Main keywords for this article are Flowmeters Selection Guide. Definitions Flowmeters Selection. Selection Criteria of Sensors. Flowmeter Materials. Flowmeter Installation. Basic concepts of all flowmeters are discussed here shortly and selection criteria of sensors flowmeters and which flowmeters are suitable for fluid medium.

Flowmeters Selection Guide

The following basic principles of operation of a particular flow sensor technology shall be understood before selecting it for a specific application. Decisions made without this technical knowledge will result in misapplication of flowmeter devices.

- Differential Pressure Devices. Head producing devices in which differential pressure is measured, represent one of the most widely used technologies for industrial flowmeters. In these devices fluid flow through the pipe is inferred by measuring differential pressure produced across a specified restriction orifice. The differential pressure measured is proportional to the square root of the flow. It should be noted that differential or dynamic pressure developed across the restriction orifice is different from the static pressure present in the pipe. Orifice plates, venturi meters, pitot tubes and elbow flowmeters use this principle for measuring flow. For details of each specific device see following standards:

a. For orifice plate, Click Here

b. For venturi tube, Click Here

c. For pitot tube see Click Here

d. For flow nozzle Click Here

e. For elbow flowmeter Click Here

f. For low loss tube Click Here - Magnetic Flowmeter. Faraday’s Law of magnetic induction is used in the design of flowmeters in the following way:

When a conductive liquid moves in a magnetic field, a voltage is generated between two electrodes positioned within the magnetic field on opposite sides of the pipe. If the distance between electrode is fixed and magnetic field is constant, the induced voltage is directly proportional to velocity of liquid. For details of magnetic flowmeter Click Here. - Variable Area Flowmeter. A free moving float is balanced inside a vertical tapered tube. The float remains in dynamic balance when the sum of forces acting on it are zero. Its movement up and down inside the tube is related to flow and produces a signal that varies linearly with flow. For details of variable area flowmeter. see Click Here.

- Target Flowmeter. This flowmeter operates by measuring force exerted on a body (target) suspended in the flow stream. The force exerted on the target is the difference between the upstream and downstream pressures integrated over the area of the target. The flow is directly proportional to the force exerted on the target and the viscosity of the fluid. For details of target flowmeter. Click Here.

- Turbine Flowmeter. The turbine flowmeter provides a frequency output signal that varies linearly with fluid flow rate over a specified flow range. The fluid enters from upstream due to static pressure and passes through the rotor mechanism. The passing fluid causes the rotor to turn with a rotational velocity proportional to volumetric flow rate. For details of turbine flowmeter. Click Here.

- Positive Displacement Flowmeters. The positive displacement meter repeatedly entraps the fluid into a known quantity as it passes through the flowmeter. The quantity of fluid that has passed is based on the number of entrapments. Helical gear, oval gear, and rotating vane operate on this principle. For details of each device see following standards:

(i) For positive displacement flowmeter, see Click Here.

(ii) For helical gear. Click Here

(iii) For oval gear Click Here

(iv) For rotating vane Click Here - Ultrasonic Flowmeter. These flowmeters use acoustic waves or vibrations to detect the flow travelling through a pipe. Ultrasonic energy is coupled to the liquid in the pipe using wetted or nonwetted transducers. The ultrasonic flowmeter may use the principle of Doppler effect or time of flight.

a. Doppler Effect. A transducer transmits acoustic energy into the flow to a receiver. Under no flow condition the frequency received is the same as frequency of transmitter, however when there is flow the frequency received is altered linearly with the amount of flow through the pipe due to Doppler effect. The net result is a frequency shift between transmitter and receiver that is proportional to flow.

b. Time of Flight. In this type of flowmeter two transducers are mounted diametrically opposite, one downstream to the other. Each of them sends an ultrasonic beam at approximately 1 MHz. The difference in travel time between the two beams is used to determine average velocity of liquid. For details Click Here. - Mass Flowmeter. In this design two tubes are forced to oscillate perpendicular to the direction of flow. The resulting Coriolis force induces a twisting movement of the tubes. This movement is sensed by a pickup and is related to mass flow.

- Thermal Flowmeter. This type of flowmeter is based on the cooling of a flowing fluid which has been heated on a resistance device. The flow is measured by one of two methods:

(i) Change in heating power required to keep heater resistance constant

(ii) Change in temperature reading at some point downstream of the heater

Mass flow is inferred from the energy balance equation. For details Click Here. - Vortex Shedding Flowmeter. In this type of meter an obstruction is placed across the pipe bore perpendicular to fluid flow. Vortices are produced from edges of obstruction at a frequency proportional to fluid velocity. Thus, rate of creation of vortices is proportional to volumetric flow rate. For details Click Here.

- Custody Transfer Flowmeter. A precision flowmetering device used for transferring ownership of fluids for accounting purposes. For details Click Here.

Selection Criteria of Sensors

- Accuracy. Flowmeter performance varies due to its type and technology and to fluctuating conditions. Flowmeter accuracy is measured either in percent of Rate or percent of Full Scale (FS). An example of this is; ± 0.25% rate or ± 1% FS.

- Rangeability. Rangeability is the range of flowmeter adjustment in the field after installation. Flowmeter range can change after installation due to design changes. Most manufacturers provide this adjustment feature.

- Turndown. Turndown varies between flowmeters, depending on technology, manufacturer, and application. It affects flowmeter accuracy. Turndown shall be examined carefully to determine the range at which the flowmeter will perform accurately. Avoid using the extremes in operating conditions claimed by the flowmeter manufacturers. Turndown ratio is stated as 10:1.

- Construction Materials. Flowmeter construction materials shall be compatible with the fluid being measured. Selection of a wrong material affects accuracy, or results in failure of flowmeter. 316 SS shall be used unless the application requires higher alloy material.

- Power Requirements. Flowmeters are available as 2-wire, 3-wire, or 4-wire designs. Selection of proper design depends on the overall plant control strategy. This is a critical factor that has a great influence on installation.

- Safety. The type of fluid to be measured, electrical area classification, and applicable codes or standards shall be considered when selecting a flowmeter.

Properties of Fluid

- Fluid Types. Fluid types are liquids, gases, and vapors, clean, dirty, solid slurry, or combinations of these.

- Pressure and Temperature. The operating pressure and temperature range of the fluid shall be considered in the selection of the flowmeter. Gas service is most affected by pressure and temperature. Available differential pressure and allowable pressure drop affect selection process.

- Density and Specific Gravity. The operating density and specific gravity of the fluid are required in sizing and calibrating the flowmeter. Compensations for temperature or pressure or both may be required in some applications where temperature variations are significant.

- Viscosity. The viscosity of fluid shall be known to estimate Reynolds number and determine the applicable flowmeter for the required service. Viscosity is more critical for liquids than gases.

Flowmeter Materials

The corrosiveness of fluid (liquid, gas, and vapor to be measured) at operating conditions shall be considered in specifying the materials of a flowmeter.

Flowmeter Installation

- Ease of Installation. Installation requirements vary significantly with flowmeter type. For this reason, no particular flowmeter should be considered superior to another. This evaluation has multiple trade-offs between piping and electrical requirements.

- Piping Considerations. Piping size, its layout and possible vibrations shall be considered in selection of a flowmeter.

Operation

- End Use. End use of flowmeter is a major factor in the selection of a flowmeter. Flowmeter use influences the required accuracy and selection economics.

- Maintainability. The frequency and ease of maintenance shall be evaluated in selecting a flowmeter. This is a complex judgment based on operating experience. Availability of spare parts shall be assured.

Selection

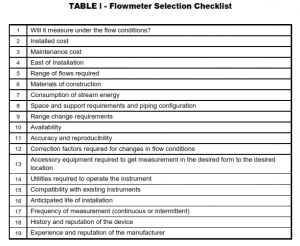

See Tables I and II for final selection of flow sensors.

Definitions Flowmeters Selection Guide

For the purpose of understanding this standard, the following definitions apply.

Coriolis Mass Flowmeter. Measures mass flow rate by determining the torque from radial acceleration of the fluid.

Custody Transfer Flowmeter. A flowmetering device used for accounting purposes.

Dowtherm. A constant boiling mixture of phenyl oxide and diphenyl oxide used in high- temperature heat transfer systems.

Elbow Flowmeter. A pipe elbow with a pressure tap at both the inner and outer radius. Flow is calculated by measurement of the pressure differential caused by differences in flow velocity between the two flow paths.

Flow Nozzle. A differential pressure producing element having a contoured entrance. Characterized by its ability to be mounted between flanges and have a lower permanent pressure loss than a plate.

Flow Transmitter. A device that senses the flow of liquids in a pipe and converts the sensor output into electric signals, which can be transmitted to a remote indicator or controller.

Helical Gear. A positive displacement meter used for extremely viscous fluids.

Laminar Flow. Streamline flow observed in viscous fluids near solid boundaries, which is characterized by the tendency for fluid to remain in thin, parallel layers to maintain uniform velocity.

Low Loss Tube. A differential pressure flowmeter used to minimize permanent pressure loss.

Magnetic Flowmeter. Used for measuring average velocity of a conductive liquid using the principle of electromagnetic induction.

Mass Flowmeter. Measures the rate of flow in a pipe, duct or channel in terms of mass per unit time.

Orifice Plate. A disc or platelike member, with a sharp-edged hole in it, used in a pipe to measure flow or reduce static pressure.

Oval Gear. A positive displacement flowmeter that traps a precise volume of fluid between an oval, toothed rotor and the meter housing as the rotor revolves in a mesh which has a second rotor. Volume flow of an incompressible fluid is indicated directly by determining mesh rotor speed.

Pitot Tube. Measures stagnation pressure of a flowing liquid. It consists of an open tube pointing upstream into the flow of fluid, and is connected to a pressure indicator or recorder.

Positive Displacement Flowmeter. Flowmeter design in which volumetric flow through the meter is broken up into discrete quantities. Flow rate is determined from the number of these quantities that pass through the meter per unit time.

Rangeability. The ratio of the maximum and minimum flow rates of a meter.

Reynolds Number. A dimensionless criterion of the nature of flow in pipes. It is proportional to the ratio of dynamic forces to viscous forces: the product of diameter, velocity and density, divided by absolute viscosity.

Rotameter. See variable area flowmeter.

Rotating Vane. Measures rate of flow of a fluid by determining the rotational speed of a vaned rotor inserted into the flowing stream. The vanes may or may not occupy the entire cross section of the flow path.

Sight Glass. A glass tube, or a glass-faced section of a process line, used for sighting liquid levels or taking manometer readings.

Target Flowmeter. Measures flow rate by means of a sharp edged disc centered in a circular flow path. The disc is usually mounted on a bar whose axis coincides with the tube axis. A secondary device attached to the bar measures the drag force exerted on the disc. This is caused by the differential pressure created by the fluid flowing through the annulus.

Thermal Flowmeter. Determines flow rate from rate of dissipation of heat injected into a flowing fluid stream. It measures either the change in temperature of some point downstream of the heater, or the amount of thermal or electrical energy required to maintain the heater at a constant temperature.

Turbine Flowmeter. Uses the rotation of a turbine type element to determine volumetric flow rate.

Turndown. The ratio of the maximum and minimum plant design flow rates.

Ultrasonic Flowmeter. Measuring flow rates across fluid streams by either Doppler effect measurements or time of flight determination. In both types, displacement of the portion of the flowing stream carrying the sound waves is determined and flow rate is calculated from the effect on soundwave characteristics.

Variable Area Flowmeter. A variable-area, constant-head, indicating-type, rate-of-flow volume meter in which fluid flows upward through a tapered tube, lifting a shaped plummet to a position where upward fluid force just balances the weight of the plummet.

Venturi Tube. A primary differential-pressure-producing device having a cone section approach to a throat and a longer cone discharge section. Used for measuring high volume flow at low pressure loss.

Viscosity. Measure of the internal friction of a fluid or its resistance to flow.

Vortex Shedding Flowmeter. Measures flow by sensing the movement of vortices in a pipe or conduit.