This article is about Differential Pressure Level Transmitters Material Selection Criteria & Design For Level Measurement of Instrumentation and Control Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Differential Pressure Level Transmitters Material Selection Criteria & Design

Material Receiving General Checklist for Instrumentation & Control

Purchase Order and Instrument specification sheet criteria shall be confirmed and compared with instrument stainless steel tags / labels and nameplates, and shipment checked for damage, prior to acceptance of the shipment

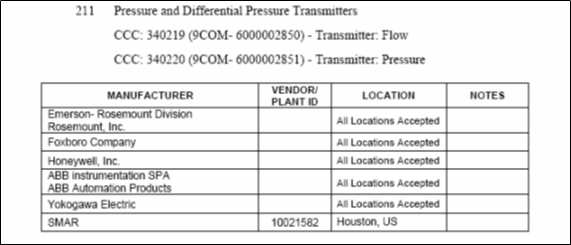

Verify that all the instruments are from technically acceptable manufacturer.

“Application

Differential pressure level transmitters may be used for process and ESD level and for liquid-liquid interface level measurements if GWR is not suitable for the application. Transmitters with diaphragm seals are recommended for process fluids that are extremely viscous, containing entrained solids or in hot service.”

“Local Indicators

Analog or digital indicators shall be provided for each level instrument. The selection of analog or digital technology shall depend on the proponent’s requirements. ”

“Local Indicators

The scale range for the analog indicators shall be from 0 to 100% of measured level range. The digital indicators shall display the liquid level in meters-cm-mm, graduations.”

The Local indicators shall meet the hazardous area classification and have a weatherproof case.

“Hazardous Area Classification

Verify that the installation drawings and specification for all equipment, installation of conduits and cables shall meet or exceed the area classification requirements, as per SAES-B-068. All enclosures and conduit sealing shall comply with section 5, SAES-J-902, “”Electrical Systems for Instrumentation””.”

“Transmitters:

All transmitters used for level service shall be HART or Foundation Fieldbus smart and microprocessor based.

International Codes and Standards for Differential Pressure Level Transmitters

- Flow Nozzle Material Selection Criteria Design & Flow Measurement

- Venturi Tube Material Selection Criteria Design & Flow Measurement

3. SAES-J-002 – Technically acceptable instruments, 23 June 2008

4. SAES-J-300 – Level, 27 Febraury 2007.

5. SAES-J-904 – FOUNDATION fieldbus Systems, 31 July 2004.

6. SAES-B-068 – Electrical Area Classification, 31 May 2003

7. SAES-J-902 – Electrical Systems for Instrumentation, 11 May 2008

8. Saudi Aramco Library Drawings, DC-950047 and DC-950048 attached as Attachment A

1. Attachment 1: DP Level Transmitters Technically Acceptable Instruments – SAES-J-002.

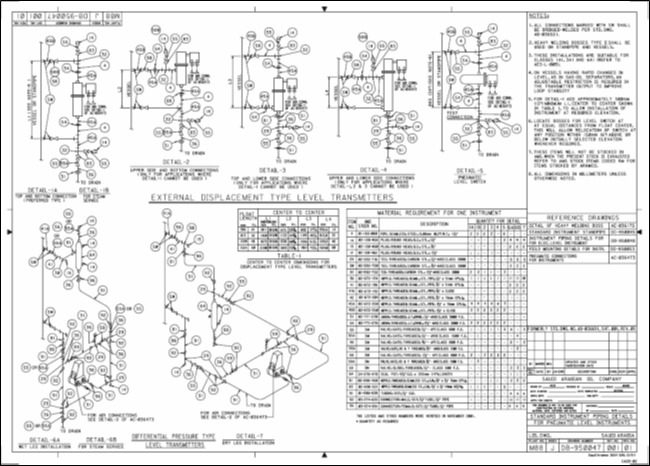

2. Attachment 2: Differential Pressure type level transmitter Library Dwg. DB 950047

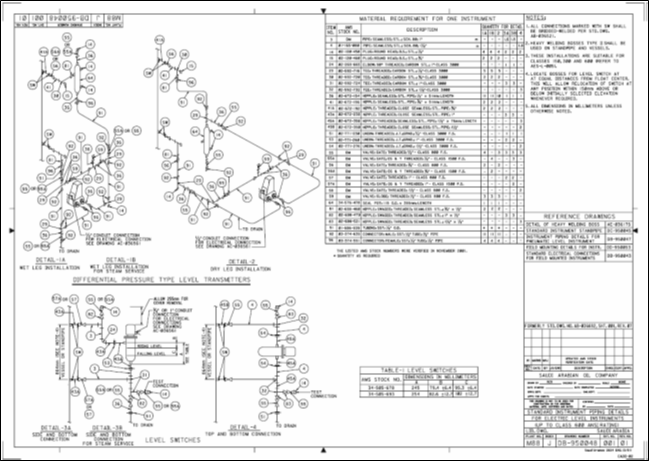

3. Attachment 3: Differential Pressure type level transmitter / Switches, Library Dwg. DB 950048