Unmanned Aerial Vehicles (UAVs), commonly known as drones, have revolutionized various industries and sectors with their versatility, efficiency, and accessibility. These aircraft operate without a human pilot onboard and can be remotely controlled or autonomously programmed to perform a wide range of tasks. From recreational use to commercial applications, UAVs have become integral tools in fields such as aerial photography, agriculture, infrastructure inspection, surveillance, and search and rescue operations.

What is Unmanned Aerial Vehicles (UAV)?

UAV Introduction

The 21st century has witnessed a significant surge in unmanned and autonomous flight, akin to the revolution in manned flight experienced in the 20th century. Unmanned aerial vehicles (UAVs), commonly known as drones, have become indispensable tools across various sectors including industry, academia, and hobbies. These are also called Unmanned Aerial System, Unmanned Aircraft System and Remotely Piloted Aircraft.

Propelled by advancements in microcontrollers, sensing technology, and control systems, UAVs have rapidly proliferated and are now a ubiquitous presence in the modern world. While initially prevalent in military applications, the affordability and versatility of UAVs have spurred their adoption in commercial markets, with ongoing technological advancements likely to drive further growth.

Despite the diverse range of applications, certain fundamental aspects remain consistent across UAV use cases. Understanding these foundational elements is crucial for individuals intending to utilize UAV technology in their professional or research endeavors. This chapter provides an overview of UAV history, current market dynamics, and essential fundamentals including components, mechanics, and regulations. Various classification systems categorize UAVs based on propulsion systems, structure, size, and mass, facilitating a better understanding of their capabilities and limitations.

Regulatory frameworks governing UAV operations are evolving, presenting challenges and opportunities for industry and research applications alike. The chapter delves into UAV regulations and their potential implications, highlighting the need for compliance and adaptation to changing regulatory landscapes. Additionally, the discussion focuses on rotary-wing UAVs due to their increasing prevalence and diverse applications.

The definition of a UAV is refined within the chapter to distinguish it from other aerial devices, emphasizing its autonomy, aerodynamic lift capability, and payload capacity. Terminology surrounding UAVs varies widely, with terms like “unmanned aircraft system” (UAS), “remotely piloted aircraft” (RPA), and “drone” used interchangeably but with subtle distinctions. While some sectors prefer technical terms, the term “drone” has gained widespread usage in the general public and consumer markets. In this chapter, UAV and drone are used interchangeably to describe the aircraft itself, while UAS refers to the integrated system comprising the UAV, ground-based controller, and communication system.

UAVs often feature additional equipment such as cameras, sensors, or other payloads to enhance their functionality and utility. As technology continues to advance, UAVs are expected to play an increasingly integral role in various fields, driving innovation, efficiency, and productivity across industries.

Classification of Unmanned Aerial Vehicles

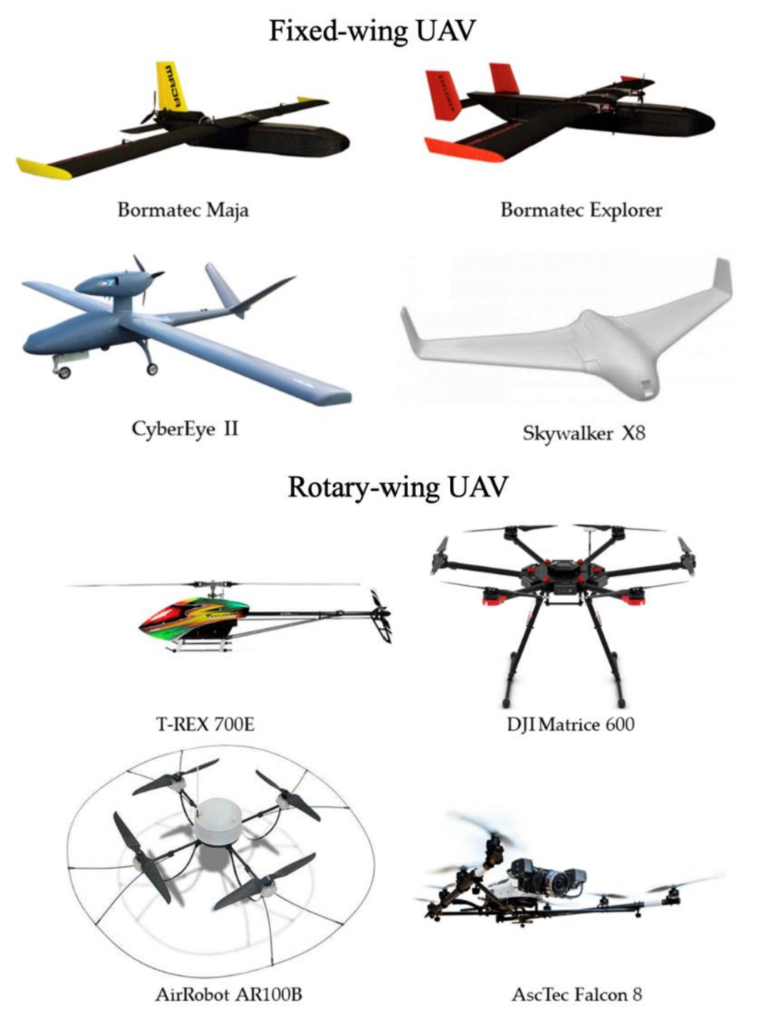

The two primary forms of UAVs are fixed-wing and rotary-wing, each with distinct characteristics and advantages:

- Fixed-Wing UAVs:

- Operate similar to traditional airplanes, generating lift from wings as they move forward through the air.

- Classified as horizontal takeoff and landing (HTOL) vehicles.

- Require a runway for takeoff and landing.

- Generally have longer flight times and range compared to rotary-wing UAVs due to their aerodynamic efficiency.

- Suitable for applications requiring extended endurance and covering large distances, such as aerial mapping, surveillance, and long-range reconnaissance.

- Rotary-Wing UAVs:

- Also known as multirotor, rotorcraft, or multi-copter UAVs, they generate lift from rotating propellers.

- Classified as vertical takeoff and landing (VTOL) vehicles.

- Can hover in place and maneuver in tight spaces, making them suitable for tasks that require stationary observation or close-quarters operations.

- Common configurations include quadcopters (four rotors) and hexacopters (six rotors), providing redundancy and stability.

- Generally less efficient in terms of flight time and range compared to fixed-wing UAVs but offer greater maneuverability and versatility.

- Ideal for applications such as aerial photography, inspection of infrastructure, search and rescue operations, and indoor surveillance.

Additionally, there are hybrid UAVs and flapping-wing UAVs, although they are less common:

- Hybrid UAVs: Combine features of both fixed-wing and rotary-wing UAVs, offering flexibility to operate in either mode. However, they tend to be heavier and less reliable than dedicated configurations.

- Flapping-Wing UAVs: Mimic the flight mechanics of birds and insects, typically designed for small-scale applications. They offer reduced flexibility and stability compared to other types of UAVs.

In summary, fixed-wing UAVs excel in tasks requiring long-endurance flights and covering large areas, while rotary-wing UAVs are more maneuverable and suitable for close-range operations or tasks that require hovering capabilities. Hybrid and flapping-wing UAVs offer unique capabilities but are less common and have specific limitations.

Various classification schemes are used to categorize UAVs based on different criteria:

- Department of Defense (DoD) Classification:

- Based on weight, speed, and altitude.

- Divided into five classes ranging from Group 1 (small) to Group 5 (large).

- Classification by Endurance and Altitude:

- Includes categories such as MAVs (Micro or Miniature Air Vehicles), NAVs (Nano Air Vehicles), VTOL (Vertical Takeoff & Landing), LASE (Low Altitude, Short-Endurance), LALE (Low Altitude, Long Endurance), MALE (Medium Altitude, Long Endurance), and HALE (High Altitude, Long Endurance).

- Other Complementary Classification Schemes:

- Presented by Brooke-Holland, Weibel and Hansman, Gupta et al., Cavoukian, and others.

- These schemes may focus on specific attributes or applications of UAVs.

- Comprehensive Classification Scheme by Hassanalian and Abdelkefi:

- Based on weight, wingspan, and propulsion system.

- Classifies UAVs into categories such as UAV, μUAV (micro unmanned air vehicles), MAV (micro air vehicles), NAV (nano air vehicles), PAV (pico air vehicles), and SD (smart dusts).

Each classification scheme offers a different perspective on categorizing UAVs, considering factors such as size, weight, altitude, endurance, and propulsion system. These classifications help in understanding the capabilities and applications of different types of UAVs across various industries and sectors.

UAV COMPONENTS

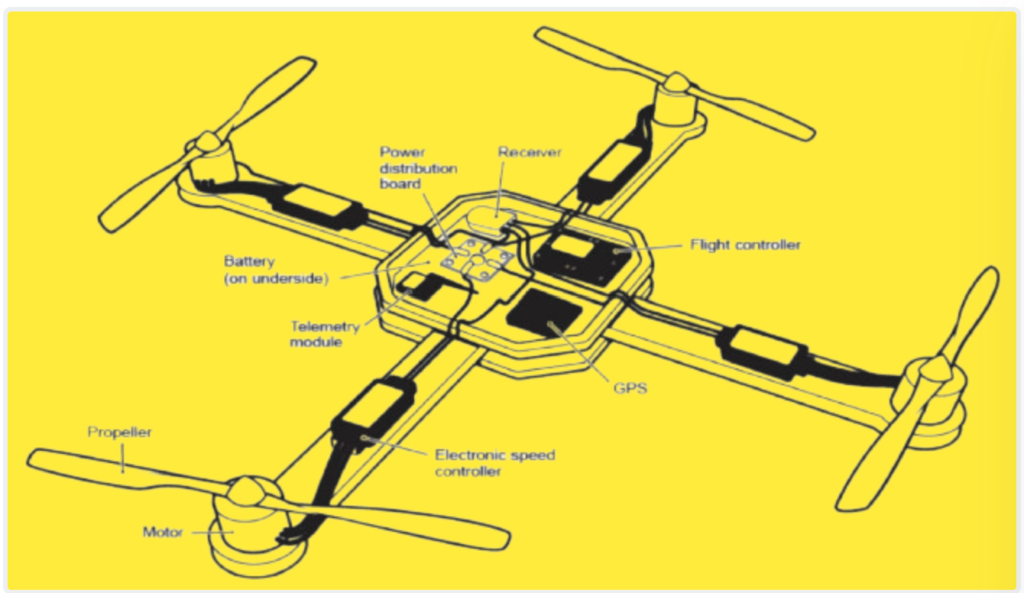

UAVs typically consist of several key components that enable their operation. These components may vary depending on the specific design and purpose of the UAV, but common components include:

1. Chassis

The chassis of a rotary-wing UAV is a critical component that serves as the foundational structure supporting the entire aircraft. Constructed from lightweight materials like duralumin or carbon fiber, the chassis is designed to minimize weight while maintaining structural integrity. This lightweight construction is essential for enhancing the UAV’s maneuverability and overall efficiency during flight. Additionally, the materials used must be capable of withstanding both static and dynamic stresses experienced during various flight operations, ensuring the chassis remains robust and durable throughout its operational lifespan.

Moreover, the chassis must be able to withstand the environmental conditions it will encounter during operation. For instance, it should resist heat stress induced by prolonged exposure to sunlight and remain resilient in cold environments to prevent issues such as brittle fracture. The chassis typically consists of a central unit housing essential electronics and communication equipment, which is connected to multiple evenly spaced arms. Each arm accommodates a motor and propeller unit, with the number of arms varying depending on the UAV’s design and requirements.

The construction of the arms can vary, with options such as trussed beams or tubes. Trussed beams offer strength and rigidity, while tubes provide a lightweight and streamlined design. The choice of arm construction depends on factors such as structural integrity, weight considerations, and desired aerodynamic performance. Additionally, the number of arms plays a crucial role in the UAV’s stability and overall flight characteristics. While fewer arms may simplify the design and reduce complexity, a larger number of arms can distribute the lifting load more evenly, enhancing stability during flight.

Overall, the chassis is fundamental to the performance, safety, and longevity of rotary-wing UAVs. Its design and construction must be carefully engineered to meet the specific requirements of the intended mission and operating environment, ensuring optimal performance and reliability in various flight conditions.

2. Propeller

Propellers are essential components of rotary-wing UAVs, responsible for generating thrust to propel the aircraft through the air. They operate by rotating horizontally and creating thrust perpendicular to the direction of rotation. Key functional parameters of propellers include blade diameter, blade pitch, and blade number. Increasing any of these parameters typically results in greater thrust and power output. However, the choice of blade design involves trade-offs, as propellers with more blades, larger pitch, or greater diameter require corresponding increases in motor torque to maintain rotational speed.

Unlike helicopters, which utilize cyclic pitch control, UAVs employ fixed-pitch propellers. This means that lift adjustments are achieved solely by varying the propeller speed, with increased pitch resulting in higher drag. To maintain stability, clockwise and counterclockwise propellers are positioned adjacent to each other to balance torques and prevent unwanted rotation about the vertical axis.

In some UAV designs, rotor blades are enclosed in casings integrated into the chassis. This configuration enhances maneuverability in confined spaces and reduces the risk of damage to the UAV and its surroundings. Additionally, many commercial UAVs feature foldable propellers to facilitate transportation and storage.

Propellers are a significant source of audible noise from UAVs, raising concerns about their impact on residents and wildlife. As UAV usage becomes more widespread, studies on propeller noise reduction and thrust optimization are gaining importance. Improvements in propeller design, such as minimizing laminar separation and adjusting diameter, angular velocity, and shape, can significantly influence both noise levels and thrust efficiency. Manufacturers are increasingly focusing on developing quieter and more efficient propeller designs to mitigate noise pollution and enhance UAV performance.

3. Motor

The motor is a critical component of a UAV’s propulsion system, converting electrical energy into mechanical energy to drive the propeller. Each motor is directly attached to a propeller and must be capable of responding swiftly and reliably to changes in electrical power. Brushless motors are commonly used in UAVs due to their reduced friction, resulting in increased power efficiency and decreased battery usage.

Brushless motors are characterized by parameters such as electrical current and rotational speed. The maximum rotational speed under no-load conditions is determined by the motor’s Kv parameter and the applied voltage. When voltage is applied, the motor draws current and exerts torque on the shaft, accelerating it until the exerted torque matches the load torque, including mechanical losses.

At low rotational speeds, the exerted torque is proportional to the applied voltage, as indicated by the motor torque constant. This torque is then converted into rotational speed and thrust based on the propeller’s characteristics. The torque produced by the motor can be expressed as a function of the input current, the no-load current, and the torque proportionality constant.

The voltage across the motor is the sum of the back-electromotive force (EMF) due to electrical inductance and some resistive loss. This voltage drop can be calculated using the motor resistance, angular velocity, and a motor constant representing back-EMF generated per unit speed. With negligible motor resistance, the power consumption of the motor is proportional to the angular velocity.

In summary, the motor plays a crucial role in driving the propeller and providing thrust to the UAV. Understanding its characteristics and power consumption is essential for optimizing the performance and efficiency of the propulsion system.

4. Electronic Speed Controller

The electronic speed controller (ESC) is an essential component in the operation of brushless motors, enabling precise control over their speed and direction. In a UAV equipped with brushless motors, each motor is paired with its own ESC, which regulates the flow of current from the battery to the motor under constant voltage. This allows for dynamic adjustments to the motor’s speed, facilitating maneuvers and maintaining stability during flight.

The ESCs are typically connected to a master power distribution board (PDB), which serves as a central hub for distributing power to all the components of the UAV. The PDB, in turn, interfaces with the flight controller, which interprets pilot commands and translates them into appropriate adjustments to the motor speeds, enabling the UAV to respond to inputs and navigate as desired.

During the selection of ESCs for a rotary-wing UAV, factors such as the maximum motor current should be carefully considered to ensure compatibility and optimal performance. Additionally, ESCs often provide telemetry data, including information on propeller speed, motor current, and temperature, which can be invaluable for monitoring the health and performance of the propulsion system during operation. Overall, the ESC plays a critical role in the effective operation and control of brushless motors in UAVs, contributing to their maneuverability, stability, and overall performance.

5. Battery

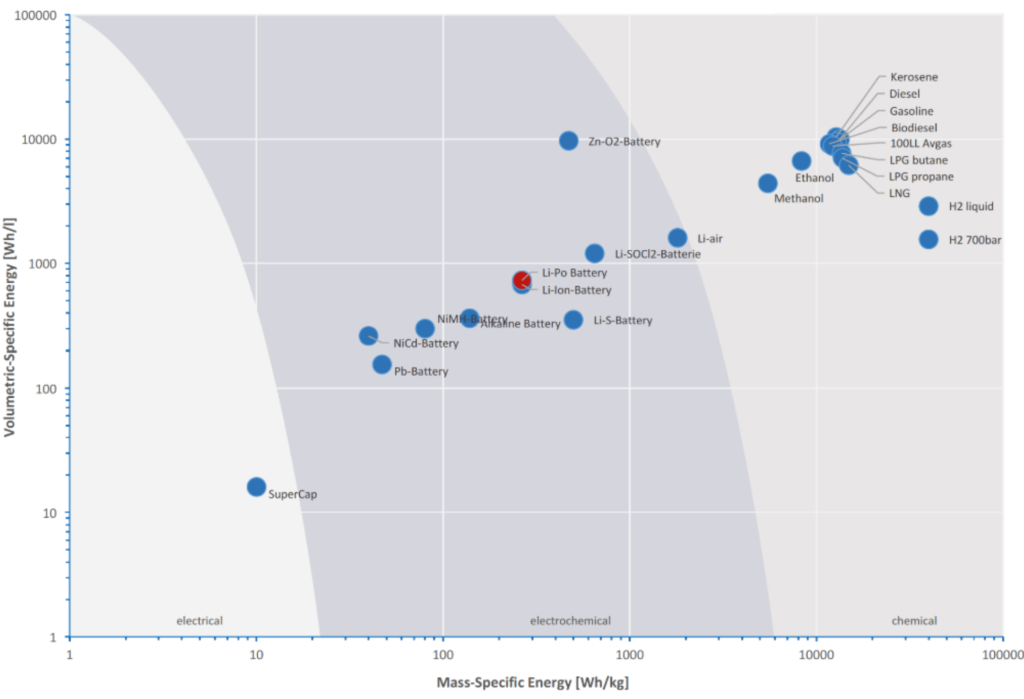

Batteries play a crucial role in providing the necessary current and voltage to power the electric components onboard UAVs, including motors and other systems. To meet the power requirements of these components, batteries are connected in series or parallel configurations, each offering different advantages in terms of current delivery and overall battery duration. The capacity of batteries is typically measured in milliampere-hours (mAh), representing the tradeoff between high battery current and long battery duration at constant voltage.

The “C-rate” of a battery, measured in units of hours to the power of negative one (h^-1), indicates the rate at which the battery can sustain its mAh capacity. A 1C rate means the battery can sustain its mAh capacity for one hour, while higher C-rates provide increased current for shorter durations. Lithium-polymer (Li-Po) and lithium-ion (Li-ion) batteries are the most commonly used types in UAVs due to their rechargeable nature, high energy density, and advancements driven by industries like computers and mobile phones. While Li-Po and Li-ion batteries have lower specific energy ratings compared to traditional fuels, their rechargeability makes them preferable for UAV applications.

Li-Po batteries are particularly favored for rotary-wing UAVs due to their high energy density and superior current discharge capabilities over other battery types. The voltage of Li-Po batteries varies depending on their electrochemistry and state of charge, typically ranging from 2.7-3.0 V when nearly discharged to 4.2 V when fully charged. It’s important to avoid discharging Li-Po batteries below 3 V to prevent permanent damage, with discharge to no more than 20% state of charge being recommended. The nominal voltage of a Li-Po battery is usually around 3.7 V, and when connected in series, multiple batteries can be used to achieve higher nominal voltages suitable for UAV propulsion systems.

6. Flight Controller

A flight controller serves as the intermediary between a human operator’s commands and the UAV’s motor system, translating high-level instructions into voltages applied to the motors. This device is essential for coordinating the rotational speeds of multiple motors simultaneously, ensuring stable flight. It relies on data from onboard sensors, including a 3-axis gyroscope for rotational movement and attitude, a 3-axis accelerometer for linear movement and position, and a pressure sensor for altitude information. Additionally, many UAVs incorporate a Global Positioning System (GPS) for autopilot functionality or as a failsafe in case of communication loss with a ground controller.

Using feedback control based on data from these sensors, the flight controller adjusts motor voltages to maintain flight stability. Drawing upon control theory principles, mathematical models are essential for designing control systems tailored to rotary-wing UAV operations. Various control methods have been employed for quadcopter control, including PID controllers, back-stepping control, LQR controllers, and nonlinear H∞ control, each with its own advantages and limitations.

The development of electronic control systems for quadcopters marked a significant breakthrough, enabled by advancements in microprocessor technology that facilitated miniaturization and cost reduction of flight controllers. Despite their simplicity in terms of independent controls compared to the six degrees of freedom exhibited by quadcopters, controlling these systems remains challenging due to inherent under-actuation. This means that while quadcopters possess six degrees of freedom, they only have four independent controls, leading to coupled translation and rotational motions. This coupling, along with nonlinear dynamics and external factors such as atmospheric turbulence, complicates flight control. Moreover, the absence of a braking mechanism necessitates the UAV to manage its own deceleration by adjusting propeller speeds, contributing to stability and dampening movements during flight.

Communication Link

Radio Frequencies

Communication between ground operators or computer systems and UAVs typically occurs via bidirectional radio links, often utilizing frequencies commonly used for computer and telephone WiFi, such as 2.4 or 5 GHz. This choice simplifies regulatory compliance but imposes limitations on maximum radio power. Commercial UAVs often feature redundant antennas for enhanced reliability, with an odd number of antennas to maintain operability even if one fails.

Radio communication is essential for controlling the UAV (control and non-payload communication) and often for transmitting payload data. While there are no inherent technical limitations on the maximum flight distance of a UAV, most commercially available models have fixed operational ranges due to cost and safety considerations. The effective range can be extended through various means, including antenna type and gain, transmission wavelength, and obstacles between the transmitter and receiver.

Radio communication involves two antennas operating as transmitters and receivers, enabling bidirectional communication. The communication system between the UAV and its ground controller, known as the data link system, largely depends on radio frequency and line-of-sight transmission through obstacles. Lower frequencies offer longer transmission ranges and better penetration through dense objects, making them suitable for remote UAV control.

Common frequencies used in UAV communication include the unlicensed industrial, scientific, and medical (ISM) bands, such as 902-928 MHz, 2.400-2.4835 GHz, and 5.725-5.850 GHz, resembling home router frequencies of type 802.11. These bands support multiple 20 MHz channel bands, with transmission power restricted by regulatory authorities like the FCC in the USA and CE in the European Economic Area.

UAVs also utilize the Global Navigation Satellite System (GNSS), incorporating signals from GPS, GLONASS, Galileo, and Beidou constellations for navigation. GPS signals operate on L1 and L2 bands, with L-band frequencies chosen for their ability to penetrate various environmental conditions. GNSS receivers in modern UAVs are often compatible with multiple satellite constellations.

Additionally, historical telemetry frequencies for UAVs include 400 MHz and 900 MHz, offering long-range communication with minimal data loss but limited data transfer capacity. Cellular network frequencies like 850 MHz, 1700 MHz, and 1900 MHz are occasionally used for telemetry, especially in remote regions.

In summary, UAV communication frequencies range from lower frequencies for long-range communication with slower data rates to higher frequencies for shorter ranges but faster data transfer, catering to various operational requirements and environmental conditions.

Link Budget

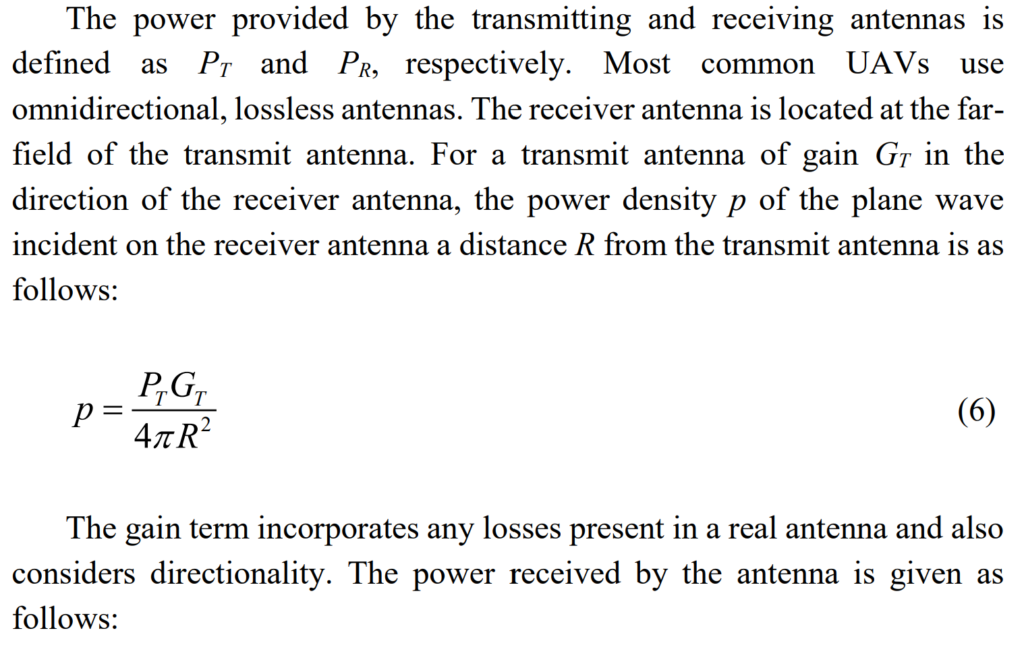

A link budget serves as a important tool for evaluating the performance of communication channels in a system, enabling estimation of received power to ensure intelligible reception with an adequate signal-to-noise ratio. Based on the Far-field transmission equation, which calculates received power from transmitting and receiving antennas separated by a distance in free space and operating at a specific frequency or wavelength, the link budget facilitates comparison of radios, antennas, and frequency bands.

In the context of UAVs, most commonly employ omnidirectional, lossless antennas, with the receiver antenna situated at the far-field of the transmit antenna. The power density of the plane wave incident on the receiver antenna is determined by the gain of the transmit antenna and the distance between the antennas. The received power is then calculated based on the effective aperture of the receiving antenna, considering directionality and any losses present in a real antenna.

Expressed in logarithmic form, the link budget equation accounts for various factors affecting received power, including path loss in reference to air or obstacles. It highlights that higher frequencies incur greater power loss, emphasizing the importance of a good link margin for maintaining a high signal-to-noise ratio. Linear polarization, commonly used by UAVs, aligns the electric field in a single plane, minimizing pointing loss but requiring careful orientation of the controller by the operator.

Increasing the link margin extends the maximum communication distance between a UAV and the ground controller, with directional antennas offering higher gains than omnidirectional ones. However, maintaining communication at longer distances becomes challenging, especially with omnidirectional antennas. Autonomously flying UAVs can help overcome this limitation, but loss of communication due to antenna damage or other factors may still occur.

To mitigate the risk of complete UAV loss in the event of communication failure, many commercial UAVs are equipped with autonomous safeguards, such as returning to the takeoff location or descending to land autonomously. These measures help ensure the safe operation of UAVs even in the absence of communication with the ground controller.

UAV Component Selection

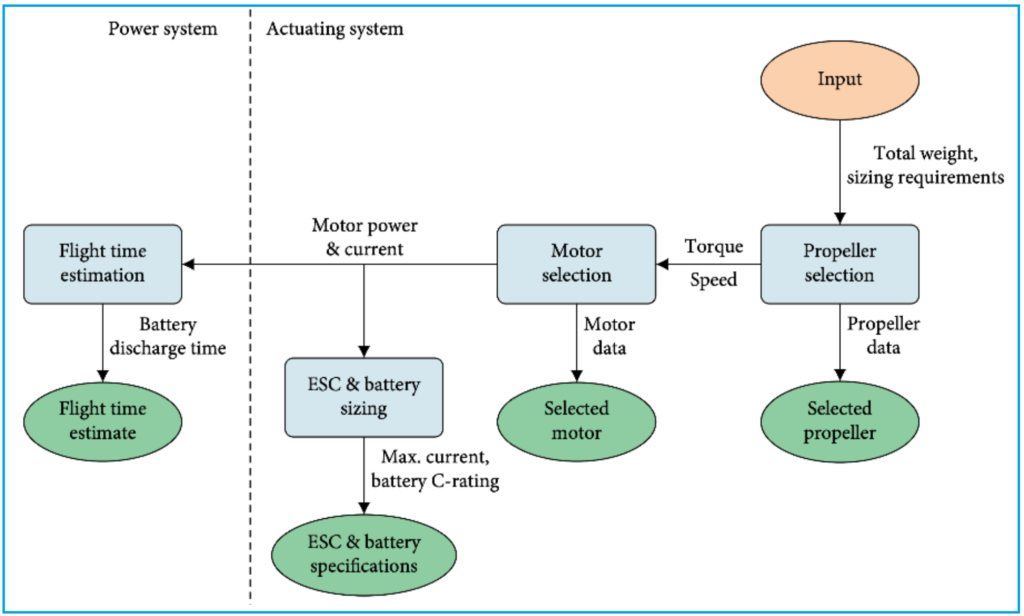

Selecting components for a UAV system involves a careful consideration of design criteria, intended purpose, and specific requirements, which can be challenging to optimize. To address this challenge, a systematic approach is necessary, often involving calculations to determine suitable motors, propellers, electronic speed controllers (ESCs), and batteries. Following figure outline a detailed procedure for component selection, providing guidance for engineers and designers.

The selection process typically begins with defining the requirements and constraints of the UAV, including payload capacity, flight duration, and environmental factors. Based on these specifications, calculations are performed to determine the optimal combination of components that can meet the desired performance metrics. Factors such as motor thrust, propeller size and pitch, ESC current rating, and battery capacity are evaluated to ensure compatibility and efficiency.

While performing these calculations manually can be complex, purchasing components from a UAV manufacturer can simplify the process. Manufacturers often offer pre-configured systems designed to meet specific requirements, saving time and effort in component selection. However, this approach may limit flexibility and customization options, making it essential to balance convenience with the need for tailored performance.

Ultimately, the selection of UAV components involves a trade-off between various factors, including cost, performance, reliability, and ease of integration. By following a structured approach and leveraging available resources, engineers and designers can optimize component selection to achieve the desired outcomes for their UAV projects.