1. SCOPE

2. REFERENCES

3. DEFINITIONS

4. GENERAL REQUIREMENTS

5. PHYSICAL LIMITATIONS 5.1 Threading Requirements 5.2 Jack Screws 5.2 Bolt Selection 5.3 Bolt Lengths and Sizes 5.4 Bolt Length 5.5 Flanges Not Covered

5.6 Washers

6. MATERIAL LIMITATIONS 6.1 General Process 6.2 Low Temperature 6.3 Materials for Upper Intermediate Temperature Services 6.4 Materials For Sour Service 6.5 Machine Bolts 6.6 Expansion and Contraction

7. PURCHASE DESCRIPTION FOR BOLTS

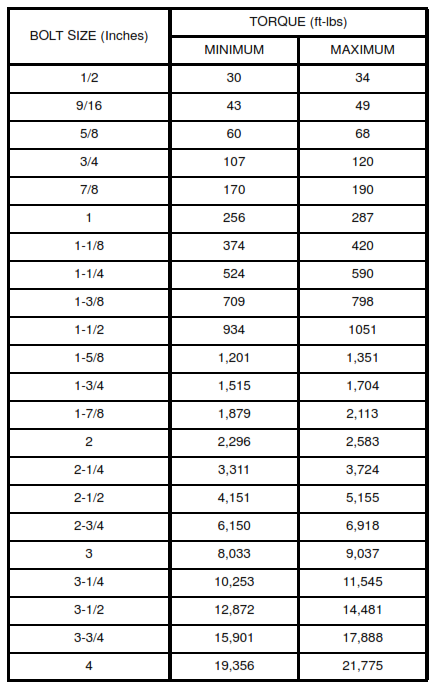

TABLE

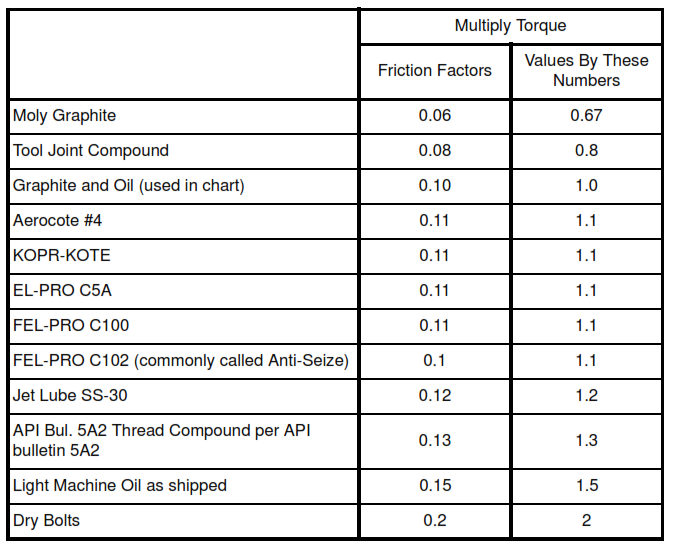

I Torque Value for A193 B7 and B7M Stud Bolts with A194 2H and 2HM Nuts II Friction Factors for Different Lubricants

1. Scope

This standard supplements the ASME B31 codes and defines mandatory requirements governing the

selection of bolting to complete flanged joints.

2. References

The selection of material and equipment, and the design, construction, maintenance, and repair of

equipment and facilities covered by this standard shall comply with the latest edition of the references

listed below, unless otherwise noted.

American Petroleum Institute (API)

6A Specification for Wellhead and Christmas Tree Equipment

American Society for Testing and Materials (ASTM)

A 193 Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for High Temperature

Service

A 194 Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure and

High-Temperature Service

A 307 Standard Specification for Carbon Steel Bolts and Studs, 60 000 psi Tensile Strength

A 320 Standard Specification for Alloy Steel Bolting Materials for Low-Temperature Service for

Pressure and High-Temperature Parts

A 563 Standard Specification for Carbon and Alloy Steel Nuts

American Society of Mechanical Engineers (ASME)

B1.1 Unified Inch Screw Threads

B16.1 Cast Iron Pipe Flanges and Flanged Fittings

B16.5 Pipe Flanges and Flanged Fittings

B16.47 Large Diameter Flanges

B31.1 Power Piping

B31.3 Process Piping

B31.4 Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum Gas, Anhydrous Ammonia,

and Alcohols

B31.8 Gas Transmission and Distribution Piping Systems

American Water Works Association (AWWA)

Manufacturers Standardization Society

SP-44 Steel Pipe Line Flanges

National Association of Corrosion Engineers (NACE)

MR0175 Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment

3. Definitions

For the purpose of understanding this standard, the following definitions apply.

Stud Tensioner. A device that stretches studs to the load position, and the nuts are tightened hand tight

only.

Weak Bolts. Delicate and brittle systems are bolted with bolting that is intentionally weaker than the

flanges, so the bolts will fail before a flange can be damaged.

4. Selection of Bolts to Complete Flanged Joints | ASME B31 General Requirements

4.1 Physical Limitations.

4.2 Material Limitations.

5. Physical Limitations

5.1 Threading Requirements

All threads shall be in accordance with ASME B1.1.

5.2 Jack Screws

Jackscrews, shall be used to facilitate flange separation for maintenance. Joint assemblies which often

require frequent separation include orifice plates, spectacle plates, spacers, screens, and drop-out spools.

Piping layout shall be designed such that flanges can be separated without excessive force. Jackscrews

shall be installed to be accessible from both sides of the pipe. For orifice flanges, jackscrews shall be

installed at 3 and 9 o’clock positions. When flange separators are used, jackscrews are not required. Jack

screws shall be the same material as the flange bolts.

5.2 Bolt Selection

Bolting for flanged joints shall be selected for service by service temperature, and corrosivity of the

environment.

5.3 Bolt Lengths and Sizes

Bolt length and diameter is determined by the flange standard used. Each of the following flange standards

has a method for the determination of bolt length.

a. ASME B16.1

b. ASME B16.5

c. ASME B16.47

d. API 6A Type 6B

e. MSS SP-44

f. AWWA

5.4 Bolt Length

Bolts shall be expressed with inch diameters, and the length in millimeters, rounded up to the nearest 5

mm.

5.5 Flanges Not Covered

Flanges not covered by the above standards shall be considered non standard, and bolting is to be

handled on an individual basis.

5.6 Washers

5.6.1 Flat Washers

Flat washers under the nuts are required for special cases only, such as on insulating flanges and under

the nuts bearing against plastic flanges.

5.6.2 Belleville Washers

Belleville washers may be required for severe cyclic service, and bolt service temperatures above 450 deg C.

6. Material Limitations

6.1 General Process

Materials for process and general services shall be ASTM A193 Grade B7 stud bolts with ASTM A194

Grade 2H nuts for service temperatures from minus 20 to plus 450 deg C.

6.2 Low Temperature

Materials for low temperature services shall be as follows:

a. Stud bolts conforming to ASTM A320 Grade L7 with nuts to ASTM A194 Grade 4 or 7 shall be

used for bolt service temperatures from minus 18 to minus 101 deg C.

b. ASTM A320 Grade L7M studs and A320 Grade 7M nuts may be used for low temperature

services from minus 18 to minus 73°C.

c. Stud bolts conforming to ASTM A320 Grade B8 with nuts to ASTM A194 Grade 8 shall be used

for bolt service temperatures from minus 101 to minus 195 deg C

6.3 Materials for Upper Intermediate Temperature Services

6.3.1 ASTM A193 Grade B7 or B7M studs with A194 Grade 7 or 7M nuts for services up to 450 deg C.

6.3.2 ASTM A193 Grade B16 stud bolts with A194 Grade 7 nuts, for bolt service temperatures from 450 to

510 deg C.

6.3.3 When spiral wound gaskets are used for high temperature, the bolts must provide adequate stress to

seat the gasket. When B8 class 2 bolts are used for temperatures over 650°C, strain hardened bolts will

be required to seat the gasket. Widings for high temperature gaskets are most likely type 347, or inconel.

At temperatures over 650°C, strain hardened will anneal. As long as the joint is not broken, the annealed

bolts have adequate strength to hold the joint.

6.4 Materials For Sour Service

Materials for sour services shall be as follows:

6.4.1 Standard quenched and tempered ASTM A193 Grade B7 stud bolts with 2H nuts shall be used for

sour wet services when the bolting is as follows:

a. Not directly exposed to hydrogen sulfide

b. Not buried or insulated

c. Not equipped with flange protectors, or not deprived of direct atmospheric exposure.

ASTM A320 Grade L7 stud bolts with Grade 4 or 7 nuts can be used under the same conditions.

6.4.2 Stud bolts conforming to ASTM A193 grade B7M with nuts to A194 Grade 2HM shall be used under

the following conditions:

a. Direct exposure to sour environments

b. When the bolting will be buried or insulated

c. When the flange is equipped with flange protectors, or otherwise deprived of direct atmospheric

exposure.

ASTM A320 Grade L7M bolts and Grade 7M nuts can be used under the same conditions.

6.5 Machine Bolts

Steel machine bolts conforming to ASTM A307 Grade B may be used on flat-faced cast-iron or

non-metallic flanges in non-sour environment. Nuts shall conform to ASTM A563 Grade D. This bolt and

nut combination may be used in sour services when the Grade D nuts are not resulfurized. This system is

also suitable when the use of “weak” bolting is specified to avoid overloading flanges. Such bolting may be

zinc coated.

6.6 Expansion and Contraction

When fluid temperatures are below minus 45 deg C, the selection of bolting material or the bolting design

shall include consideration of differential contraction between flanges and bolts such that changes in

gasket seating pressure will not result in leakage. Similarly, differential expansion shall be considered at

operating temperatures above 300 deg C.

7. Purchase Description for Bolts

The following information shall be included in the Purchase Description:

a. Type of Bolt

b. Fit

c. Material

d. Material Grade

f. Size of bolt, diameter X length

h. Additional requirements

The additional requirements may be simple, or be a reference to a specification.

TABLE I

Torque Value for A193 B7 and B7M Stud Bolts with A194 2H and 2HM Nuts

Note: The torque values used above are based on an average

friction factor of 0.10. The friction factor is a combination of various

components due to s such as considerations as the conditions of

the threads, the relationship between the flange to the nut bearing

surface and the type of lubricant used. These variables make up

the friction factor which can vary from 0.04 to 0.20 or as much as

500 percent.

TABLE II

Friction Factors for Different Lubricants