Following topics to be discussed in this article are

1. SCOPE

2. REFERENCES

3. GENERAL

3.1 Joint Sealant Application

3.2 Performance Requirements

3.3 Submittals

3.4 Quality Assurance

3.5 Delivery, Storage, and Handling

3.6 Project Conditions

3.7 Warranty

4. PRODUCTS

4.1 Materials, Genera

4.2 Elastomeric Joint Sealants

4.3 Latex Joint Sealants

4.4 Acoustical Joint Sealants

4.5 Joint-sealant Backing

4.6 Miscellaneous Materials

5. EXECUTION

5.1 Examination

5.2 Preparation

5.3 Installation of Joint Sealants

5.4 Field Quality Control

5.5 Cleaning

5.6 Protection

5.7 Elastomeric Joint-sealant Schedule

5.8 Latex Joint-sealant Schedule

5.9 Acoustical Joint-sealant Schedule

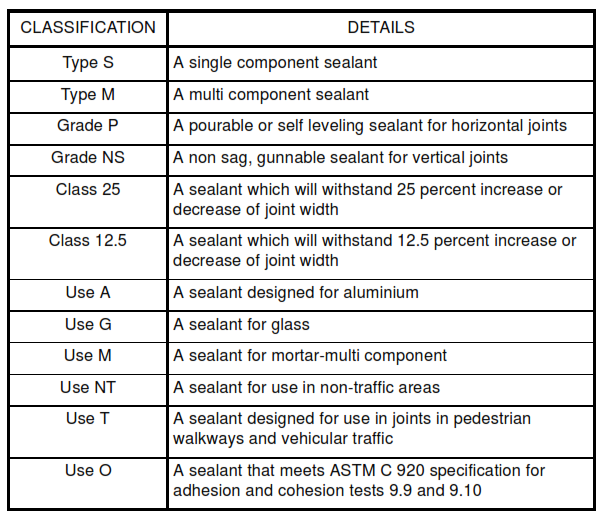

Table I – Classification of Sealants

Installation of Joint Sealants | Types | Joint Sealant Application

1. Scope

This specification covers all materials and accessories necessary for the completion of all joint sealant applications.

2. Joint Sealants References

Reference is made in this article to the following documents.

American Society for Testing of Materials (ASTM)

C 719 Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle).

C 834 Specification for Latex Sealants.

C 919 Practice for Use of Sealants in Acoustical Applications.

C 920 Specification for Elastomeric Joint Sealants.

C 1193 Guide for Use of Joint Sealants.

C 1248 Test Method for Staining of Porous Substances by Joint Sealant.

D 1056 Specification for Flexible Cellular Materials – Sponge or Expanded Rubber.

E 90 Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions.

3. General

3.3 Submittals

The following shall be submitted to Company:

a. Product data for each joint-sealant product indicated.

b. Samples for initial selection. Manufacturer’s color charts consisting of strips of cured sealants showing the full range of colors available for each product exposed to view.

c. Samples for verification, for each type and color of joint sealant required. Joint sealants shall be installed in 13 mm wide joints formed between two 150 mm long strips of material matching the appearance of exposed surfaces adjacent to joint sealants.

d. Product certificates, signed by manufacturers of joint sealants, certifying that products furnished comply with requirements and are suitable for the use indicated

3.6 Conditions for Installation of joint sealants

3.7 Warranty

4.1 Materials, General

4.2 Elastomeric Joint Sealants

4.3 Latex Joint Sealants

4.4 Acoustical Joint Sealants

4.5 Joint-sealant Backing

4.6 Miscellaneous Materials

5.1 Examination

5.2 Preparation

5.3 Installation of Joint Sealants

5.7 Elastomeric Joint-sealant Schedule

5.8 Latex Joint-sealant Schedule

5.9 Acoustical Joint-sealant Schedule