Jet engines, also known as gas turbine engines, come in several types, each designed for specific aircraft and performance requirements:

- Turbojet Engines: These are the simplest form of jet engines and consist of a compressor, combustion chamber, turbine, and nozzle. They are most commonly found in military aircraft and early commercial jets. Turbojet engines operate efficiently at high speeds but are less fuel-efficient at lower speeds.

- Turbofan Engines: Turbofan engines are widely used in commercial airliners due to their fuel efficiency and quieter operation. They consist of a large fan at the front, which provides additional thrust by bypassing air around the engine core. Turbofans are categorized into low-bypass, medium-bypass, and high-bypass engines based on the ratio of bypass air to core air.

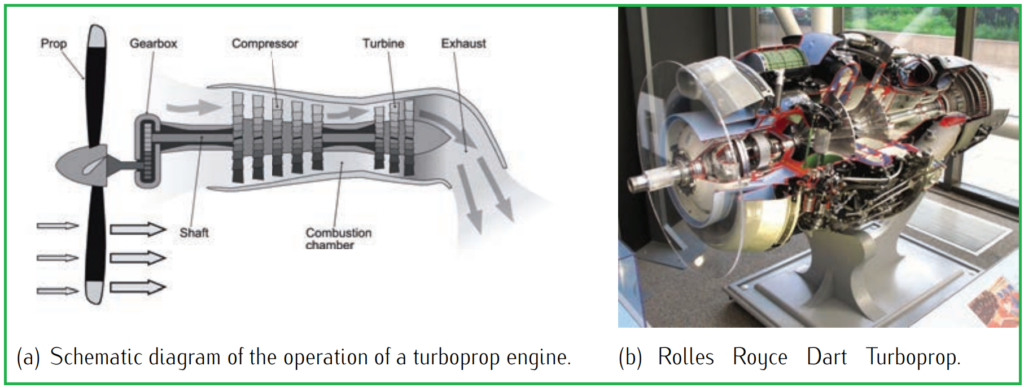

- Turboprop Engines: Turboprop engines are used primarily in smaller aircraft and regional airliners. They feature a gas turbine engine that drives a propeller through a gearbox. Turboprops are known for their fuel efficiency and are suitable for short to medium-haul flights.

- Turbo-shaft Engines: Turbo-shaft engines are similar to turboprops but are used to drive rotary-wing aircraft such as helicopters. They provide power to the rotor blades through a shaft, enabling vertical takeoff and landing capabilities.

- Ramjet Engines: Ramjet engines operate by compressing incoming air at high speeds without the need for a compressor. They are typically used in missiles and other high-speed applications where airflow is supersonic.

- Pulsejet Engines: Pulsejet engines operate on the principle of intermittent combustion, with fuel being injected into a combustion chamber and ignited periodically. They are relatively simple in design and have been used in applications such as model aircraft and cruise missiles.

Each type of jet engine has its advantages and limitations, making them suitable for different aircraft and mission requirements.

Types of Jet Engines

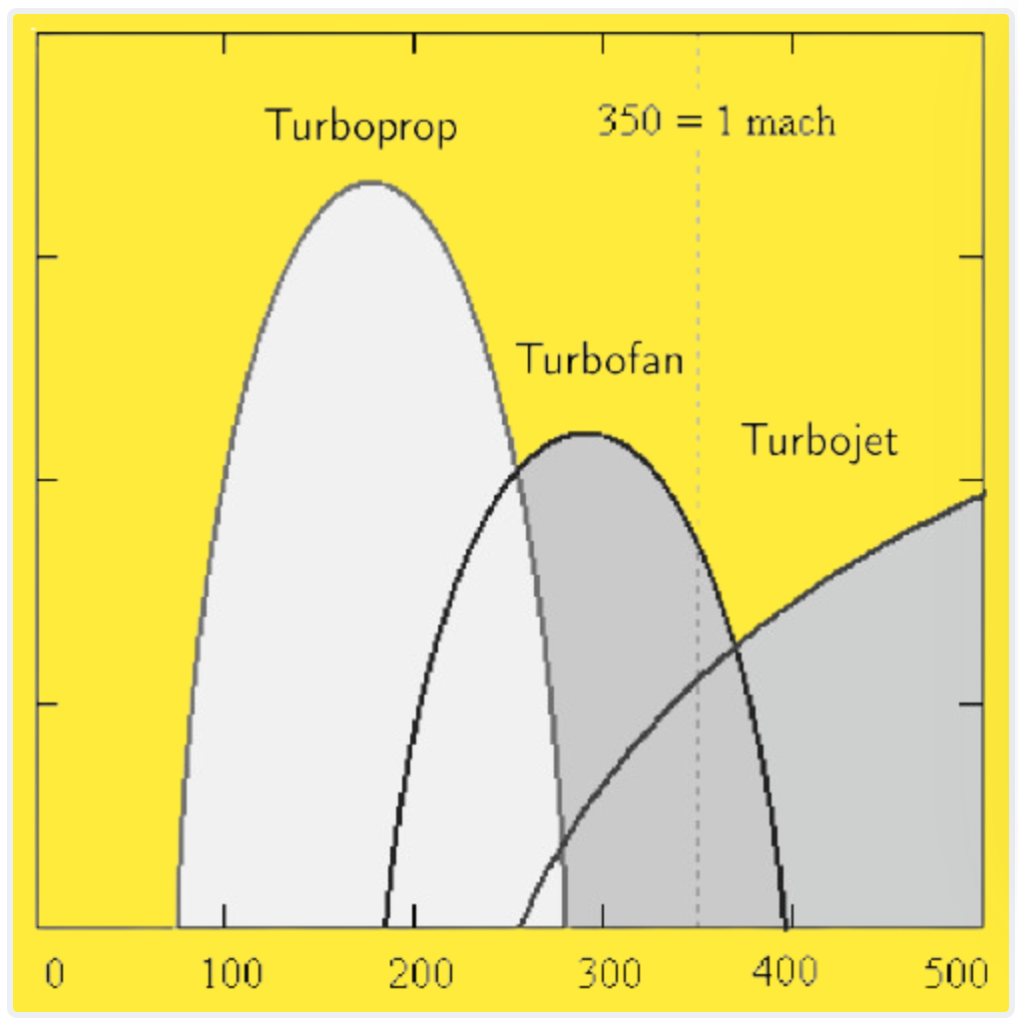

The discussion will now focus on some of the most important types of jet engines: turbojets, turbofans, turboprops, and afterburning turbojets. Figure below provides a visual representation of the relative suitability of these jet engine types for different flight regimes. Turboprops are noted for their efficiency in low subsonic regimes, making them ideal for shorter flights and regional aircraft. Turbofans excel in high subsonic regimes, offering efficient propulsion for commercial airliners and long-haul flights. Turbojets, including afterburning turbojets, are most effective in supersonic regimes, providing the necessary thrust for high-speed military aircraft and some early commercial jets. For even higher Mach numbers (exceeding 3-4), alternative propulsion systems such as ramjets, scramjets, or rockets are required, although these are beyond the scope of this article.

1. Turbojets

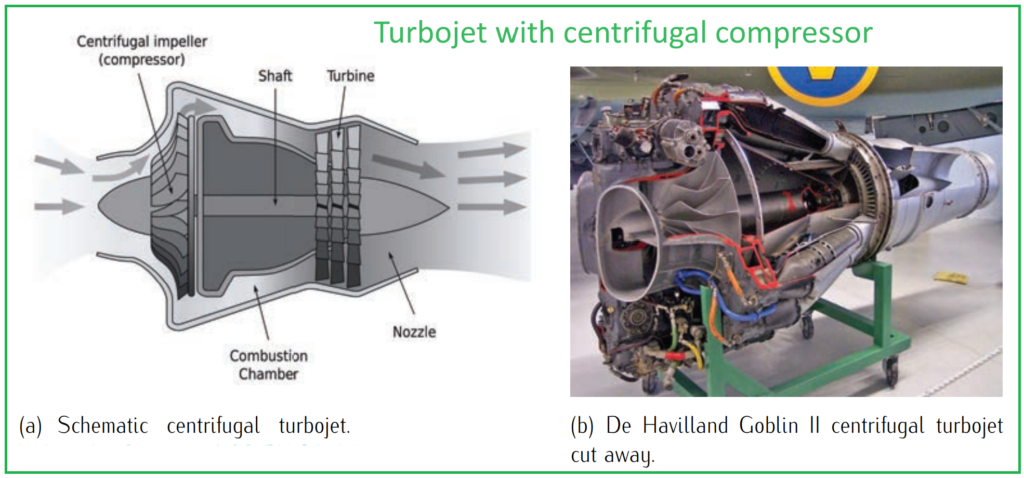

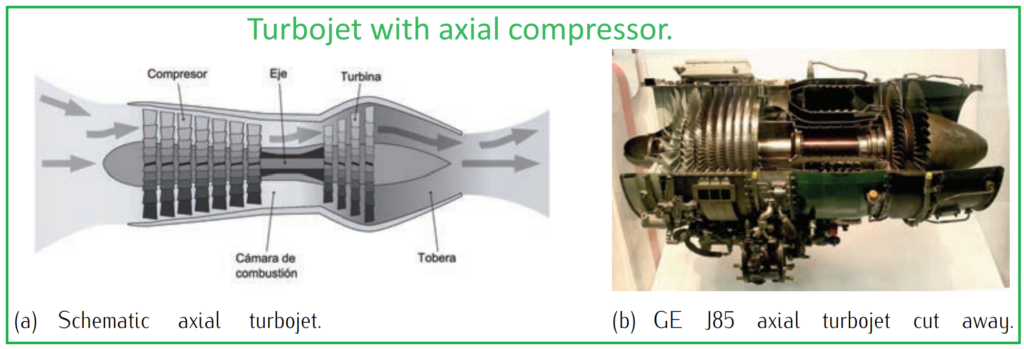

A turbojet engine consists of several key components, including an inlet, a compressor, a combustion chamber, a turbine, and a nozzle, as illustrated in Figure 1. The engine’s operation involves the intake of air through the inlet, compression of the air by the compressor, mixing of compressed air with fuel in the combustion chamber where combustion occurs, expansion of the high-temperature exhaust gases through the turbine to produce mechanical work, and finally, the ejection of exhaust gases through the nozzle to generate thrust. Turbojets can feature either axial or centrifugal compressors, with each type offering distinct advantages. Figures 6.12 and 6.13 provide schematic and real-life representations of turbojet engines with centrifugal and axial flow compressors, respectively.

2. Turbofans

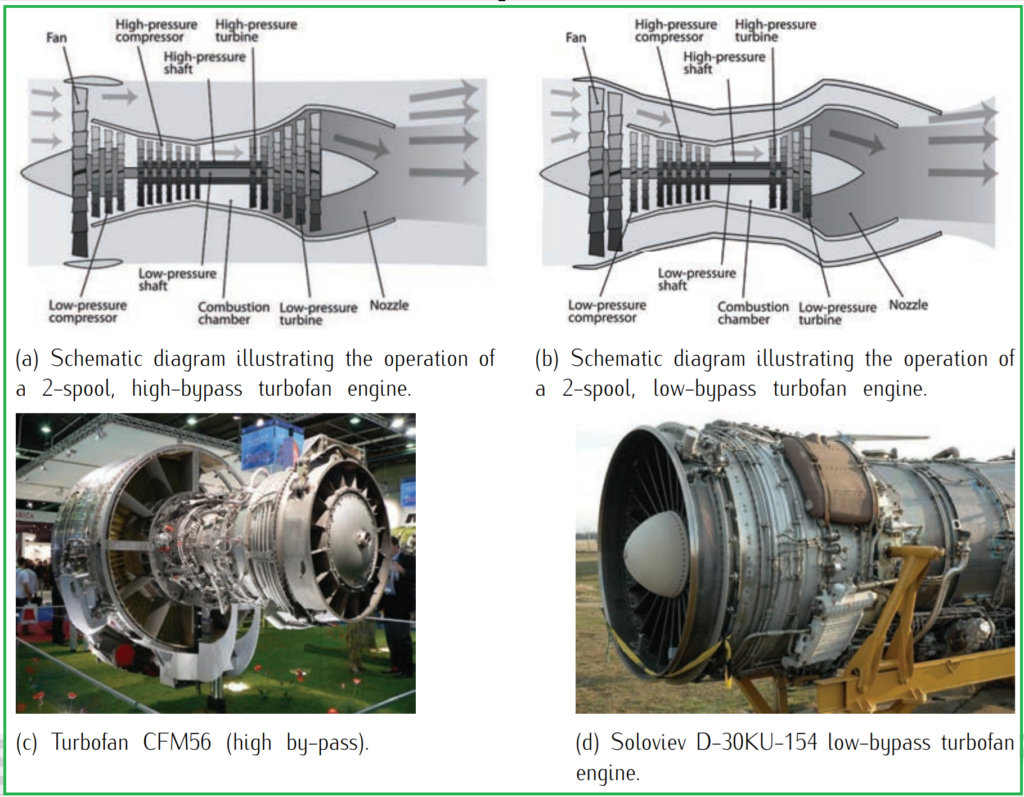

Turbofan engines are widely used in modern commercial aircraft due to their high thrust and fuel efficiency, particularly in high subsonic regimes. These engines are similar to basic jet engines but feature additional components, namely a fan at the front and an extra fan turbine at the rear, connected by a separate shaft. This configuration, known as a two-spool engine, allows for improved efficiency. Some turbofans may incorporate additional spools for even higher efficiency.

The operation of turbofans closely resembles that of basic jet engines: incoming air is drawn in through the engine inlet and passes through the compressor, combustor, turbine, and nozzle. However, in turbofans, some of the air is diverted through the fan, which causes additional airflow around (bypassing) the engine. This bypass airflow contributes to greater thrust and reduced specific fuel consumption. The ratio between the bypass airflow and the airflow passing through the core engine is termed the bypass ratio.

There are two main types of turbofans: high bypass and low bypass. High bypass turbofans feature large fans in front of the engine and are driven by a fan turbine located behind the main turbine that drives the compressor. In contrast, low bypass turbofans have a smaller bypass area and are more suitable for supersonic regimes.

Turbofans offer high fuel efficiency, with high bypass turbofans nearly rivaling turboprops at low speeds. Additionally, because the fan is integrated into the inlet, it operates more efficiently at high subsonic speeds compared to a propeller. Therefore, turbofans are typically employed in high-subsonic commercial aircraft, while propellers are used in low-speed transports like regional aircraft.

3. Turboprops

Turboprop engines are commonly utilized in regional aircraft. These engines consist of two main components: the core engine and the propeller. The core engine resembles a basic turbojet but differs in that instead of directing all the hot exhaust gases through the nozzle to generate thrust, a significant portion of this energy is utilized to drive the turbine. The shaft connected to the turbine then drives the propeller via gear connections, which generates the majority of the thrust.

In a turboprop engine, the total thrust is the combination of the thrust produced by the propeller and the small amount of thrust generated by the core engine. However, as aircraft speed increases, propellers become less efficient, limiting turboprops to low subsonic speed regimes.

A variant of the turboprop engine is the turboshaft engine, where the gearbox is not connected to a propeller but instead drives other devices. Turboshaft engines are commonly used in helicopters, where the power generated is directed to the rotor system for lift.

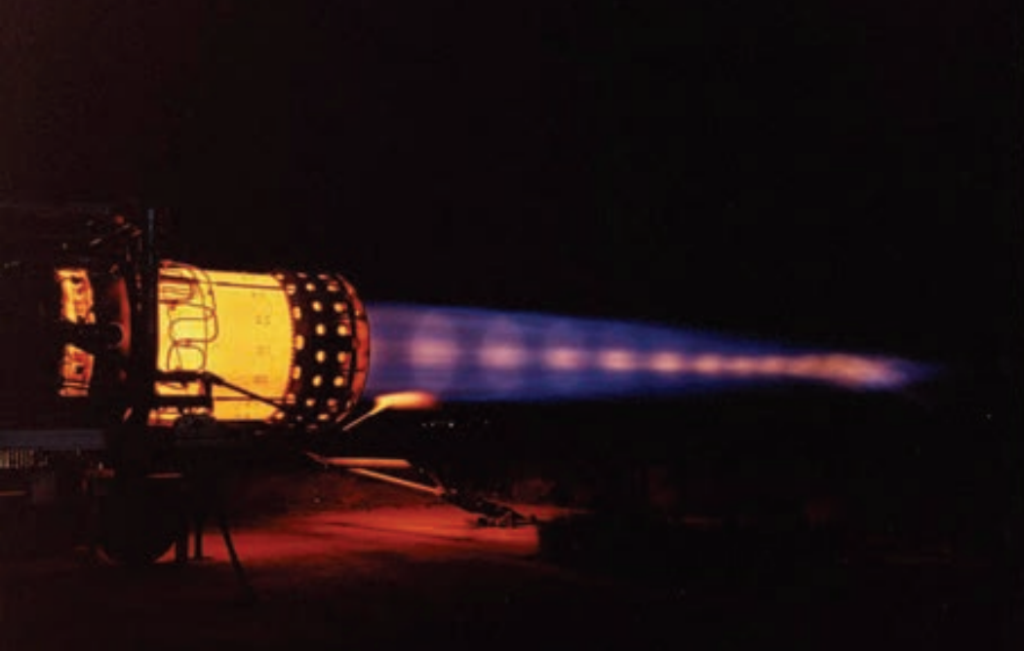

4. After-burning turbojet

The after-burning turbojet is a common feature in modern fighter aircraft, providing them with additional thrust when needed for maneuvers and mission requirements. Essentially, an afterburner is a long tailpipe into which extra fuel is injected directly into the hot exhaust and burned, generating additional thrust. When the afterburner is activated, the engine operates as a basic turbojet, but with increased exhaust velocity due to the higher temperatures involved. This allows fighter aircraft to achieve greater performance during sharp maneuvers and high-speed flights.

For even higher Mach numbers (exceeding 3-4), alternative propulsion systems such as ramjets, scramjets, or rockets are required, although these are beyond the scope of this article.