Pipe routing refers to the process of designing the layout or path for pipes within a system, such as a plumbing, heating, ventilation, air conditioning (HVAC), or industrial piping system. It involves determining the most efficient and practical routes for pipes to connect various components, such as fixtures, equipment, valves, and fittings, while considering factors such as space constraints, safety, functionality, and ease of maintenance.

What is Pipe Routing?

Pipe routing is an essential engineering practice utilized to select an appropriate piping layout that meets code and standard requirements, economic considerations, and, most importantly, safety regulations. Piping designers and engineers responsible for piping layout ensure the design of the most economical and safe piping route while considering all engineering requirements.

Pipe routing is a complex task and a fundamental aspect of piping engineering, particularly in industries such as oil & gas, chemical, and power plants. During pipe routing, engineers must adhere to various engineering requirements, including process specifications, accessibility, safety measures, constructability, maintenance needs, and operational criteria. To develop a technologically sound, economical, safe, and efficient pipe routing plan, piping professionals must effectively manage the following major piping components:

- Pipe and Pipe Fittings: Selecting appropriate pipes and fittings to ensure compatibility with the intended application, pressure, temperature, and fluid properties.

- Valves: Incorporating valves at strategic points along the piping route for flow control, isolation, and safety purposes.

- Pipe Support Systems: Designing and implementing support systems to ensure proper alignment, stability, and structural integrity of the piping system, considering factors such as thermal expansion, vibration, and loads.

- Instruments: Integrating instrumentation devices such as flow meters, pressure gauges, temperature sensors, and control valves to monitor and regulate the flow, pressure, and temperature within the piping system.

By effectively managing these key components, piping engineers can design and develop comprehensive pipe routing plans that fulfill technical, safety, and economic requirements, contributing to the successful operation of industrial piping plants.

How to design good pipe routing?

Designing a good pipe routing involves a systematic approach that considers various factors such as engineering requirements, safety standards, economic considerations, and operational needs. Here are some steps to guide you through the process of designing a good pipe routing:

- Input Reading and Interpreting Skills: The ability to read and interpret various inputs such as Piping and Instrumentation Diagrams (P&IDs), Piping Material Specifications (PMS), project specifications, engineering guidelines, codes and standards, equipment general arrangement (GA) drawings, and other design requirements is crucial. This ensures that the design aligns with project requirements and industry standards.

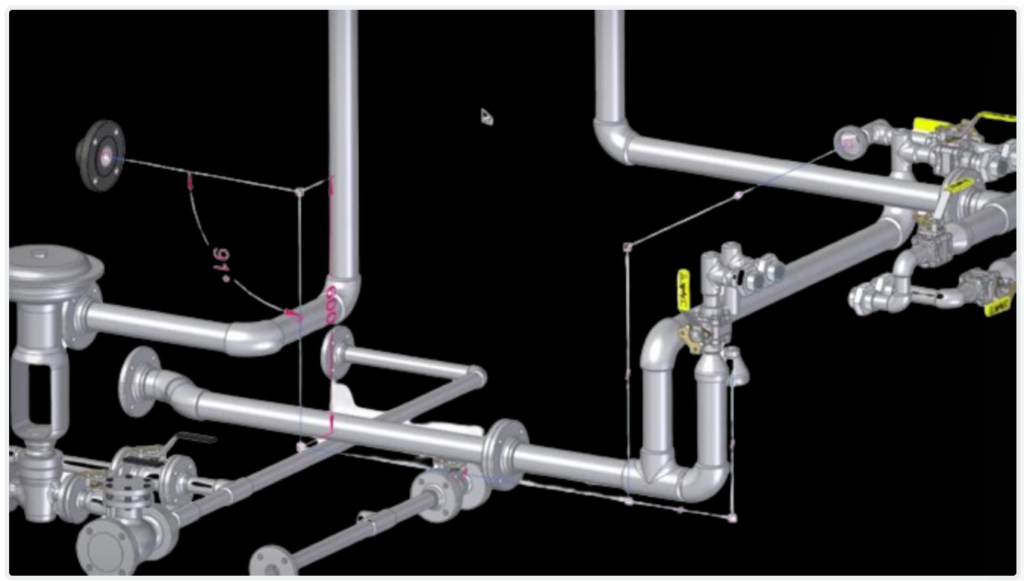

- 3D and 2D Software Skills: Proficiency in using both 2D and 3D software tools is essential for creating detailed piping layouts and models. Familiarity with software such as AutoCAD, CADWorx, Plant 3D, or PDMS enables the designer to efficiently develop and visualize pipe routing designs.

- Understand Requirements: Gain a thorough understanding of the project requirements, including process specifications, fluid properties, flow rates, pressure levels, temperature ranges, and environmental conditions.

- Comply with Codes and Standards: Familiarize yourself with relevant codes, standards, regulations, and industry best practices governing piping design, including safety guidelines such as ASME B31.1 (Power Piping) or ASME B31.3 (Process Piping).

- Consider Accessibility and Maintenance: Design the piping layout to ensure ease of access for maintenance activities, such as equipment servicing, valve operation, and pipe inspection. Consider providing adequate clearance around components and locating valves and instrumentation for convenient access.

- Ensure Safety: Prioritize safety by identifying potential hazards, such as high-pressure zones, hot surfaces, or corrosive environments, and implementing appropriate measures to mitigate risks, such as using safety valves, pressure relief devices, and corrosion-resistant materials.

- Optimize Layout: Plan the piping route to optimize space utilization, minimize pipe lengths, and reduce pressure drops. Consider factors such as pipe diameter, routing angles, and the avoidance of sharp bends or obstacles that could impede flow or create maintenance challenges.

- Address Thermal Expansion: Account for thermal expansion and contraction by incorporating expansion loops, expansion joints, or flexible connectors to accommodate temperature variations and prevent stress buildup within the piping system.

- Select Appropriate Materials: Choose materials that are compatible with the conveyed fluid, temperature range, pressure rating, and environmental conditions. Consider factors such as corrosion resistance, mechanical properties, and cost-effectiveness when selecting piping materials.

- Provide Adequate Support: Design and install pipe support systems to ensure proper alignment, stability, and load-bearing capacity. Use supports such as hangers, anchors, and guides to prevent sagging, vibration, and excessive movement of the piping system.

- Integrate Instrumentation: Incorporate instrumentation devices, such as flow meters, pressure gauges, and temperature sensors, at strategic locations to monitor and control process parameters effectively.

- Review and Iterate: Conduct thorough reviews of the piping layout to identify potential design flaws, conflicts, or inefficiencies. Iterate the design as needed to address any issues and optimize the overall performance and reliability of the piping system.

- Piping Skills: A strong understanding of piping components, including pipes, fittings, valves, instruments, and other inline items, is necessary. Knowledge of different types of piping materials, their properties, and compatibility with various fluids and operating conditions is also important. Additionally, expertise in designing piping supports, such as pipe hangers, anchors, and supports spans, ensures the structural integrity and stability of the piping system.

By following these steps and leveraging engineering expertise, you can design a good pipe routing that meets technical requirements, complies with safety standards, and achieves cost-effective and efficient operation.

Concepts of Pipe Routing

Pipe routing concepts encompass various principles and considerations involved in designing the layout of piping systems. Here are some key concepts:

- Support Placement and Selection: Support placement and selection are integral parts of pipe routing. Engineers must determine the locations for pipe supports based on factors such as pipe material, diameter, temperature, and support span. The selection of support types and placement must ensure structural integrity, minimize stress, and accommodate thermal expansion and contraction.

- Parameters for Finalizing Pipe Routing:

- Simple and Straight Routing: Whenever possible, routes should be straightforward to minimize material usage, reduce pressure drop, and simplify construction.

- Grouping Lines: Grouping together parallel lines reduces the number of support structures required and streamlines maintenance and inspection activities.

- Minimizing Fittings: The use of fewer fittings reduces costs and pressure losses in the system.

- Flexibility: Critical lines should be designed with sufficient flexibility to accommodate thermal expansion and contraction, as recommended by pipe stress analysis.

- Space Optimization: Efficient space utilization ensures that piping layouts fit within available infrastructure while allowing for safe operation and maintenance access.

- Expansion Loop Optimization: Expansion loops should be strategically placed to accommodate thermal expansion while minimizing the need for excessive loops.

- Clearance Considerations: Headroom clearance, accessibility of valves and equipment, bridge and road crossings, and provision for future expansions should be taken into account to ensure safety and maintainability.

- Clash Checking: Clash checking involves verifying that piping routes do not interfere with other structures, equipment, or piping systems. Consideration of thermal movements is essential to anticipate potential clashes under various operating conditions.

- Flow Optimization: Pipe routing aims to optimize the flow of fluids within a system. This involves designing routes that minimize frictional losses, pressure drops, and turbulence, while ensuring smooth and efficient flow from one point to another.

- Space Utilization: Efficient space utilization is crucial in pipe routing. Designers must consider available space, equipment layout, structural constraints, and accessibility requirements to determine the most compact and practical routing solutions.

- Safety: Safety is paramount in pipe routing. Engineers must ensure that piping layouts comply with safety codes, regulations, and industry standards to prevent hazards such as leaks, spills, and overpressure incidents. Proper routing also minimizes the risk of interference with other equipment or structures.

- Material Selection: Choosing the right materials for pipes, fittings, and supports is essential. Factors such as fluid properties, temperature, pressure, corrosion resistance, and cost must be considered to select materials that meet performance requirements and budget constraints.

- Thermal Expansion: Pipe routing must account for thermal expansion and contraction to prevent stresses and distortion in the system. Incorporating expansion loops, expansion joints, or flexible connectors allows pipes to expand and contract freely with changes in temperature.

- Accessibility and Maintenance: Accessibility for maintenance and inspection is critical. Piping layouts should provide clear access to valves, instruments, and other components for routine maintenance, troubleshooting, and repair activities.

- Support and Anchoring: Proper support and anchoring of pipes are necessary to maintain structural integrity and prevent sagging, vibration, and displacement. Engineers must design support systems that distribute the weight of the piping evenly and securely anchor pipes to the surrounding structure.

- Instrumentation and Control: Integration of instrumentation devices such as flow meters, pressure gauges, and control valves enables monitoring and control of process parameters. Pipe routing should accommodate the placement of instrumentation at strategic locations for effective operation and control of the system.

- Flexibility and Adaptability: Piping layouts should be flexible and adaptable to accommodate future modifications or expansions. Designers should anticipate potential changes in process requirements or system configurations and plan routing solutions that allow for easy modification and scalability.

By considering these parameters and conducting thorough planning and analysis, engineers can develop technically sound, cost-effective, and safe pipe routing designs for industrial piping systems.

Read Also: Plant Layout, Spacing and Clearances for Equipment Piping