In this article we are going to discuss about steam turbine working principle, its types and parts.

A steam turbine is a device that converts thermal energy from pressurized steam into mechanical energy, which can then be used to generate electricity or perform mechanical work. It is a type of rotary engine that operates on the principle of expanding steam to produce rotational motion.

Steam turbines are widely used for power generation in various industries and applications.

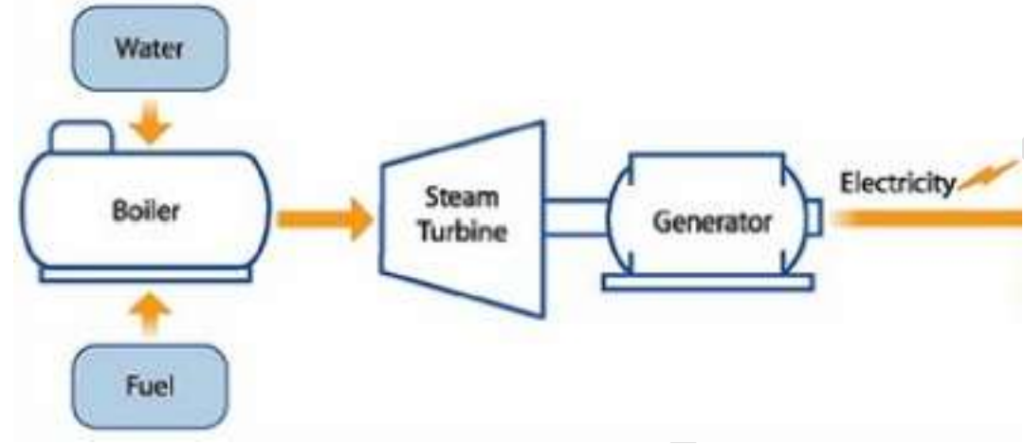

Steam Turbine Working Principle for Power Plant

In a steam turbine-based power plant, the process begins with the steam turbine, which acts as the primary engine. Its role is to consistently transform the energy from high-pressure, high-temperature steam, provided by a steam generator, into shaft work. This shaft work is essentially the mechanical energy used to drive various components within the power plant.

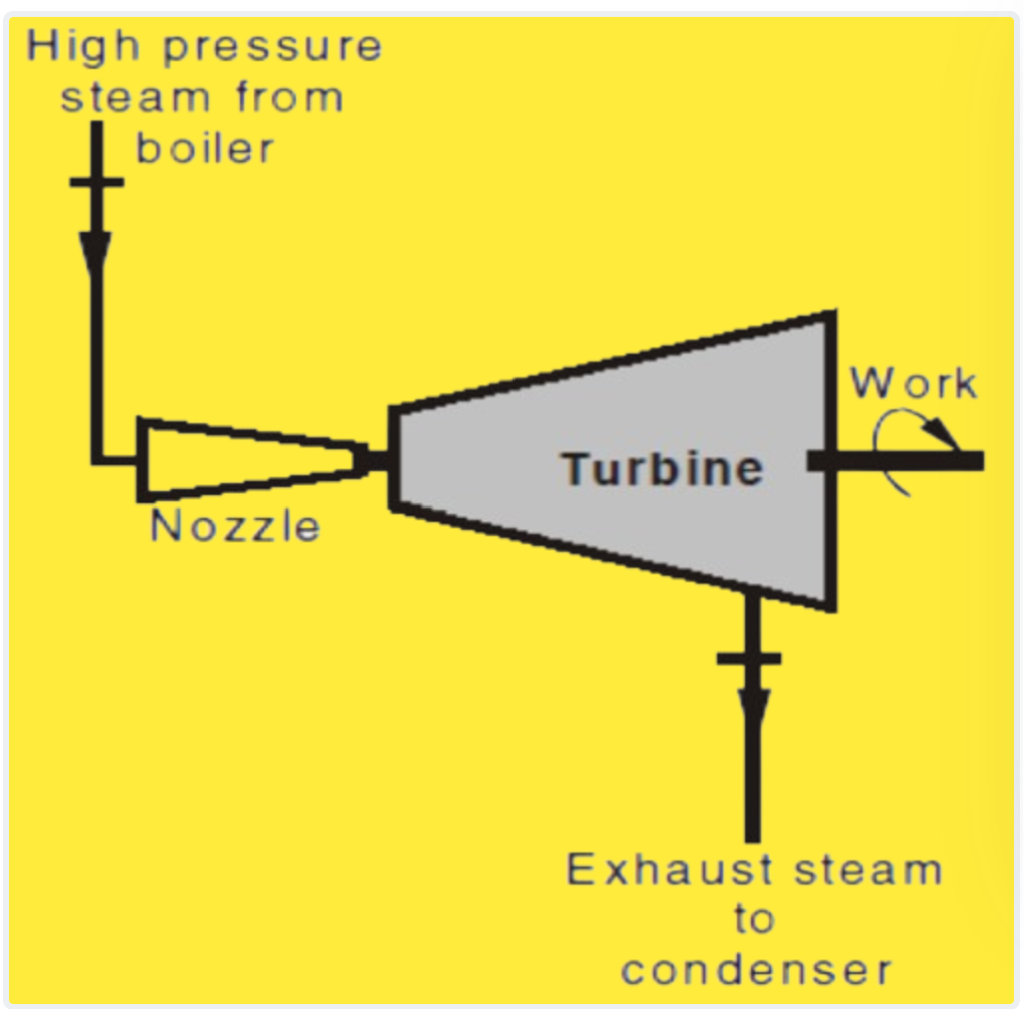

The steam turbine operates by directing the high-pressure steam onto a series of blades and nozzles. These components are meticulously arranged to efficiently harness the energy of the steam as it flows through them. As the steam passes over the blades, its pressure and temperature drop, causing the turbine blades to spin rapidly.

This spinning motion of the turbine blades generates mechanical energy, which is transmitted through a shaft connected to the turbine. This mechanical energy can be utilized to power electrical generators, machinery, or other equipment within the power plant.

Once the steam has passed through the turbine and performed its work, it exits the turbine at a lower temperature and pressure. This low-temperature steam is then directed to a condenser, where it is cooled and condensed back into water. The condensation process releases heat, which is typically transferred to cooling water circulating through the condenser.

The condensed water, now returned to its liquid state, is recycled and sent back to the steam generator to be reheated and transformed back into steam. This completes the steam cycle, allowing the continuous operation of the power plant.

Overall, a steam turbine-based power plant is an intricate system that efficiently converts the energy of high-pressure, high-temperature steam into mechanical energy, which is then used to generate electricity or perform other work within the plant. It relies on the precise arrangement of blades and nozzles in the turbine to harness the steam’s energy effectively.

Choice of steam turbine

When selecting a steam turbine for a power plant, several important factors must be considered:

(i) Capacity of Plant: The size and capacity of the power plant play a crucial role in determining the appropriate steam turbine. Larger plants typically require more powerful turbines capable of handling higher steam flow rates and generating larger amounts of electricity.

(ii) Plant Load Factor and Capacity Factor: The plant load factor, which is the ratio of average load to the maximum load, and the capacity factor, which is the ratio of actual output to maximum potential output, influence the choice of turbine. Turbines must be selected to match the expected operating conditions and demand fluctuations of the plant.

(iii) Thermal Efficiency: The thermal efficiency of the steam turbine, which measures its ability to convert heat energy into mechanical work, is an essential consideration. Higher thermal efficiency turbines are preferred as they result in greater energy output for a given amount of fuel input.

(iv) Reliability: The reliability and durability of the steam turbine are critical factors in ensuring continuous and uninterrupted operation of the power plant. Turbines with a proven track record of reliability and minimal downtime are preferred to minimize maintenance and repair costs.

(v) Location and Water Availability: The location of the power plant relative to the availability of water for condensation is important. Steam turbines require a reliable source of water for condensing steam back into water after it passes through the turbine. Plants located near abundant water sources have more flexibility in turbine selection.

Overall, the choice of steam turbine depends on a combination of factors including plant capacity, operational efficiency, reliability, and environmental considerations. It’s essential to carefully evaluate these factors to select the most suitable turbine for the specific requirements of the power plant.

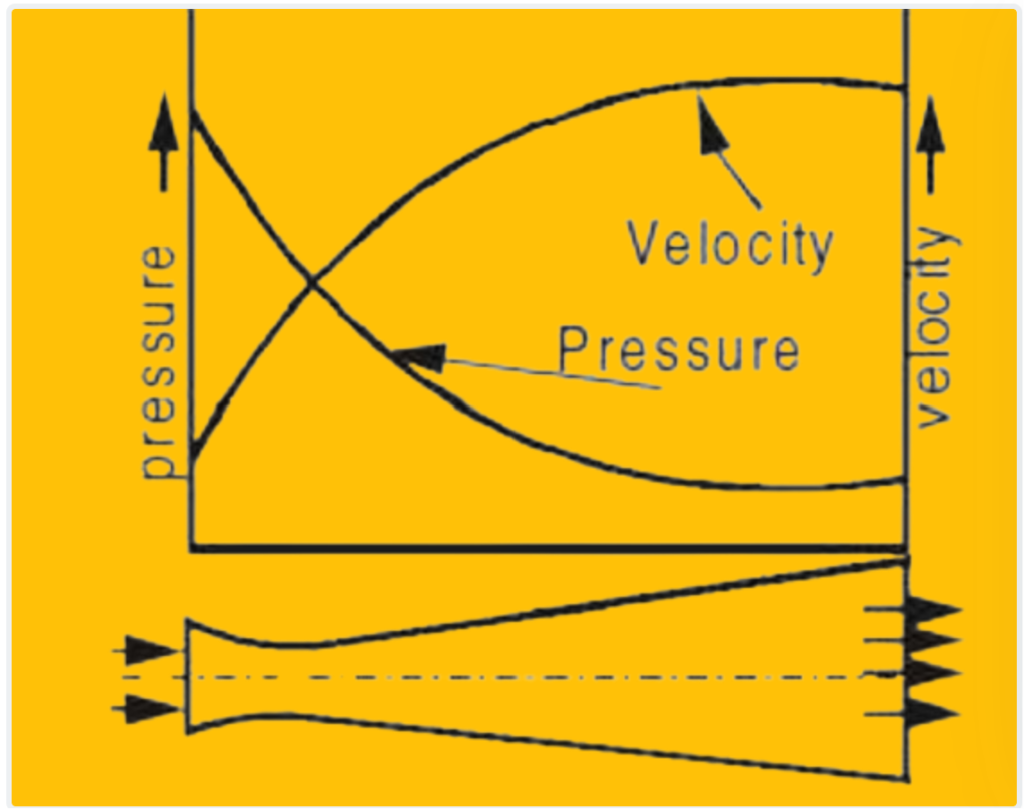

Flow through Nozzle:

Flow through a nozzle involves the passage of fluid through a duct where its velocity increases at the cost of a pressure drop. Initially, at the entrance of the nozzle, the fluid’s velocity is low while its pressure is high. As the fluid passes through the nozzle, it expands, resulting in a decrease in pressure but an increase in velocity.

Types of Steam Turbines:

Based on the types of blades used and the method of energy transfer from the fluid to the rotor wheel, turbines can be classified into two main types:

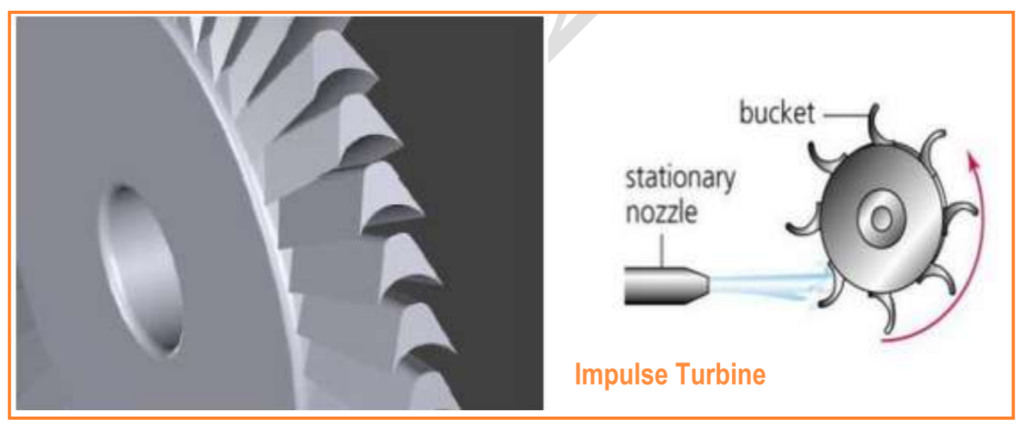

1. Impulse Turbine (e.g., De-Laval, Curtis, and Rateau):

- In an impulse turbine, there is no change in the pressure of the steam as it moves through the rotor blades.

- The steam enters the turbine at high pressure and passes through a nozzle, where its velocity increases significantly.

- The high-velocity steam jet strikes the blades of the turbine, causing them to rotate.

- The rotation of the turbine shaft is driven by the force resulting from the change in momentum of the steam.

Get More Technical Details about Impulse Turbine. Where included Impulse Turbine Working Principle, Compounding, Calculation etc..

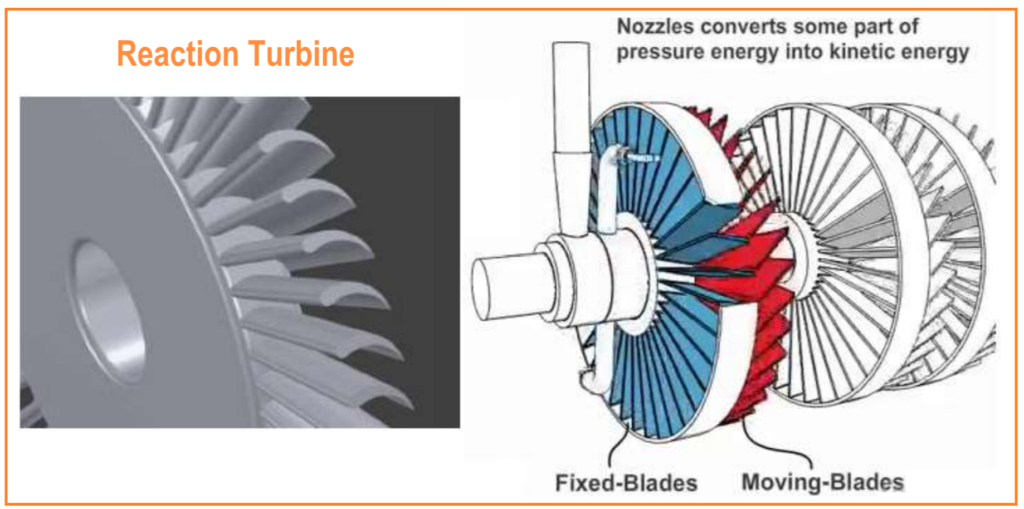

2. Reaction Turbine:

- In a reaction turbine, both pressure and velocity of the steam change as it flows through the rotor blades.

- The steam leaving a fixed blade (acting as a nozzle) enters the curved blades, where it glides over the inside surface.

- As the steam passes through the curved blades, both its pressure and velocity are altered.

- The steam then exits the blades from the other edge, having transferred some of its energy to the turbine rotor, causing it to rotate.

These two types of turbines differ in their method of energy transfer from the fluid to the rotor wheel. Impulse turbines rely solely on the change in velocity of the steam, while reaction turbines utilize both changes in pressure and velocity for energy conversion.

Get More Technical Details about Reaction Turbine. Where included Reaction Turbine Working Principle, Calculation etc..

Losses in steam turbines

Losses in steam turbines can significantly impact their efficiency and performance. Here are some common types of losses:

- Admission Losses: These occur when steam enters the turbine and experiences a decrease in kinetic energy due to various factors such as viscous forces, heat loss, deflection, turbulence, and friction in the nozzles.

- Leakage Losses: Steam leakage across seals and joints can result in energy losses, reducing the overall efficiency of the turbine.

- Friction Losses: Frictional resistance encountered by steam as it flows through the turbine’s nozzles and over the moving and stationary blades contributes to energy losses.

- Exhaust Losses: Despite operating at low pressure, the steam exiting the turbine and entering the condenser still retains some kinetic energy and useful enthalpy, representing a direct loss of energy.

- Radiation and Convection Losses: Steam turbines operate at high temperatures, causing some of the heat energy to be radiated and convected from the turbine’s body to its surroundings, resulting in energy losses.

- Losses due to Moisture: Steam passing through the last stage of the turbine may have a high velocity and significant moisture content, leading to energy losses.

Minimizing these losses through proper design, maintenance, and operational practices is crucial for improving the efficiency and performance of steam turbines.

What is steam turbine and how it works?

What is the function of the turbine?

What are the three stages of steam turbine?

High Pressure (HP) Stage: In this stage, high-pressure steam from the boiler is admitted into the turbine. The steam expands and passes through the HP turbine blades, causing them to rotate. This stage is responsible for extracting energy from the high-pressure steam and converting it into mechanical work.

Intermediate Pressure (IP) Stage: After passing through the HP turbine, the steam enters the IP stage. Here, it undergoes further expansion and drives the IP turbine blades, contributing to additional rotation of the turbine shaft. The IP stage helps to extract more energy from the steam before it enters the final stage.

Low Pressure (LP) Stage: The steam exiting the IP stage is directed to the LP stage. In this stage, the remaining energy in the steam is extracted, and the LP turbine blades are driven by the expanding steam. The LP stage completes the energy extraction process from the steam, maximizing the overall efficiency of the turbine.