant Information system (PIS) with respective signal and system characteristics representation.

- Thermostat boxes shall be of digital type located in respective zone/system. The thermostat shall enclosed within plastic key locked box to limit temperature adjustment to buildings/facilities authorized individual(s).

- The HVAC control system shall integrated with fire suppression system such as FM200, NOVEC 1230 and CO2.. etc controls to assist the adequate performance of the fire protection system.

- Hydrogen detection system shall be installed as part of the DDC system where level of Hydrogen concentration are monitored for high limits. Local visual and audio indicators shall be provide in door entrance of the protected space/room.

- The HVAC control system, in addition to the components necessary for the performance of the system, shall include the following as minimum requirements:

- Deferential pressure switches on filters, coils and motor driven equipment (fans, dampers,…etc).

- Temperature sensor (duct mounted) for return air measurement c. Buildings/Rooms static pressure gage and transmitter

- Smoke detector (duct mounted) per NFPA 90A requirements e. CO2 level indicator (duct mounted) for return air

- Digital readout for both the temperature, humidity for each room or spac

Building Management System (BMS) could be recommended for buildings use.

HVAC Interface with Fire and Gas Detection Systems (Click Here)

HVAC Testing, Adjusting and Balancing (TAB)

The HVAC system shall be deemed acceptable only after approval of TAB report. See Testing, Adjusting and Balancing TAB of HVAC System for testing, adjusting and balancing (TAB).

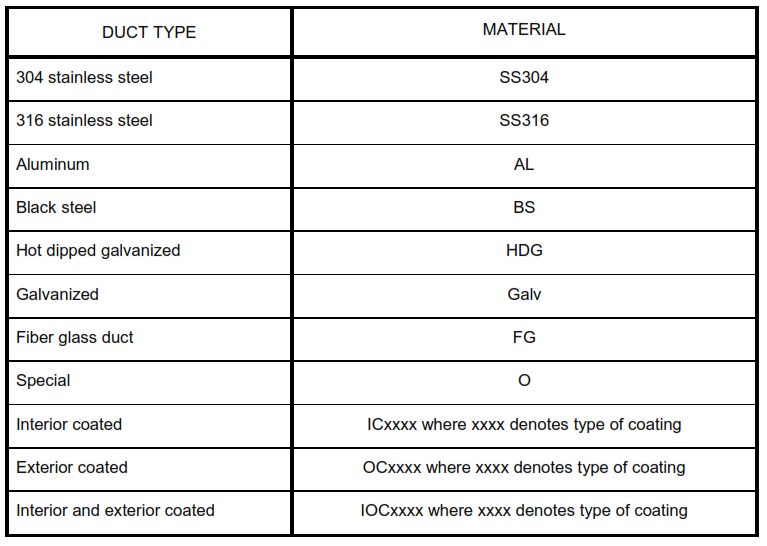

HVAC equipment and materials selection and installation

Table III – Duct Coding System

HVAC References.

Reference is made in this article to the following documents.

American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

- ASHRAE Handbooks.

- ASHRAE 62.1 Ventilation for Acceptable Indoor Air Quality.

- ASHRAE 62.2 Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings.

- ASHRAE 90.1 Energy Standard for Buildings Except Low-Rise Residential Buildings.

- ASHRAE 90.2 Energy –Efficient Design of Low-Rise Residential Buildings.

American Industrial Hygiene Association

AIHA Z9.5 – Laboratory Ventilation.

American Conference of Governmental Industrial Hygienists (ACGIH)

Industrial Ventilation: A Manual of Recommended Practice for Design, 27th Edition.

American Society for Testing And Materials (ASTM)

ASTM A653/ A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc- Iron Alloy-Coated (Galvanized) by the Hot-Dip Process.

The international Society of Automation (ISA)

S71.04 – Environmental Conditions for Process Measurement and Control Systems: Airborne Contaminants.

International Code Council (ICC)

IBC – International Building Code.

National Fire Protection Association (NFPA)

- NFPA 70 – Standard on National Electrical Code.

- NFPA 90 – Standard for the Installation of Air-Conditioning and Ventilating Systems.

- NFPA 92B – Standard for Smoke Management Systems in Malls, Atria, and Large Spaces.

- NFPA 496 – Standard for Purged and Pressurized Enclosures for Electrical Equipment.

Steel Metal and Air Conditioning Contractors National Association (SMACNA)

HVAC Duct Construction Standards—Metal and Flexible.