![Electrical Equipment Commissioning Procedure [PDF]](https://paktechpoint.com/wp-content/uploads/2023/09/Electrical-Equipment-Commissioning-Procedure-1024x576.png)

Electrical Equipment Commissioning Procedure:

This technical specification and method statement serve as a comprehensive guide for the commissioning of electrical equipment within an industrial facility. It encompasses a wide range of equipment and provides references to industry standards and codes that are relevant to the manufacturing and installation of this equipment. Additionally, reference tables are included to facilitate the commissioning process.

The scope of this technical specification encompasses all electrical equipment that is undergoing commissioning. It outlines the various stages of commissioning, including visual and mechanical inspections, as well as operational and functional testing. These tasks are to be carried out by qualified electrical commissioning professionals who have been approved by the appropriate personnel within the Electrical Engineering Department.

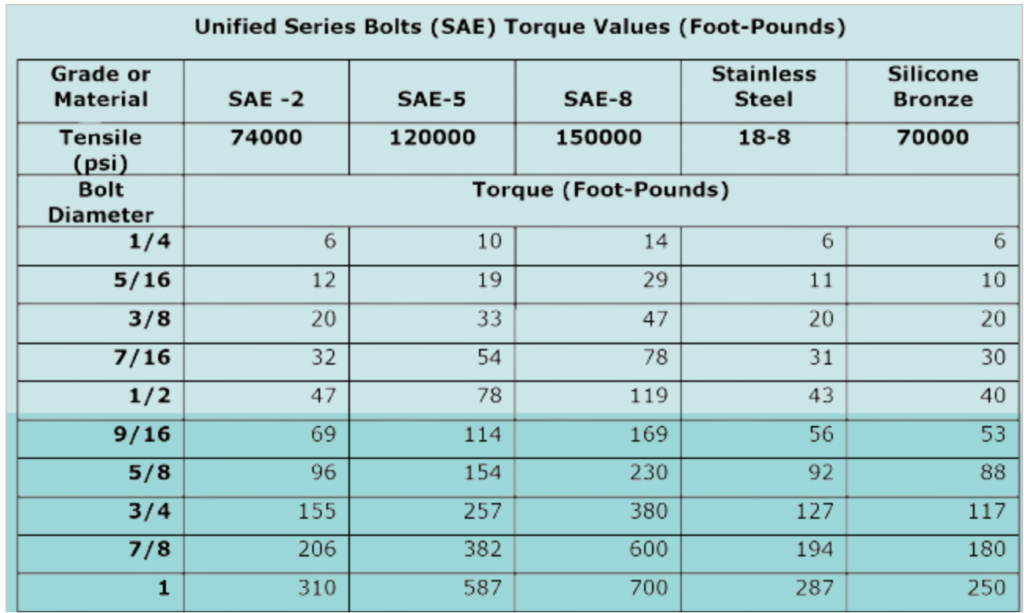

TORQUE VALUE REFERENCES

When manufacturer-specific torque values are not provided in the instruction manual for electrical connections, the following recommended torque values should be applied. These torque values are applicable to standard dry, coarse-thread bolts. If dealing with fine-thread bolts, it’s important to note that the torque values listed here should be increased by 9% to ensure proper tightening.

To facilitate torque value conversions from Newton-meters (N-m) to foot-pounds (ft-lb), the following conversion factor can be employed:

N-m (Newton-meter) = ft-lb (foot-pound) x 1.356.

In essence, this conversion factor allows you to convert torque values between different units of measurement, enabling precise torque application during the assembly or maintenance of electrical connections. This standardization ensures that fasteners are tightened to the correct specifications for safe and effective electrical installations.

Unified Series Bolts (SAE) Torque Values (Foot-Pounds):

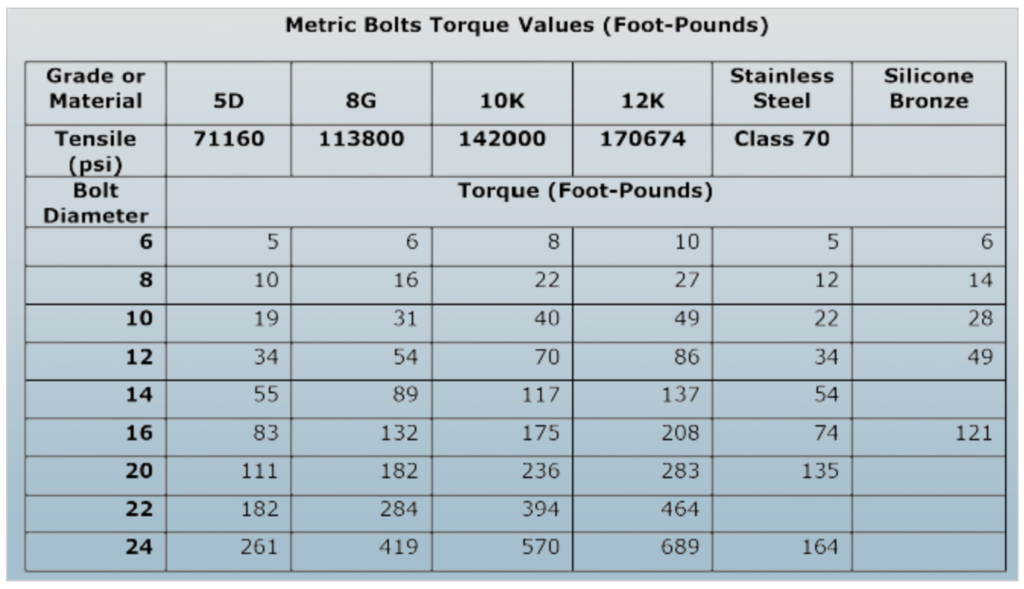

Metric Bolts Torque Values (Foot-Pounds)

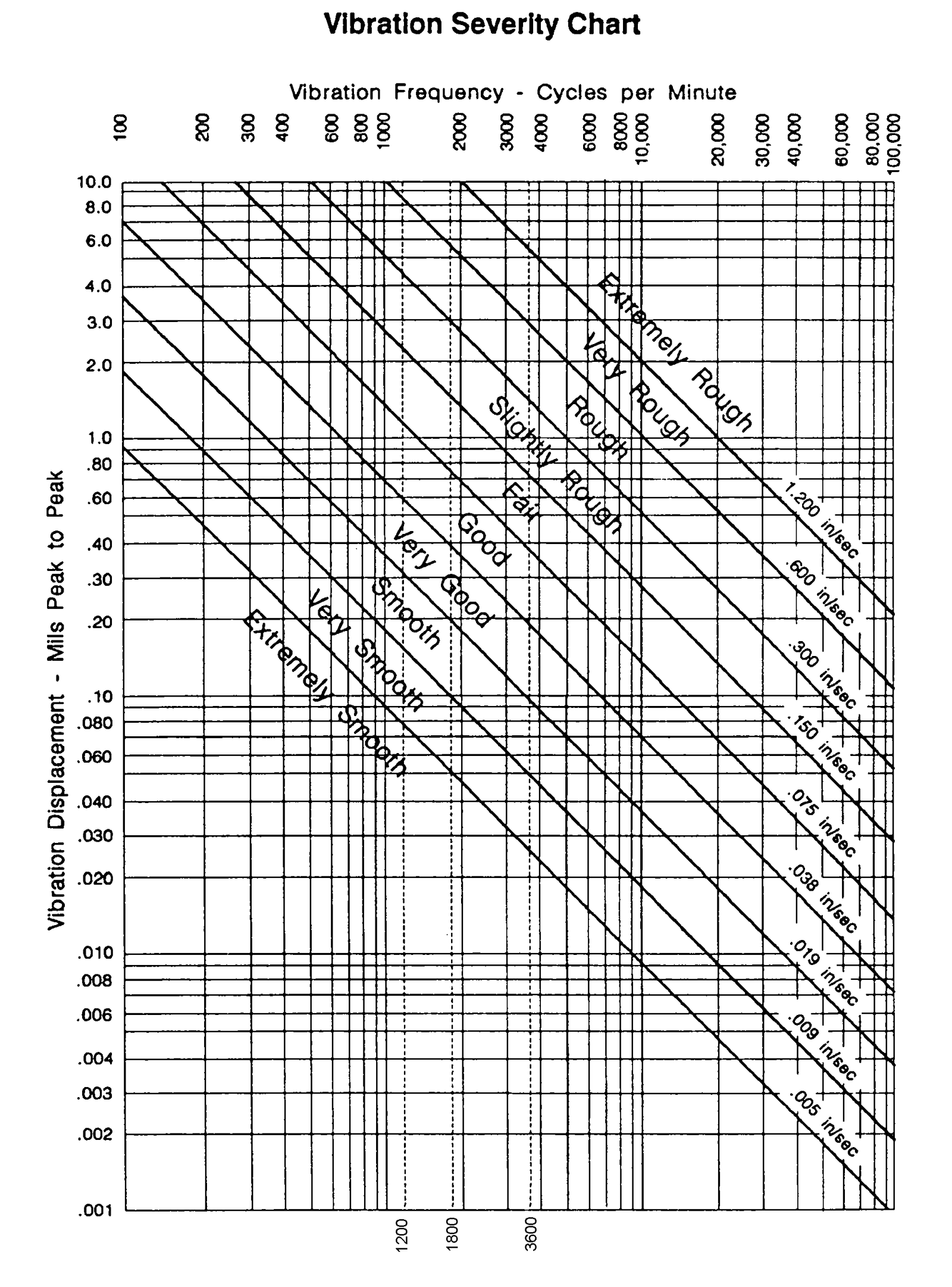

MACHINERY VIBRATION REFERENCE

The following vibration severity chart provides a reference for motor vibrations.

Vibration Analysis Troubleshooting Guide:

| Machine Parts | Frequency Relative to Machine RPM | Other Symptoms | Probable Causes | Corrective Action |

|---|---|---|---|---|

| Rotors and Shafts | 1 x RPM | High axial and radial vibration. | Bent shaft (See text details.) | Prove with strobe before straightening. |

| Armatures and Electric Motors | Not always related to speed. | High axial vibration or high thrust bearing wear. | Non-level or non-vertical motor axis. | Correct axis position and alignment with connecting members. |

| Gears | 1 x RPM | Looks like unbalance but motion is torsional vibration. | Eccentric gear pitch circle caused by machining or mounting errors. | Correct eccentricity. Try other line-to-line contact points between gear box and shaft. |

| Couplings, Shafts, and Bearings | Often 1 x RPM; often 2 x RPM; rarely 3 or 4 x RPM | High axial vibration, especially when axial vibration reaches half or more of radial vibration. | Misaligned coupling or shaft bearings. Occurs also in flexible couplings. Especially prominent in slender, long shafts to coupling position. | Align to tolerance required for smoothness. Suggestion: 0.0005″ of face diameter up to 1750 RPM. Higher speeds align much closer. |

| Universal Joints | 1 x RPM | Looks like unbalance. | Too tight universal joint. | Relieve tightness. |

| Gears | Number of teeth x RPM | Usually torsional vibration but not always. Could be in torsional resonance. | Bending as a result of unbalance causes side thrust between mating teeth. Eccentric gear pitch circle caused by machining errors causing pulsating acceleration and deceleration of gear rotation. | If resonant, change shaft or bearing stiffness or RPM or number of teeth. |

| Armatures and Electric Motors | 7200 cycles/minute. | Buzzing sound. | Normal characteristic of 2 pole (3600 RPM, synchronous speed) motors. None other than isolation or damping. |

| Machine Parts and Components | Frequency Relative to Machine RPM | Other Symptoms | Probable Causes | Corrective Action |

|---|---|---|---|---|

| V belts and other drive belts | 1 x RPM | High axial vibration (sometimes not too noticeable due to mass structure but shows up in bearing wear). | Drive and driven sheaves not aligned so as to be in the same plane of action. | Align sheaves to act in the same plane. |

| Sleeve bearings | No special relationship to RPM except vibration shows up at a frequency much lower than RPM – usually less than half. | Friction whip: Rotor speed usually high compared to critical speed. Vibration remains always at the critical speed of the rotor or support; therefore, a change in speed would not produce a change in frequency. | Excessive friction or other instability, for many possible reasons. Excites the critical speed of the rotor in self-excited vibration. | Implement any means to improve lubrication or change frequency because of friction or instability. |

| Anti-friction bearing | Usually relatively high frequency. | Usually very low amplitude, noisy. Most often, the frequency is unsteady and many times rotor RPM. | Excessive friction or rumble caused by bad balls, rollers, rough races, poor lubrication, polygonality, and too tight fit. | Replace the bearing. When applicable, relieve the press fit. |

| Universal joints and driveshaft | 2 x RPM | Double image strobe picture. | Unequal corresponding angles between input and output ends of the driveshaft. | Equalize corresponding angles through proper alignment. |

| Sleeve bearings | Slightly less than ½ x RPM | Oil whirl: Very rough amplitude; disappears suddenly with sufficient reduction in speed. | Excessive clearance or bearing loads that are too light relative to its high rotational speed. Can also be caused by a misaligned coupling. | Use a pressure pad or pivoted shoe bearing or relieve sides of the sleeve to decrease oil wedge pressure. Temporary: Raise oil temperature. |

| V belts | 1 x RPM | Very high axial vs. radial vibration. | Mismatched multiple belt tensions. | Replace with matched belts. |

| Machine Parts and Components | Frequency Relative to Machine RPM | Other Symptoms | Probable Causes | Corrective Action |

| V belts and other drive belts | No special relationship to RPM of belt or pulleys. | Tension side of belt has high vibration similar to a vibrating string. | Static belt tension coupled with drive tension produces a belt critical speed excited by vibration in the machine. | Change belt tension or belt length. |

| Machine Parts | Frequency Relative to Machine RPM | Other

Symptoms | Probable

Causes | Corrective Action | |

| Universal joints and driveshaft | 2 x RPM | Double image strobe picture. | Unequal corresponding angles between input and output ends of driveshaft. | Equalize corresponding angles through proper alignment. | |

| Sleeve bearings | Slightly less than ½ x RPM | Oil whirl: Very rough amplitude; disappears suddenly with sufficient reduction in speed. | Excessive clearance or bearing loads that are too light relative to its high rotational speed. Can also be caused by misaligned coupling. | Use pressure pad or pivoted shoe bearing or relieve sides of sleeve to decrease oil wedge pressure. Temporary: Raise oil temperature. | |

| Sleeve bearings | No special relationship to RPM except vibration shows up at frequency much lower than RPM- usually less than half. | Friction whip: Rotor speed usually high compared to critical speed. Vibration remains always at critical speed of rotor or support; therefore, change in speed would not produce change in frequency. | Excessive friction or other instability, for many possible reasons. Excites the critical speed of rotor in self excited vibration. | Any means to improve lubrication or change frequency because of friction or instability. | |

| Anti-friction bearing | Usually relatively high frequency. | Usually very low amplitude, noisy. Most often frequency is unsteady and many times rotor RPM. | Excessive friction or rumble caused by bad balls, rollers, rough races, poor lubrication, polygonality, and too tight fit. | Replace bearing. When applicable, relieve press fit. | |

| V belts | 1 x RPM | Very high axial vs. Radial vibration. | Mismatched multiple belt tensions. | Replace with matched belts. | |

| V belts and other drive belts | No special relationship to RPM of belt or pulleys. | Tension side of belt has high vibration similar to vibrating string. | Static belt tension coupled with drive tension produces a belt critical speed excited by vibration in machine. | Change belt tension or belt length. | |

| V belts and other drive belts | 1 x RPM | High axial vibration (sometimes not too noticeable due to mass structure but shows up in bearing wear). | Drive and driven sheaves not aligned so as to be in same plane of action. | Align sheaves to act in same plane. | |

Machinery Phenomena Vibration Analysis:

| Cause | Frequency Relative to Machine RPM | Phase | Amplitude |

|---|---|---|---|

| Misalignment Coupling or Bearing | 2 x RPM. Sometimes 1 or 3 x RPM. | Usually 2 reference marks. Sometimes 1 or 3. | High axial. Axial vibration can be twice radial. Use dual indicator as a check. |

| Defective Gears | High RPM x gear teeth | Radial amplitude. Use velocity measurement. | |

| Resonance | Specific critical | Single reference mark. | High phase will change with speed. Amplitude will decrease above and below resonant speed. Resonance can be removed from the operative range by stiffening. |

| Electrical | Power line frequency x 1 or 2 (3600 or 7200 RPM.) | 1 or 2 reference marks. | Usually low vibration stops instantly when power is turned off. |

| Unbalance | 1 x RPM | Single, steady reference mark. | Radial-steady. Proportional to unbalance, common cause of vibration. |

| Aerodynamic | 1 x RPM or number of blades on fan x RPM | May cause trouble in case of resonance. | |

| Oil Whirl | Less than RPM | Unstable. | Frequency may be as low as 1/2 RPM. Radial unsteady. |

| Defective Anti-friction Bearing | 10 to 100 x RPM | Unstable. | Measure velocity 0.2 to 1.0 inches/second. Radial velocity largest at defective bearing. As failure approaches, velocity signal will increase and the frequency will decrease. |

| Defective Belt | Belt RPM x 1 or 2 | Erratic strobe light will freeze belt. | |

| Mechanical Looseness | 1 or 2 x RPM | 1 or 2 reference marks. | Proportional to looseness. Radial vibration is largest in the direction of looseness. |

| Beat Frequency | 1 x RPM | Rotates at beat rate. | Variable at beat rate. Caused by two machines running at close RPM. |

| Bent Shaft | 1 or 2 x RPM | 1 or 2 reference marks. | High axial. |

Standard and Codes used for this Article:

All inspections and tests shall be in accordance with the following applicable codes and standards except as provided otherwise herein.

- Association of Edison Illuminating Companies – AEIC.

- American National Standards Institute – ANSI.

- American Society for Testing and Materials – ASTM.

- International Electrotechnical Commission – IEC.

- Institute of Electrical and Electronic Engineers – IEEE.

- Insulated Power Cable Engineers Association – IPCEA.

- National Electrical Code – NEC.

- National Electrical Manufacturer’s Association – NEMA.

- National Electrical Testing Association – NETA.

- OSHA Part 1910; Subpart S, 1910.308 State and Local Codes and Ordinances.

All inspections and tests shall utilize manufacturer’s instruction manual applicable to each particular apparatus.

Related Articles:

Commissioning of High Voltage Circuit Breakers, Contactors & Switches.

Electrical Commissioning of Substations and Outdoor Bus Structures

Electrical Commissioning of Substations High Voltage Oil, Vacuum, Gas Circuit Breakers

Electrical Commissioning of Liquid-Filled Transformers

Commissioning of Electrical Motors Greater than 600 hp

Commissioning of Low Voltage Distribution System, MCC, Load Centers, ATS.

Commissioning of Low Voltage Power and Control Distribution Equipment

Commissioning of Uninterruptible Power Systems, Batteries and Chargers

Electrical Commissioning of Emergency Generators

Commissioning: Bus Duct Systems

Commissioning: Grounding Systems

NEMA Substation Transformers, 2500 KVA to 60,000 KVA

NEMA Substation Transformers, 750 KVA to 2000 KVA

Pad-Mounted Transformers, 75 KVA to 500 KVA

Static Power Controllers

Large Stand Alone Induction Motor Starter

NEMA Low Voltage Motor Control Centers

NEMA E2 Motor Controllers

Low Voltage Soft Starters

Large Uninterruptible Power Supply Systems

Small Uninterruptible Power Supply Systems

Metal-Enclosed Load Interrupter Switchgear

Metal-Clad Switchgear

Type 1 – Brushless Exciter Synchronous Motor Full-Voltage Starting Switchgear Unit

Type 3 – Induction Motor Full-Voltage Starting Switchgear Unit

Type 4 – Main Incoming Line Switchgear Unit

Type 5 – Plant Feeder Switchgear Unit

Type 6 – Load Interrupter Switchgear Unit

Type 7 – Source Protection Equipment Group

Type 8 – ANSI Single Motor Autotransformer Starting Switchgear Unit

Variable Frequency Drives Low Voltage Motors (600 V or Less)

NEMA Standard Reliability Low Voltage Induction Motors

Optional Standby Diesel Engine-Generator Set

To Download PDF of this article please Enter Ctrl+P and then save as PDF.

GREAT WORK CONTINUE WITH THIS PASSION