POWER TRANSFORMER INSTALLATION PROCEDURE

Industry Codes and Standards for Transformer

ANSI/NFPA 70

American National Standard Institute/National Electrical Code

ANSI/IEEE C57.106-2015

Guide for Acceptance and Maintenance of Insulating Mineral Oil in Electrical Equipment

ANSI/NETA ATS-2009

Standard for Acceptance Testing Specification for Electrical Power Equipment and Systems

TOOLS AND EQUIPMENT FOR TRANSFORMER INSTALLATION

Tools and equipment needed should be in good condition and must be checked by Supervisor / Safety Engineer prior to use in the construction area. These includes but not limited to:

- Boom Truck

- Electrical Hand Tools

- Mobile Crane

- Hydraulic Pallet Jack

- Spirit Level

- Torque Wrench

- Common Hand Tools

- Measuring tape

- Insulation Resistance Test Set

- Transformer Turn Ratio (TTR) Test Set

- Secondary Current Injection Unit

- Transformer Winding Resistance Test

- Current Transformer Test Set

- Power Factor/ Dissipation Test Set

- Digital multi-meter, Clamp on Ammeter, Thermometer

- 3ph, AC power Supply

All tools utilized in a classified area should be intrinsically safe and suitable for hazardous areas.

GENERAL PREPARATORY WORKS

- All permanent materials (including pre-fabricated supports), consumables, equipment to be installed and its accessories, construction area and resources shall be prepared and checked prior to installation works.

- Ensure that working areas are safe and ready for installation in coordination with other discipline for the use of the area.

- Work Transfer Sheet shall be duly signed and processed by other subcontractors or discipline for the preceding works to avoid confusion and discrepancies in the work responsibilities.

- Subcontractor shall appoint qualified employees to perform the activities in a safe manner. Such persons shall be capable of working safely and shall be knowledgeable on the precautionary techniques, personnel protective equipment, shielding and insulating materials and tools.

- A competent person will be designated by the sub-contractor who has the capability to identify the existing and predictable hazards in the surrounding or working conditions which are unsanitary, hazardous, or dangerous to personnel, and who has authorization to take prompt corrective measures to eliminate them.

- Study erection procedures of heavy power transformer prior to installation.

- Special tools shall bear a valid calibration certificates traceable to a national standard indicating calibration validity and periodically (at least six months) checked by a third party laboratory testing facility.

- Electrical materials shall conform to all applicable requirements, standard, and specifications prior to release to be used as part of the work.

- Review all references such as the latest approved for construction

(IFC) drawings, layout, and Technical Scope of Work. - All equipment related to power transformer installation works shall be checked after confirming the availability at company warehouse. Visual Inspection shall be conducted for possible factory or handling damage and recorded in appropriate QC Material Receiving Inspection Report form.

STORAGE, HANDLING AND PRESERVATION OF POWER TRANSFORMER

- Upon delivery of materials, QC Inspector will conduct receiving inspection as per Schedule G for Handling and Preservation to verify conformance to vendor drawings. Any deviation shall be documented through a QCIR.

- Verify impact recorder has been attached to transformer during shipment. Check the graph and observe abnormalities during transportation.

- If possible, the transformer should stored in its correct position on the prepared foundation at the installation site. If the permanent foundation is not ready, then the transformer must be stored on a solid platform that is suitably prepared to provide proper support for the transformer base.

- Transformer should be covered with plastic sheets. All equipment parts must be kept in the unopened original shipping case with all braces and plugs intact and shall be covered with plastic sheets.

- Air intake openings should remain covered to reduce dust, waster or other unwanted entry accumulation.

- Keep the bushings and external surface clean and the unconnected valves are closed.

- Regular visual inspection shall be conducted to check any dust accumulation, dampness, oil level, and silica gel air dryer on the transformer.

- Ground all bushing and the tank to prevent damage by unexpected lightning. Space heaters, when supplied in terminal chambers, and control cabinets shall be energized.

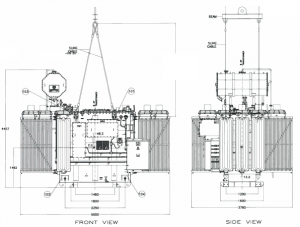

- Transformer should be lifted only through lifting points provided for attaching the slings or lifting chains.

- Use spreader beam with lifting chains or slings connected to the holes located on both sides near the top of the case.

- Check the total weight of the transformer prior for lifting. To ensure that the capacity of the crane to be used in lifting the transformer is suitable to the weight of the transformer.

- Check the tires of trailer truck and specification (whether low bed or high bed) prior to loading the transformer.

- Ensure the right position of the transformer at the trailer bed and it should be lightened with the steel chains prior to dispatch for installation.

POWER TRANSFORMER INSTALLATION

- Prior to hauling, review all possible routes and check obstructions to avoid delays in the activities. Hydraulic pallet jack and other necessary tools in mounting the equipment shall be check and ready upon receiving of equipment.

- Form works, grouting and finishing touch for concrete foundation shall be executed with respect to project standard specification.

- Obtain work transfer sheet from civil contractor for transformer foundation prior to bringing the transformer for installation.

- Transformer should be mounted on flat level pad strong enough to support the weight of the transformer. It should be installed in a safely manner and following the procedure provided by the transformer vendor (if any), and Approved for Construction (IFC) drawings.

- Conduct preliminary inspection to the completed installed transformer to ensure that all components have been installed completely and properly for final inspection.

- Ensure that nameplate and warning signs are properly installed accordingly to the transformer as per latest Approved for Construction (IFC) drawing.

- Transformer installed shall be properly grounded to the system grounding as per latest Approved for Construction (IFC) drawing and Saudi Aramco Standard.

- Transformer and its components shall be tested as per vendor’s recommendation and Saudi Aramco Test Procedure. Testing result shall be recorded/filed and submitted to Contractor.

NEUTRAL EARTHING EQUIPMENT INSTALLATION

- Study and check possible routes when bringing the equipment to its location to consider overhead clearances, turn radius and path are clear from any obstructions.

- Assemble all components carefully, following the instructions provided by the equipment vendor. Perform resistance measurement through bolted connections with a low-resistance ohmmeter, if applicable in accordance with NETA ATS 2009.

- Align the equipment and level to its location. Surveyor shall check its alignment and directions using the surveying equipment, as required.

- Install the equipment carefully avoiding possible damages to the equipment and maintain a safe work activity.

- Initial inspection to the completely installed equipment shall be conducted making sure that all requirements has been followed with respect to the latest Approved for Construction (IFC) drawings and equipment vendor’s instructions. Panels shall be opened up and inspected for cleanliness to ensure no foreign bodies are present. Dust and dirt shall be removed by using appropriate vacuum cleaner or rags.

- Perform resistance measurement through bolted connections with a low-resistance ohmmeter, if applicable in accordance with NETA ATS 2009. Connect all power connections and torque all bolted connection with the required value including bus bars using calibrated torque wrench in accordance with the manufacturer’s data and marked with a visual indicator.

- Formworks, grouting and finishing touches for concrete foundation shall be executed with respect to latest approved for construction (IFC) drawing and standard specification.

- Power capacitor and grounding resistor shall be properly connected to grounding system as per latest Approved for Construction (IFC) drawing and standard specification.

- Ensure that nameplate and warning signs are properly installed accordingly to the equipment as per latest Approved for Construction (IFC) drawing.

- Initial testing for insulation shall be conducted by Field Operation Group (FOG) and witnessed by QC Inspector; results shall be recorded and submitted to Contractor prior to pre-commissioning.

SAFETY PRECAUTION FOR TRANSFORMER INSTALLATION

- Secure the approved work permit from the concerned Representative before starting any work.

- Fire Watcher with Fire Extinguisher shall be assigned at work area whenever there is hot work.

- All electrical tools shall be checked and color-coded.

- Hazardous area and its precautionary measure requirements shall be properly discussed to the working crew following all safety requirements.

- Continuous monitoring and checking shall be conducted by concerned supervisor/foreman to detect and correct unsafe practices while performing the work activities.

- Provide warning sign and sufficient barricade on working areas to avoid unauthorized entry. Only assigned personnel shall be allowed in the area.

- Safety harness with double lanyards shall be used when working at elevated temporary platforms (1.8 meters and above).

- Safety Supervisor shall monitor the work activities to help and protect all assigned workers against exposure to safety hazards. He shall ensure that Personal Protective Equipments (PPE’s) are being supplied and used and shall comply with Saudi Aramco applicable general instruction and standards.

- Toolbox meeting shall be conducted by Electrical Supervisor daily so that work activities will be properly coordinated to all concerned and all safety measures will be carried out on the entire work duration.

- Housekeeping shall be maintained and working area shall be kept clean and tidy in accordance with Site Housekeeping Procedure.

- Job Hazard and Risk Assessment of this procedure shall be disseminated and explained to workers for safety awareness.