- PURPOSE

1.1 This standard defines the requirements for organizing, performing, and documenting an Operational Readiness Inspection (ORI).

1.2 The ORI process is used to ensure safe startup and operation of a new plant or a modification to an existing plant. It is an organized process of inspection, review, and verification to ensure that a new plant or a modification to an existing plant complies with design, construction, and testing standards (including applicable EH&S design standards).

1.3 For Air Products and Chemicals, Inc. owned and/or operated facilities, the ORI shall also ensure that:

- The new plant or modification complies with environmental, health, and safety regulations, and

- The necessary management systems to ensure safe operation and compliance with applicable laws and codes are in place.

- SCOPE

2.1 This standard applies to:

- Projects and plant modifications executed by Air Products for designed, owned, or operated facilities.

- Projects for which Air Products provides commissioning or performance testing services prior to startup.

- Subsidiaries and majority-owned joint ventures.

- Air Products R&D activities.

2.2 Plant modifications that can be executed by Management of Change (MOC) checklists and that meet the following requirements will meet the intent of this standard:

- Comply with environmental, health, and safety regulations and Air Products standards,

- Have the necessary management systems to ensure safe operation,

- Have been installed as designed, and

- Have been inspected and tested before startup.

2.2.1 A typical ORI checklist for an MOC is included in the Appendix of Global EH&S Standard 25‑010905.

- DEFINITIONS

3.1 Operational Readiness Inspection (ORI) – An organized process of review, verification, and inspection of a new plant or modification of an existing plant to ensure that it can be started up and operated safely.

3.2 ORI Chairperson – The person responsible for the performance and implementation of a specific ORI.

3.3 ORI Report – The documentation of the ORI results and closeout. This may be a series of reports until all open items are completed.

3.4 ORI Team – Individuals selected or assigned to perform the ORI.

3.5 Operations Manager – The person responsible for the day-to-day operation of the process unit(s) or plant(s).

3.6 Pre-ORI Checklist Review – A review of the ORI checklist that occurs before the ORI to develop the project specific ORI checklist.

3.7 Pre-Startup Safety Review (PSSR) – Another term used in the United States for ORI. This is the term commonly referred to in the OSHA PSM regulation.

3.8 Project – An activity, funded by a capital or extraordinary expenditure request, for the design, construction, installation, modification, and/or acquisition of equipment, process, facility, or pipeline.

3.9 Project Manager – A capital projects manager, plant project engineer, plant technical manager, technology manager, or individual accountable for the performance of a project.

3.10 Startup – The definition of this term varies depending on the project scope or unit operation being considered. Examples of how startup can be defined include water batching, chemical delivery, introduction of process chemicals, etc. In this standard, the introduction of process chemicals or fuels to the equipment is considered startup.

- SUMMARY

4.1 This standard defines the requirements for performing Operational Readiness Inspections (ORI). It requires that an ORI is performed on all projects and plant modifications executed by Air Products for designed, owned, or operated facilities and on all projects for which Air Products provides commissioning or performance testing services prior to startup.

4.2 This standard:

- Defines roles and responsibilities for performing an ORI and for measuring compliance,

- Provides a work process for performing and documenting an ORI,

- Provides a detailed checklist of items to be verified complete so that an ORI team can determine if a plant or system is ready to begin operation in a safe and environmentally acceptable manner, and

- Permits a project engineer or product line manager to develop and use an ORI checklist that is more appropriate for a particular project or product line.

4.3 The ORI checklist included in the appendix of this standard is somewhat detailed and can be reduced in size or expanded to meet the needs of a particular ORI team, however certain elements of the detailed checklist must be retained to meet the intent of this standard. A comprehensive checklist has been provided to help ensure all important items will be considered in the development of project or product line specific checklists.

4.4 The detailed checklist was developed with the expectation that the design of the plant has been completely defined and documented at the time of the ORI.

- PROCEDURE

5.1 Introduction

5.1.1 An ORI must be performed on all projects and plant modifications executed by Air Products and Chemicals, Inc. for designed, owned, or operated facilities and on all projects for which Air Products provides commissioning or performance testing services prior to startup. Air Products includes subsidiaries, majority-owned joint ventures, and Air Products R&D activities.

5.2 ORI Process

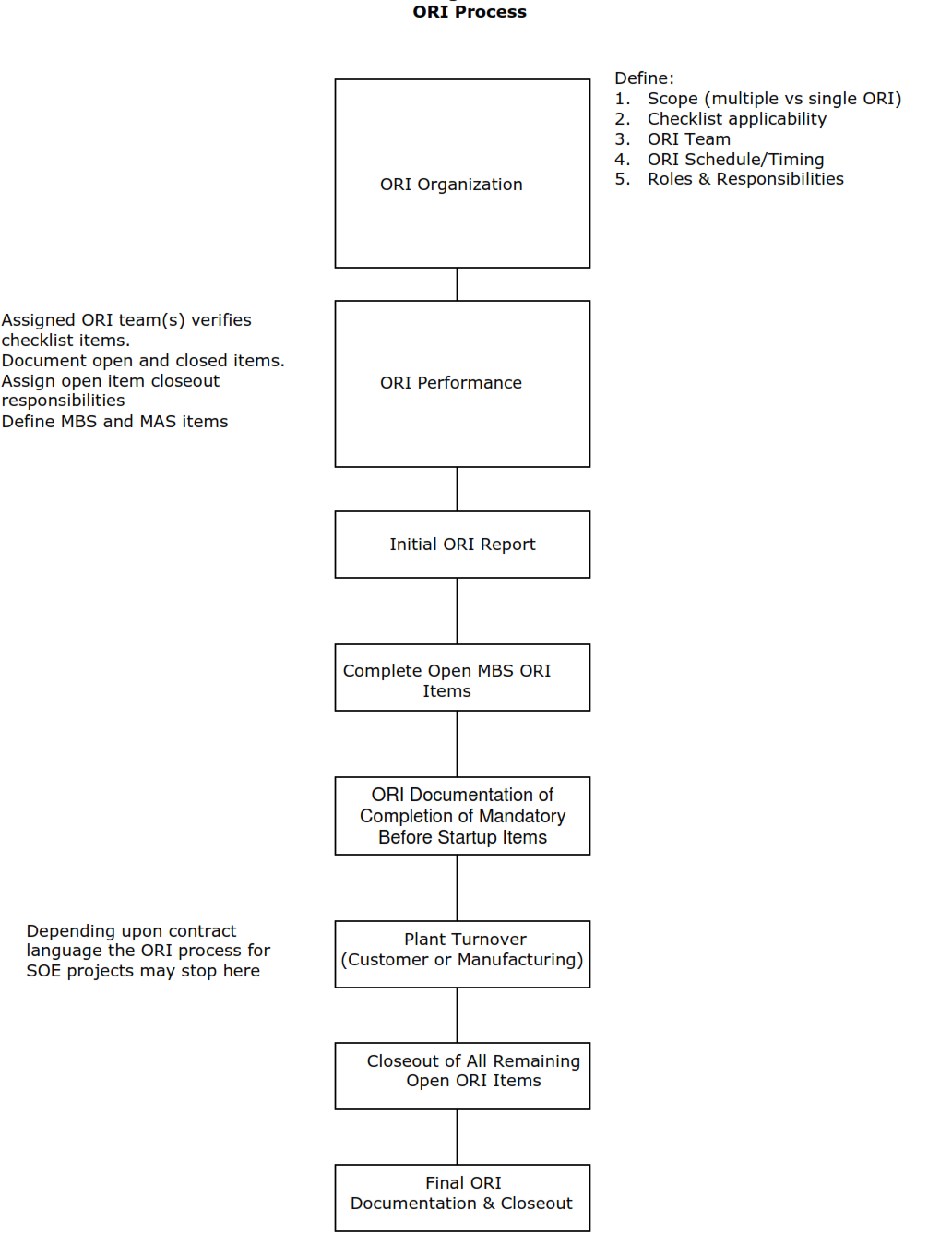

5.2.1 Figure 1 is a diagram of the ORI Process.

5.3 ORI Organization

5.3.1 The Project Manager or designee shall organize the ORI activities before the actual plant inspection is performed. The following items shall be considered during the ORI planning:

- At the pre-ORI meeting(s) the ORI checklist in the Appendix shall be reviewed. This review:

- Shall determine which items on the checklist are applicable to the project (referred to in the remaining portions of this standard as the project-specific checklist).

- Can be done on a product basis.

- Shall assign the ORI checklist responsibilities for completion of the applicable items to the appropriate project team members and the appropriate manufacturing or operations group.

- Shall define those items that must be completed before unit or facility startup [mandatory before startup (MBS)] and those that may be completed after startup [mandatory after startup (MAS)].

- At the pre-ORI meeting(s), the scope of the inspection should be defined using the ORI checklist in the appendix as a guide. Items on the ORI checklist that are not applicable to the project strategy, scope of equipment supply, or site location or are not required by regulatory requirements should not be audited by the ORI team.

- At the pre-ORI meeting(s), the scope of the ORI(s) should be defined.

- The ORI can be conducted as a series of inspections and meetings or as a single meeting, depending upon the scope of the project.

- If Air Products is supplying equipment to a customer, the ORI must include any areas of the customer’s process/facility that could be affected by the new equipment. The project manager must coordinate the ORI of that part of the project with the customer’s operations manager.

- The auditors must be assigned for each checklist item as appropriate for the size of the project.

- Project-specific closeout criteria for each checklist item must be defined.

5.4 ORI Performance

The ORI shall consist of:

- An on-site audit and/or inspection of the actual work area and

- An ORI team meeting to discuss the results of the audit and/or inspection.

5.4.1 On-Site Audit and/or Inspection

5.4.1.1 The on-site audit and/or inspection shall address each item on the project-specific checklist. It shall confirm completion of each item as defined in the closeout criteria selected during the organizational (pre-ORI) meeting.

5.4.1.2 All sections of the ORI checklist that were identified as applicable to the project must be audited during the on-site ORI.

5.4.1.3 The ORI must identify any items that do not meet the ORI checklist objectives. These items are called deficiencies.

5.4.1.4 If a deficiency is identified, corrective action to eliminate the deficiency from the installation, procedures, or equipment is required.

5.4.1.5 If the auditor has identified checklist items that are not complete, the auditor may identify possible alternative completion strategies. These strategies must provide an equivalent level of safety as the defined checklist item. The auditor can suggest these alternatives to the ORI team.

5.4.2 ORI Team Meeting

5.4.2.1 After the on-site audit and/or inspection is completed, the ORI team shall meet to discuss findings with the ORI Chairperson.

5.4.2.2 The status of each applicable project-specific checklist item must be discussed in this meeting.

5.4.2.3 The timing for closing out each specific deficiency shall be noted as either:

- Completion mandatory before startup (MBS)

- Completion mandatory after startup (MAS)

5.4.2.4 Project-specific subsets to these MBS and MAS classifications, such as before chemical delivery, before introduction of process chemicals, before water batching, before light off of the burner, etc. may be required. These subsets should have been defined and documented during the ORI planning stages. However, they may be modified or identified during this ORI meeting.

5.4.2.5 Responsibility for completion and completion dates for all open items on the checklist that are mandatory before startup must be assigned to meet facility or unit startup commitments.

5.4.2.6 To avoid startup delays, the ORI team can identify alternative, temporary solutions that meet the intent of the ORI item. These temporary solutions must provide the same level of safety to plant personnel as the ORI checklist item would provide.

5.4.3 Initial ORI Report

5.4.3.1 The ORI Chairperson is responsible for ensuring that all recommendations from the on-site ORI are recorded.

5.4.3.2 An Initial ORI report must be developed. It must include the following:

- Date of the ORI session and report issue date.

- Scope of the ORI.

- A list of ORI team members.

- A copy of the completed ORI checklist with references to closeout documentation as required. Documentation of closure of an ORI checklist item must provide sufficient detail so that personnel who are not part of the team can understand the technical basis of the closeout.

- All closeout criteria used to confirm completeness of an ORI checklist item shall be documented on the checklist.

- Identification of the auditor who confirmed that a checklist item is complete. Recording the auditor name or initials on the checklist is sufficient identification.

- Identification of all open items resulting from the inspection and the timing requirements for their completion (MBS or MAS designations).

- A note on the checklist about the nature of the deficiency of the item being inspected and a corrective action.

- A reference to the need to follow different operating instructions, equipment test frequencies, logging of measurements, etc., for deferred tasks or inspections if required. The necessary revised instructions, equipment test frequencies, logging of measurements, etc. must then be implemented by site management to safely operate the facility.

- Assignment of responsibilities for closeout of each open item.

5.4.4 Closeout of Mandatory Before Startup Items

5.4.4.1 All MBS items must be completed before startup of the applicable unit. Startup of the unit is as defined during the ORI organizational/planning meeting.

5.4.4.2 The unit may not be started up until all identified MBS items on the ORI checklist have been verified as complete by the individual given responsibility in the initial ORI report or designee.

5.4.4.3 If the MBS item cannot be resolved before startup, alternative temporary solutions that provide the same level of safety can be implemented. This alternative temporary solution must be reviewed and agreed by the ORI team. For design engineering changes, an action plan should be put in place by project and operations to remove or close out these alternative temporary solutions, and revert the change to the original intended design”.

5.4.5 Documentation of Closeout of Mandatory Before Startup Items

5.4.5.1 The Project Manager or designee must update the ORI checklist or other documentation used to track closure of any MBS ORI recommendation. This updated checklist must be available before startup of the unit or facility.

5.4.5.2 The following documentation must accompany that closeout:

- Revision number and date of the ORI report update.

- The completion date for each MBS ORI item.

- Identification of the individual(s) who confirmed that a MBS checklist item is complete. Recording the auditor name or initials on the checklist is sufficient identification.

- Technical rationale for ORI item completion.

5.4.6 Approval for Startup

5.4.6.1 The Project Manager or designee is responsible for reporting the ORI status to the Operations or Startup Manager.

5.4.6.2 Formal approval for startup will be documented by completion of Safe to Commission and Safe to Operate certificates (See Global EH&S Standard 25-011703).

5.4.7 Closeout of All Remaining ORI Open Items

5.4.7.1 Project and Operations Managers must jointly develop a plan to track closure of any open ORI items and identified deficiencies remaining after startup of the facility. A responsible person must be identified to close out each incomplete item.

5.4.7.2 The responsibility for completion and closeout of longer term ORI actions can be transferred to the Operations Manager at a time agreed to by the Project and Operations Managers.

5.4.7.3 All recommendations noted in the ORI report as to be completed after startup must be completed within the time period specified.

5.4.8 Final ORI Documentation Closeout

5.4.8.1 In general, the Project Manager is responsible for documenting completion of all final ORI items. The responsibility for closeout of longer term ORI actions can be transferred to the Operations Manager at a time agreed to by the Project and Operations Managers.

5.4.8.2 The Project Manager or designee is responsible for documenting completion of all final ORI items for sale of equipment projects.

5.4.8.3 The final ORI report shall provide sufficient documentation to verify closure of all applicable ORI items and shall include the following:

- Date of completion of the ORI

- Scope of the ORI

- A complete list of the ORI participants

- A copy of the completed ORI checklist with references to closeout documentation as required. Documentation of closure of an ORI checklist item must provide sufficient detail so that personnel who are not part of the team can understand the technical basis of the closeout.

- Identification of the individual(s) who confirmed that all checklist items are complete. Recording the auditor name or initials on the checklist is sufficient identification.

5.5 Documentation Retention

5.5.1 The ORI reports for an operating plant or unit must be maintained for the life of the facility at that facility’s location. If a plant is to be relocated, a new ORI report must be developed and retained at the new location. The old reports can be discarded.

5.5.2 The ORI report and any related information shall be readily accessible to all employees and any affected contract personnel at the facility as required by national or local regulation or practice.

5.5.3 ORI reports can be located and retained in the project electronic filing systems currently in use (for example, STAC).

- ROLES AND RESPONSIBILITIES

6.1 The Regional Manager of Process Safety is responsible for:

6.1.1 Updating this standard and procedure on a regional basis.

6.1.2 Assisting with defining ORI boundaries for projects at facilities that are not wholly owned and/or operated by Air Products. Project and/or operations managers share this responsibility with the Regional Manager of Process Safety.

6.1.3 Participating in the selection of ORI team members. Project and operations managers share this responsibility with the Regional Manager of Process Safety.

6.1.4 Establishing the criteria used by the Manager of EH&S Assurance to measure if operating groups are following the requirements of this standard.

6.1.5 Developing a Tier 3 ORI procedure and/or checklist for specific EH&S regulatory requirements for the region. The following items must be identified and addressed in the procedure or checklist developed:

- ORI action items.

- Timing requirements.

- Item status.

- Person responsible for implementing the action items.

- Actual completion dates for the actions.

- Closeout information including closeout criteria.

6.1.5.1 The checklist included in the appendix of this standard shall be used as a basis for compliance with the above requirements.

6.2 Project Manager(s) are responsible for:

6.2.1 Ensuring that an ORI is conducted for the project.

6.2.2 Selecting appropriate project team members for performing the pre-ORI checklist review and determining the timing for this review.

6.2.3 Ensuring that the site construction team is aware of the ORI requirements.

6.2.4 Selecting the ORI team, including its chairperson. The Regional Process Safety Manager shares this responsibility with the project manager(s).

6.2.5 Organizing an ORI prior to startup.

6.2.6 Determining the number of ORI reviews necessary based on the number of units at the facility, coordinating the ORI for individual units of a new facility as the units are nearing completion, and ensuring that proper communications are provided to affected individuals.

6.2.7 Preparing and maintaining an ORI report and ensuring that it is transmitted to the plant owner/operator with all mandatory before startup (MBS) items completed.

6.2.8 Establishing system(s) for monitoring progress, reconciling, and tracking closure of all ORI recommendations.

6.2.9 Establishing and maintaining project ORI documentation and transmitting this file to the plant owner/operator. This file must be compatible with the operating facility’s documentation system that supports compliance with the authority having jurisdiction [for example, in the United States, Occupational Health and Safety Administration (OSHA) and Environmental Protection Agency (EPA), in Europe Health and Safety Executive (HSE), Air Products].

6.2.10 Working with the Operations Manager to develop a closeout plan for the ORI that includes agreement on responsibility and schedule for completion of all mandatory after startup (MAS) recommendations and associated documentation.

6.2.11 Developing project-specific or product line-specific ORI procedures and/or checklists as necessary. To meet the intent of this standard, these product line and project specific checklists must contain the following minimum items:

- Definition of the scope and applicability for the checklist.

- A listing of ORI action items.

- Timing requirements for closure of open ORI action items.

- Item status.

- Person responsible to implement the actions.

- Actual completion dates for the actions.

- Definition of closeout criteria.

Note: Reference to an item on a punchlist is not acceptable closeout documentation for an ORI. Without a specific standard for punchlists, maintaining the punchlist for the life of the plant will not be assured and future tracking of the closure of each ORI item cannot be accomplished.

- Information confirming closure of each ORI action item.

- Revision control of checklists.

6.2.11.1 The detailed checklist included in the appendix of this standard shall be used as a basis for compliance with the above requirements.

6.2.11.2 All new and revised product line ORI checklists must be reviewed and approved for posting in this standard by a team consisting of Process Safety and the Product Line Owner or their designees. Additional review team participants can be identified as necessary.

6.2.11.3 Only approved product line ORI checklists will be posted in this standard. See the appendix for links to the approved product line ORI checklists

6.2.12 Ensuring that an ORI is conducted for third party equipment sales and for installations owned by Air Products but installed within customer sites.

6.3 Operations Manager(s) are responsible for:

6.3.1 Ensuring that MBS ORI requirements are complete prior to startup of the equipment.

6.3.2 Reconciling recommendations resulting from the ORI.

6.3.3 Participating in the selection of ORI team members. Project and Regional Process Safety Managers share this responsibility with the Operations Manager(s).

6.3.4 Ensuring that employee participation requirements for ORIs are met.

6.3.5 Adding ORI information to the hazard review report as needed.

6.3.6 Providing a method for closing out of and tracking closure of any ORI items that the Project Manager transfers in accordance with paragraph 5.4.7.

6.3.7 Managing changes to an existing plant site. The Operations Manager or designee may have assumed responsibility for overall project execution. In such cases, the appropriate individuals from the site will assume the overall responsibility for the ORI. These responsibilities must be identified in a scope report or technical description for the project.

6.3.8 Maintaining records of the ORI at the site for Air Products owned or operated facilities. This is the responsibility of the Operations Manager or designee. The records of the ORI are to be retained in accordance with the record retention guidelines of the group.

6.4 The Chairperson of the ORI Team is responsible for:

6.4.1 Scheduling the ORI(s).

6.4.2 Ensuring that all relevant information is either sent or made available to all ORI team members and others who need the information before and following each ORI.

6.4.3 Ensuring that any questions, study items, and recommendations are addressed at an appropriate level of detail to justify completion of the item.

6.5 ORI Team

6.5.1 Selection of ORI team members shall be performed by a team consisting of the Project Manager and Regional Process Safety Manager and/or Operations Manager or their designees.

6.5.2 The ORI team membership will vary depending on the project scope, the degree of complexity of the project, and/or the technology involved.

6.5.3 The ORI team members must have the following understanding or knowledge:

- Understanding of the risks to the company based on the project scope

- Knowledge of regulations, policies, and corporate standards that impact the project

- Knowledge of the chemical process

- Knowledge of the equipment installed at the site and the ability to evaluate compliance with the design intent

· Knowledge of the project execution strategy

- Knowledge of operating and maintenance responsibilities for the site.

- ORI Chairperson should have experience with the ORI work process and use of the ORI checklist.

6.6 Manager of EH&S Assurance

6.6.1 The Manager of EH&S Assurance is responsible for ensuring that audits for compliance with this standard are conducted at a frequency that meets regulatory or Air Products requirements.

- RELATED INFORMATION

7.1 U.S. Department of Labor; Occupational Safety and Health Administration (OSHA) and Environmental Protection Agency (EPA)

Å · OSHA 29 CFR–Part 1910.119–Process Safety Management of Highly Hazardous Chemicals.

Å · Environmental Protection Agency 40 CFR–Part 68–Accidental Release Prevention Requirements; Risk Management Programs Under Clean Air Act Section 112(R)(7).

7.2 European Directives

Å Council Directive 96/82/EC on the Control of Major Accidents Hazards Involving Dangerous Substances

7.3 Air Products EH&S Documents

Å 25-010901a Process Hazard Review Process

Å 25-010901b Operating Plant Hazard Review Process

25-010905 Management of Change

01.17.03 Facility Safety During Construction and Commissioning

7.4 Air Products Environment Document

Å 25-804 Hazard Reviews

Å Provided for background information only (not referenced in the text)

|

|||

Appendix A

Global ORI Checklist

The ORI checklist has suggested timing requirements for each ORI checklist item (MBS, MAS). It also includes a new column that gives guidance on whether each ORI item needs to be confirmed on the site (S) or whether it can be closed before going to the site for the onsite inspection (O).

Links to Approved Product Line ORI Checklists

Product supply teams may choose to develop product specific checklists to improve the ease of implementation of the ORI work process by removing checklist items that do not apply to a product, inserting standardized responses to ORI items or adding product specific checklist items. The following table provides links to approved product line specific ORI checklists.

| System | Checklist Owner | Link | |

| Bulk Liquid Gas Installations | Jim Lucas | http://apshare.apci.com/publish/GLOBPROCPUB/34Operations/34-030917.doc | |

| Food Freezers

Nitrogen Membranes and PSA Oxygen VSA up to 25 tonnes/day Micro VSA |

Mark Anderson | http://apshare.apci.com/publish/GLOBPROCPUB/34Operations/34-030917.doc | |

| Megasys | Gary Miller | http://apshare.apci.com/publish/GLOBPROCPUB/34Operations/Vol10/09101.doc | |

| Pipelines | Stephen D. Fisher (PA) | http://apshare.apci.com/publish/GLOBPROCPUB/28%20Engineering/28-PPL09012.doc | |

| Hydrogen Fueling Stations | Julie Granger | ||

| High Purity Nitrogen (HPN) | Nigel Lucas | In STAC under document NHPN-PROJ-9804C SH.2 (NOTE: This is not a link) | |

| Cabinets

Gas Room/Gas Pad VMB/VMP Houseline Pipeline BSGS Bulk Atmospheric Gas Spec Chem Bulk Chem Chem VMB Chem Room/Pad APCI Nitrogen Purifier Ambient Temp Purifier Atmospheric Purifier/ 3rd Party |

Gary Miller |