ELECTRICAL COMMUNICATION SYSTEM PROCEDURE

- All permanent materials (including fabricated supports), consumables, construction area and resources shall be prepared and checked prior to installation works.

- Ensure that all Electrical Equipment and materials, which would suffer damage or deterioration from exposure to the elements has been properly stored indoor, off the ground in suitable warehousing.

- Materials and equipment to be installed shall be inspected to ensure the conditions. Should there be factory and handling damages found in the equipment and/or materials, Subcontractor shall record to QC Material Receiving Inspection report form and immediately inform EPC for disposition.

- Ensure that working areas are ready for installation of electrical equipment, properly turned over to Subcontractor Electrical Department by Building subcontractor with a duly accomplished Work Transfer Sheet.

- All equipment foundation, base plates, cable entries, oil pits and firewalls (if any) shall be checked for its line and grade against actual dimension of the equipment. Foundation of particular equipment shall be checked to include stub-up prior to acceptance of work transfer sheet. Surveyor shall verify the elevation of the equipment and to be incorporated in the “AS-BUILT” drawings. Any deviations found against AFC drawings, shall be brought to the attention of Company.

- Work Transfer Sheet shall be duly signed and processed by other subcontractors or discipline for the preceding works to avoid confusion and discrepancies in the work responsibilities.

- Architectural finishing works of the building (needed for selected activities) shall have been completed; in particular, room ventilation, temperature, and humidity level shall be within the limits recommended by the equipment vendor. Indoor equipment to be installed in the building shall be maintained at required room temperature.

- Review all references such as the latest Approved for Construction (AFC) drawings, layout, and technical scope of work, work permit requirements, and work procedures including safety standard requirements.

- Equipment that has been shipped in sections and/or has loose components shall be identified and checked with corresponding equipment package lists.

- Equipment tags shall be identified and scheduled with respect to the latest issued Approved for Construction drawings as well as to the approved milestones schedules.

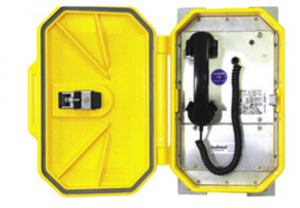

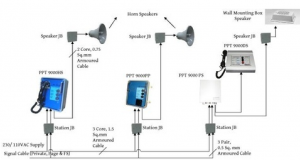

PAGING SYSTEM INSTALLATION

- Survey and study the designed location of paging system

- Check locations and provide markings to which elevations, mounting height and orientations should conform in the latest issued Approved for Construction drawings.

- Install necessary fabricated supports as required per installation detail. Ensure that the orientation shall comply with the drawing layout.

- Verify the installed support against equipment to be installed if suited as per requirements of EPC technical scope of works and latest issued Approved for Construction drawing.

- All cabinets shall be correctly leveled and aligned before fastening to the support as per Saudi Aramco specification.

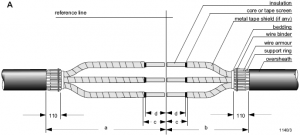

- Prior to installation of cable tray underneath tile flooring at Communication room the following item shall be considered.

- Base plate of cable tray supports shall be anchored at the floor through expansion bolt floor drilling at communication.

- Align the cable tray supports and ensure that tray routes are accessible starting from end of trench to building cable entry.

7. Cable tray installation shall be underneath floor tiles at communication room. Complete with fittings and accessories as per requirement.

8. Installation of grounding bus bar to accommodate the possibility of excessed number of grounding cable to be connected from different communication boxes based on the detailed approved for construction drawing.

9. Provide grounding bonding for supports and trays connected to grounding bus bar.

10. QC shall inspect, accept or reject installed cabinet rack and cable tray support.

MAIN AMPLIFIER CABINET INSTALLATION (INDOOR)

- Survey and study the designed location of main amplifier cabinet.

- Check locations and provide markings to which elevations, mounting height and orientations should conform in the latest issued Approved for Construction Drawings.

- Fabricate and install cabinet rack for Main Amplifier cabinet at communication room.

- Unload the main amplifier cabinet by utilizing crane equipment.

- Uncrate the main amplifier cabinet before moving to communication room.

- Pallet truck should have been ready for bringing amplifier cabinet inside the communication room.

- All cabinets shall be correctly leveled and aligned before fastening to the support as per Saudi Aramco specification.

- Provide grounding bonding for supports and trays connected to grounding bus bar.

- QC shall inspect, accept or reject installed cabinet rack and cable tray support.